125ksi anti-hydrogen sulfide stress corrosion high-strength oil casing steel and preparation process thereof

A stress corrosion and hydrogen sulfide resistance technology, applied in the field of 125ksi hydrogen sulfide stress corrosion resistance high-strength oil casing steel and its preparation technology, can solve the problems of casing string scrapping, drilling rig ecological damage, blowout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

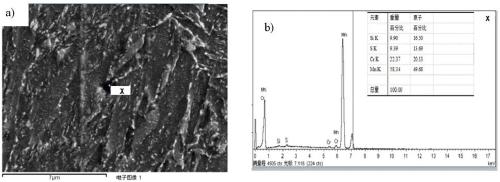

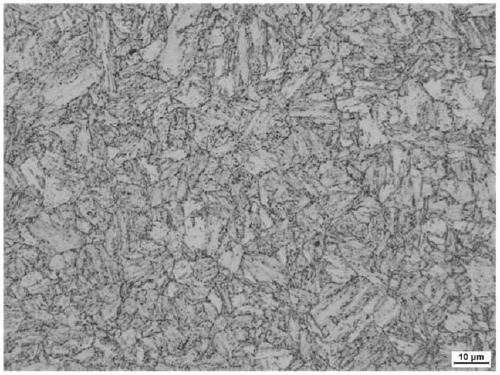

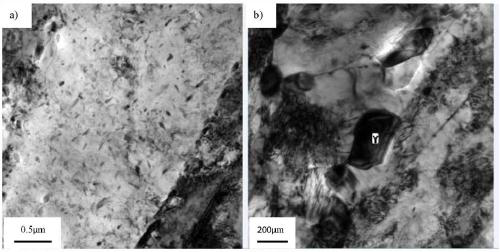

[0087] Table 1 is the chemical composition of the hydrogen sulfide stress corrosion resistant oil casing steel of the present invention, and Table 2 is the heat treatment method of the hydrogen sulfide stress corrosion resistant oil casing steel of the present invention (heat-treat the steel plate after hot rolling, see Table 2). According to the chemical composition set in Table 1, the oxide metallurgy process was used to smelt in a vacuum induction furnace, and then cast to form a steel ingot, and cooled to room temperature. Then the steel ingot is heated to 1050°C for forging, and cooled to room temperature to form a billet of 80×80mm. Then the billet is kept in the furnace at a heating temperature of 1150° C. for 2 hours, then hot rolled, and finally rolled into a steel plate with a thickness of 13 mm, and then air-cooled to room temperature. Normalize the hot-rolled and cooled steel plate at 900°C, keep it warm for 10 minutes, air cool to room temperature, then quench it...

Embodiment 2

[0089] Table 1 is the chemical composition of the hydrogen sulfide stress corrosion resistant oil casing steel of the present invention, and Table 2 is the heat treatment method of the hydrogen sulfide stress corrosion resistant oil casing steel of the present invention (heat-treat the steel plate after hot rolling, see Table 2). According to the chemical composition set in Table 1, the oxide metallurgy process was used to smelt in a vacuum induction furnace, and then cast to form a steel ingot, and cooled to room temperature. Then the steel ingot is heated to 1100°C for forging, and cooled to room temperature to form a billet of 80×80mm. Then hot rolling is carried out in a furnace at a heating temperature of 1200° C. for 2 hours, and finally rolled into a steel plate with a thickness of 15 mm, which is air-cooled to room temperature. Normalize the hot-rolled and cooled steel plate at 910°C, keep it warm for 15 minutes, air cool to room temperature, then quench it at 830°C, ...

Embodiment 3

[0091] Table 1 is the chemical composition of the hydrogen sulfide stress corrosion resistant oil casing steel of the present invention, and Table 2 is the heat treatment method of the hydrogen sulfide stress corrosion resistant oil casing steel of the present invention (heat-treat the steel plate after hot rolling, see Table 2). According to the chemical composition set in Table 1, the oxide metallurgy process was used to smelt in a vacuum induction furnace, and then cast to form a steel ingot, and cooled to room temperature. Then the steel ingot is heated to 1100°C for forging, and cooled to room temperature to form a 100×100 square billet. Then hot rolling is carried out in a furnace at a heating temperature of 1200° C. for 2 hours, and finally rolled into a steel plate with a thickness of 15 mm, which is air-cooled to room temperature. Normalize the hot-rolled and cooled steel plate at 920°C, keep it warm for 20 minutes, air-cool it to room temperature, then quench it at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com