Granular non-noble-metal efficient integrated air purification composite material

A non-precious metal, air purification technology, applied in the direction of organic compound/hydride/coordination complex catalyst, other chemical processes, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

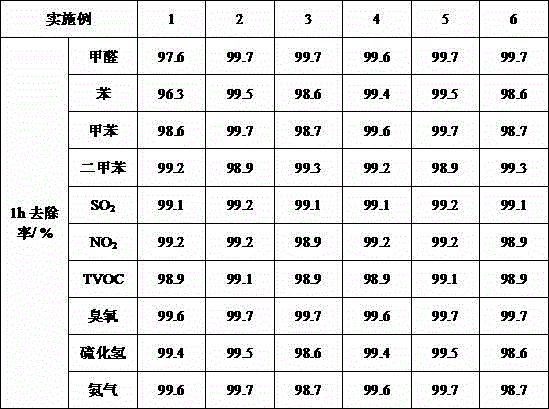

Examples

Embodiment 1

[0014] Accurately weigh 51 g of silica, 35 g of alumina and 14 g of magnesium oxide, mix and stir them evenly, and add 10 g of kaolin, 1.0 g of carboxymethyl cellulose, 0.5 ml of paraffin oil and a certain amount of water, stir into a mud, squeeze Pressed into columnar granules, aged for 24 hours, 80 o C, 4 h drying, 1350 o C, 4 h high temperature roasting to obtain the cordierite columnar granular carrier; the honeycomb cordierite carrier was immersed in a 10% nitric acid solution for 2 h, and then taken out for 60 o C, 2 h dry. According to the water absorption rate of the carrier, a mixed solution of manganese nitrate and lanthanum nitrate of a certain concentration was prepared. o C, 2h drying, and 500 o C, 4h air atmosphere roasting to prepare granular non-noble metal high-efficiency integrated air purification composite material.

[0015] Take 500 g of the prepared granular non-precious metal high-efficiency integrated air purification composite material and fill it in the h...

Embodiment 2

[0017] Accurately weigh 51 g of silica, 35 g of alumina and 14 g of magnesium oxide, mix and stir them evenly, and add 10 g of kaolin, 1.0 g of carboxymethyl cellulose, 0.5 ml of paraffin oil and a certain amount of water, stir into a mud, squeeze Pressed into columnar granules, aged for 24 hours, 80 o C, 4h drying, 1350 o C, 4h high-temperature roasting to obtain columnar granular carrier; immerse the above honeycomb columnar granular carrier in a 10% nitric acid solution for 6h, take it out and pass 100 o C, dry for 1h. According to the water absorption rate of the carrier, a mixed solution of tetraethylorthosilicate and nickel nitrate of a certain concentration was prepared, and the carrier was immersed in the solution for 6 hours. o C, 1h drying, and 250 o C, 6 h air atmosphere roasting to prepare granular non-noble metal high-efficiency integrated air purification composite material.

[0018] Take 500 g of the prepared granular non-precious metal high-efficiency integrated ai...

Embodiment 3

[0020] Accurately weigh 100 g of zeolite powder, add 20 g of kaolin, 1.5 g of carboxymethyl cellulose, 0.5 ml of paraffin oil and a certain amount of water, mix and stir to form a muddy shape, squeeze it into columnar granules, and aging for 24 hours Of, 80 o C, 4h drying, 500 o C, 4h high-temperature roasting is enough; the columnar granular zeolite carrier is immersed in a 10% hydrogen peroxide solution for 4h, and then taken out at 80 o C, 2h dry; according to the carrier water absorption rate, prepare a certain concentration of copper nitrate and ferric nitrate mixed solution, soak the above carrier in the solution for 2h, take it out and dry naturally, and mix with 60 o C, 2h drying, with 350 o C, 2h air atmosphere roasting to prepare granular non-noble metal high-efficiency integrated air purification composite material.

[0021] Take 500 g of the prepared granular non-precious metal high-efficiency integrated air purification composite material and fill it in the honeycomb p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com