Method for designing long-distance small-spacing tunnel

A design method and technology of small clear distance, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of blasting vibration long-distance small clear distance tunnels, difficult reinforcement of rock pillars, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

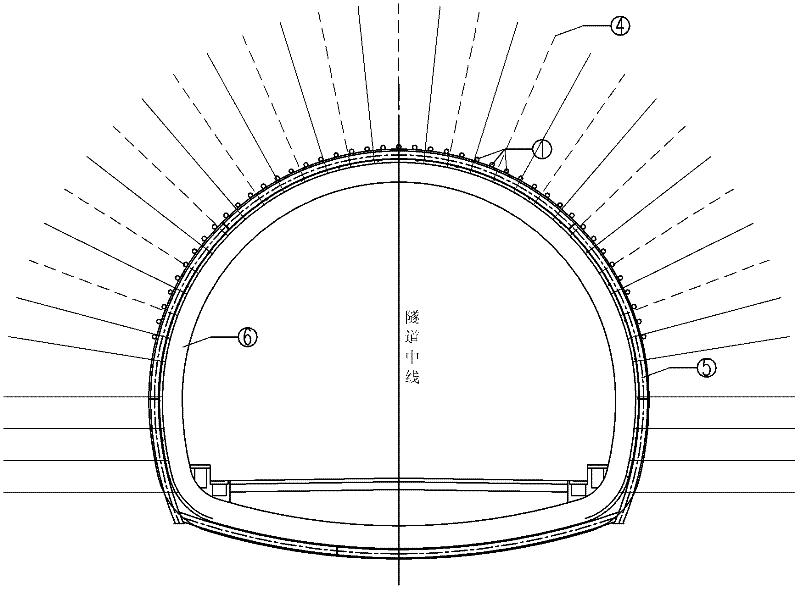

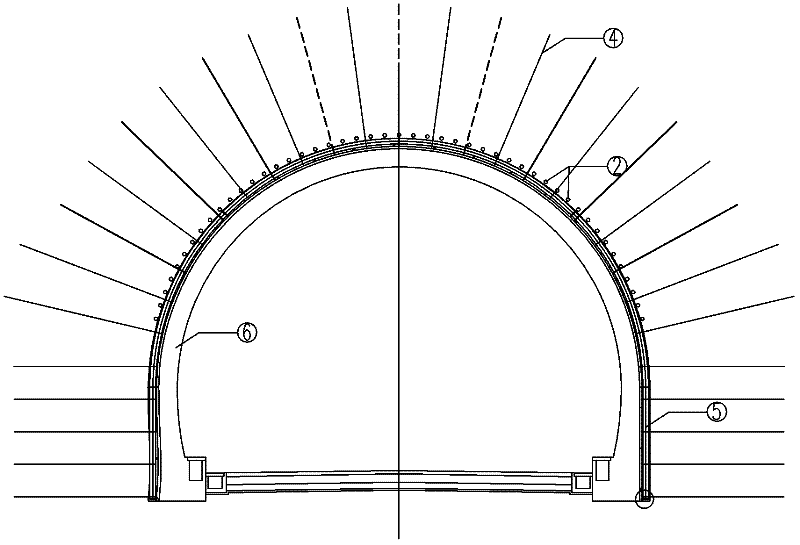

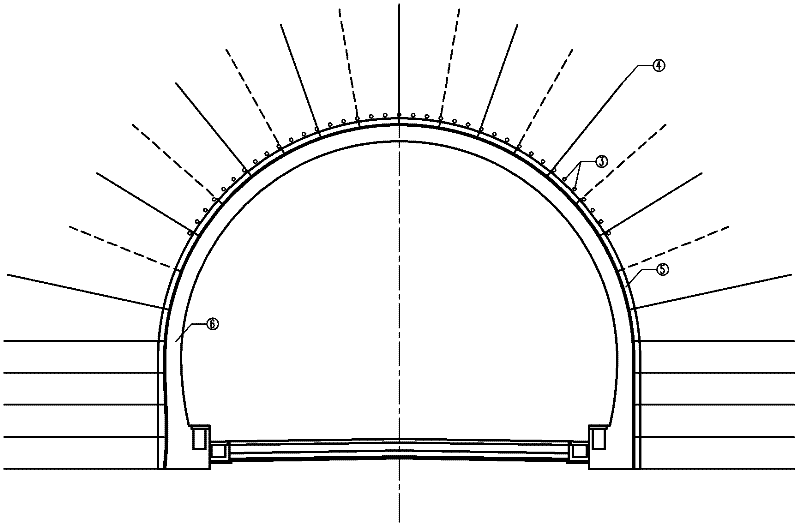

[0033] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a long-distance tunnel design method with small clearance includes the following steps:

[0034] A. Advanced support

[0035] Before tunnel excavation, the following advanced support methods are selected according to different levels of surrounding rock:

[0036] A1. For the V-level surrounding rock, the large pipe shed 1 advanced support method is adopted. The specific construction steps are as follows: first install the arch, which is the foundation of the pipe shed. It is an arch structure erected by concrete and I-shaped steel , there is a casing on it. During the construction of the large pipe shed 1, the pipe shed drilling machine is used to drill the pipe shed according to the position of the casing. After drilling, a steel pipe with a diameter of 108mm is inserted in the hole, and the steel pipe is inserted in sections. Use thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com