Patents

Literature

33results about How to "Deterioration of physical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface crosslinking treatment method of water-absorbing resin powder

ActiveUS7378453B2Good physical propertiesMade stableAbsorbent padsDyeing processAqueous solutionIndustrial scale

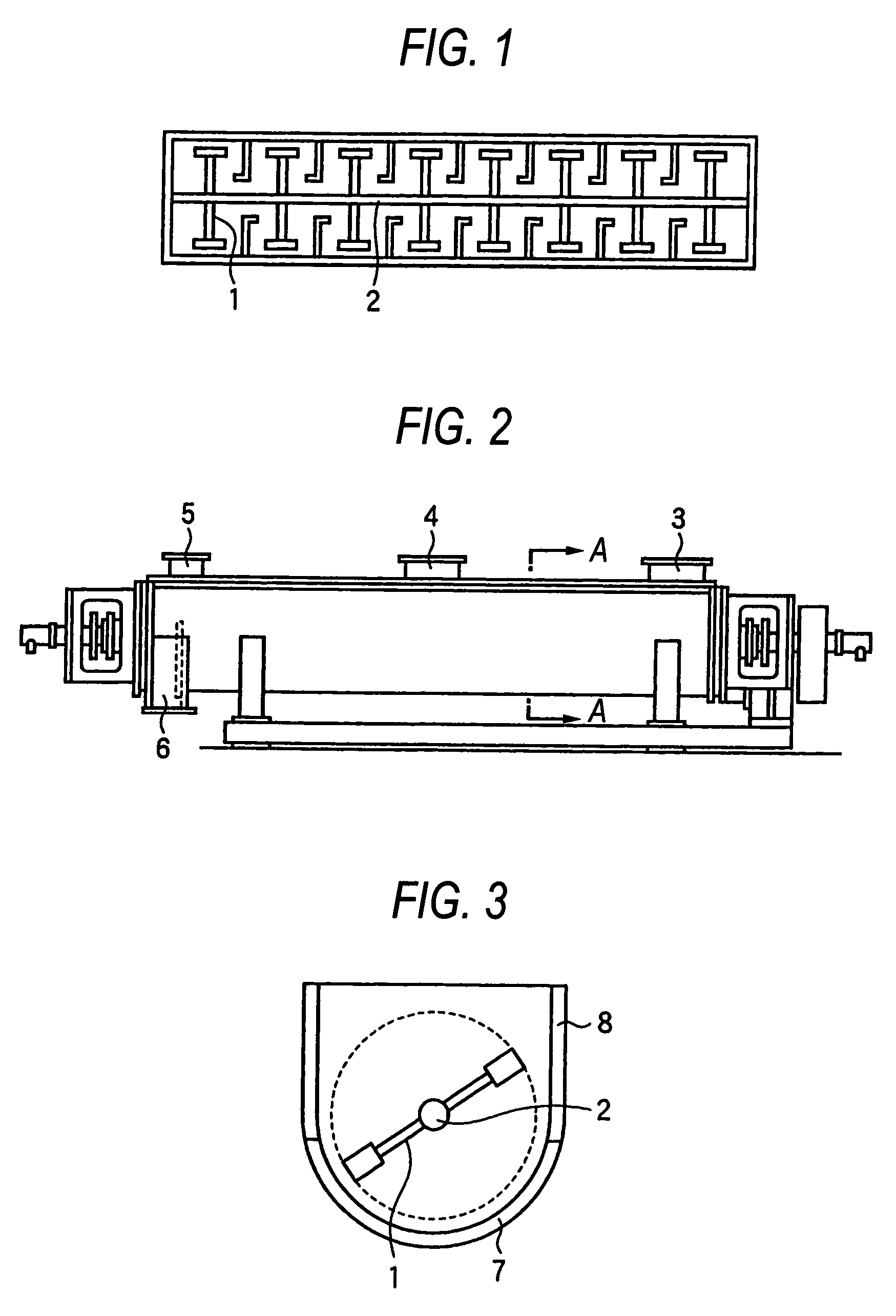

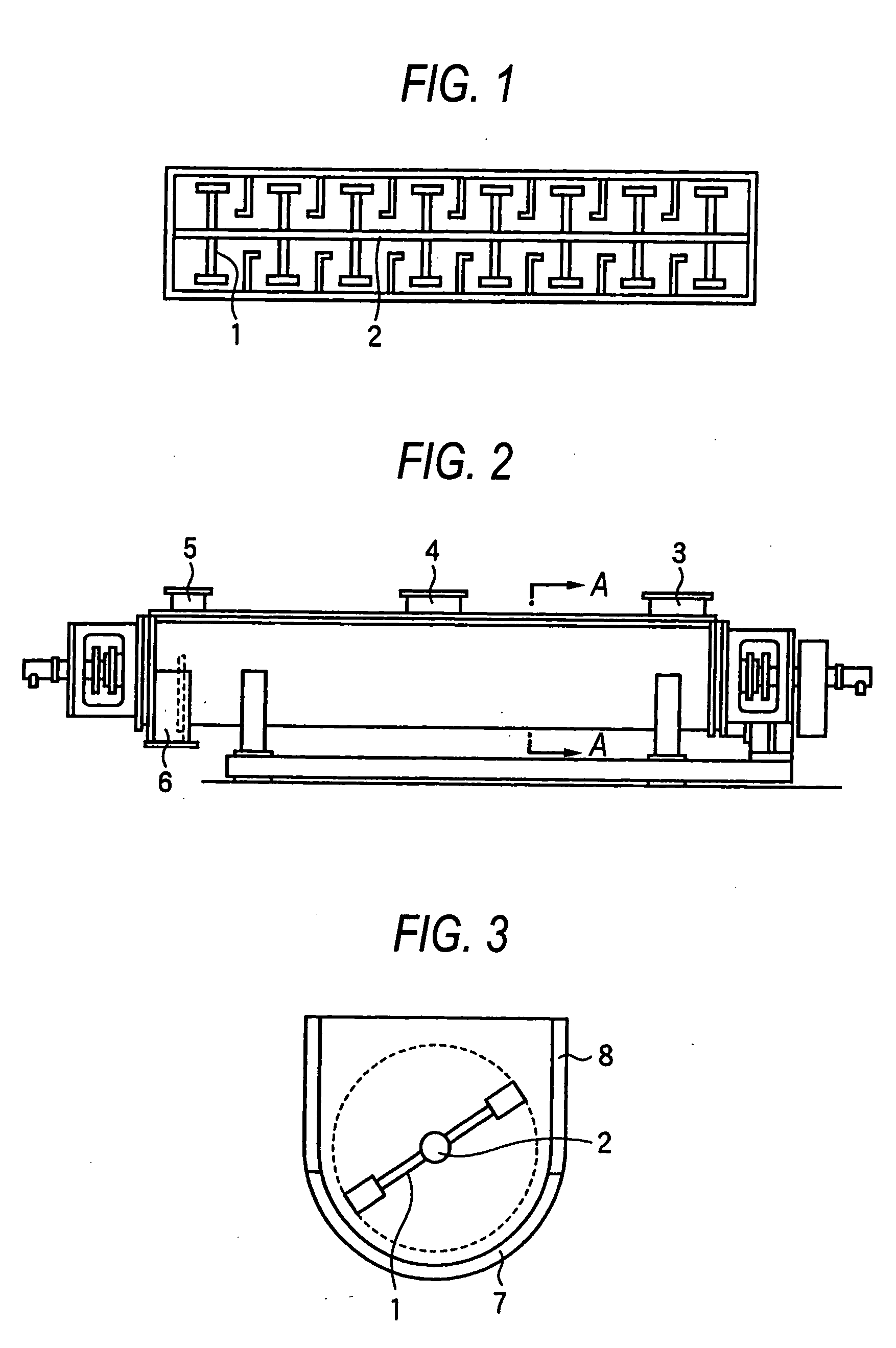

A surface crosslinking treatment method of a water-absorbing resin powder is disclosed that can overcome various problems in production encountered in the production of surface crosslinked water-absorbing resin powders on an industrial scale and can produce a water-absorbing resin powder having excellent physical properties without causing deterioration in physical properties of resin. The surface crosslinking treatment method of a water-absorbing resin powder includes adding a surface crosslinking agent to a water-absorbing resin powder and heat treating the mixture, wherein (1) the water-absorbing resin powder after the heat treatment is stirred and cooled under an air flow; (2) the water-absorbing resin powder after the heat treatment is cooled under an air flow, and at the same time, at least a part of fine particles of the water-absorbing resin powder and / or the residual crosslinking agent is removed by the air flow; or (3) the water-absorbing resin powder after the heat treatment is cooled and simultaneously granulated, and preferably an aqueous solution is added to the water-absorbing resin powder at a temperature of 40-100° C. during the cooling treatment.

Owner:NIPPON SHOKUBAI CO LTD

Water-absorbing resin and method for manufacturing the same

The present invention provides a highly productive method for manufacturing a water-absorbing resin, the amounts of fine powder and dust of which are small, the amount of residual monomer of which is small, and whose absorption rate is high. That is, the method for manufacturing the water-absorbing resin of the present invention is a method for crosslinking and polymerizing an aqueous solution of an acid-group containing unsaturated monomer, and is characterized in that stationary polymerization is carried out in such a manner that a solid matter is added to the monomer aqueous solution, and an initiation temperature of the polymerization is adjusted to 40° C. or more or a maximum temperature of the polymerization is adjusted to 100° C. or more.

Owner:NIPPON SHOKUBAI CO LTD

Surface crosslinking treatment method of water-absorbing resin powder

ActiveUS20040181031A1Good physical propertiesMade stableAbsorbent padsDyeing processAqueous solutionIndustrial scale

A surface crosslinking treatment method of a water-absorbing resin powder is disclosed that can overcome various problems in production encountered in the production of surface crosslinked water-absorbing resin powders on an industrial scale and can produce a water-absorbing resin powder having excellent physical properties without causing deterioration in physical properties of resin. The surface crosslinking treatment method of a water-absorbing resin powder includes adding a surface crosslinking agent to a water-absorbing resin powder and heat treating the mixture, wherein (1) the water-absorbing resin powder after the heat treatment is stirred and cooled under an air flow; (2) the water-absorbing resin powder after the heat treatment is cooled under an air flow, and at the same time, at least a part of fine particles of the water-absorbing resin powder and / or the residual crosslinking agent is removed by the air flow; or (3) the water-absorbing resin powder after the heat treatment is cooled and simultaneously granulated, and preferably an aqueous solution is added to the water-absorbing resin powder at a temperature of 40-100° C. during the cooling treatment.

Owner:NIPPON SHOKUBAI CO LTD

Water absorbing agent, water absorbing article and method for production of water absorbing agent

ActiveUS20100062252A1Promote absorptionReduce the amount requiredSynthetic resin layered productsCellulosic plastic layered productsCarboxylic acidEster bond

An object of the present invention is to provide a water absorbing agent having a low amount of residual monomer, small variance of the amount of residual monomer among ranges of particle size distribution and favorable absorption properties, and being sanitary; an absorbing article; and a method for the production of a water absorbing agent. The water absorbing agent of the present invention has the amount of residual monomer of not higher than 500 ppm, and a residual monomer index of not greater than 0.30. The method for the production includes a first step of obtaining a hydrogel polymer by polymerizing an aqueous solution of a monomer including an unsaturated carboxylic acid and / or a salt thereof in the presence of a crosslinking agent; a second step of obtaining a water absorbent resin precursor which is in powder form and includes particles having a particle size of 300 to 850 μm and particles having a particle size of smaller than 300 μm as main components by drying said hydrogel polymer followed by pulverization and classification to adjust the particle size distribution, a third step of obtaining a water absorbent resin by heating a mixture of said water absorbent resin precursor and a surface crosslinking agent, which can form an ester bond around the surface of said water absorbent resin precursor, a fourth step of adding by spraying an aqueous solution that includes a sulfur-containing reducing agent to said water absorbent resin, and a fifth step of subjecting the mixture of the water absorbent resin and said aqueous solution to a heat treatment under an airflow of not lower than 40° C. but not higher than 120° C.

Owner:NIPPON SHOKUBAI CO LTD

Polyacrylic acid (salt)-based water-absorbent resin and method for producing same

InactiveUS20110034603A1Color stableHigh whitenessAbsorbent padsEmulsion paintsPolymer scienceALLYL SUCROSE

In order to realize, while preventing gelatification of a monomer not yet to be polymerized, a water-absorbent resin which is more stable in color over time and has a significant enhancement in a problem concerning surface color and an excellent absorption property, a method for producing a polyacrylic acid-based water-absorbent resin includes: a preparation step in which a monomer is prepared from acrylic acid including hydroxyacetone in an amount not larger than 300 mass ppm; a polymerization step in which the monomer is polymerized so that a hydrogel is obtained; and a drying step in which the hydrogel is dried. Also, a method of the present invention for producing polyacrylic acid-based water-absorbent resin includes: a preparation step in which a monomer is prepared from acrylic acid; a polymerization step in which the monomer is polymerized in presence of phenol so that a hydrogel is obtained; and a drying step in which the hydrogel is dried.

Owner:NIPPON SHOKUBAI CO LTD

Filled perfluoropolymer composition

InactiveUS20050187328A1Improve performanceGood physical propertiesSynthetic resin layered productsCellulosic plastic layered productsPlenum cablePolymer chemistry

The present invention relates to plenum cables jacketed with a composition comprising perfluoropolymer, inorganic char-forming agent, and hydrocarbon polymer, which passes the NFPA-255 burn test.

Owner:MEXICHEM AMANCO HLDG DE C V +1

Thermoplastic elastomeric resin composition and a process for the preparation thereof

InactiveUS20030060557A1Deterioration of physical propertyFacilitate cross-linkingSpecial tyresFibre mechanical structuresThermoplasticPolymer science

The invention provides a process for the preparation of a thermoplastic elastomeric resin composition comprising melt kneading (a) 100 parts by weight of a block copolymer consisting of at least two polymeric blocks (A) composed mainly of a vinyl aromatic compound and at least one polymeric block (B) composed mainly of a conjugated diene compound, and / or a hydrogenated block copolymer obtained by hydrogenating said block copolymer, (b) 40 to 240 parts by weight of a non-aromatic softening agent for rubber, (c) 5 to 300 parts by weight of polyethylene or a copolymer composed mainly of ethylene, and (d) 5 to 60 parts by weight of polypropylene or a copolymer composed mainly of propylene, characterized in that the process comprises the following steps: (I) melt kneading the whole amounts of components (a), (b) and (d) and a part of component (c), and, at the same time or subsequently, melt kneading these with (f) an organic peroxide, and (II) melt kneading the product obtained from step (I) with the remaining part of component (c), and component (c) is one which has been prepared using a single site catalyst. The obtained composition is soft and excellent in heat deformation resistance and mechanical strength, moldability and processability. The present invention also provide a thermoplastic elastomeric resin composition comprising the above components (a), (c) and (d) in an amount of 100 parts by weight, 5 to 150 parts by weight and 5 to 80 parts by weight, respectively. The composition is soft and excellent in heat deformation resistance and mechanical strength, moldability and processability and shows good results in the extraction tests.

Owner:RIKEN TECHNOS CORP

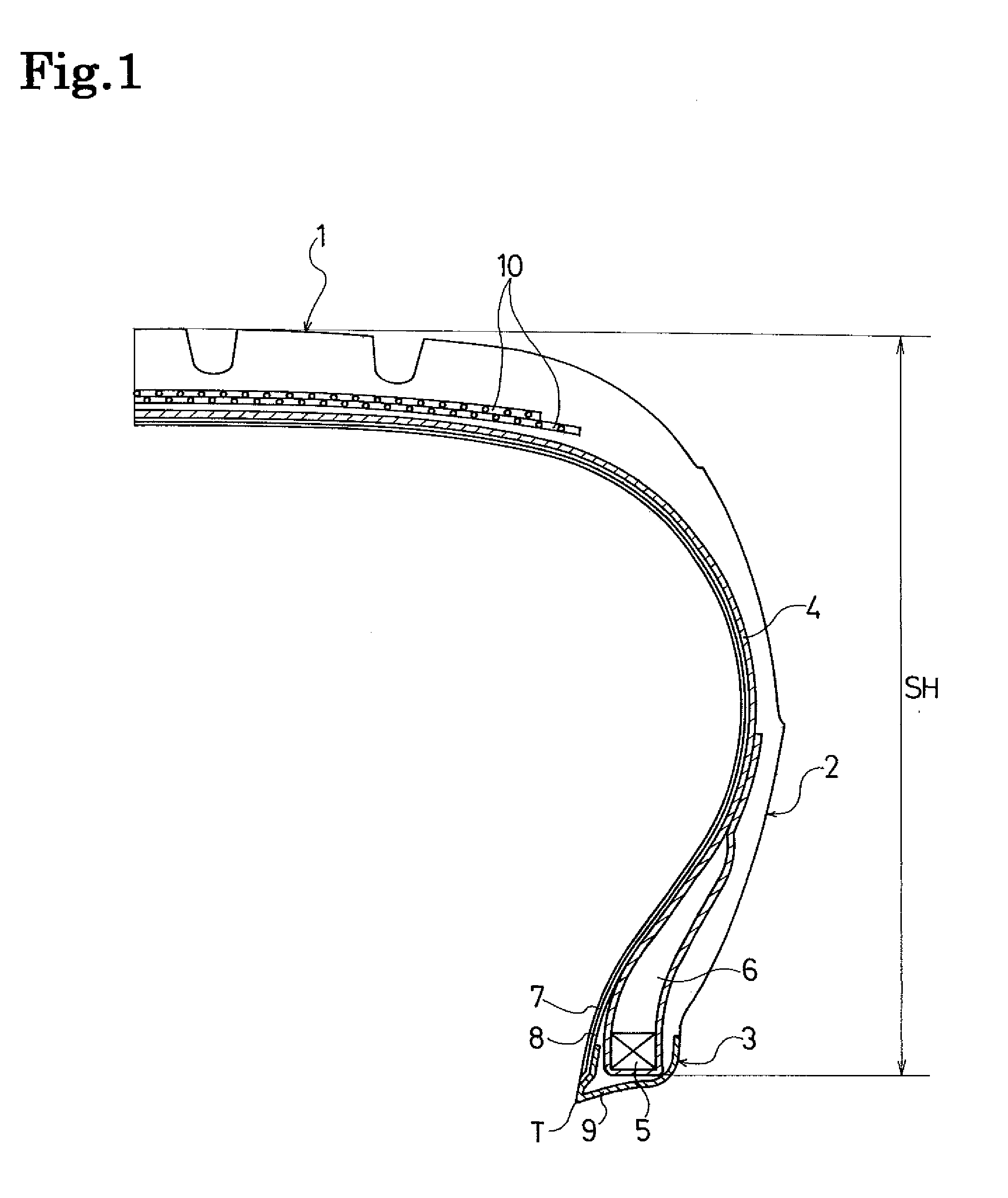

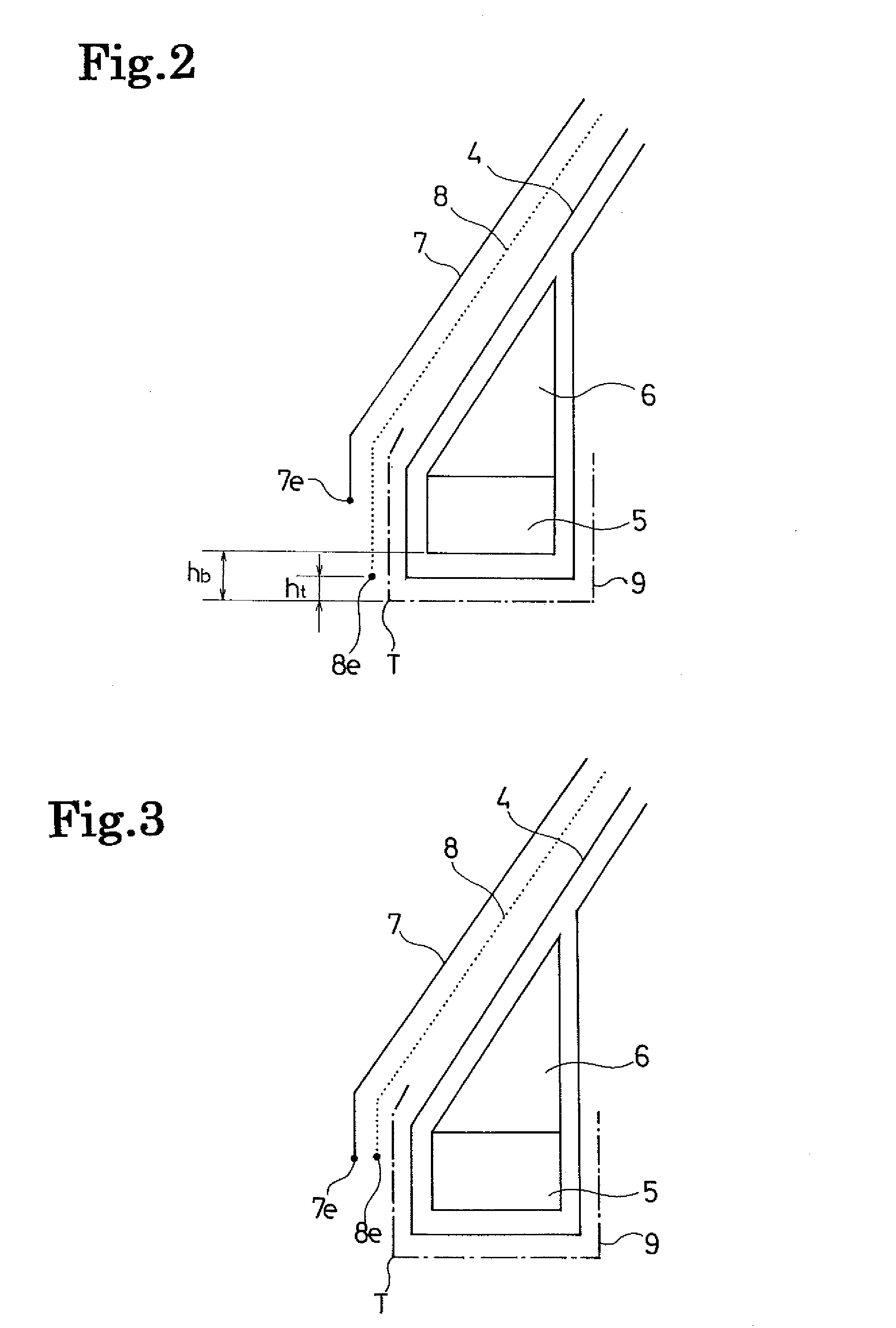

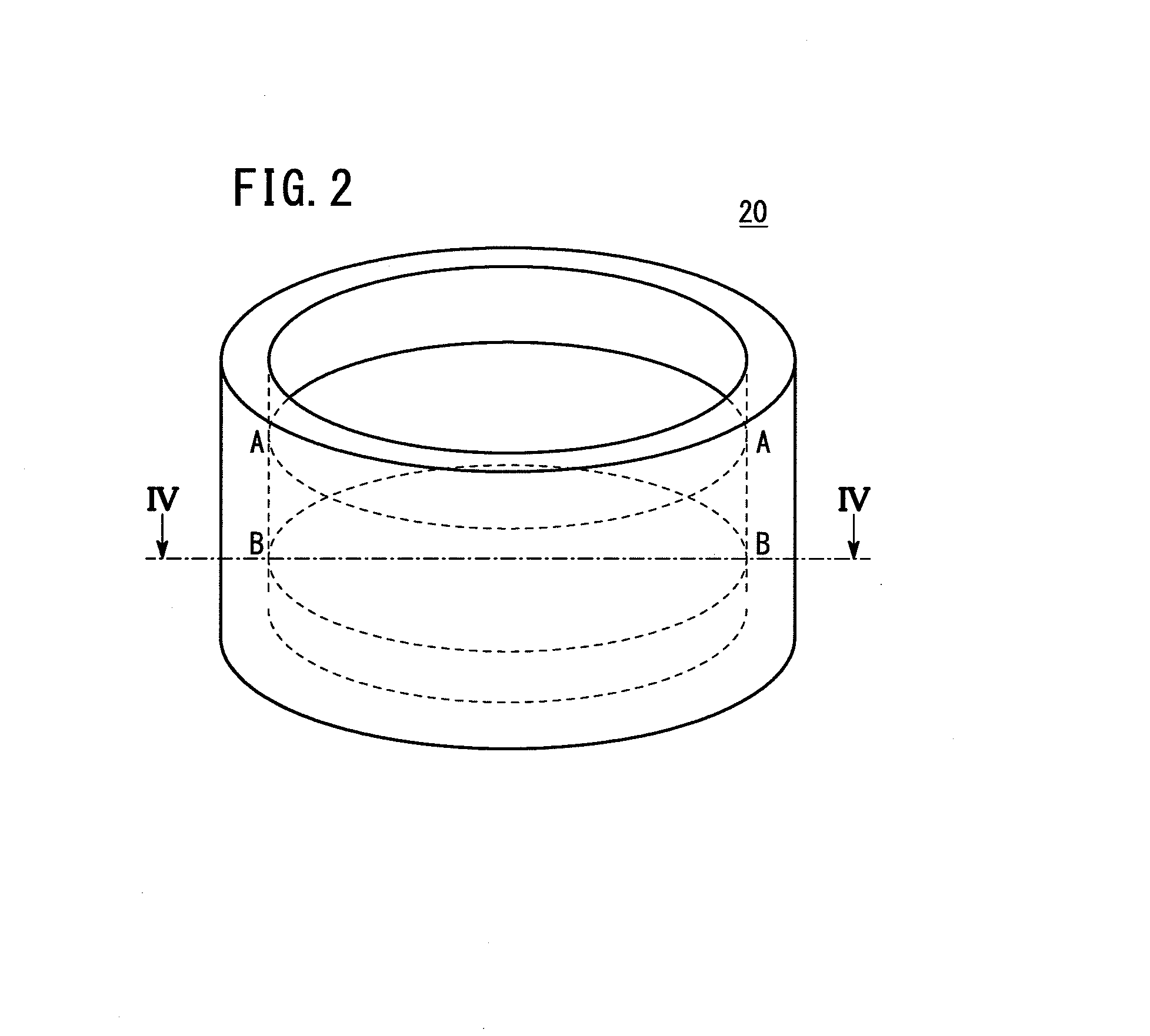

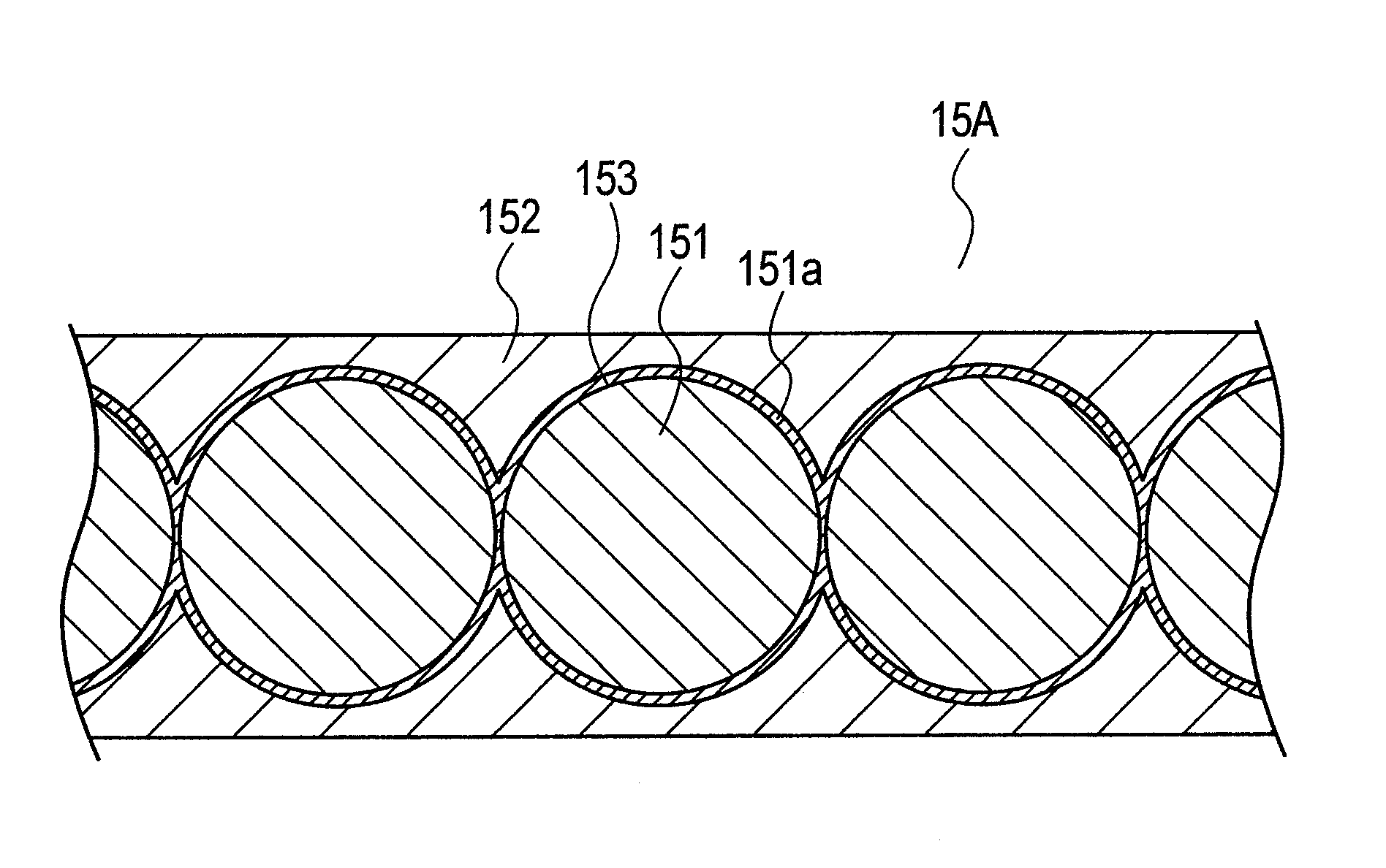

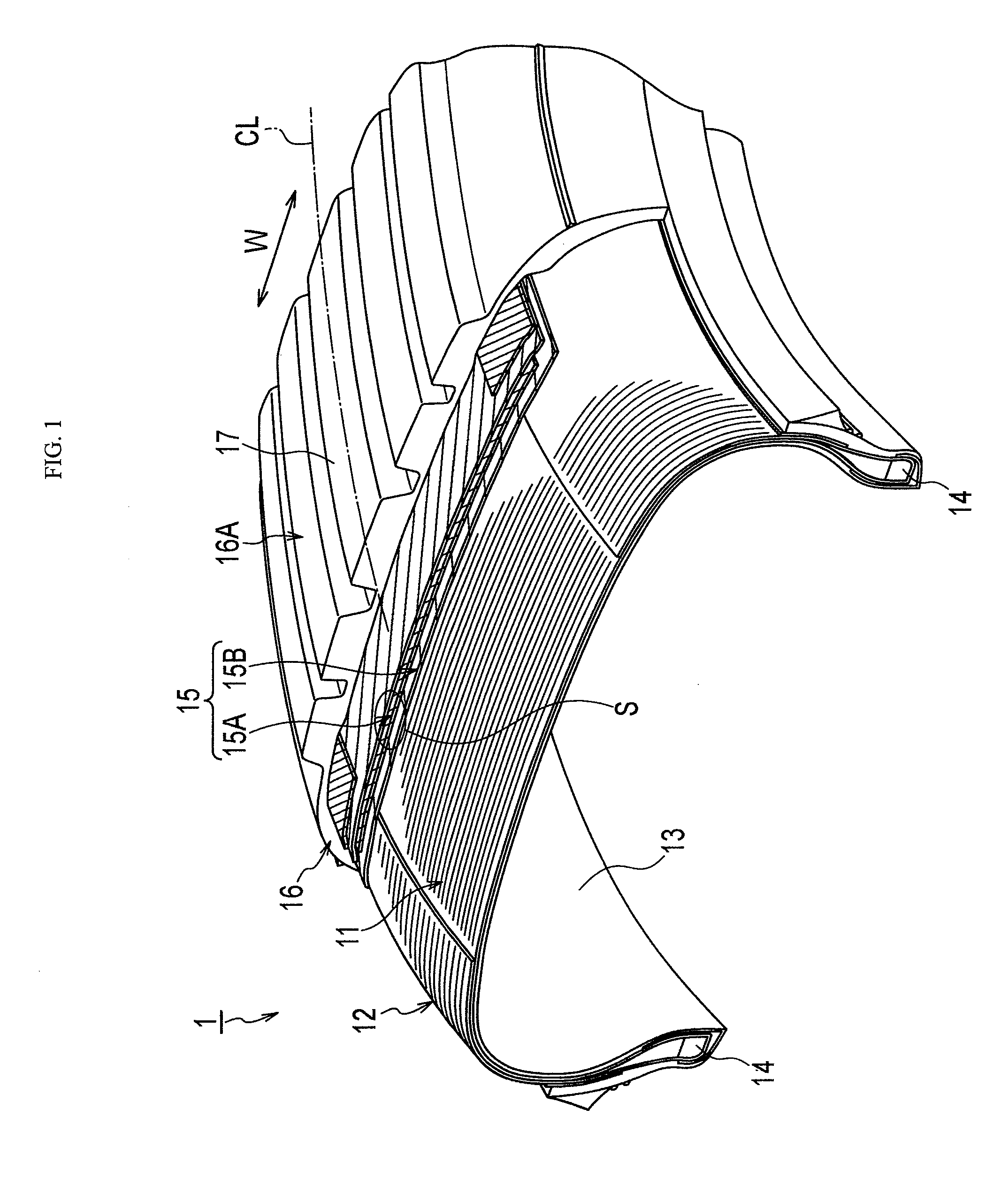

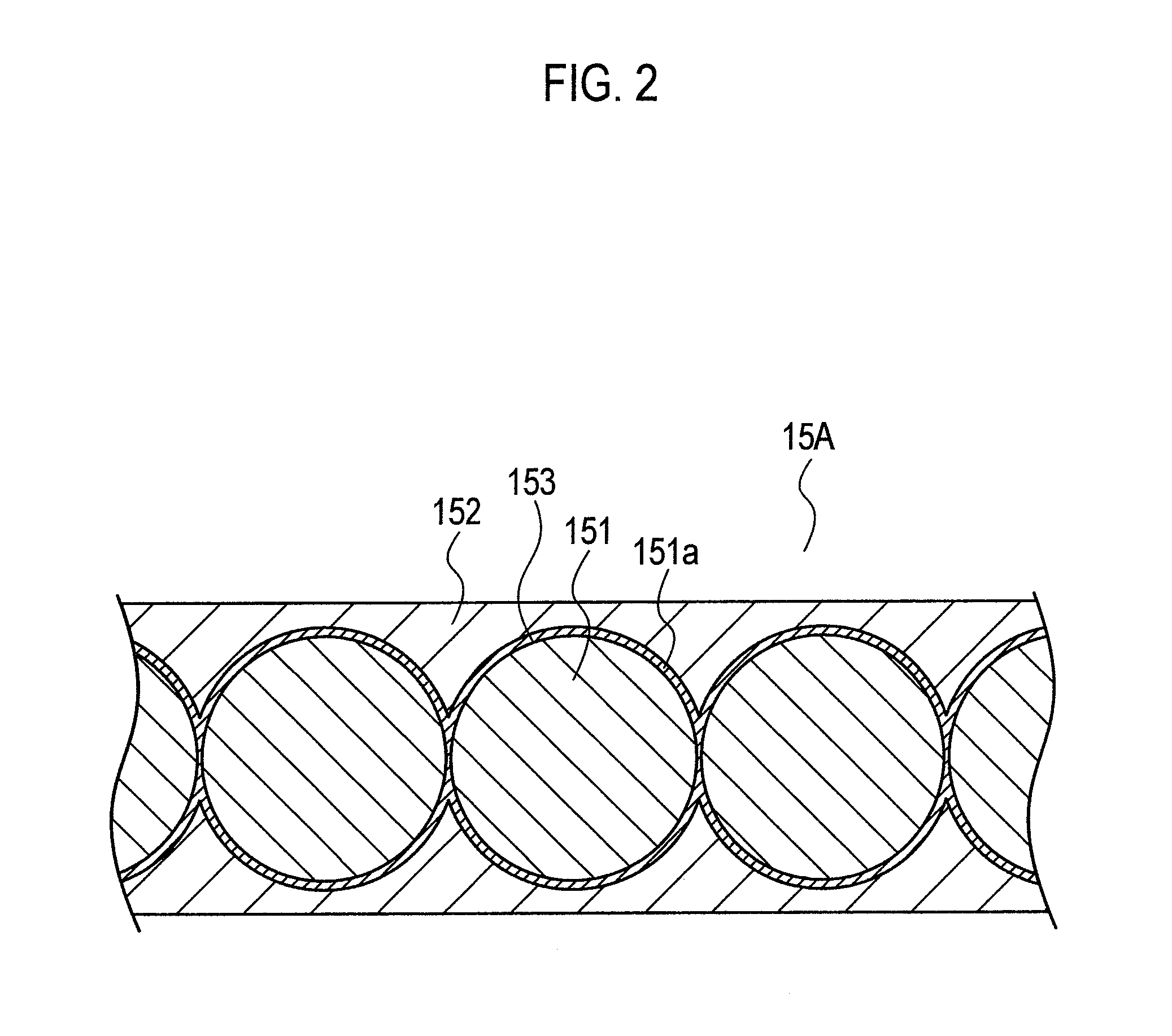

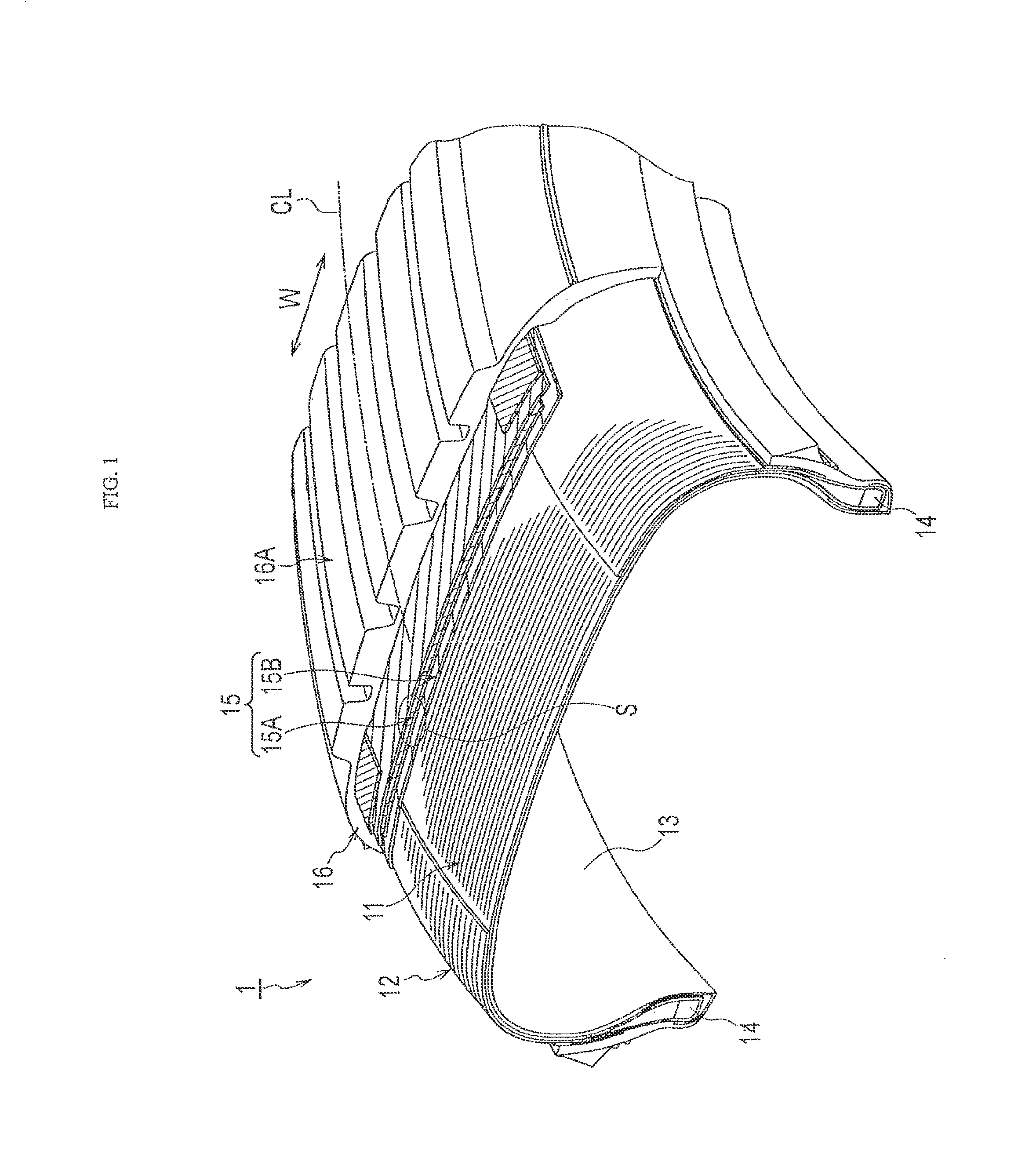

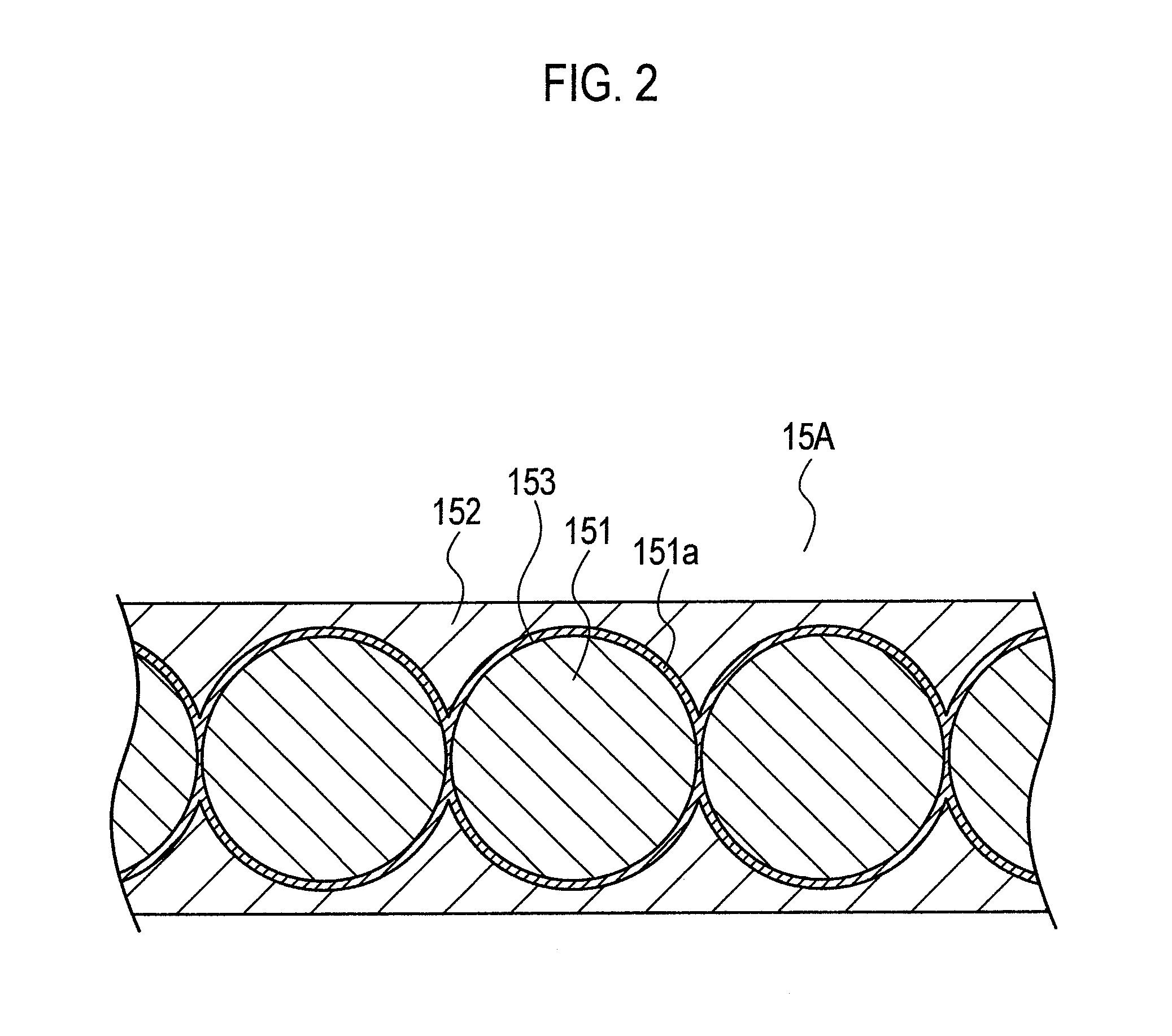

Pneumatic tire

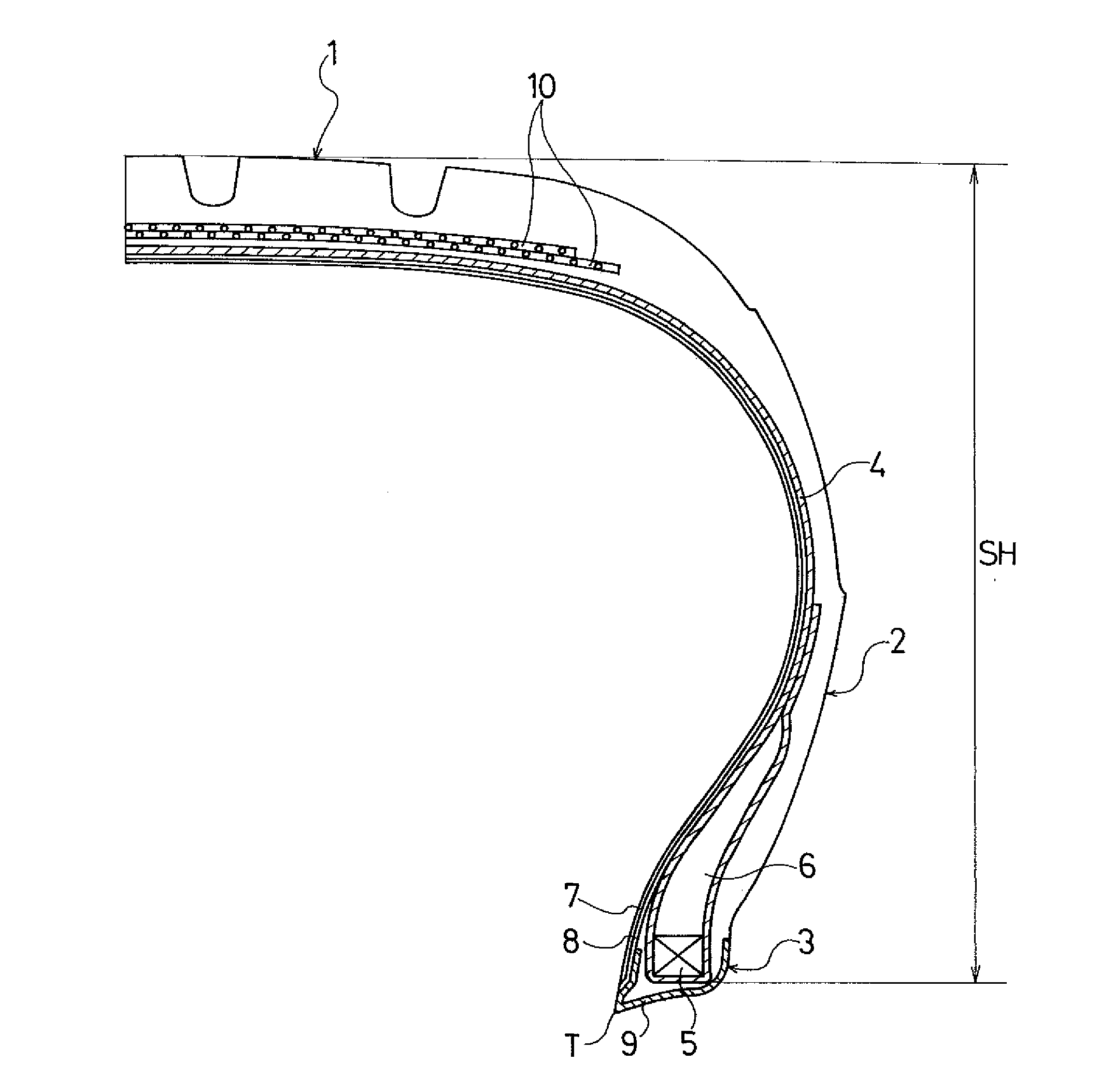

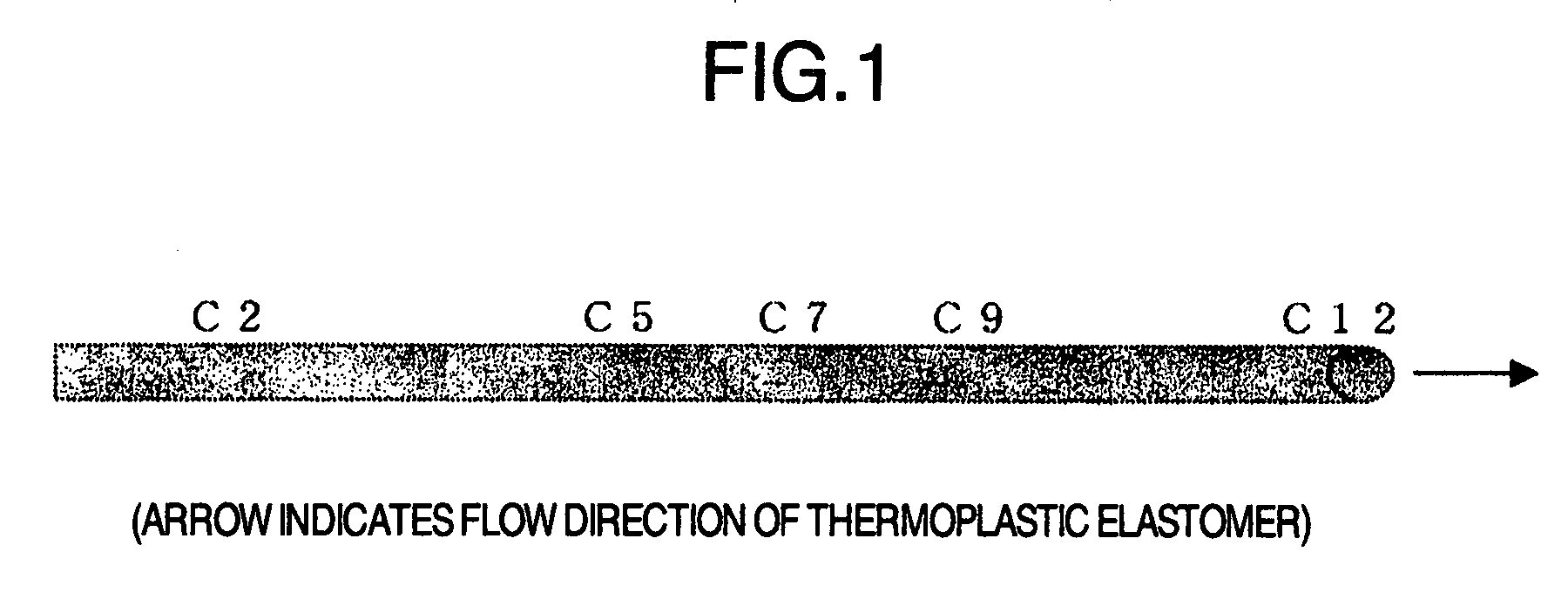

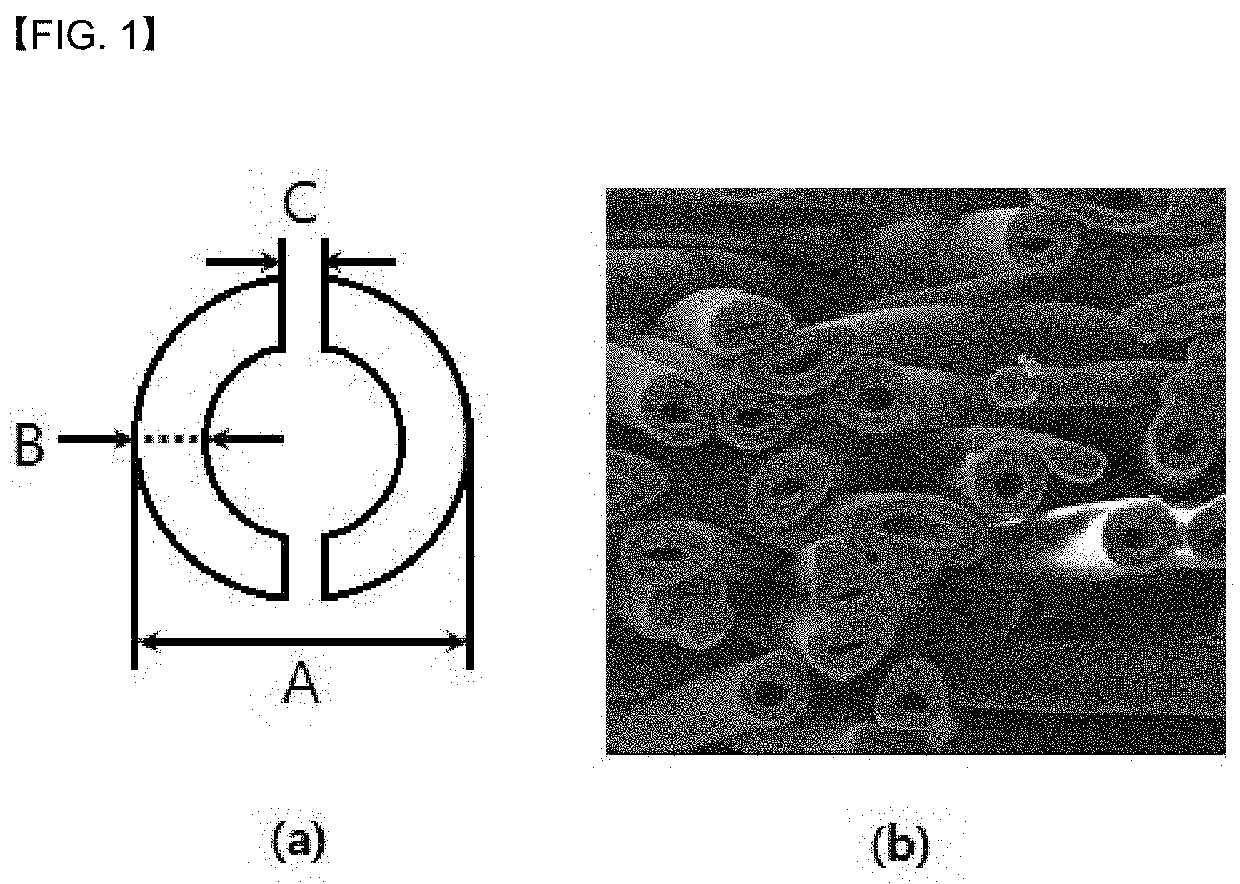

InactiveUS20110198011A1Prevent curingAvoid it happening againWithout separate inflatable insertsTyresElastomerThermoplastic elastomer

Provided is a pneumatic tire: which has an inner liner layer formed of a thermoplastic resin or a thermoplastic elastomer composition containing a blend of a thermoplastic resin with an elastomer; and which, despite of this, is free from air inclusion in bead parts and is capable of preventing curing failure attributable to the air inclusion. The pneumatic tire of the present invention includes: a carcass layer laid between a pair of bead parts; an inner liner layer disposed at a tire cavity side of the carcass layer; a tie rubber layer interposed between the carcass layer and the inner liner layer; and chafers for protecting the respective bead parts, an end portion on a tire cavity side of each chafer being inserted between the carcass layer and the inner liner layer. In the pneumatic tire, the inner liner layer is formed of a thermoplastic resin or a thermoplastic elastomer composition containing a blend of a thermoplastic resin with an elastomer; and the tie rubber layer is disposed between the inner liner layer and the chafer.

Owner:YOKOHAMA RUBBER CO LTD

Thermoplastic elastomeric resin composition and a process for the preparation thereof

InactiveUS6433062B1Deterioration of physical propertyFacilitate cross-linkingFibre mechanical structuresThermoplasticPolymer science

The invention provides a process for the preparation of a thermoplastic elastomeric resin composition comprising melt kneading(a) 100 parts by weight of a block copolymer consisting of at least two polymeric blocks (A) composed mainly of a vinyl aromatic compound and at least one polymeric block (B) composed mainly of a conjugated diene compound, and / or a hydrogenated block copolymer obtained by hydrogenating said block copolymer,(b) 40 to 240 parts by weight of a non-aromatic softening agent for rubber,(c) 5 to 300 parts by weight of polyethylene or a copolymer composed mainly of ethylene, and(d) 5 to 60 parts by weight of polypropylene or a copolymer composed mainly of propylene,characterized in that the process comprises the following steps:(I) melt kneading the whole amounts of components (a), (b) and (d) and a part of component (c), and, at the same time or subsequently, melt kneading these with (f) an organic peroxide, and(II) melt kneading the product obtained from step (I) with the remaining part of component (c),and component (c) is one which has been prepared using a single site catalyst.The obtained composition is soft and excellent in heat deformation resistance and mechanical strength, moldability and processability. The present invention also provide a thermoplastic elastomeric resin composition comprising the above components (a), (c) and (d) in an amount of 100 parts by weight, 5 to 150 parts by weight and 5 to 80 parts by weight, respectively. The composition is soft and excellent in heat deformation resistance and mechanical strength, moldability and processability and shows good results in the extraction tests.

Owner:RIKEN TECHNOS CORP

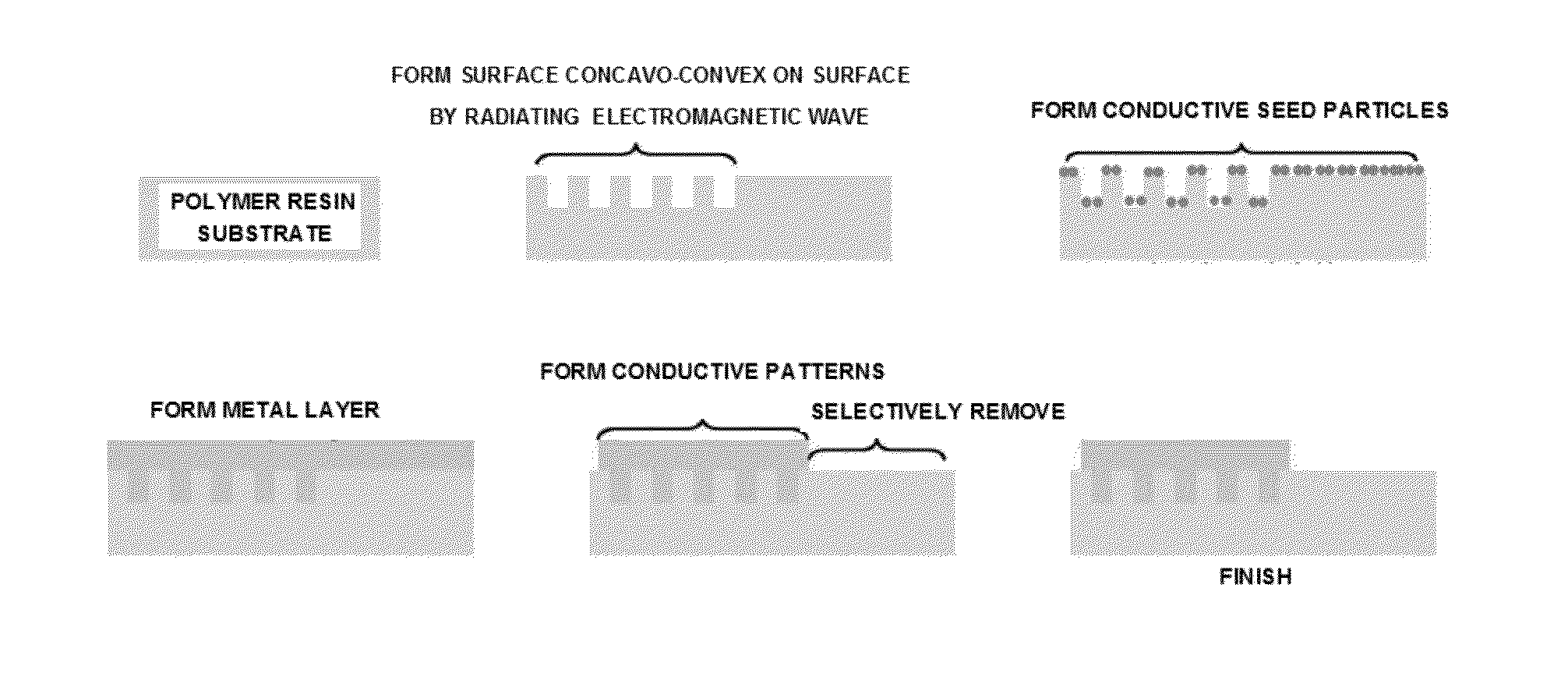

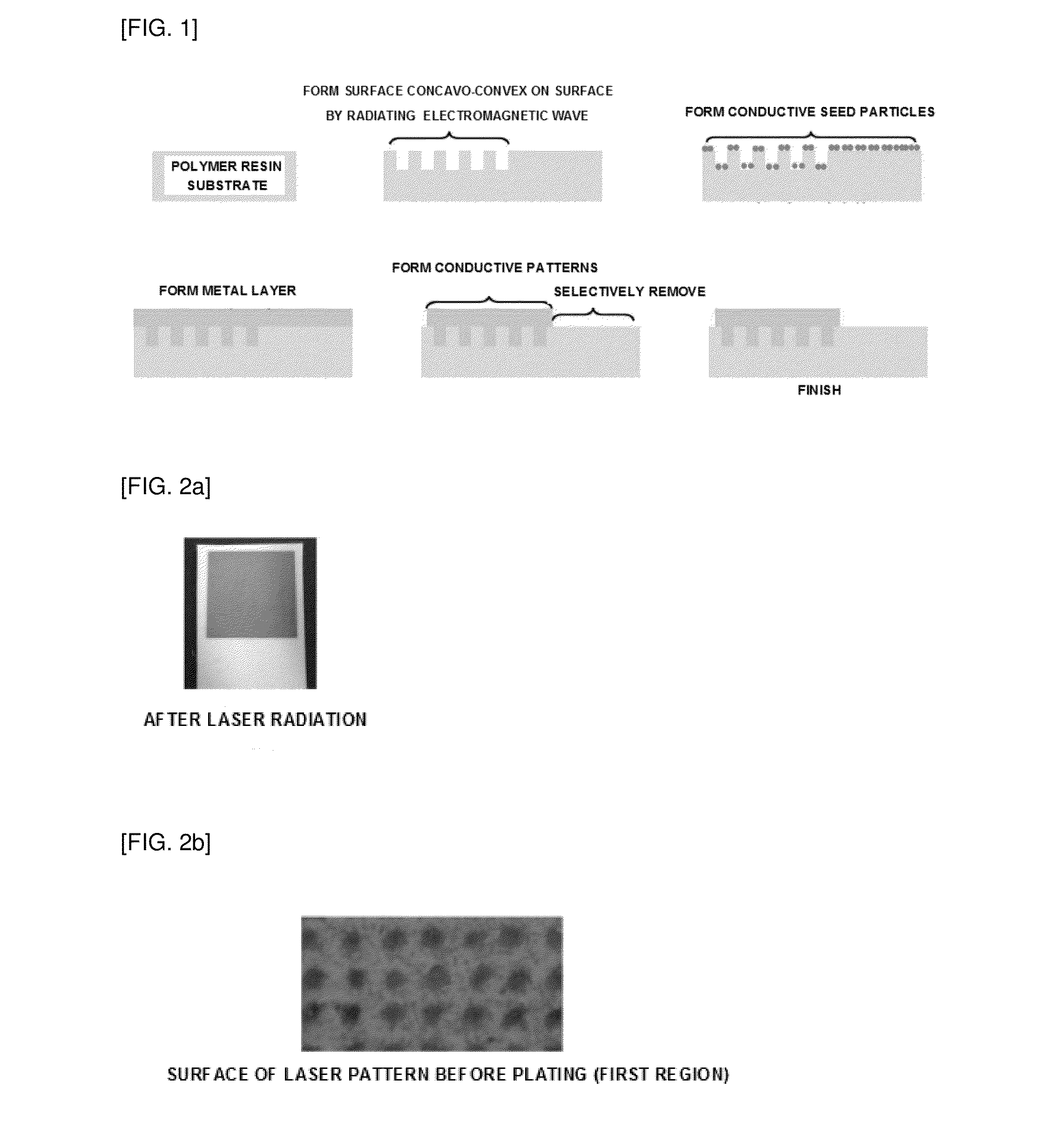

METHOD FOR FORMING CONDUCTIVE PATTERN BY DIRECT RADIATION OF ELECTROMAGNETIC WAVE, AND RESIN STRUCTURE HAVING CONDUCTIVE PATTERN THEREON (As Amended)

ActiveUS20160194759A1Simple processFormed satisfactorilyConductive layers on insulating-supportsRadiation applicationsPolymer resinSurface roughness

Provided are a method for forming conductive pattern by direct radiation of an electromagnetic wave capable of forming fine conductive patterns on various kinds of polymer resin products or resin layers by a simplified process, and appropriately implementing the polymer resin products having white color or various colors, and the like, even without containing specific inorganic additives in the polymer resin itself, and a resin structure having the conductive pattern formed therefrom.The method for forming the conductive pattern by direct radiation of the electromagnetic wave includes: forming a first region having a predetermined surface roughness by selectively radiating the electromagnetic wave on a polymer resin substrate containing titanium dioxide (TiO2); forming a conductive seed on the polymer resin substrate; forming a metal layer by plating the polymer resin substrate having the conductive seed formed thereon; and removing the conductive seed and the metal layer from a second region of the polymer resin substrate, wherein the second region has surface roughness smaller than that of the first region.

Owner:LG CHEM LTD

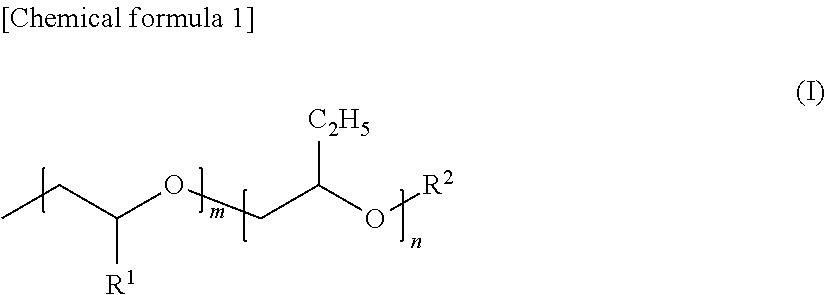

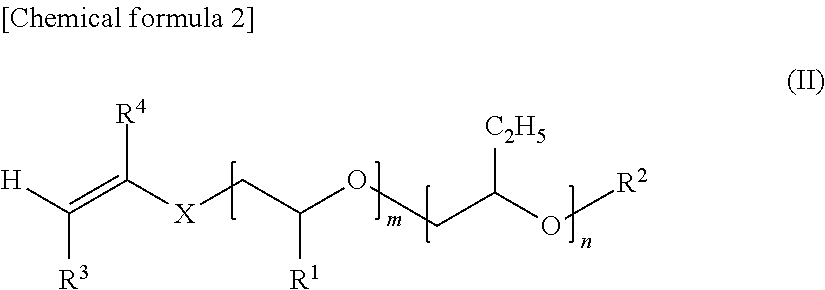

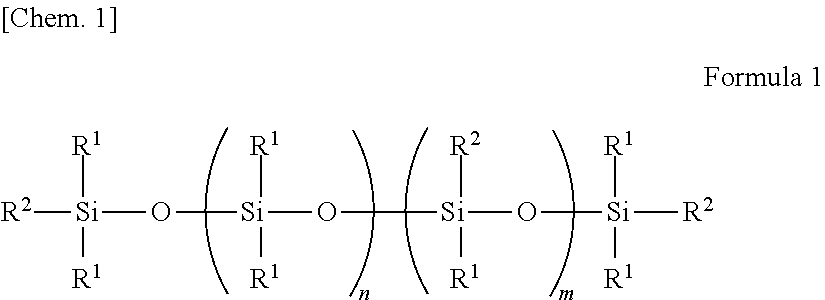

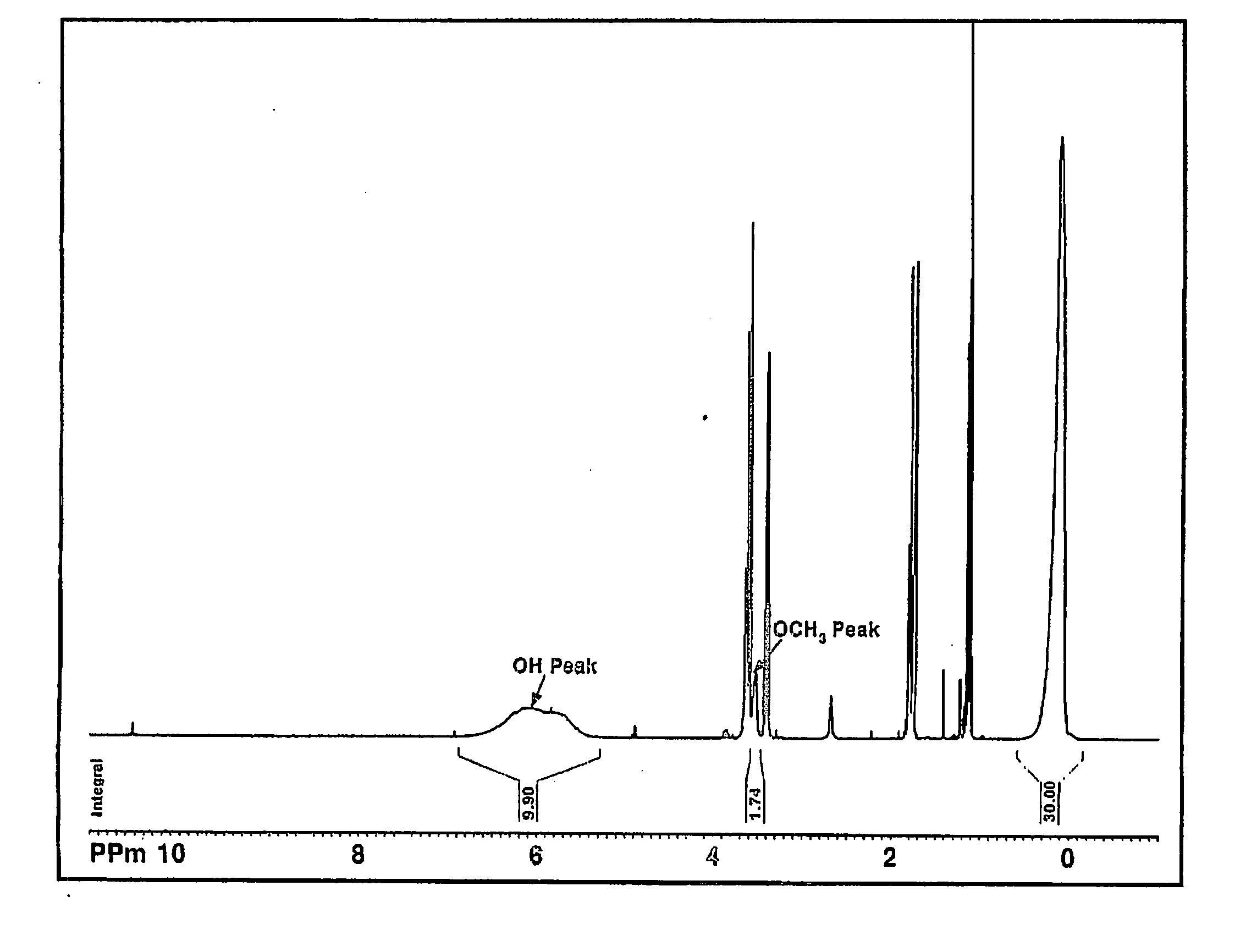

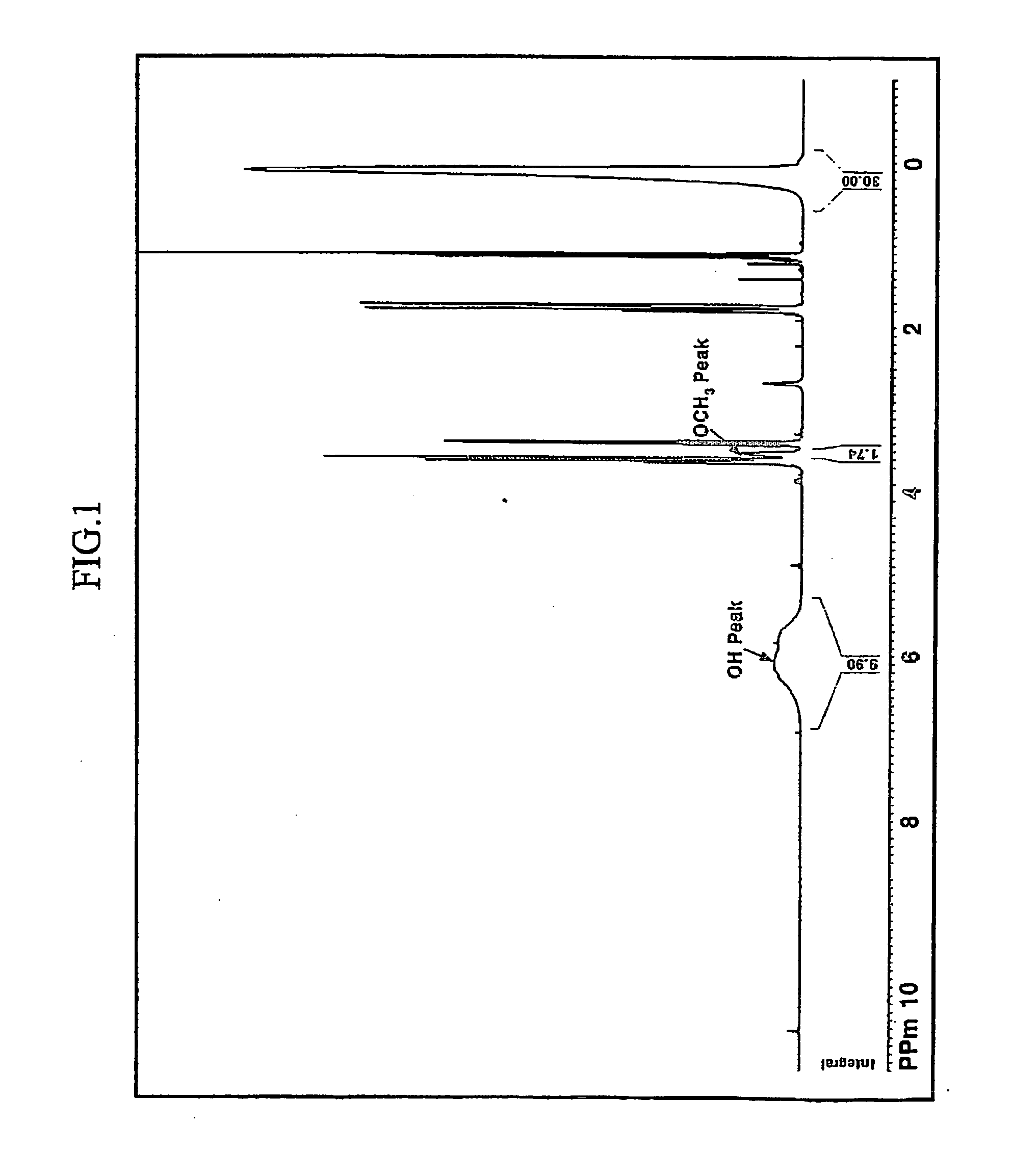

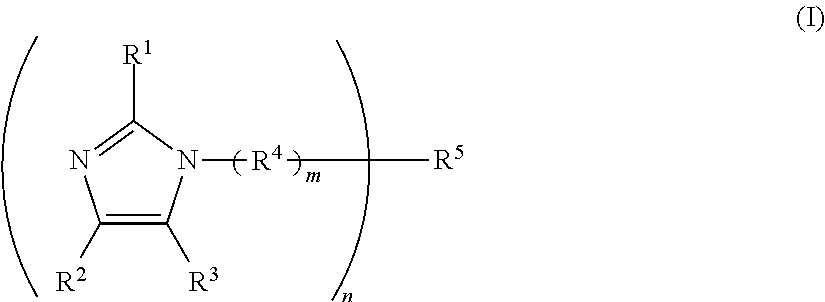

Polyoxyalkylene-modified vinyl acetal polymer, and composition comprising same

InactiveUS20130338306A1High mechanical strengthLess amount of plasticizerColloidal chemistry detailsHydrogen atomSide chain

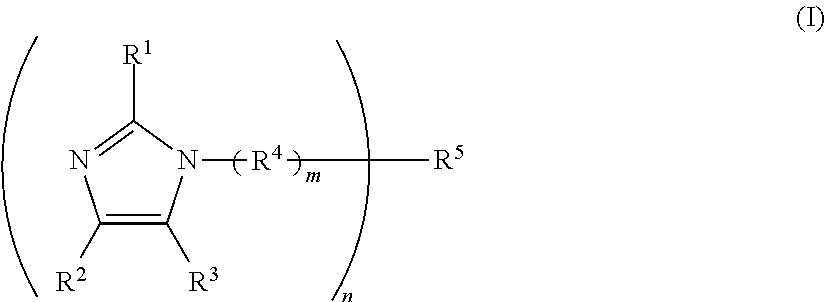

There is provided a polyoxyalkylene-modified vinyl acetal polymer which has polyoxyalkylene groups represented by general formula (I) in side chain, in which a viscosity-average polymerization degree P is 150 to 5000, an acetalization degree is 10 to 85 mol % and a polyoxyalkylene modification rate S is 0.1 to 10 mol %. Such a polymer has a feature that a film or sheet produced therefrom has improved film strength and flexibility, as well as a feature that a resin composition therefrom is free from phase separation.wherein R1 represents a hydrogen atom or a methyl group, R2 represents a hydrogen atom or an alkyl group having 1 to 8 carbon atoms, and 1≦m≦10 and 3≦n≦20.

Owner:KURARAY CO LTD

Thermoplastic elastomer composition and production method of the same

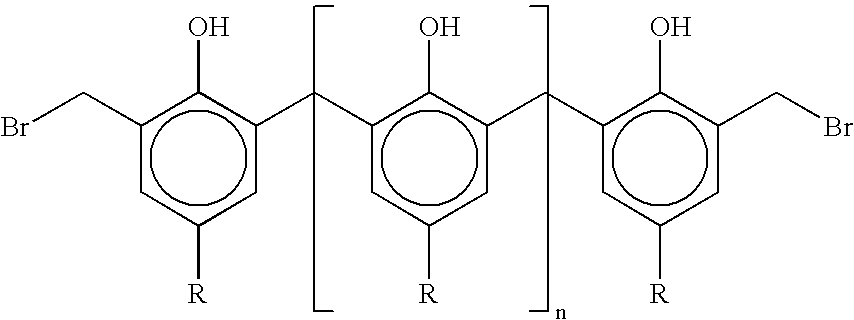

InactiveUS20080021145A1Good extrusion processing performanceUnacceptable appearancePigment pastesPolyolefinAlpha-olefin

It is an object of the present invention to provide an olefin thermoplastic elastomer composition which, through dynamic crosslinking of an olefin resin and an ethylene-α-olefin copolymer rubber as polymer components, has excellent appearance of the extrusion molding while also having excellent physical properties such as compression set and tensile strength. The present invention is directed to a method for producing a thermoplastic elastomer composition having the steps of: dynamically heat treating the following components (A) to (D); adding a component (E) to a resulting composition; and kneading the resulting mixture, and a thermoplastic elastomer composition obtained by the production method,(A): 40 to 95 parts by weight of an ethylene-α-olefin-based copolymer rubber;(B): 5 to 60 parts by weight of a polyolefin-based resin;(C): 0.1 to 20 parts by weight of a halogenated alkylphenolic resin-based crosslinking agent;(D): 0.001 to 0.7 part by weight of iron oxide; and(E): 0.1 to 20 parts by weight of a halogen capturing agent.

Owner:SUMITOMO CHEM CO LTD

Moisture-curing composition

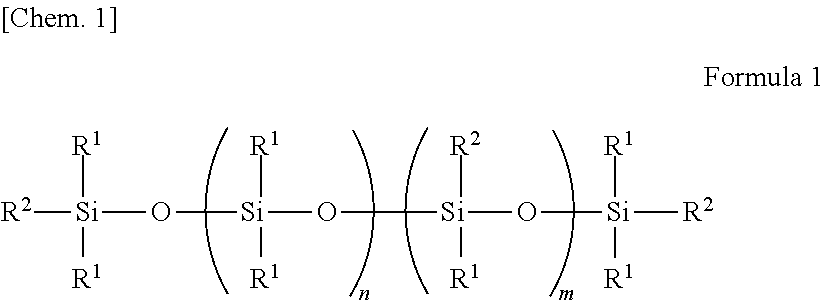

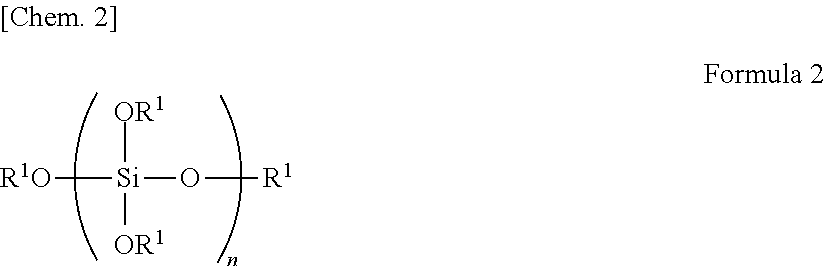

ActiveUS20160160035A1Deterioration of physical propertySuppressed over-time deteriorationOther chemical processesOrganic non-macromolecular adhesiveMeth-Oligomer

In durability tests of a moisture-curing composition, it is difficult to both suppress foaming inside of the cured product and to stably maintain the physical properties of the cured products. [Solution] This moisture-curing composition contains components (A)-(D), and contains 0.5-5.0 parts by mass of component (C) per 100 parts by mass of component (A). Component (A): An oligomer which has a polymer of (meth)acrylic monomers as the primary chain and which has a hydrolyzable silyl group in the molecule Component (B): A specific polydialkylsiloxane Component (C): A silicate Component (D): A curing catalyst

Owner:THREEBOND FINE CHEM CO LTD

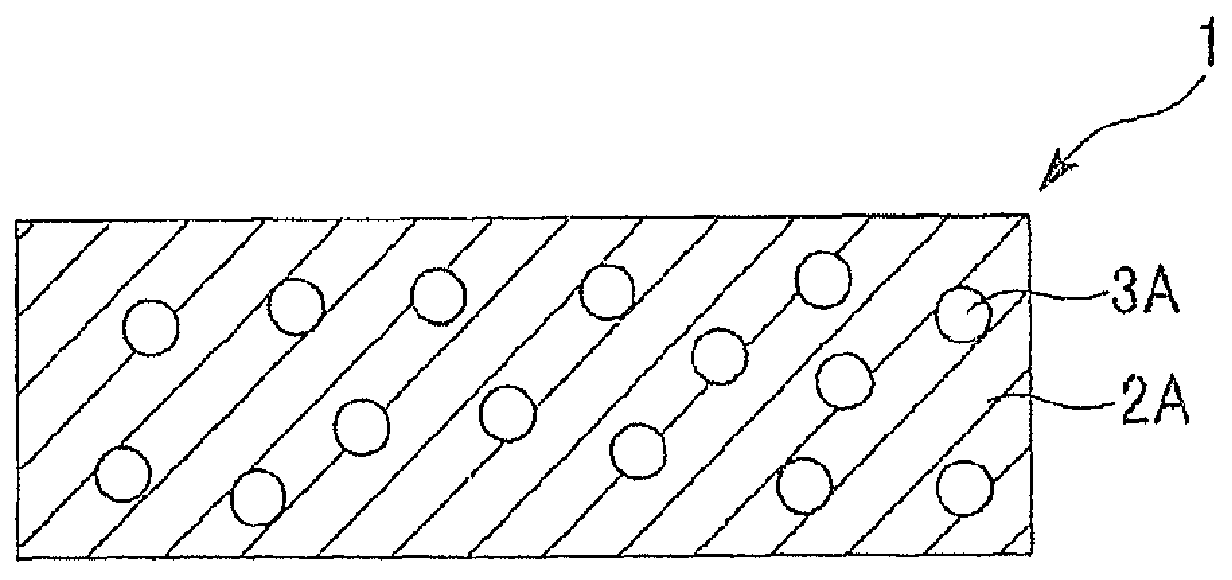

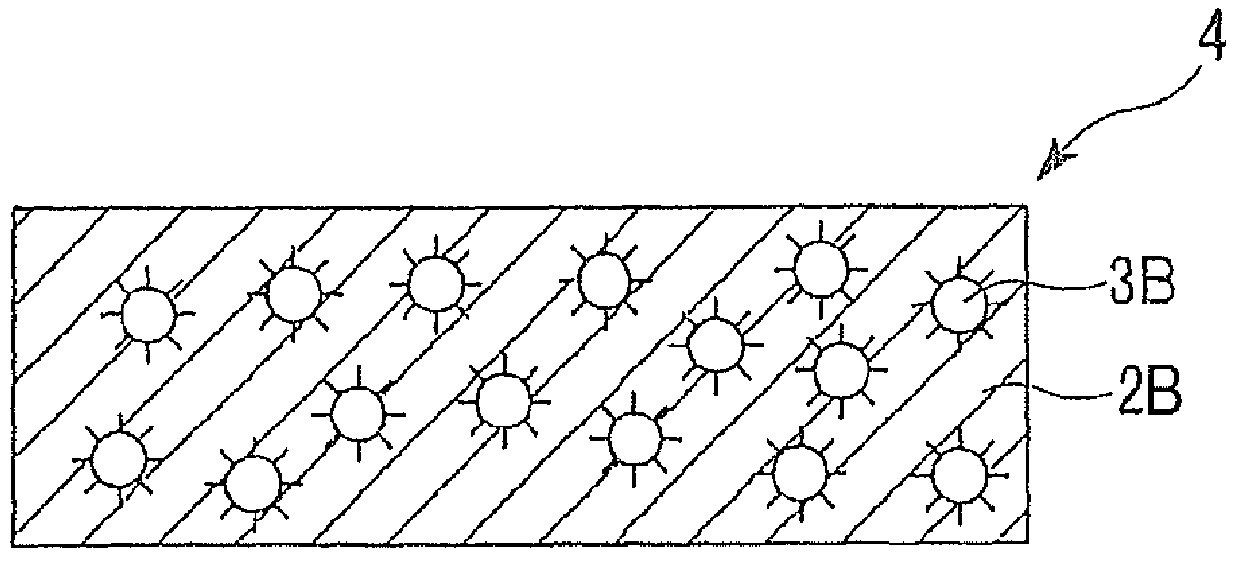

Antistatic film, antistatic foam sheet and antistatic bubble sheet

InactiveUS20050238867A1Good antistatic effectDeterioration of physical propertyLayered productsThin material handlingPolymer scienceAntistatic agent

To provide an antistatic film, an antistatic foam sheet or an antistatic bubble sheet which has favorable physical properties, such as a continued antistatic effect and a high strength, and which causes little contamination of rollers or other devices when the sheet is formed. The antistatic film according to the present invention is characterized in that it is made of a polyethylene-based resin composition containing a polyethylene-based resin and a high-polymer-type, polyether-based antistatic agent. Furthermore, the antistatic foam sheet and the bubble sheet according to the present invention are characterized in that they are made of a polyolefin-based resin composition containing a polyolefin-based resin and a high-polymer-type antistatic agent.

Owner:NAKANO TOSHIO +5

Water-absorbing resin and method for manufacturing the same

The present invention provides a highly productive method for manufacturing a water-absorbing resin, the amounts of fine powder and dust of which are small, the amount of residual monomer of which is small, and whose absorption rate is high. That is, the method for manufacturing the water-absorbing resin of the present invention is a method for crosslinking and polymerizing an aqueous solution of an acid-group containing unsaturated monomer, and is characterized in that stationary polymerization is carried out in such a manner that a solid matter is added to the monomer aqueous solution, and an initiation temperature of the polymerization is adjusted to 40° C. or more or a maximum temperature of the polymerization is adjusted to 100° C. or more.

Owner:NIPPON SHOKUBAI CO LTD

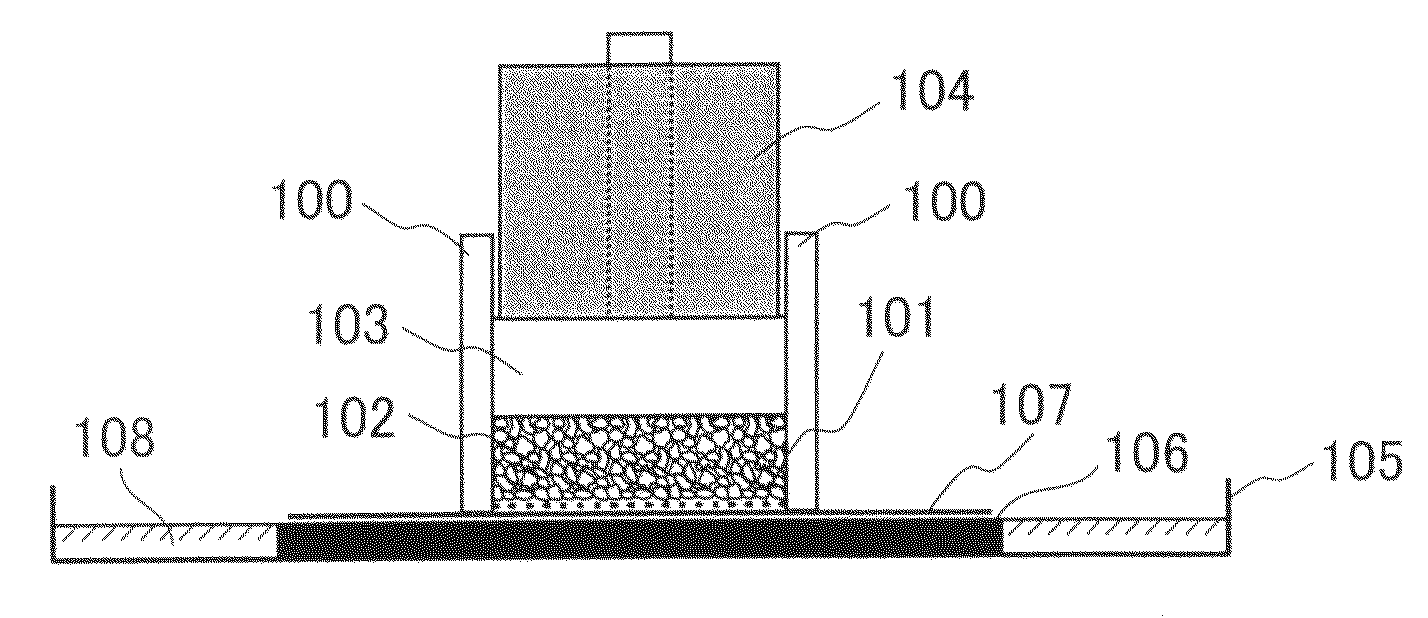

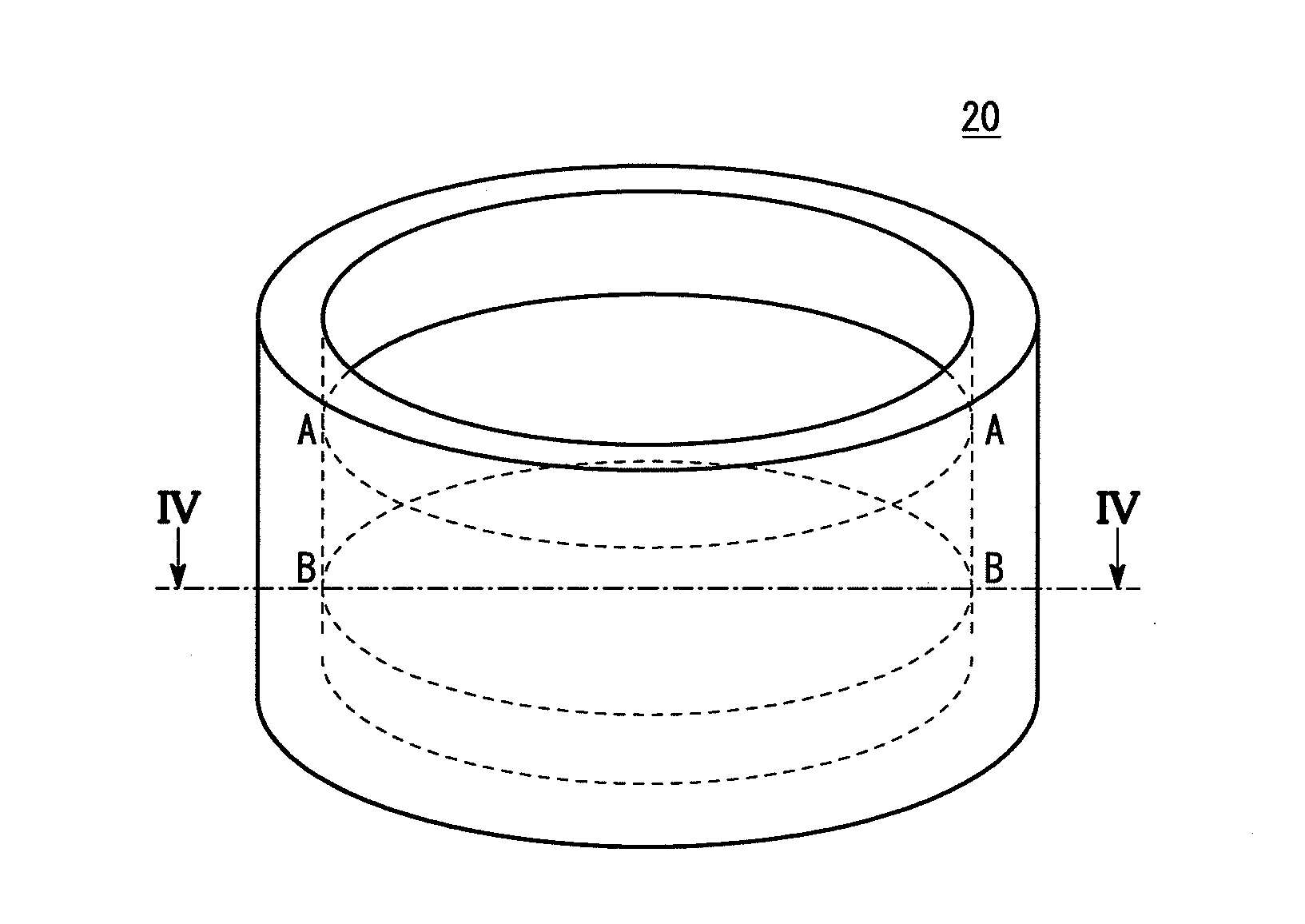

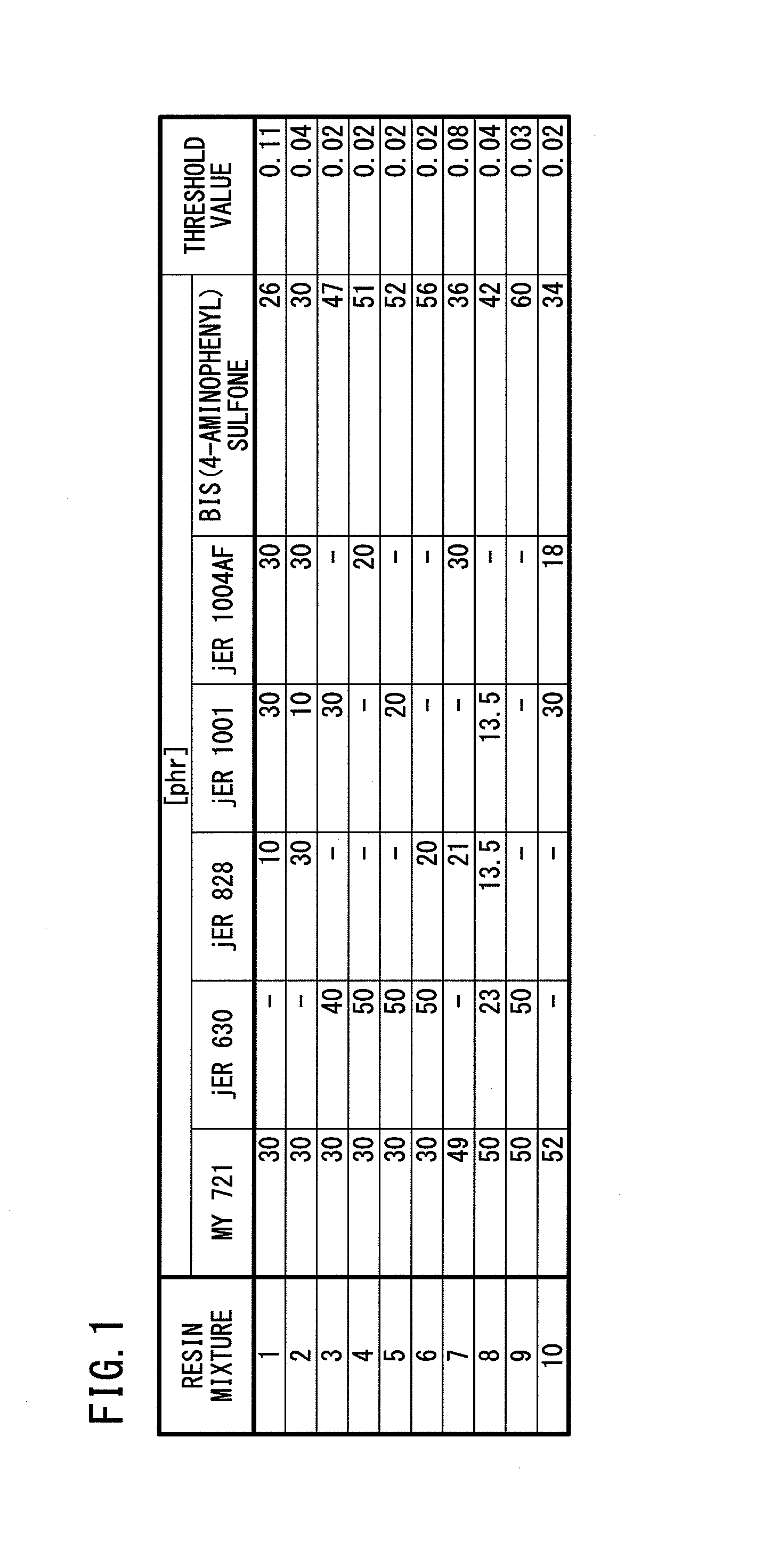

Method of evaluating dispersion degrees of mixed epoxy resins

ActiveUS20140152984A1Efficiently obtainedSufficient dispersion degreeRadiation pyrometryAbsorption/flicker/reflection spectroscopyEpoxyPhysical chemistry

A method of evaluating dispersion degrees of mixed epoxy resins includes, first, obtaining a resin mixture by mixing a plurality of aromatic epoxy resins, and taking a plurality of measurement samples from a plurality of sites of the resin mixture. The measurement samples are spectroscopically analyzed to obtain the spectra, and a plurality of common functional group peaks in the spectra are selected. The absorbances of the selected peaks are standardized to obtain absorbance ratios, based on the absorbance of a standard peak, in each of the spectra. Then, the standard deviations of the absorbance ratios of the selected peaks are calculated between the measurement samples. The maximum value of the obtained standard deviations is compared with a predetermined threshold value to evaluate the dispersion degrees of the aromatic epoxy resins.

Owner:HONDA MOTOR CO LTD

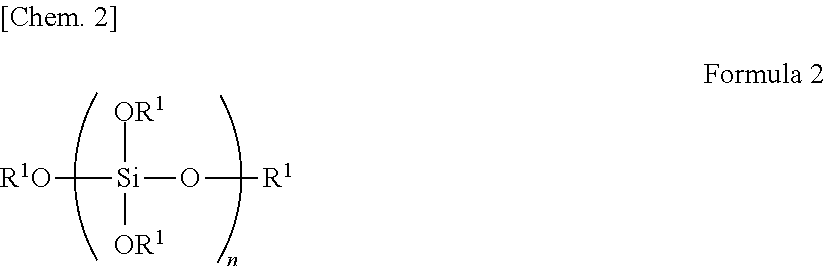

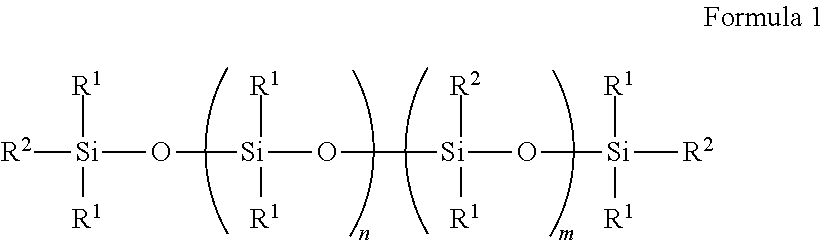

Coating composition for insulating film production, preparation method of insulation film by using the same, insulation film for semi-conductor device prepared therefrom, and semi-conductor device comprising the same

ActiveUS20060045984A1High mechanical strengthLow dielectric constantTransistorOrganic detergent compounding agentsPolymer scienceDevice material

The present invention relates to a coating composition for insulating film production, a preparation method of a low dielectric insulating film using the same, a low dielectric insulating film for a semiconductor device prepared therefrom, and a semiconductor device comprising the same, and more particularly to a coating composition for insulating film production having a low dielectric constant and that is capable of producing an insulating film with superior mechanical strength (elasticity), a preparation method of a low dielectric insulating film using the same, a low dielectric insulating film for a semiconductor device prepared therefrom, and a semiconductor device comprising the same. The coating composition of the present invention comprises an organic siloxane resin having a small molecular weight, and water, and significantly improves low dielectricity and mechanical strength of an insulating film.

Owner:LG CHEM LTD

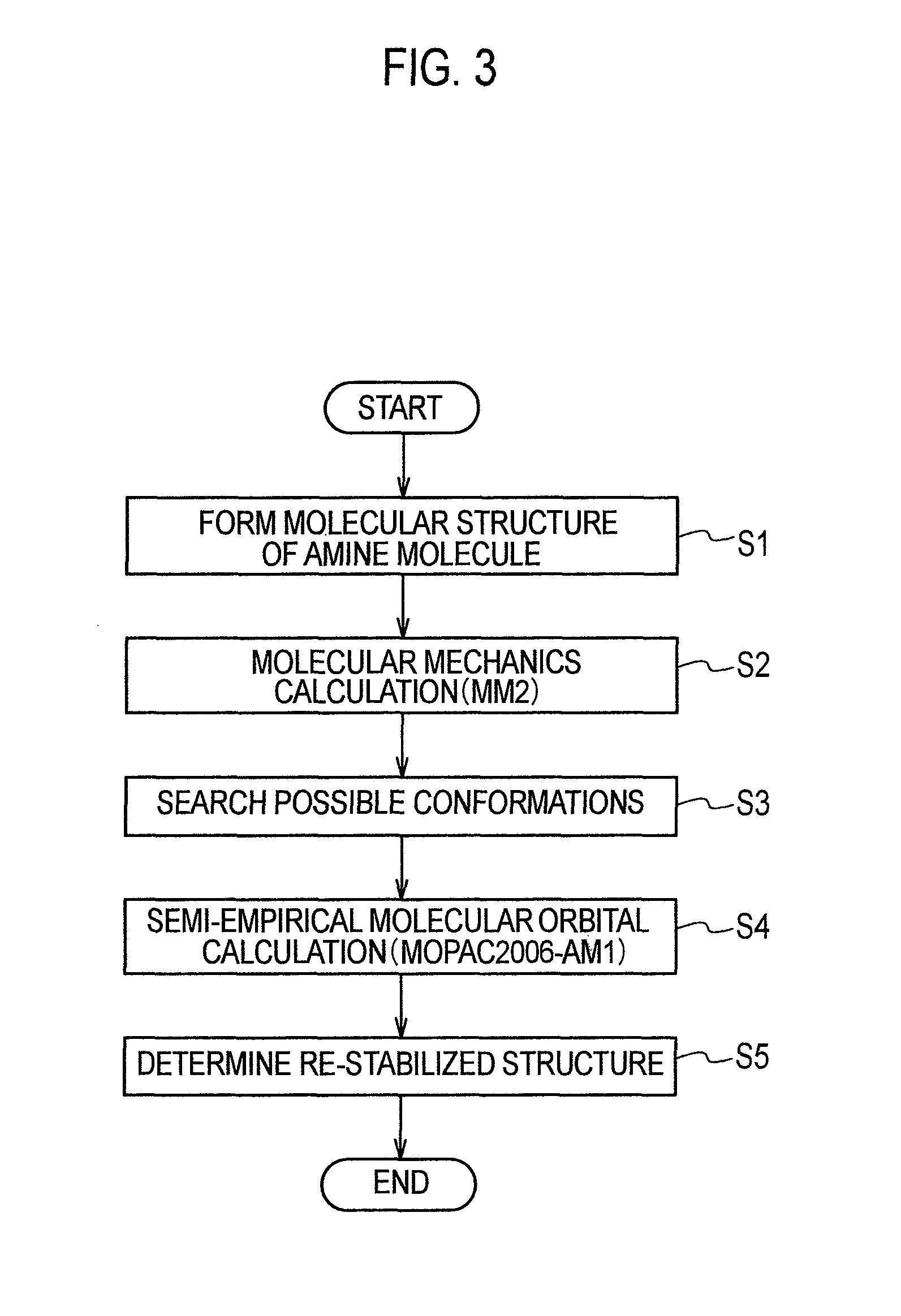

Rubber composite and rubber composition

InactiveUS20120141810A1Improve adhesionReduce manufacturing costSynthetic resin layered productsSpecial tyresBond orderSulfenamide

The rubber composite was fabricated by use of direct vulcanization adhesion method with a sulfenamide-based vulcanization accelerators, and the sulfenamide-based vulcanization accelerator is used for a rubber composite using a sulfenamide compound as a vulcanization accelerator, the adhesion properties of the steel cord / rubber adhesion boundary surface and the anti-scorch properties can be achieved simultaneously, the sulfenamide-based vulcanization accelerator being such that the bond order between an amine generated form the sulfenamide compound and a surface of a metal material is zero, and the distance of the S—N (amine moiety) bond of the sulfenamide compound is less than 1.67 Å, and the electric charge on N of the amine radical generated as a result of dissociation of the S—N bond is −0.295 or less.

Owner:BRIDGESTONE CORP

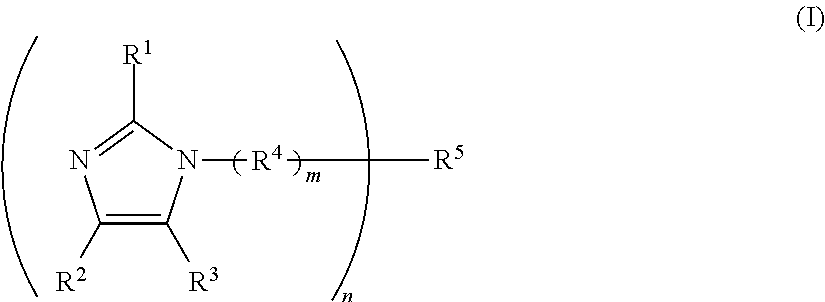

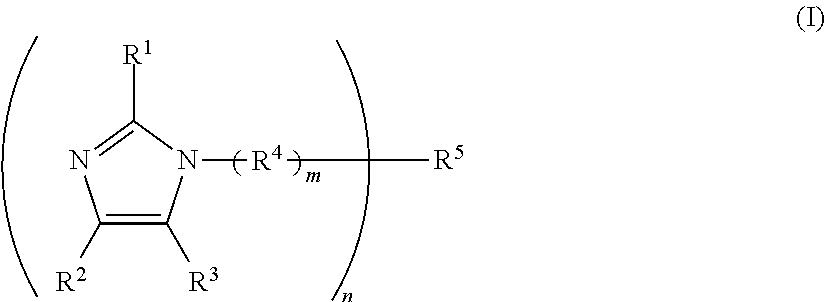

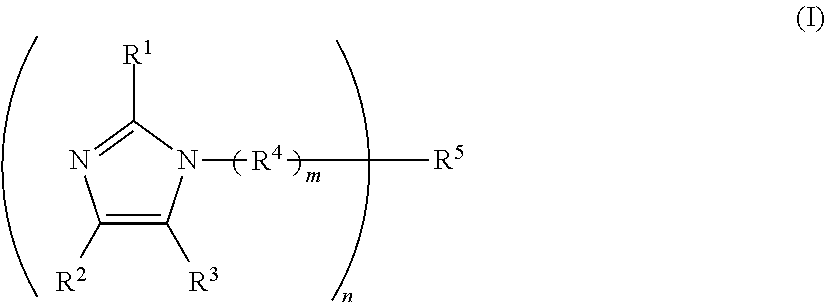

One-component curable resin composition

ActiveUS10144799B2Excellent curing property and storage stabilityImprove machinabilityThiol groupIsocyanate compound

A one-component curable resin composition that does not contain an isocyanate compound, comprised of uniformly blended (A) a compound having two or more epoxy groups within a molecule, (B) a compound having two or more thiol groups within a molecule, and (C) an imidazole compound of formula (I), wherein the component (C) exists in the form of liquid.

Owner:ADEKA CORP

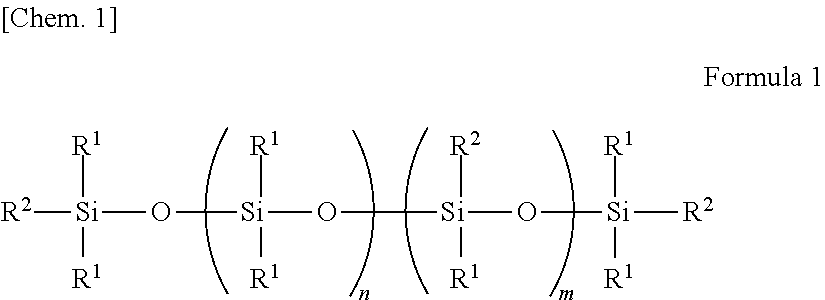

Moisture-curing composition

ActiveUS9676933B2Deterioration of physical propertySuppressed over-time deteriorationOther chemical processesOrganic non-macromolecular adhesiveOligomerMeth-

Regarding a durability test of a moisture-curing composition, it is difficult to both suppress foaming in the inside of a cured product and to stably maintain the physical properties of a cured product.A moisture-curing composition containing the components (A) to (D), the moisture-curing composition containing 0.5 to 5.0 parts by mass of the component (C) relative to 100 parts by mass of the component (A):Component (A): an oligomer which has a polymer of (meth)acrylic monomers as a main chain and which has a hydrolyzable silyl group in the moleculeComponent (B): specific polydialkylsiloxaneComponent (C): silicateComponent (D): a curing catalyst.

Owner:THREEBOND FINE CHEM CO LTD

Rubber composite and rubber composition

InactiveUS8609251B2Improve adhesionReduce manufacturing costSynthetic resin layered productsSpecial tyresBond orderMetallic materials

Owner:BRIDGESTONE CORP

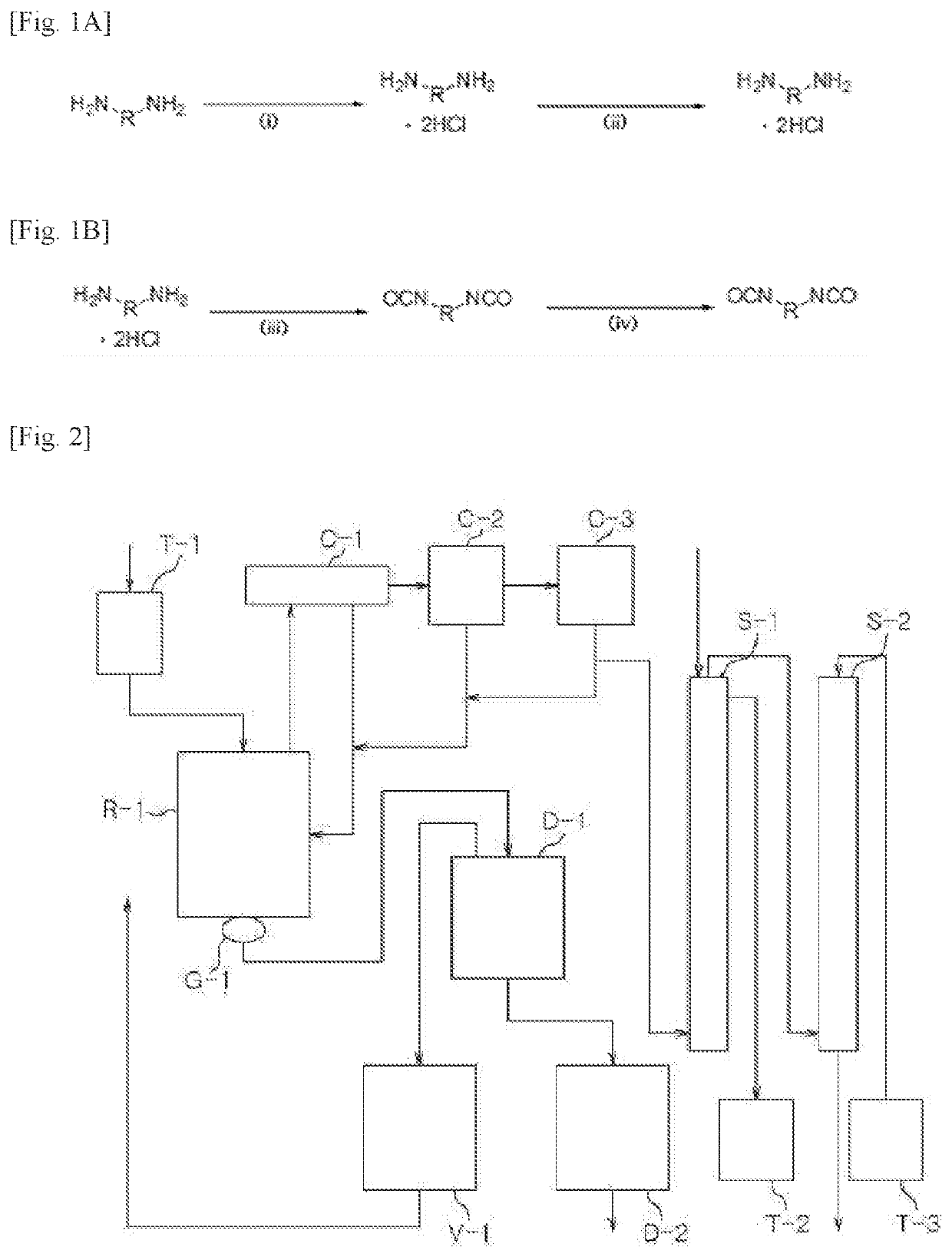

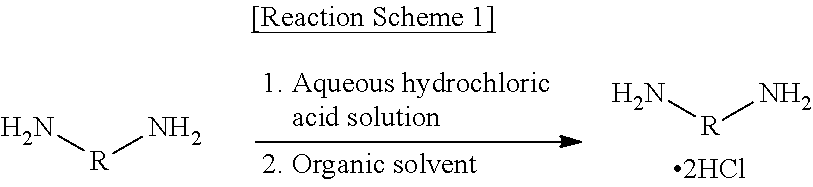

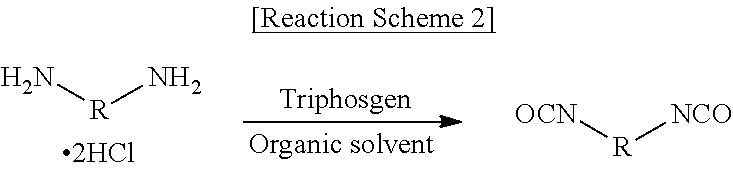

Method of preparing diisocyanate composition and optical lens

ActiveUS20210171445A1Toxic reductionImprove convenienceAmino preparation from aminesOrganic compound preparationOrganic solventOptic lens

In the embodiments, an aqueous hydrochloric acid solution and an organic solvent instead of hydrogen chloride gas and solid triphosgene instead of phosgene gas may be used in the process of preparing a diisocyanate from a diamine through a diamine hydrochloride. In addition, the embodiments provide processes for preparing a diisocyanate composition and an optical lens, which are excellent in yield and quality with mitigated environmental problems by controlling the total content of metals, cations, or anions in a diamine hydrochloride composition.

Owner:SKC CO LTD +1

One-component curable resin composition

ActiveUS20160200860A1Excellent curing property and storage stabilityImprove machinabilityThiol groupIsocyanate compound

A one-component curable resin composition that does not contain an isocyanate compound, comprised of uniformly blended (A) a compound having two or more epoxy groups within a molecule, (B) a compound having two or more thiol groups within a molecule, and (C) an imidazole compound of formula (I), wherein the component (C) exists in the form of liquid.

Owner:ADEKA CORP

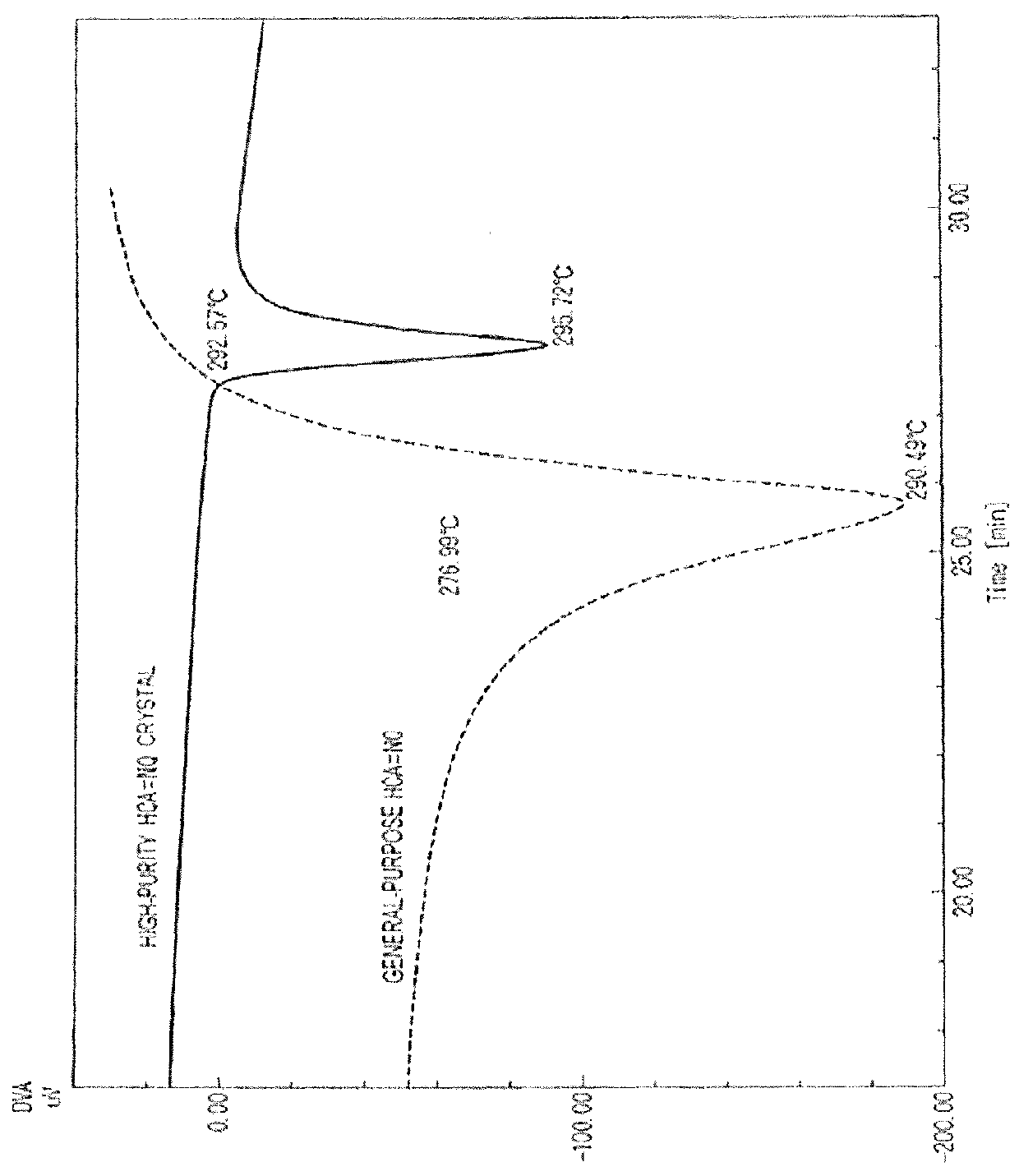

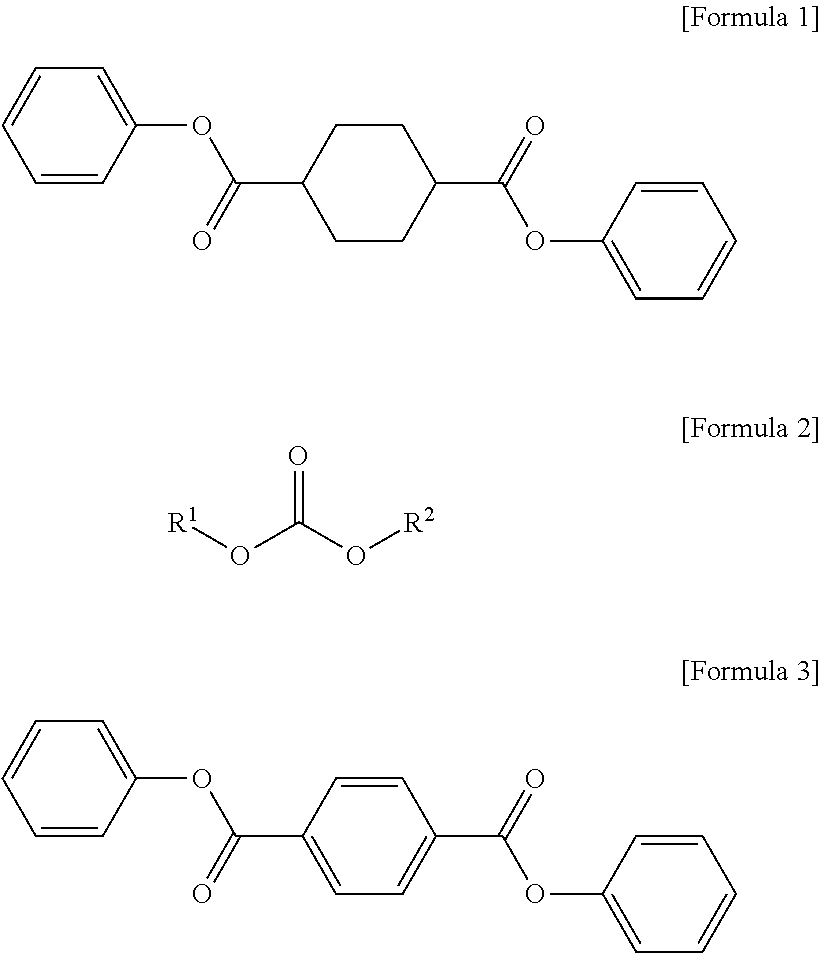

High melting point flame retardant crystal and method for manufacturing the same, epoxy resin composition containing the flame retardant, and prepreg and flame retardant laminate using the composition

ActiveUS20130053473A1Excellent heat resistance reliabilityImprove high temperature reliabilityPlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsEpoxyCyclohexanone

Owner:SANKO CO LTD

Spunbonded nonwoven and tile carpet using the same

PendingUS20220228307A1Excellent price competitivenessReduce contentTextile/flexible product manufactureCarpetsHollow fibrePolyester

The present disclosure relates to a spunbond nonwoven fabric for a tile carpet base fabric which can manufacture tile carpets with excellent sound absorption performance and tuft withdraw force, including high-thickness nonwoven fabrics made of hollow fibers to which recycled polyester raw materials are applied, and a tile carpet using the same.

Owner:KOLON IND INC

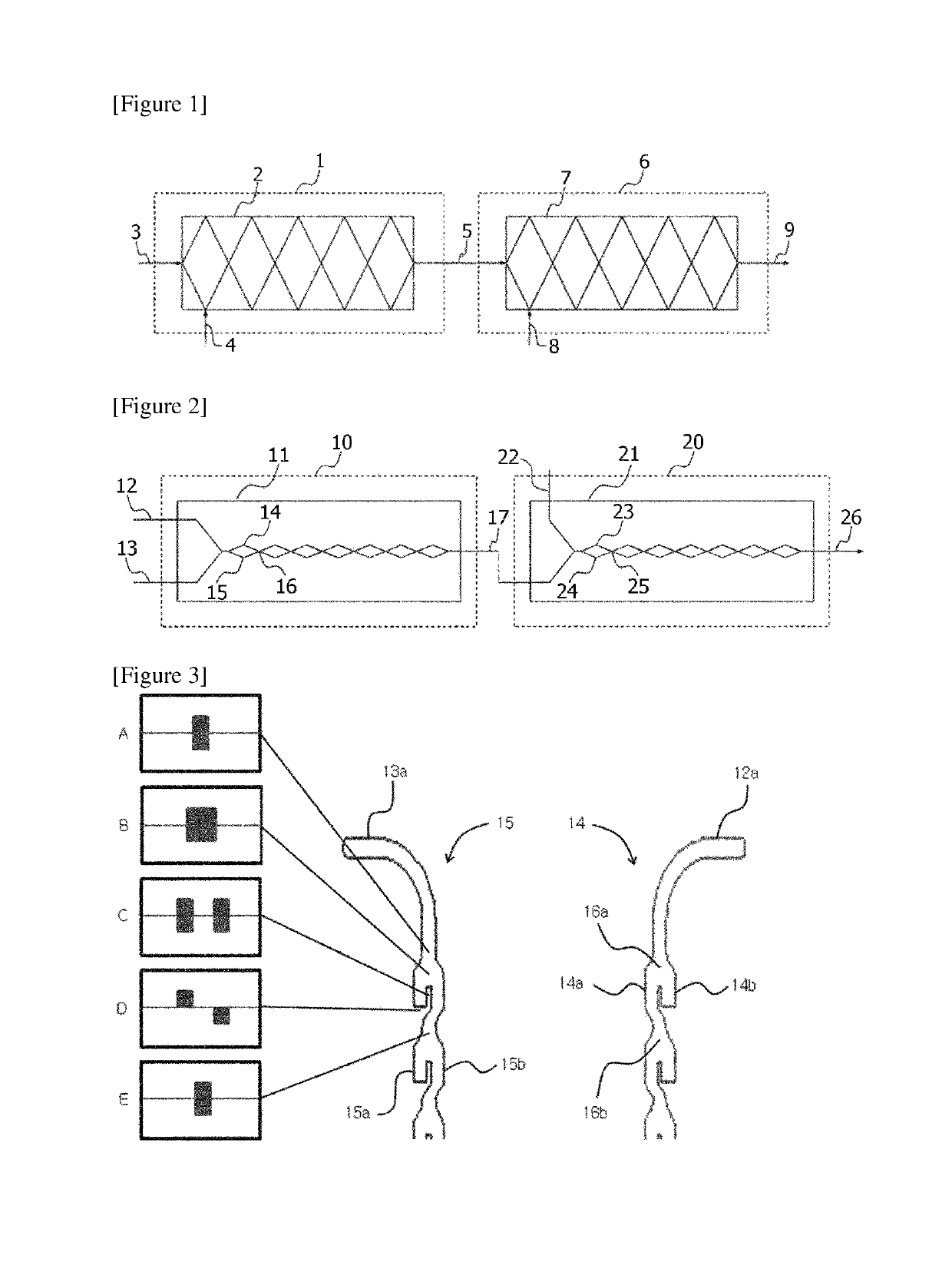

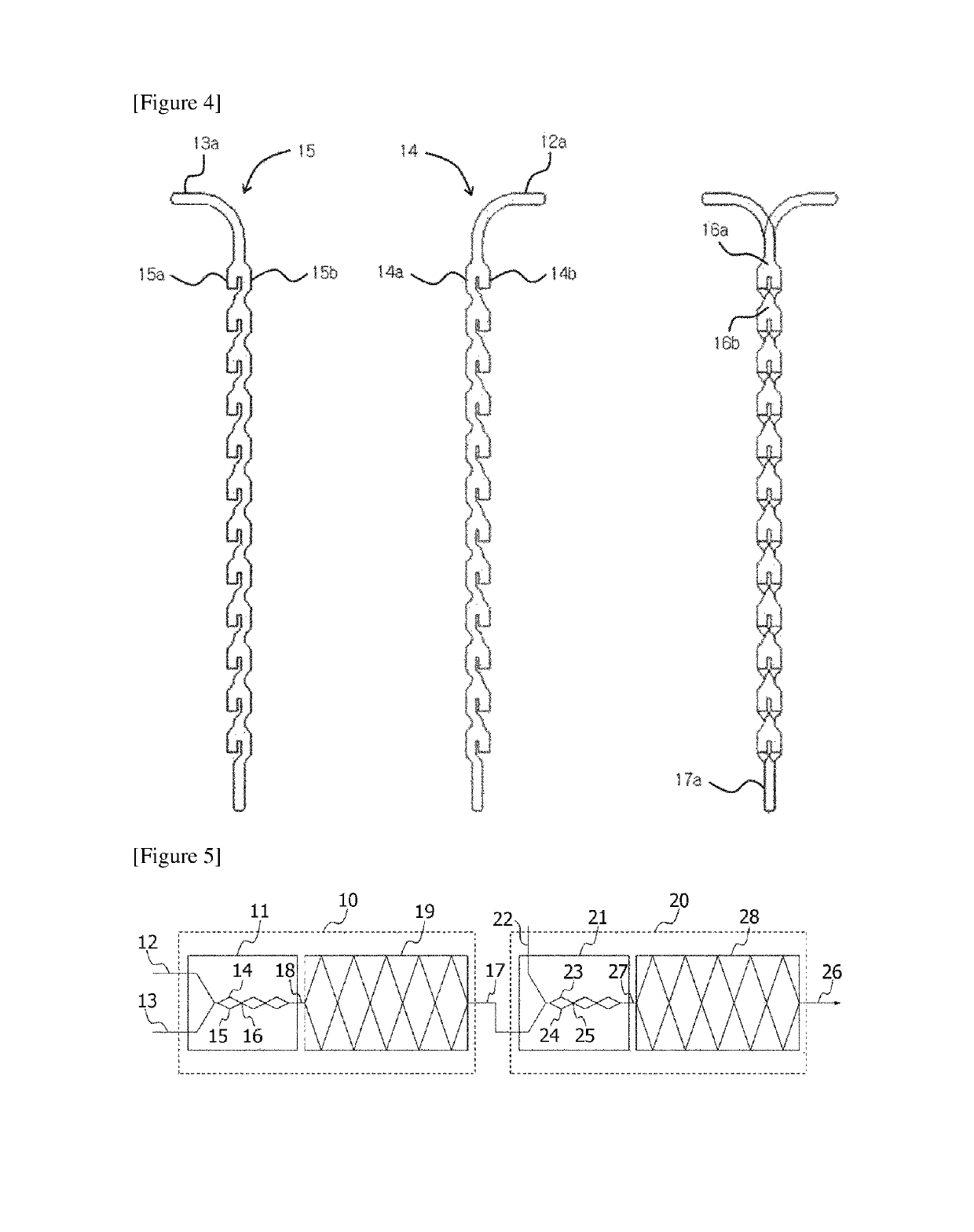

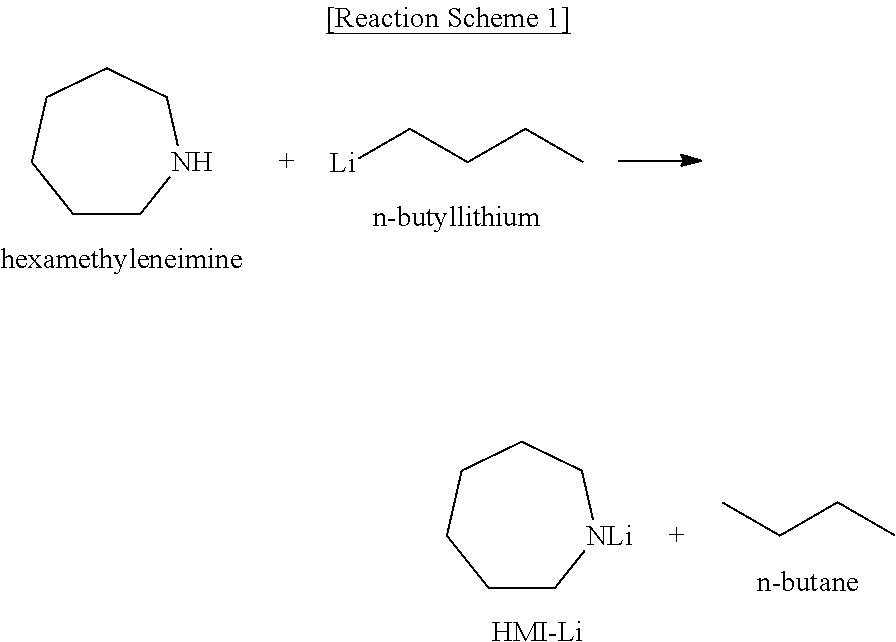

Preparation method of anionic polymerization initiator, device for manufacturing anionic polymerization initiator and anionic polymerization initiator prepared therefrom

ActiveUS10301327B2Improve conversion rateAvoid inactivationLithium organic compoundsSpecial tyresContinuous reactorMetal

A method for preparing an anionic polymerization initiator, a device for manufacturing the same, and an anionic polymerization initiator prepared therefrom is provided. And the method for preparing an anionic polymerization initiator according to the present invention is characterized in that in a continuous reactor an amine compound of Formula 1 and / or Formula 2; an organometallic compound; and / or a conjugated diene compound are introduced in the form of a solution and reacted.

Owner:LG CHEM LTD

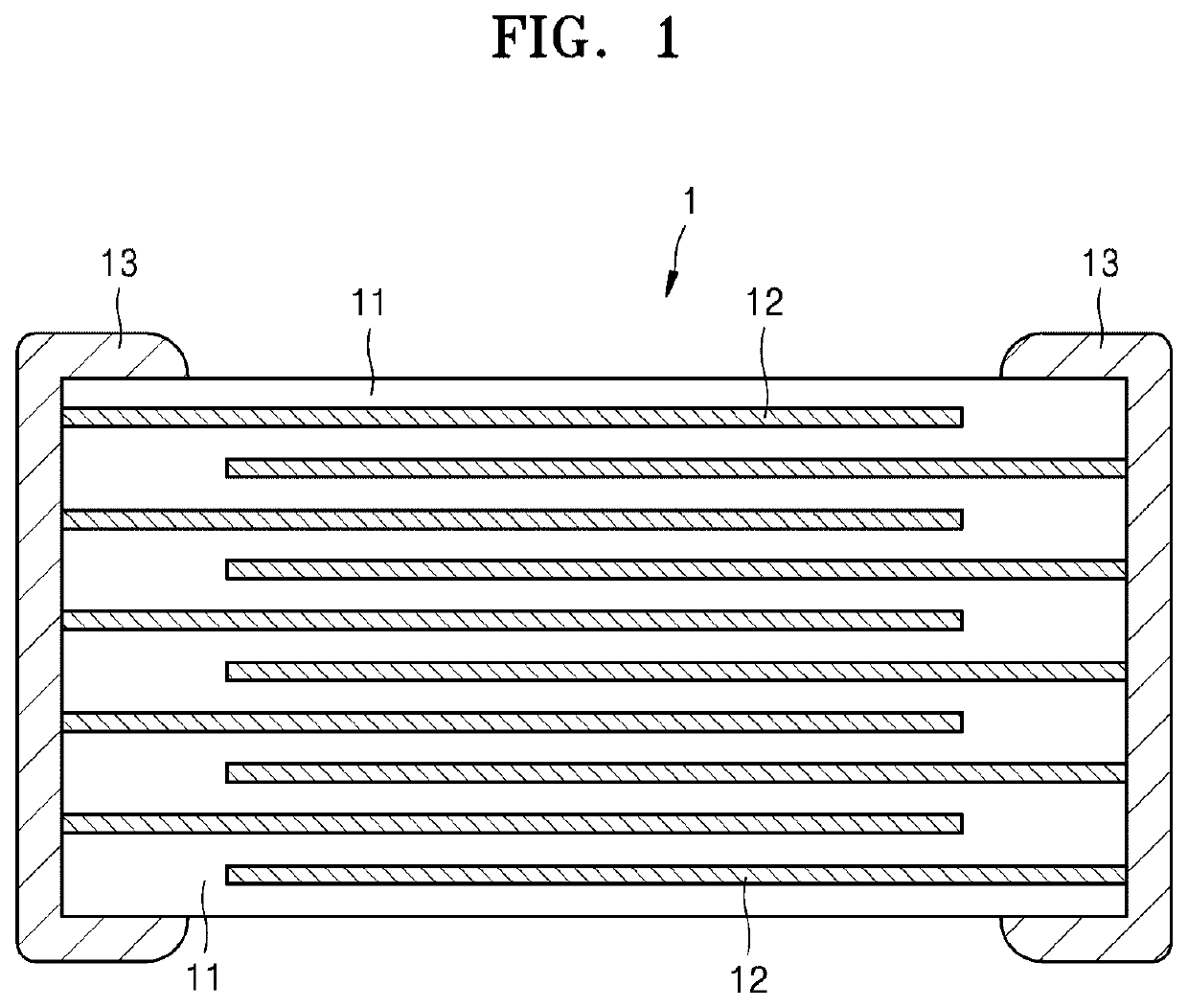

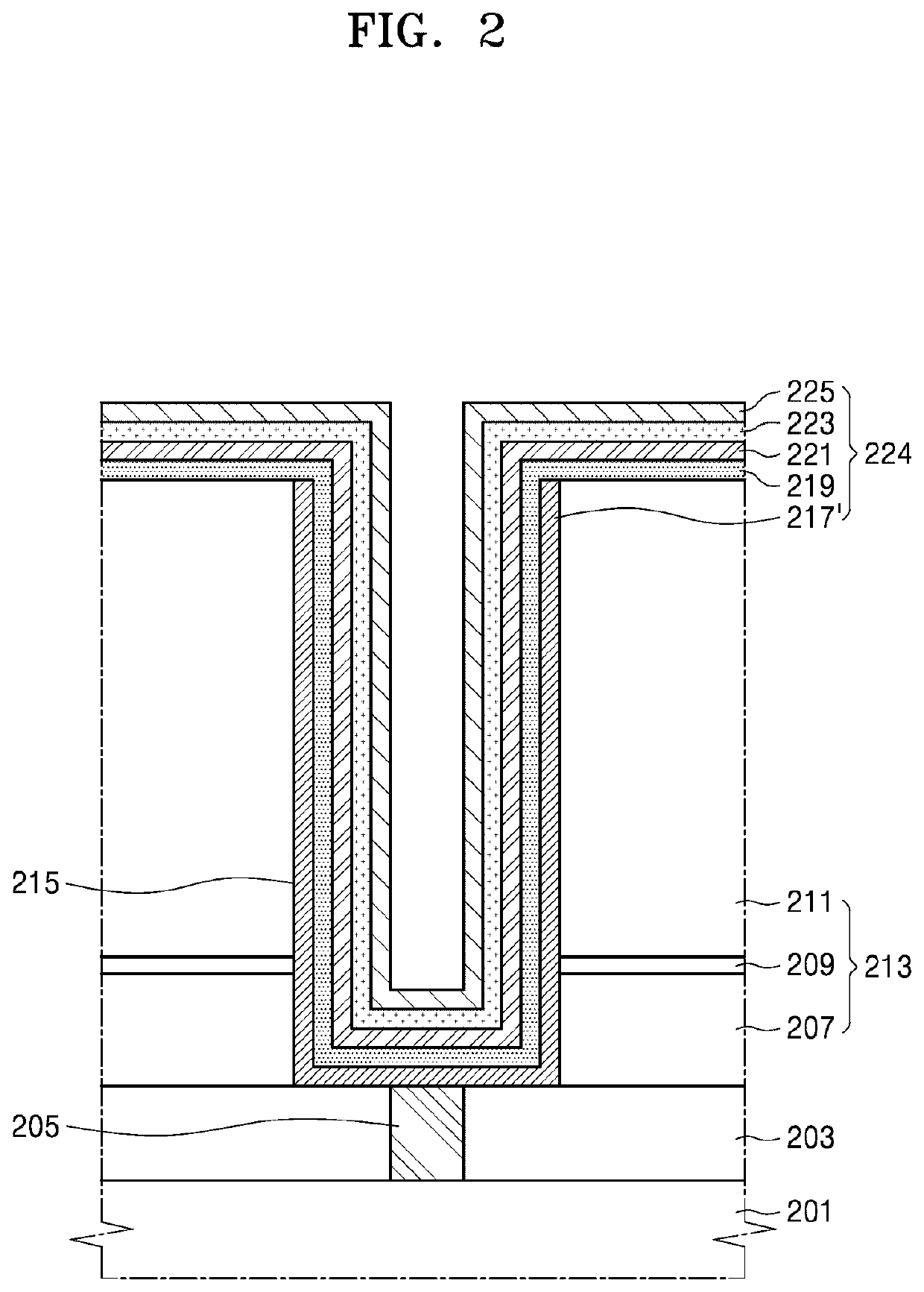

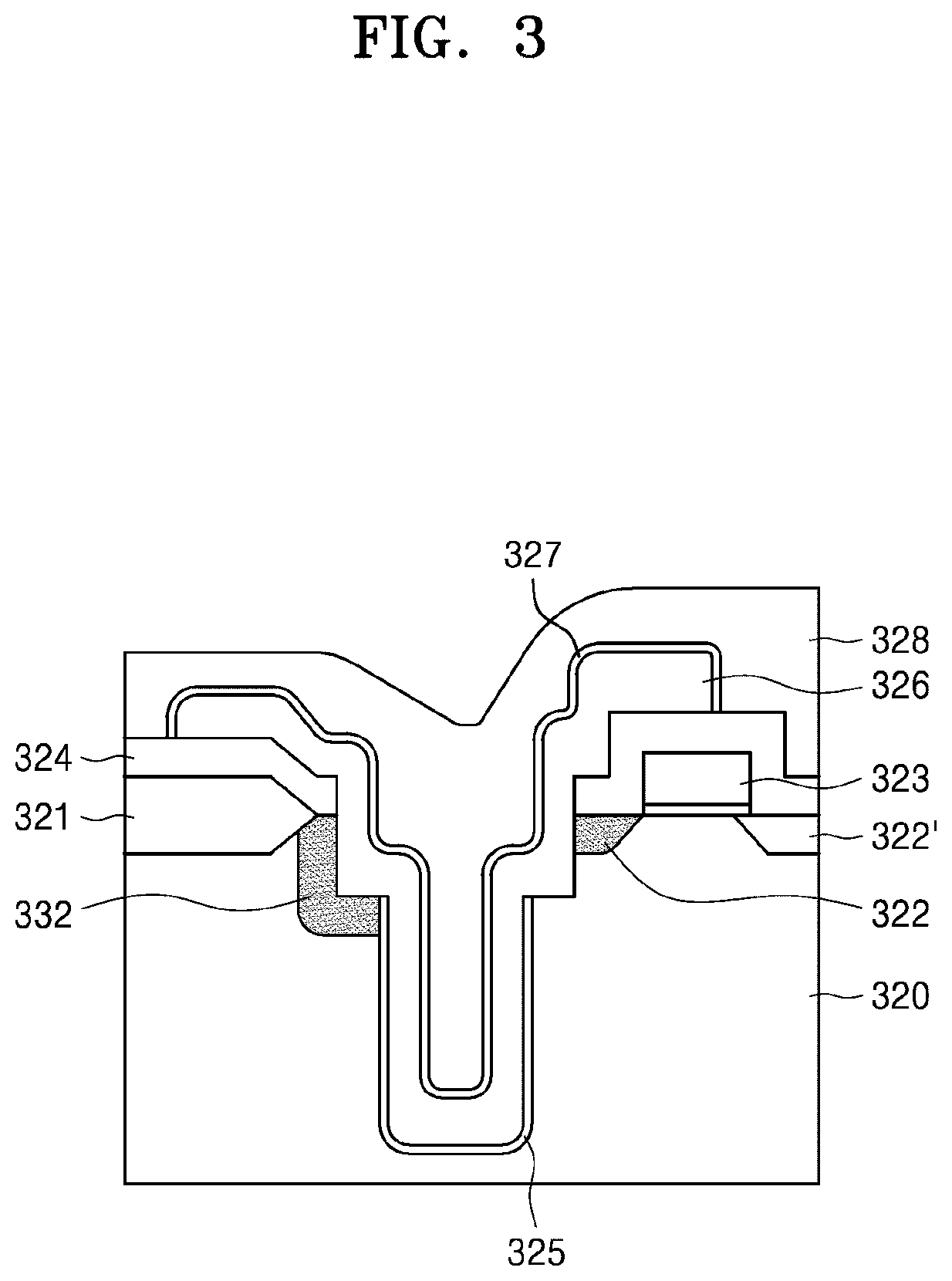

Dielectric material, device comprising dielectric material, and method of preparing dielectric material

PendingUS20210198801A1Large capacityPrevent oxidationFrom solid stateStacked capacitorsPhysicsComposite material

Owner:SAMSUNG ELECTRONICS CO LTD

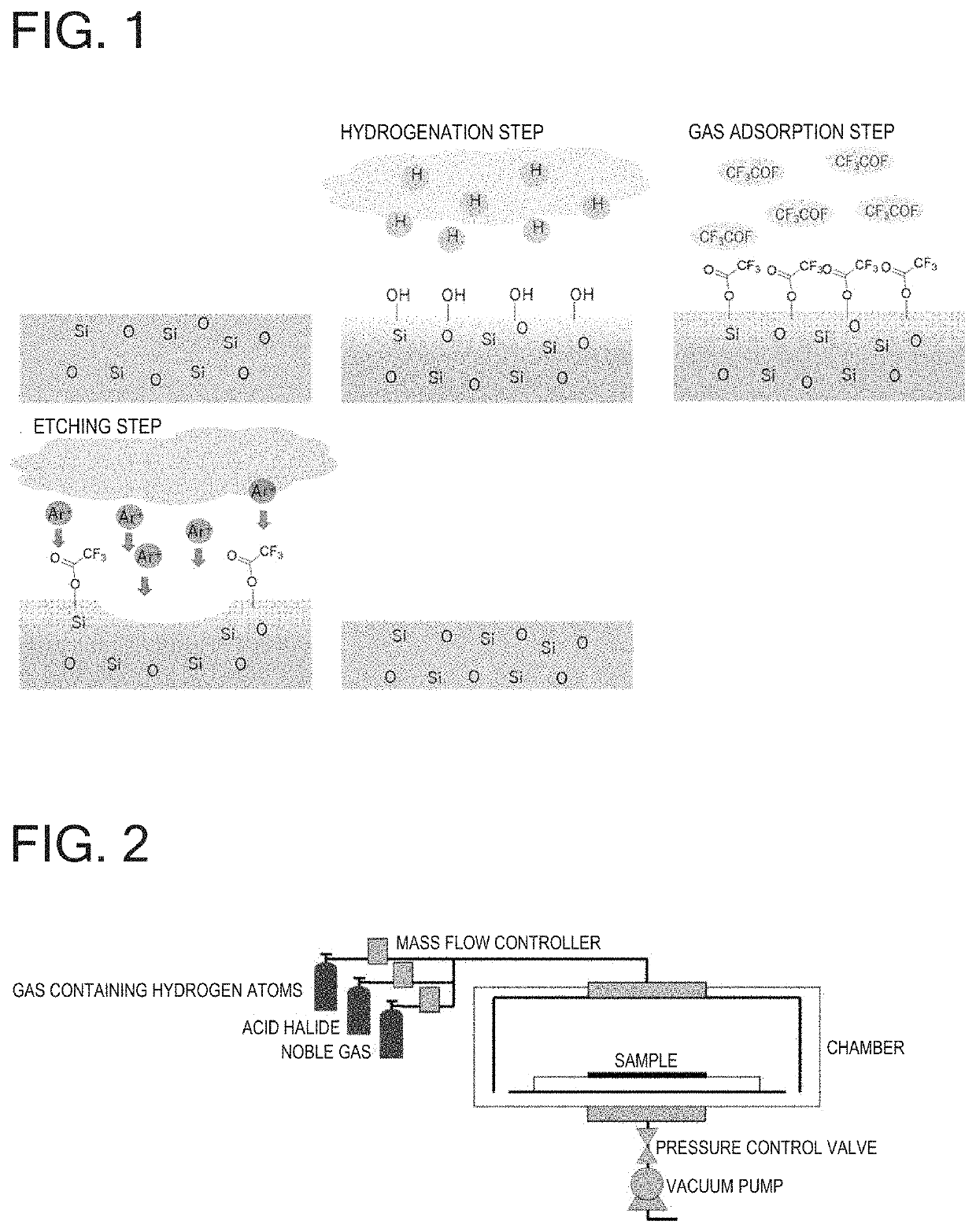

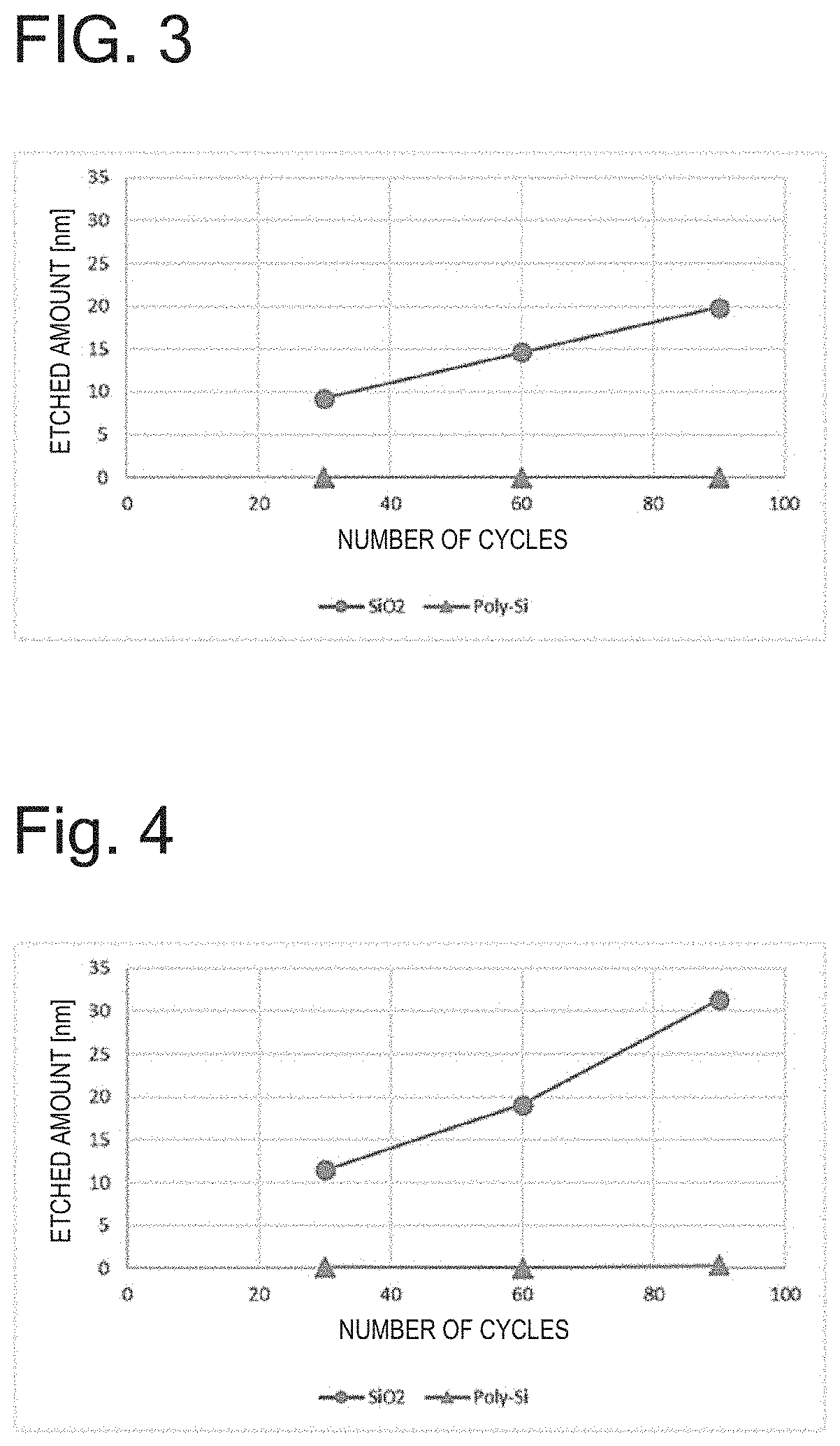

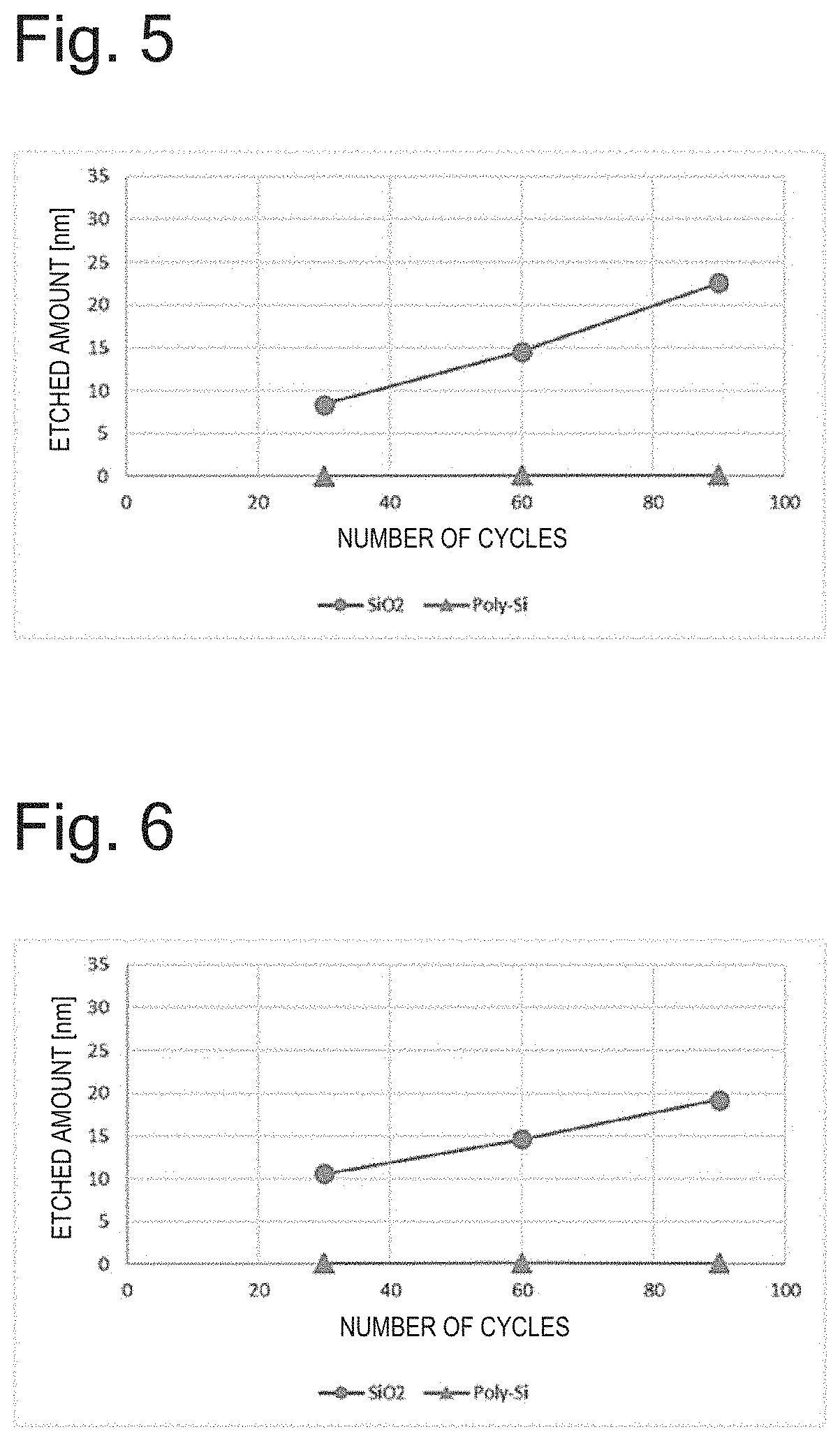

Atomic layer etching using acid halide

ActiveUS11183393B2Good controllability and reproducibilityEasy to controlSemiconductor/solid-state device manufacturingSurface treatment compositionsSurface reactionChemical reaction

A method of atomic layer etching a silicon oxide film or a silicon nitride film is provided. Atomic layer etching (ALE) is performed by repeating three steps of (1) hydrogenation step of hydrogenating a surface by irradiating a silicon oxide film or a silicon nitride film with a plasma containing H, (2) acid halide adsorption step of causing chemisorption of an acid halide represented by a formula of Rf—COX (Rf is H, F, a substituent consisting of C and F or consisting of C, H, and F, or —COX; each X is independently any halogen atom of F, Cl, Br and I) on the surface by reacting the acid halide with the hydrogenated surface through exposure to the acid halide, and (3) etching step of etching a single atomic layer by inducing chemical reactions on the surface of the acid halide-adsorbed silicon oxide film or silicon nitride film through irradiation with a plasma containing a noble gas (at least any one of He, Ar, Ne, Kr, and Xe).

Owner:KANTO DENKA IND CO LTD

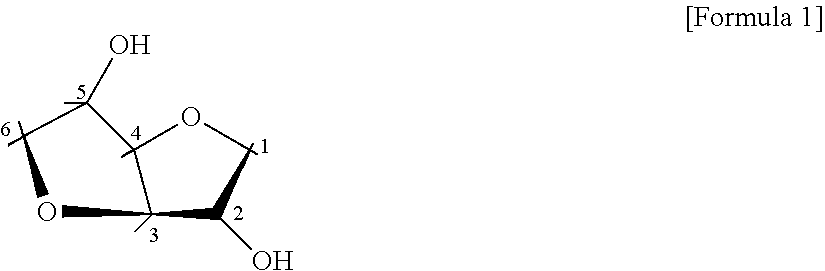

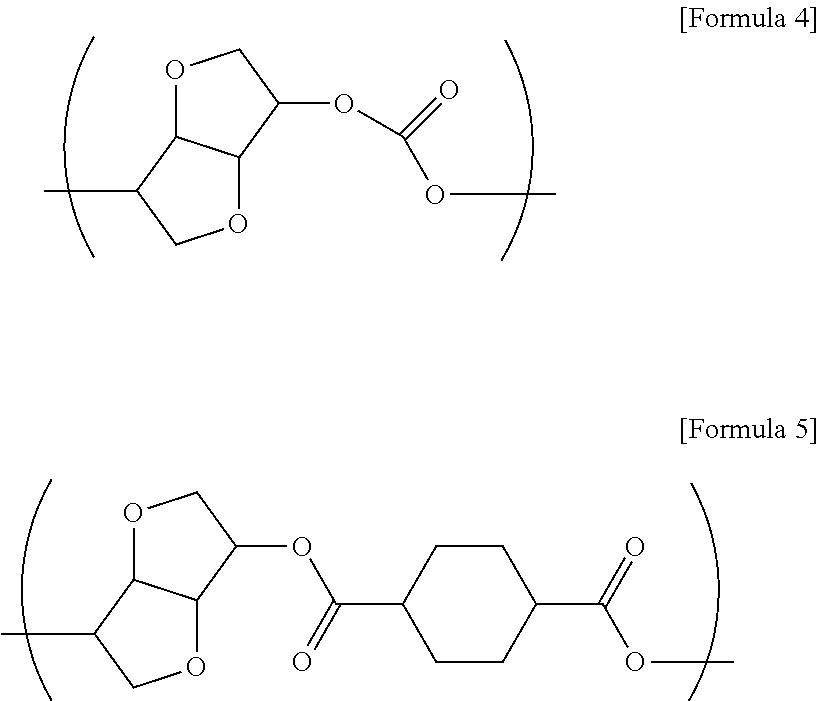

Polylactic acid resin and copolymer polyester resin blend, and molded product using same

A blend of polylactic acid resin and copolyester resin, which has excellent impact resistance and heat resistance, and a molded article manufactured using the same are disclosed. The blend of polylactic acid resin and copolyester resin, comprises 5 to 94 wt % of a polylactic acid resin; 3 to 92 wt % of a copolyester resin comprising a dicarboxylic acid component, which contains a terephthalic acid residue, and a diol component which contains 3 to 99 mol % of a cyclohexanedimethanol residue and 1 to 60 mol % of an isosorbide residue; and 3-30 wt % of a compatibilizer containing at least one reactive functional group selected from the group consisting of glycidyl, maleic anhydride, epoxy, isocyanate, amino, carboxylic acid and oxazoline groups, and mixtures thereof.

Owner:SK CHEM CO LTD

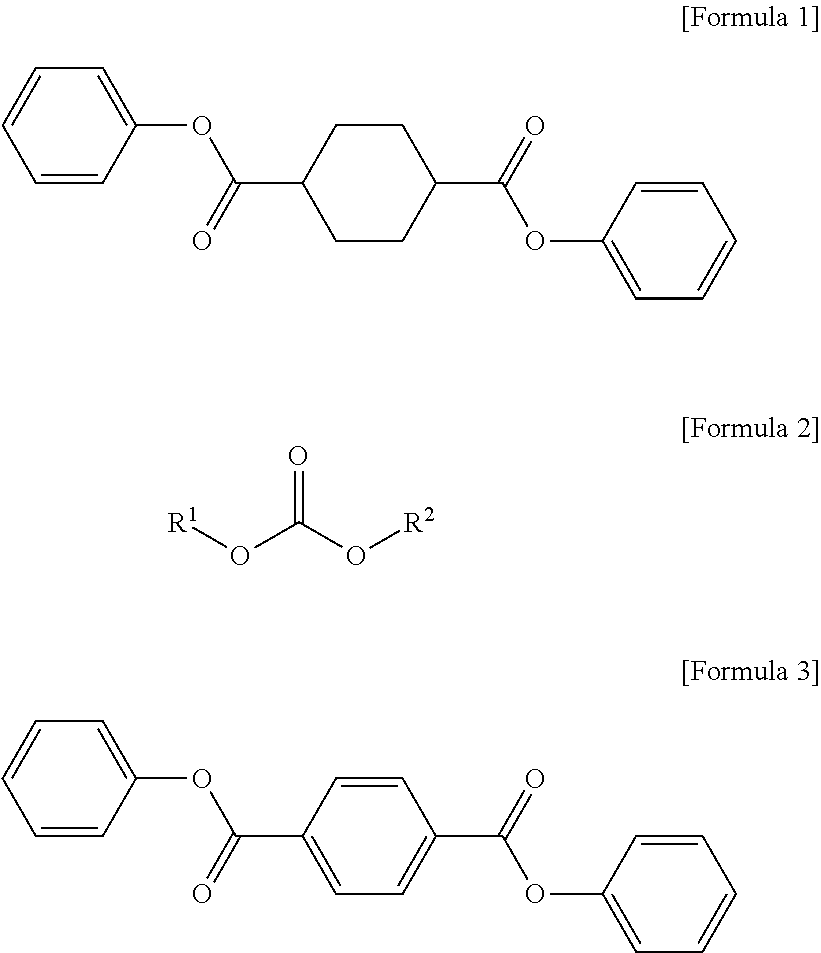

Bio-based polycarbonate ester and preparation method therefor

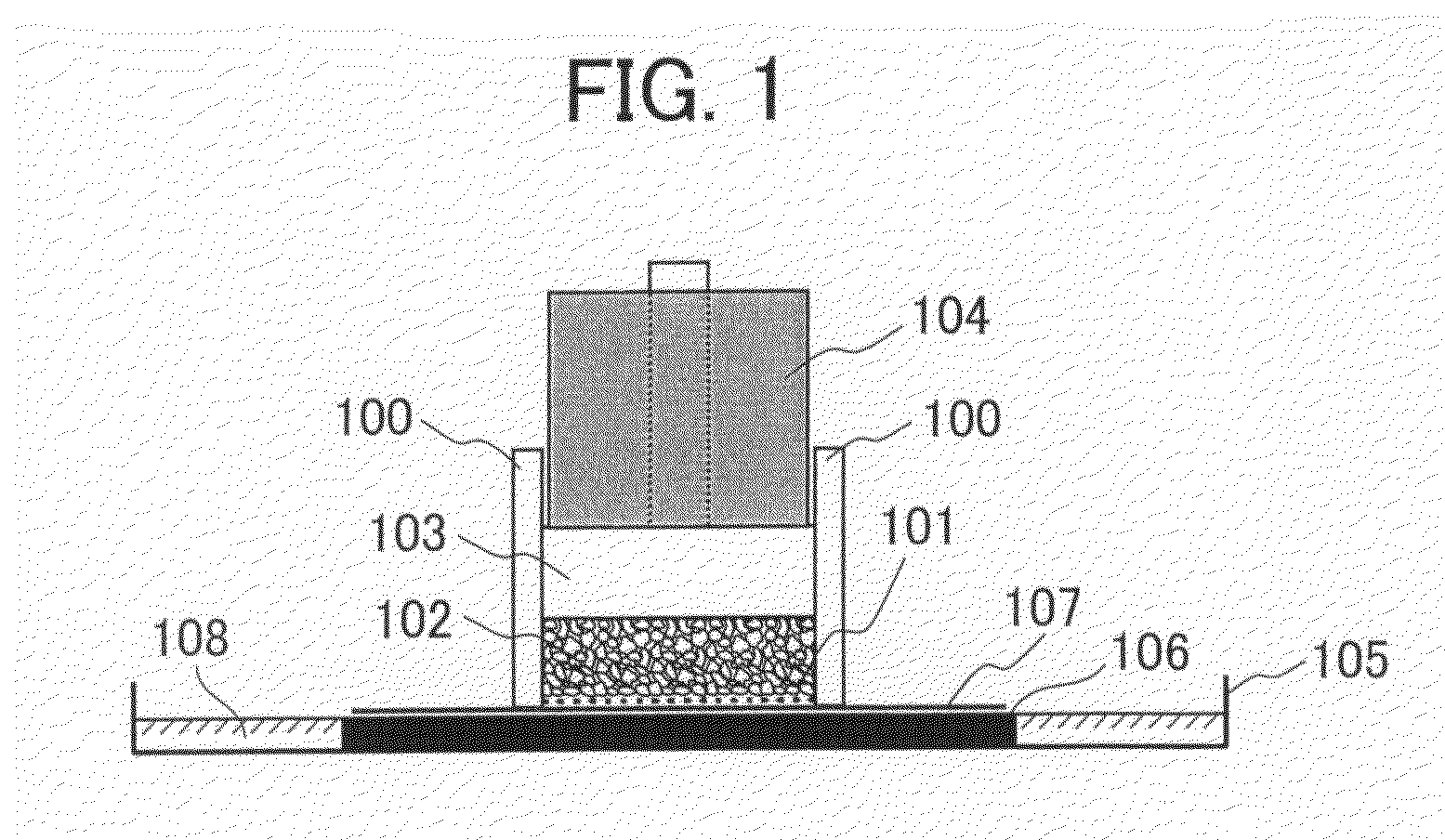

ActiveUS20200362105A1Improve mechanical propertiesProcess environmental protectionPolymer sciencePolycarbonate

A bio-based polycarbonate ester and a method for making the bio-based polycarbonate are disclosed. The bio-based polycarbonate ester has excellent mechanical properties, such as tensile strength and impact strength. The method produces the bio-based polycarbonate ester using a high-viscosity polycondensation reactor.

Owner:SK CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com