Preparation method of anionic polymerization initiator, device for manufacturing anionic polymerization initiator and anionic polymerization initiator prepared therefrom

a technology anionic polymerization initiator, which is applied in the field of preparation of anionic polymerization initiator, can solve the problems of unstable modification initiator thus prepared, difficult to maintain a constant quality, and low reactivity, so as to prevent instability and inactivation of polymerization initiator and deterioration of physical properties of ssbr, and minimize by-products and unreacted products. , the effect of improving the conversion ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

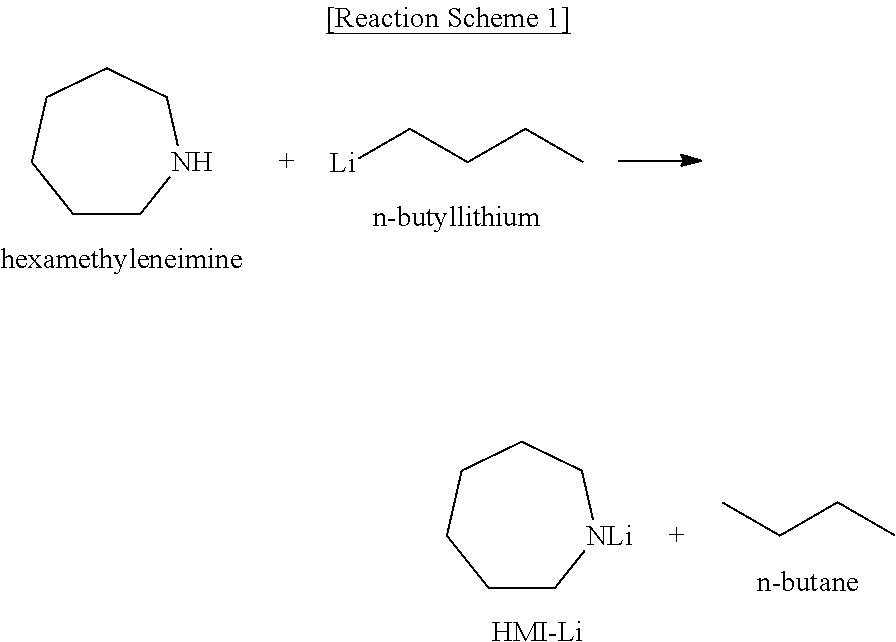

[0202]Three vacuum-dried stainless steel pressure vessels were prepared. 47 g of hexane, 100 g of 3-vinyl-N,N-dimethylbenzylamine and 101 g of tetramethylethylenediamine were placed in the first pressure vessel to prepare a 3-vinyl-N,N-dimethylbenzylamine solution. Then, 171 g of 2.5M liquid n-butyllithium and 77 g of hexane were placed in another pressure vessel to prepare an n-butyllithium solution.

[0203]The pressure of each pressure vessel was maintained at 4 bar. Then, using a mass flow meter, the 3-vinyl-N,N-dimethylbenzylamine solution was injected into a first inflow line at 0.5 g / min and the n-butyllithium solution was injected into a second inflow line at 0.5 g / min, where each flow meets on a T-union or Y-shaped channel. At this time, the width of the tube or channel was ⅛ inch, the temperature was kept at −30° C., and the internal pressure was maintained at 2 bar using a back pressure regulator. After the two raw materials were mixed, the residence time was adjusted to be ...

example 2

[0204]The anionic polymerization initiator was prepared in the same manner as in Example 1, except that the mixed solution, in which isomers of 2-vinyl-N,N-dimethylbenzylamine, 3-vinyl-N,N-dimethylbenzylamine and 4-vinyl-dimethylbenzylamine were mixed, was used other than the 3-vinyl-N,N-dimethylbenzylamine solution.

example 3

[0205]The anionic polymerization initiator was prepared in the same manner as in Example 1, except that a static mixer other than the tube reactor was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com