Modified activated carbon, preparation method thereof and method for adsorbing hydrogen sulfide using modified activated carbon

A technology of activated carbon and hydrogen sulfide, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problem that hydrogen sulfide is difficult to meet the needs, and achieve good effect and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

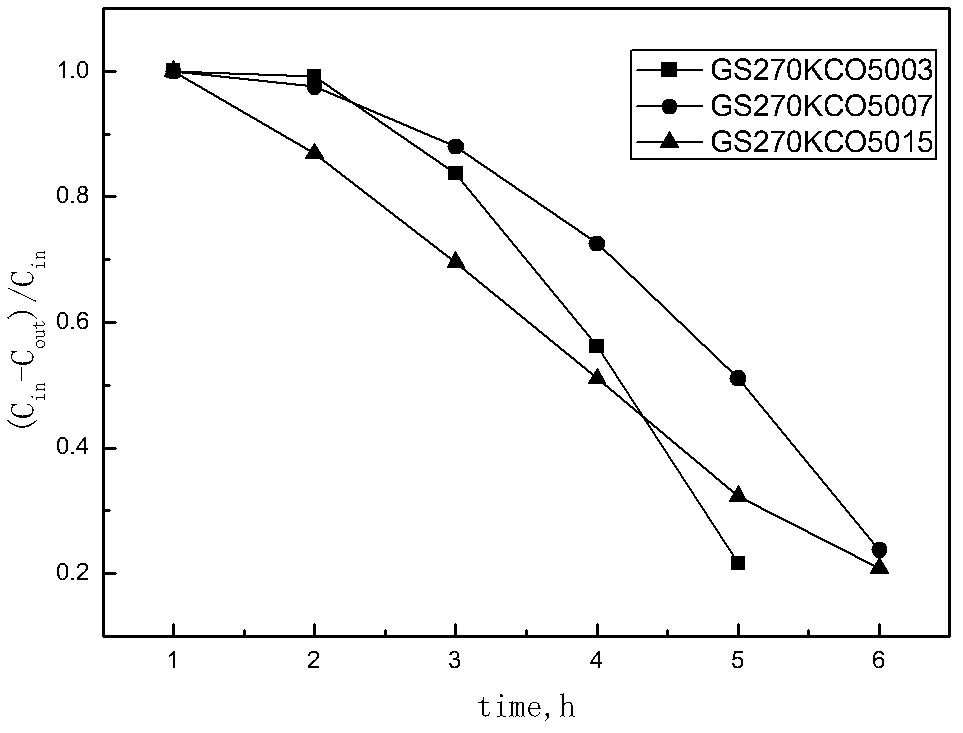

[0052] Measure 3 parts of 20ml activated carbon, place activated carbon and water in a high-temperature reactor according to the volume ratio of 2:3, first modify it in a high-temperature reactor at 270°C for 3 hours, and bake it in an oven at 85°C for 3 hours, then Respectively with mass fractions of 3%, 7% and 15% K 2 CO 3 The solution is used as the impregnating liquid, the volume ratio of activated carbon and impregnating liquid is 4:3, impregnated at 50°C for half an hour, the impregnated activated carbon is washed with distilled water until neutral, then baked in an oven at 85°C for 3 hours, and calculated For: GS270KCO5003, GS270KCO5007 and GS270KCO5015, the three kinds of activated carbon are heated at a temperature of 80°C and a space velocity of 900h -1 , the imported hydrogen sulfide concentration is 750-850mg / m 3 Adsorption of hydrogen sulfide under certain conditions, detection of H at the inlet and outlet 2 S concentration, the adsorption curve as figure 1 . ...

Embodiment 2

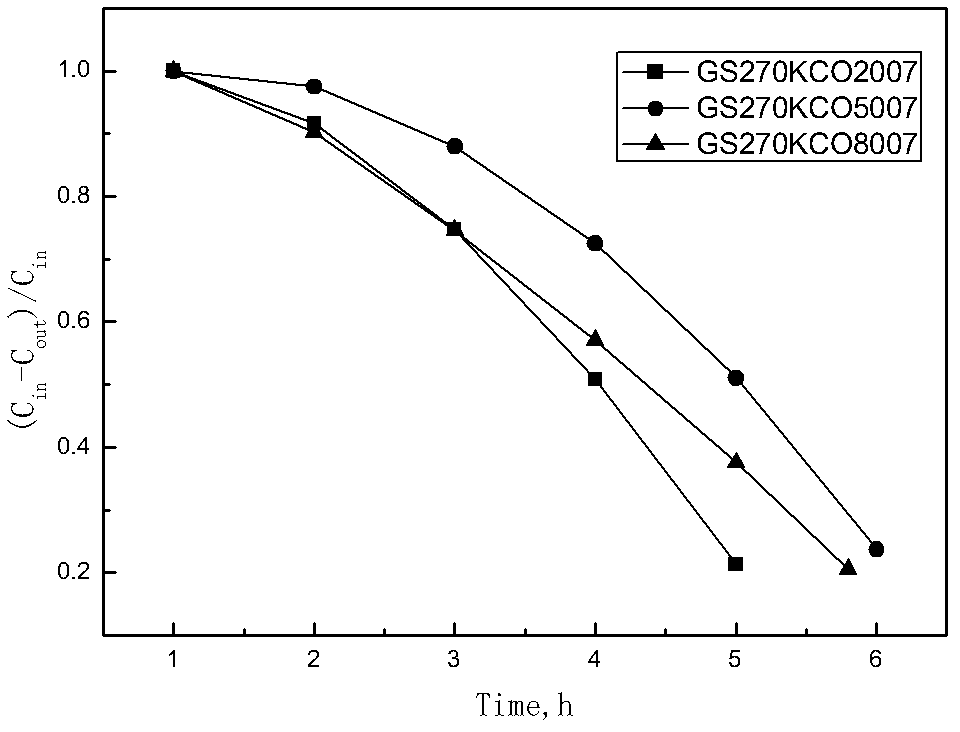

[0054] Measure 3 parts of 20ml activated carbon, respectively in the high-temperature reactor, the volume ratio of activated carbon and water is 2:3, first modify it in the high-temperature reactor at 270°C for 3 hours, and bake it in an oven at 85°C for 3 hours, use mass Score 7% K 2 CO 3 The solution was impregnated at 20°C, 50°C, and 80°C for half an hour (the volume ratio of activated carbon to impregnation solution was 4:3), and the impregnated activated carbon was washed with distilled water until it was neutral, and then dried in an oven at 85°C. 3 hours, and counted as: GS270KCO2007, GS270KCO5007 and GS270KCO8007, made of activated carbon with different impregnation temperatures. Prepared activated carbon at a temperature of 80°C and a space velocity of 900h -1 , the imported hydrogen sulfide concentration is 750-850mg / m 3 The adsorption of hydrogen sulfide is carried out under the conditions, and the adsorption curve is as follows figure 2 .

Embodiment 3

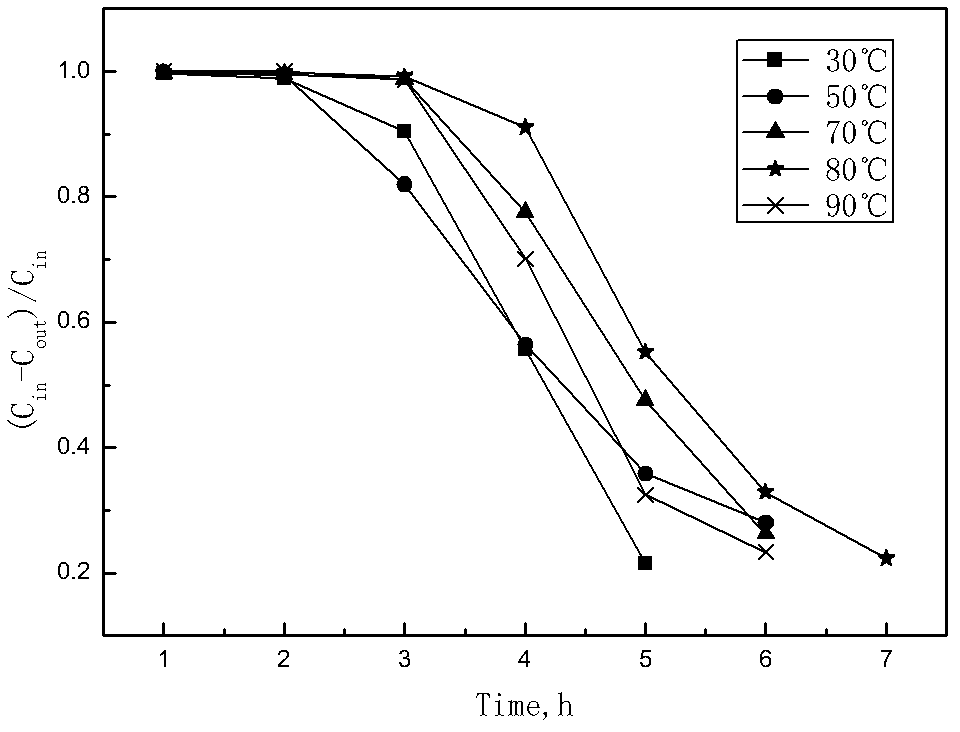

[0056] Measure 2 parts of 20ml activated carbon, respectively in the high-temperature reaction kettle, the volume ratio of activated carbon and water is 2:3, first modify it in a high-temperature reaction kettle at 270°C for 3 hours, bake it in an oven at 85°C for 3 hours, and then dry it in a high-temperature reaction kettle for 3 hours. With mass fraction of 7% CuSO 4 and KOH solution at 50°C for half an hour (the volume ratio of activated carbon to impregnation solution is 4:3), the impregnated activated carbon is washed with distilled water until neutral, and then baked in an oven at 85°C for 3 hours, and calculated as : GS270CuSO5007 and GS270KOH5007 to obtain different modified solutions. The prepared GS270CuSO5007 and GS270KOH5007, at a space velocity of 900h -1 , Intake concentration 750-850mg / m 3 , investigated their removal of H at different temperatures of 30°C, 50°C, 70°C, 80°C and 90°C 2 S capacity, CuSO 4 The adsorption curves of modified activated carbon imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com