Deformed aluminum alloy

A technology for deforming aluminum alloys and aluminum alloys, applied in the field of deformed aluminum alloys, can solve problems such as deformation, low productivity, poor cross-sectional shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiments of the present invention will be explained in detail below with reference to the accompanying drawings. But the present invention is not limited to the embodiments disclosed below, and can also be embodied in various ways that are different from each other. The following embodiments are provided to fully disclose the present invention and facilitate those skilled in the art to fully understand the scope of the present invention. In addition, for convenience of explanation, the sizes of constituent elements may be enlarged or reduced in the drawings.

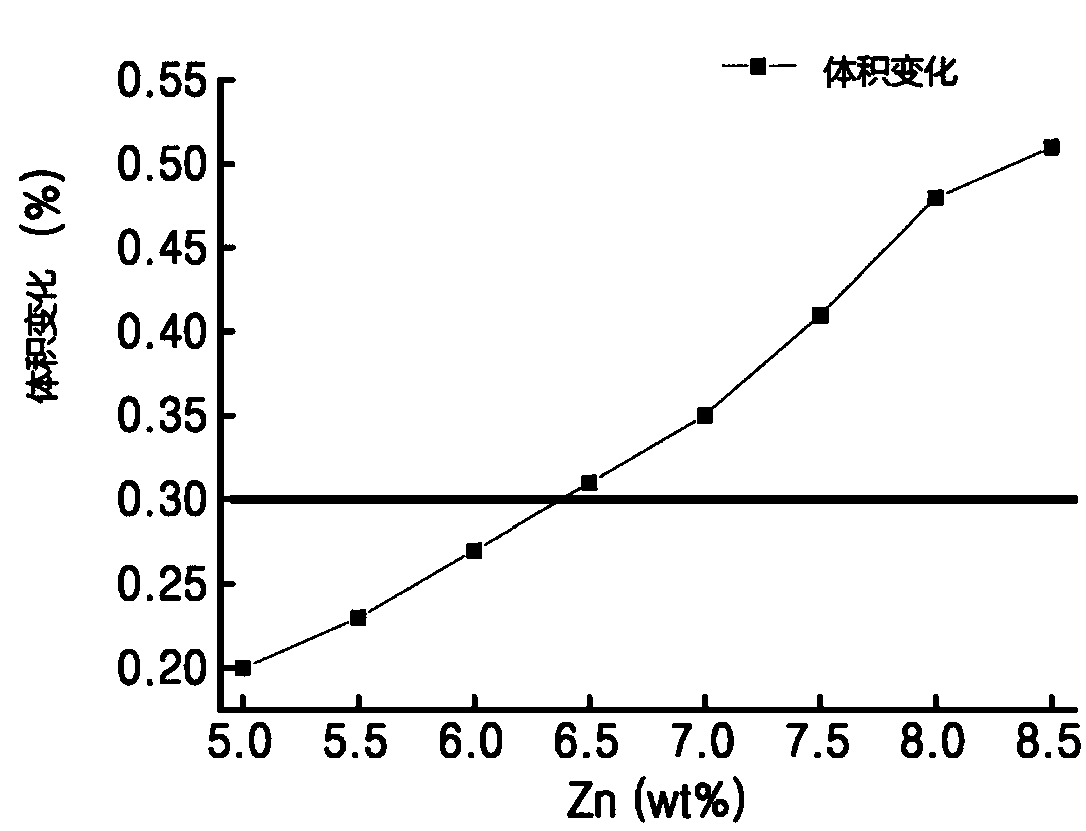

[0061] The wrought aluminum alloy (A7075) provided as a comparative example of the present invention may contain: 5.1% to 6.1% by weight of Zn; 2.1% to 2.9% by weight of Mg; 1.2% to 2.0% by weight of Cu; 0.18 wt% to 0.28 wt% Cr; 0.5 wt% or less Fe; 0.3 wt% or less Mn; 0.4 wt% or less Si; 0.2 wt% Ti;

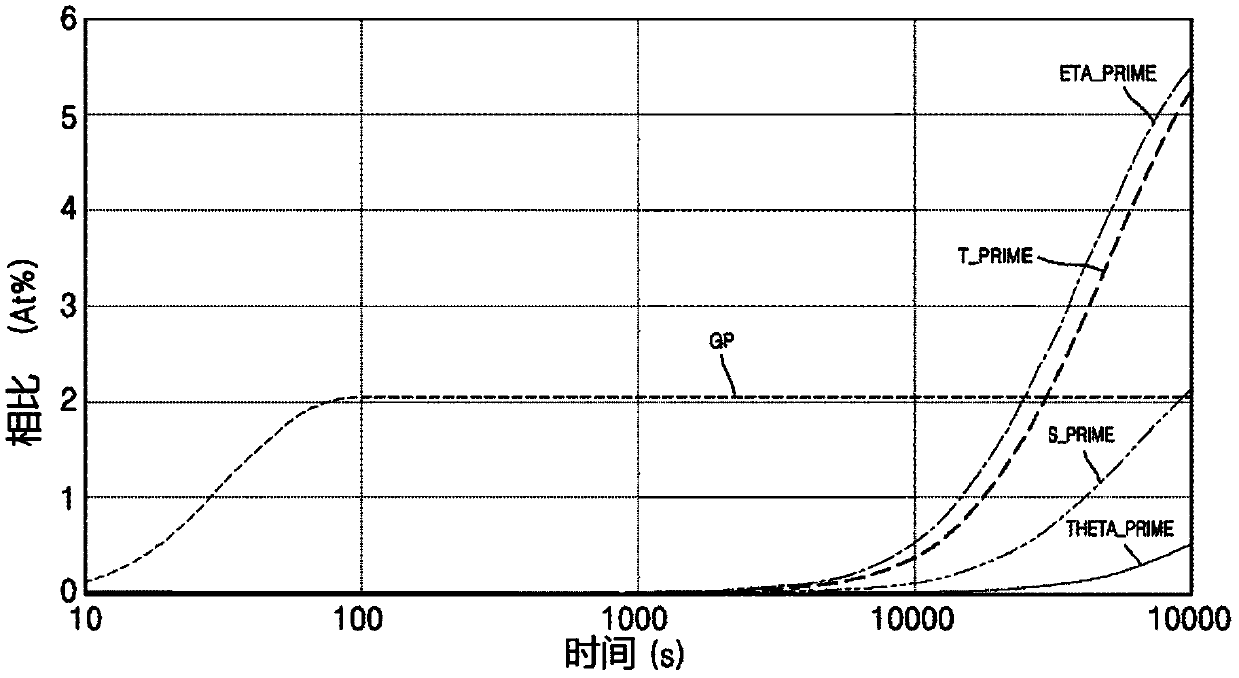

[0062] Among wrought aluminum alloys, the so-called 7000 series aluminum alloy has a yield strength of over 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com