Hot wire consumable electrode gas protection welding method and realization device thereof

A melting gas and shielded welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor welding quality, inability to realize heat input of welding wire and molten pool, low welding efficiency, etc., and achieve improved welding efficiency. The effect of improving the quality, improving the quality of the weld seam, and improving the welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

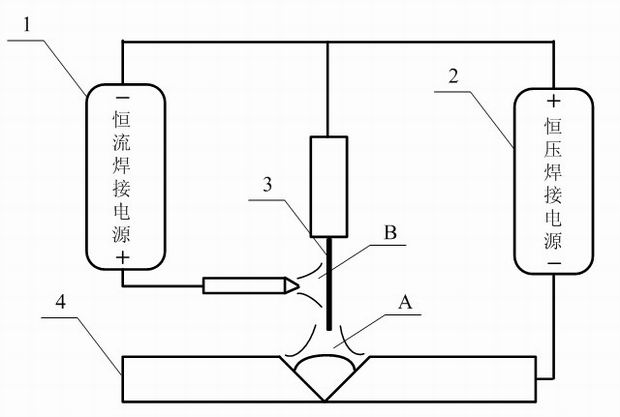

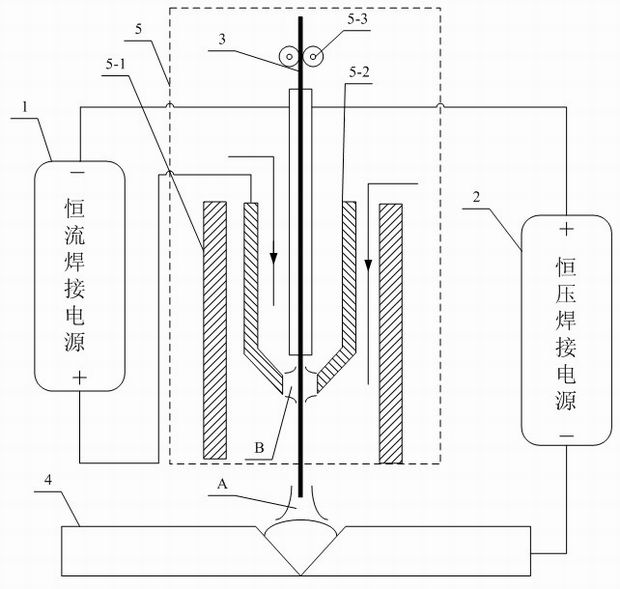

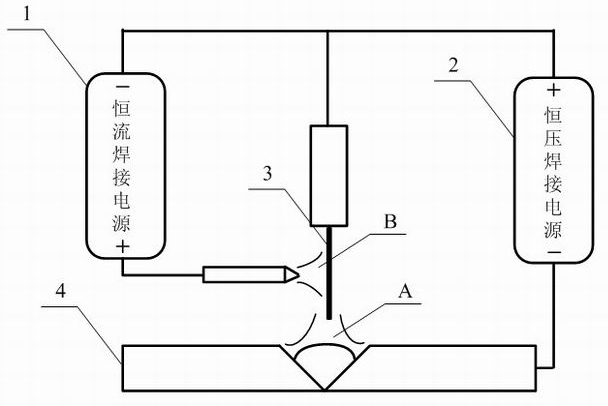

[0012] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, this embodiment adopts constant-current welding power source 1 and constant-voltage welding power source 2 to implement, and the positive output end of constant-current welding power source 1 is connected with the conductive ring sleeve 5-2 of welding torch 5, and constant-current welding power source 1 The negative output terminal of the welding torch 5 is connected to the electrode clamp 5-3 of the welding torch 5, and the melting electrode welding wire 3 is clamped on the electrode clamp 5-3 of the welding torch 5; the positive output terminal of the constant voltage welding power supply 2 is connected to the electrode clamp 5-3 of the welding torch 5 connection, the negative output end of the constant voltage welding power supply 2 is connected to the workpiece 4 to be welded, and its welding method is:

[0013] Put the end of the consumable electrode wire 3...

specific Embodiment approach 2

[0022] Specific Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the main arc adopts CO 2 Gas or other mixed gas for protection. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is a further limitation of Embodiment 1. In this embodiment, the preheating arc is protected by Ar gas. Others are the same as the first embodiment.

[0024] The shielding gas Ar is passed between the conductive annular sleeve 5-2 of the welding torch 5 and the electrode holder 5-3 to protect the preheating arc, which can prevent the preheating arc and the consumable electrode wire 3 from being attacked by gases such as oxygen, nitrogen, and hydrogen. Adjust the parameters of the constant current welding power source 1 to ensure that the preheating arc burns stably under the protection of the Ar inert atmosphere. The melting electrode welding wire 3 is continuously fed through the wire feeding device. The welding main arc is generated in between. The heat of the main arc continuously melts the melting electrode welding wire 3 to form molten droplets, which stably transition to the molten pool, and the wire feeder continuously feeds the mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com