Narrow gap welding monitoring and welding line deviation detecting method based on infrared vision sensing

A technology of infrared vision sensing and weld deviation, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of single function, low sensing detection accuracy, poor monitoring effect, etc. Strong process adaptability and good real-time monitoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

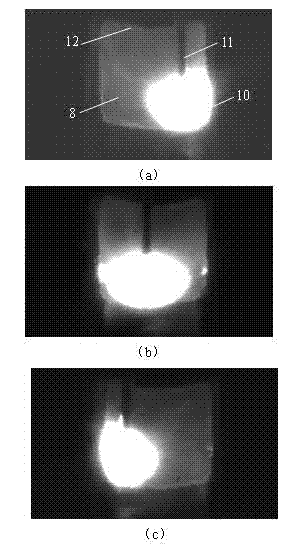

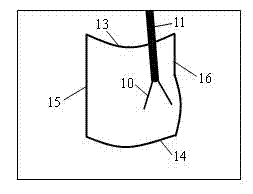

[0034] The invention is suitable for moving arc welding such as oscillating arc narrow gap welding, rotating arc narrow gap welding, swing arc narrow gap welding, and non-moving arc (such as ultra-narrow gap welding) narrow gap welding and other occasions. Below in conjunction with the accompanying drawings, the embodiment and implementation process of the present invention will be described in detail.

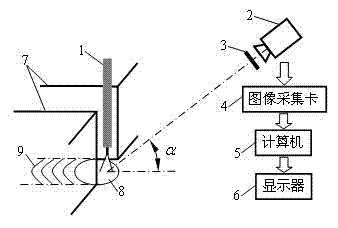

[0035] The narrow gap welding monitoring and welding seam deviation detection method based on infrared vision sensing of the present invention adopts such as figure 1 The infrared vision sensing system shown, the system includes: narrow gap welding torch 1, infrared CMOS (complementary metal oxide semiconductor) camera 2 (including macro lens), filter system 3, image acquisition card 4, computer 5, monitor6. Among them, the infrared CMOS camera 2 has a zoom range of 18-45mm and an aperture value of 5.6-32. It is mechanically connected to the welding torch 1 and placed in fron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| aperture value | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com