Aluminum alloys and methods of making same

A technology of aluminum alloy and aluminum alloy plate, applied in the field of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

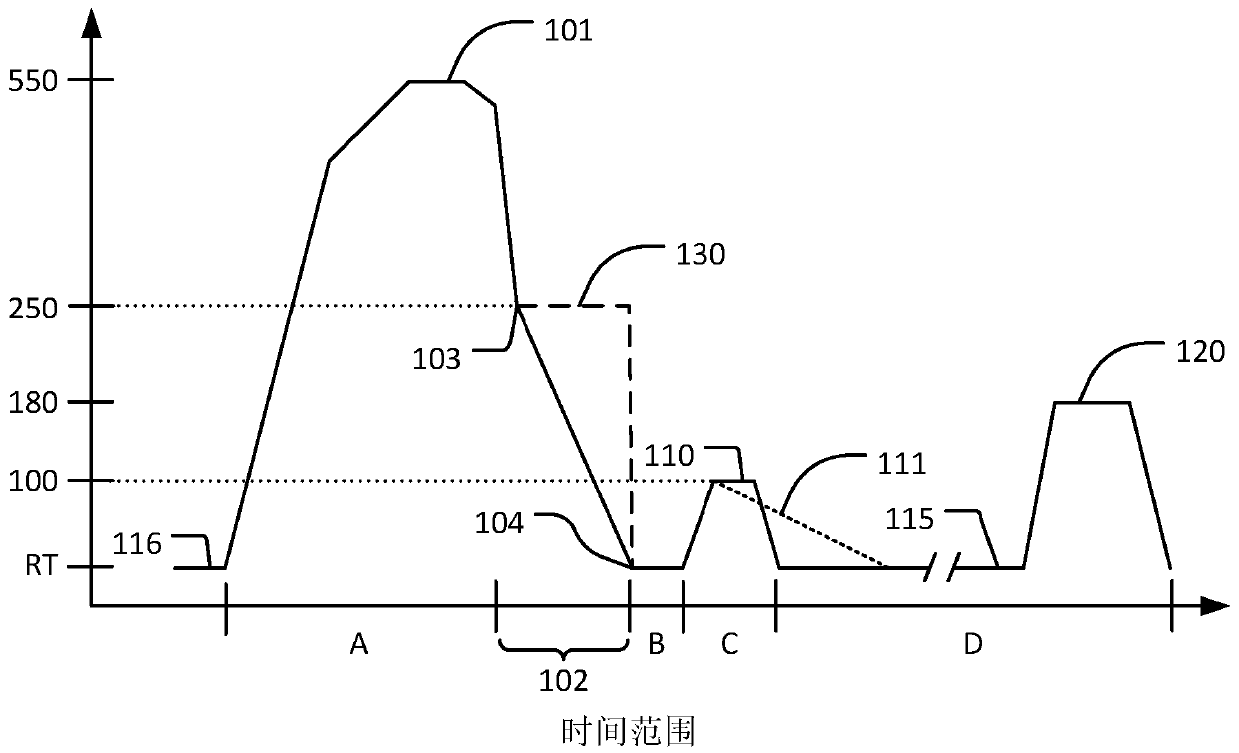

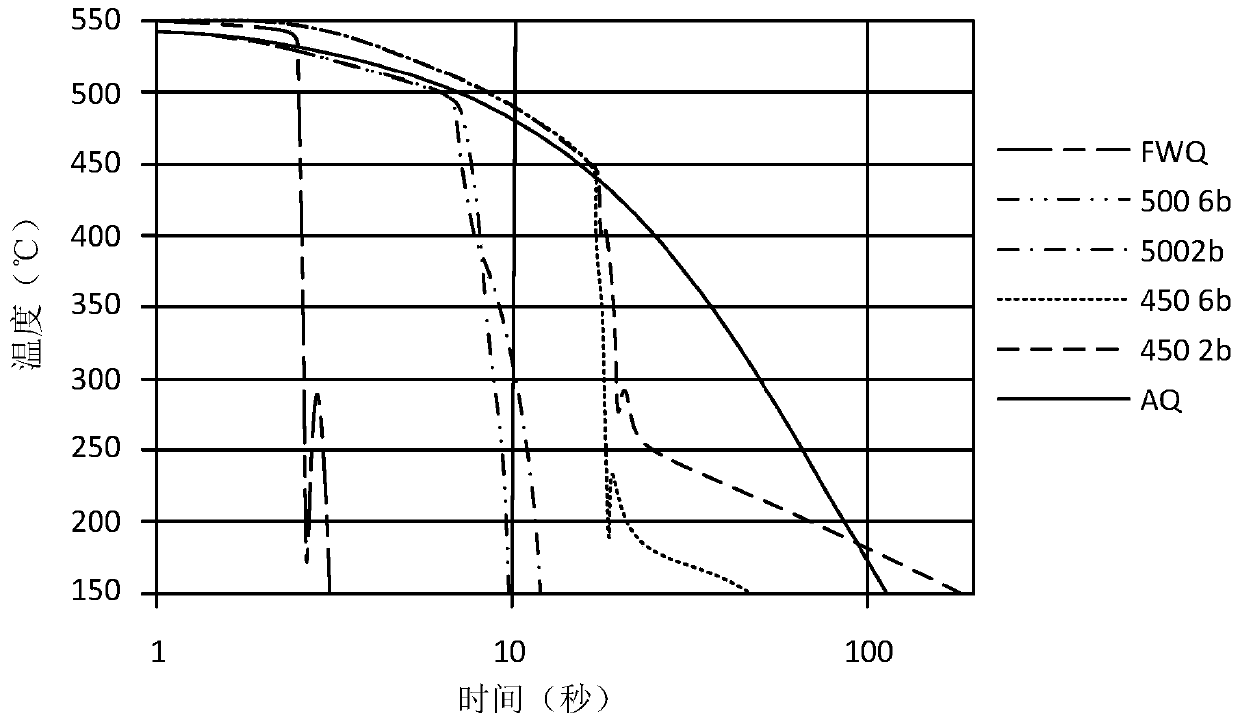

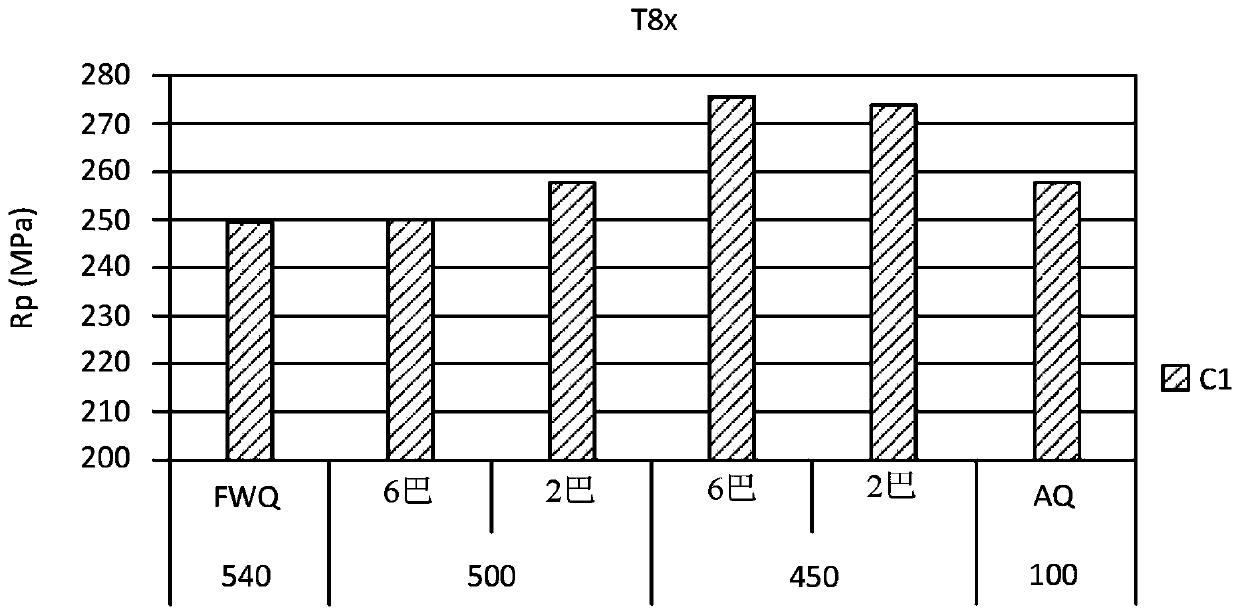

[0081] figure 2 It is a graph of the thermal history of alloy C1 during the exemplary quenching technique and the comparative continuous quenching technique. For comparison, continuous full water quenching (FWQ) and continuous air only quenching (AQ) are shown. The discontinuous exemplary method starts with various alloy C1 coil temperatures of 500°C and 450°C when exiting the solid melting furnace. Water quenching is carried out under various water spray pressures including 6 bar (b) and 2 bar (b). The graph details the fast cooling of FWQ and the slower cooling of AQ. Alloy C1 was quenched by exemplary discontinuous quenching. Starting from the alloy exiting the solid-melting furnace, it was cooled to 500°C by air quenching (referred to as "5006b" and "500 2b"), showing the rapid cooling of the alloy but no second comparison. Slow quenching step. When quenching was changed from water to air at about 250°C, the alloy C1 sample quenched by exemplary discontinuous quenching ...

example 2

[0086] Image 6 The yield strength test results of exemplary quench deformation and paint baking techniques used during processing of exemplary aluminum alloys with various Mn contents are presented. Table 2 describes the exemplary aluminum alloy V1 and V2 compositions in this example (the balance composition is consistent with the example described herein):

[0087] Table 2-Exemplary alloy composition

[0088] alloy Si FeCu Mn Mg V10.850.200.080.070.65 V20.850.200.080.200.65

[0089] Image 6 Shows the increase in yield strength of exemplary alloy V1 and exemplary alloy V2 undergoing exemplary discontinuous quenching, air quenching is started when the solutionized coil exits the solid melting furnace, and becomes water quenched to be quenched to about 450°C Temperature, and then become air quenched when the coil cools to about 250°C. An alloy undergoing exemplary quenching, deformation, and aging (2% strain then heated to 185°C and maintained at 185°C for 20 minutes) produces...

example 3

[0093] Picture 9 Shown are the yield strength test results of samples having a composition including alloy A1 (see Table 1) produced in the manufacturing context. Alloy A1 undergoes various quenching techniques during processing. Such as Picture 9 As shown, complete water quenching (the first group of histogram bars, called "standard water"), air-only quenching (the fourth group of histogram bars, called "standard air") and exemplary discontinuous quenching are used. The exemplary discontinuous quenching starts from exiting the solid melting furnace and then quenching with water to 100°C (the second set of histogram bars, called "water, exit at 100°C") and 220°C (the third set of histogram bars, called "Water, exit at 220°C") temperature. It shows the yield strength after natural aging (T4 state) and deformation plus artificial aging (T8x state, 2% strain and then heating to 185°C and maintaining 185°C for 20 minutes). Picture 9 The effect of exemplary quenching techniques ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com