Real-time high-precision detection method and system for bolt pre-tightening force based on piezoelectric ultrasonic wafer

A bolt pretightening force, piezoelectric ultrasonic technology, applied in force/torque/work measuring instruments, force sensors related to bearings, measuring torque/torsion force during tightening, etc., can solve problems such as high cost and achieve low cost , Eliminate errors and improve repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

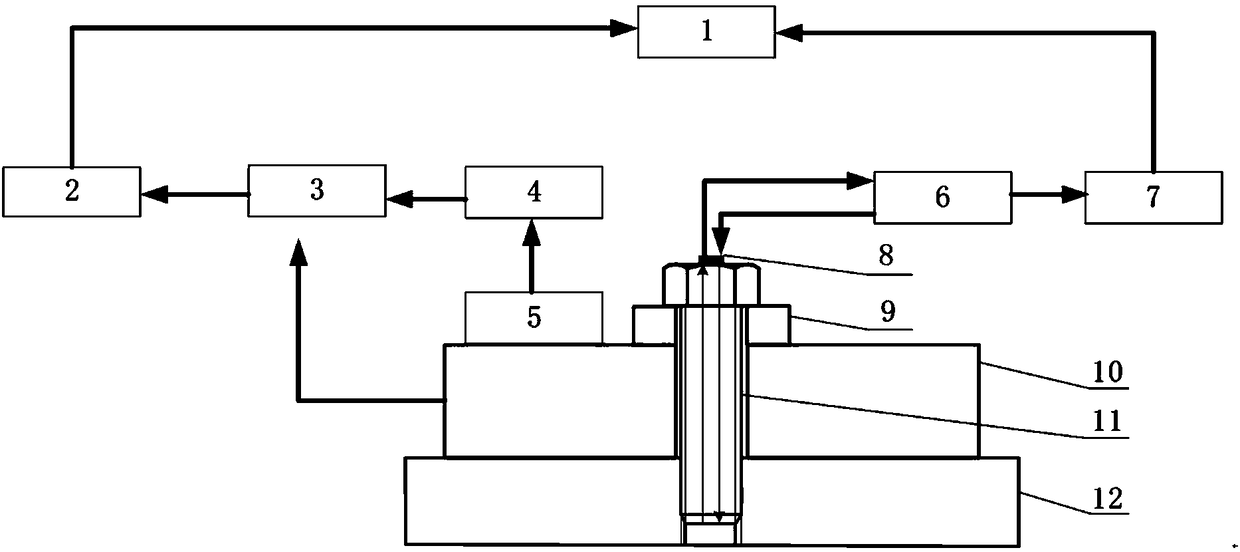

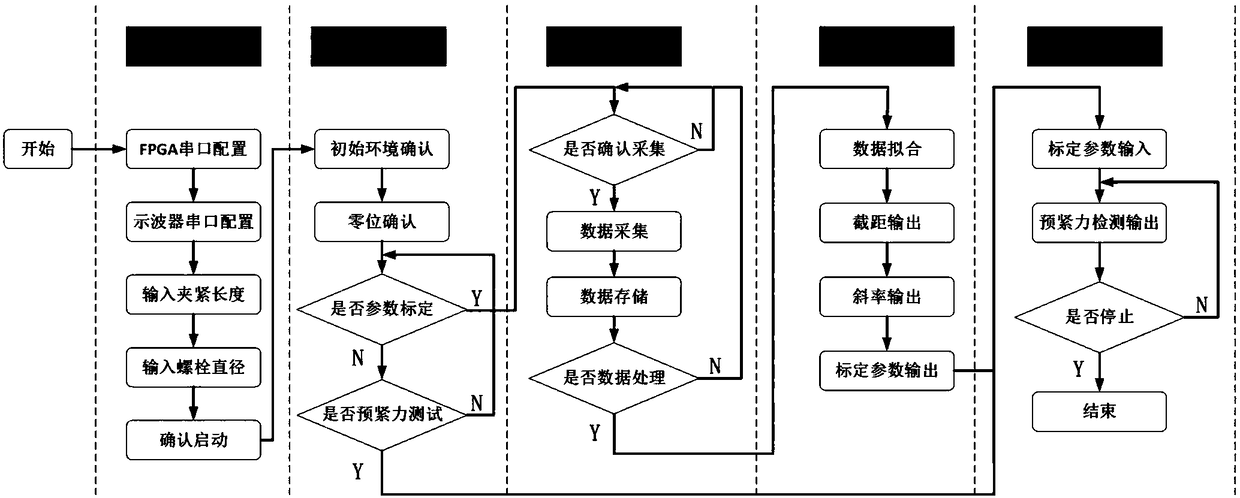

[0034] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0035] A method for real-time and high-precision detection of bolt pretightening force based on piezoelectric ultrasonic chips, the steps are as follows:

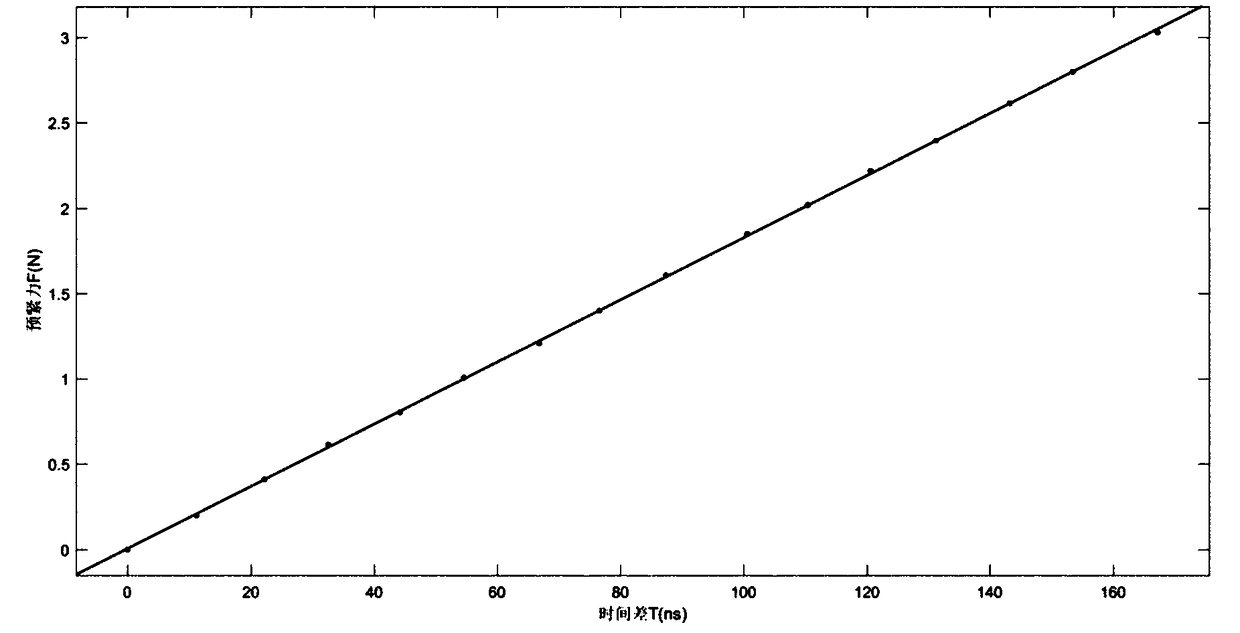

[0036] 1. Preload test model based on single-wave flight time difference

[0037] By detecting the time-of-flight difference (the time difference between the first wave of the first reflected wave and the first wave of the second reflected wave), the service condition of the preload is characterized.

[0038] In the case of plane waves in homogeneous and isotropic materials, the velocity of the longitudinal wave is in the same direction as the applied stress and can be expressed in their first-order approximation as

[0039] V L =V 0 (1+A L σ)

[0040] Among them, V L is the propagation velocity of the longitudinal wave under the stress state, V 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com