Pretightening force measuring system and method of bolt set connection

A technology of measurement system and measurement method, which can be used to measure the direction of torque/torsional force during tightening, and can solve the problems of inability to monitor the bolt pre-tightening force and the inability to directly measure the pre-tightening force of the bolt group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

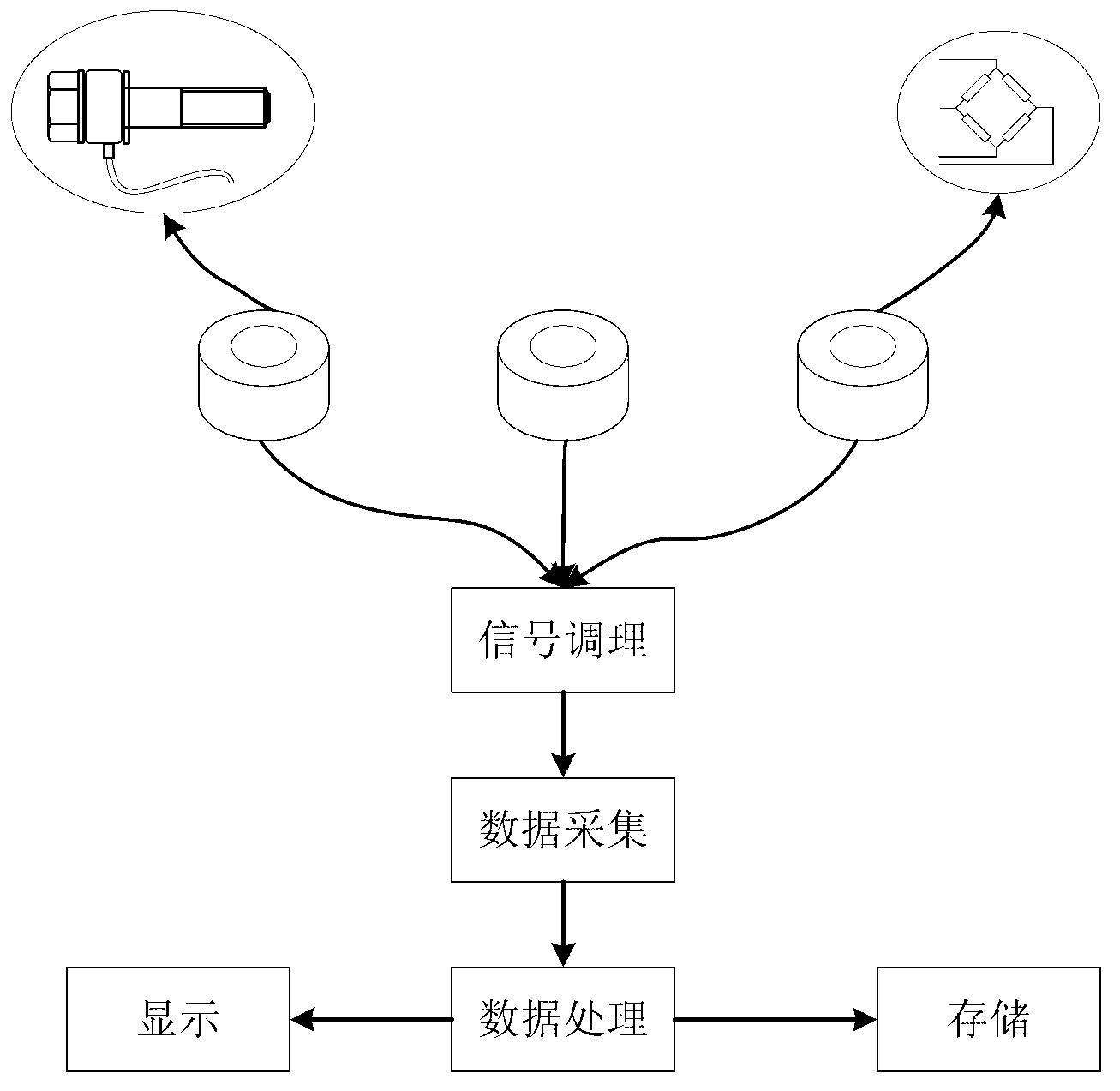

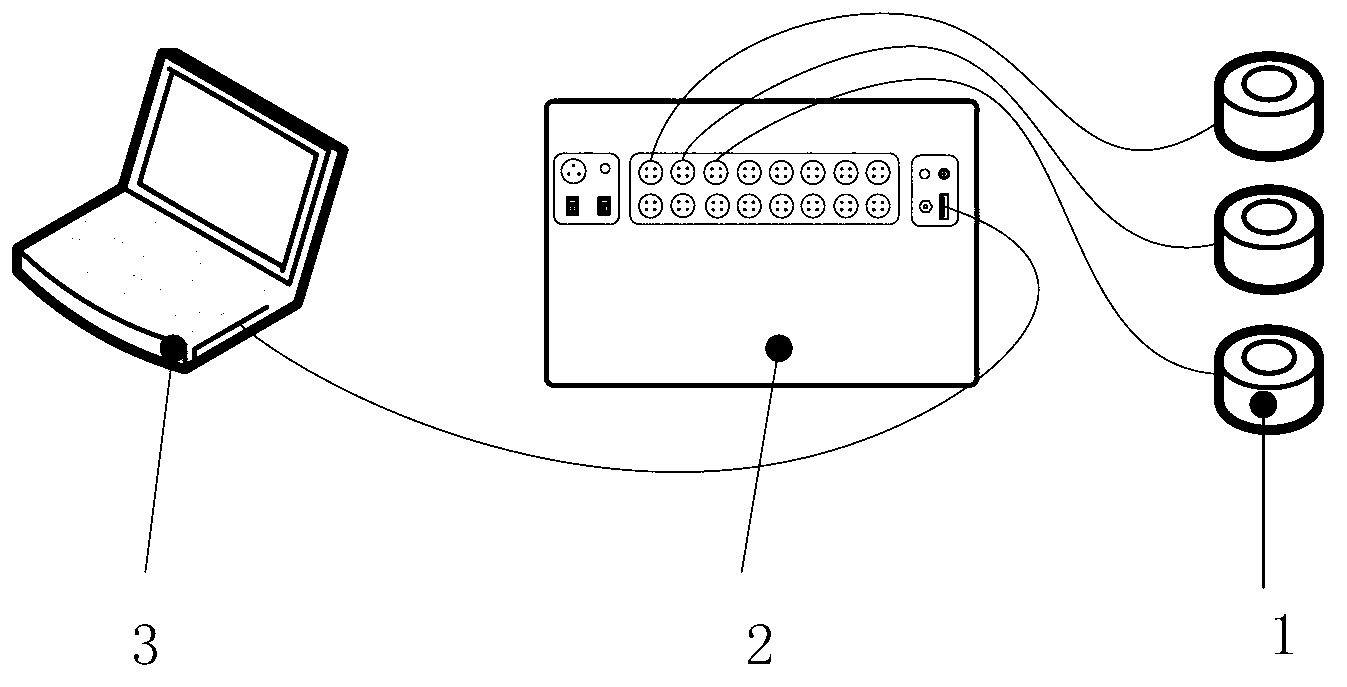

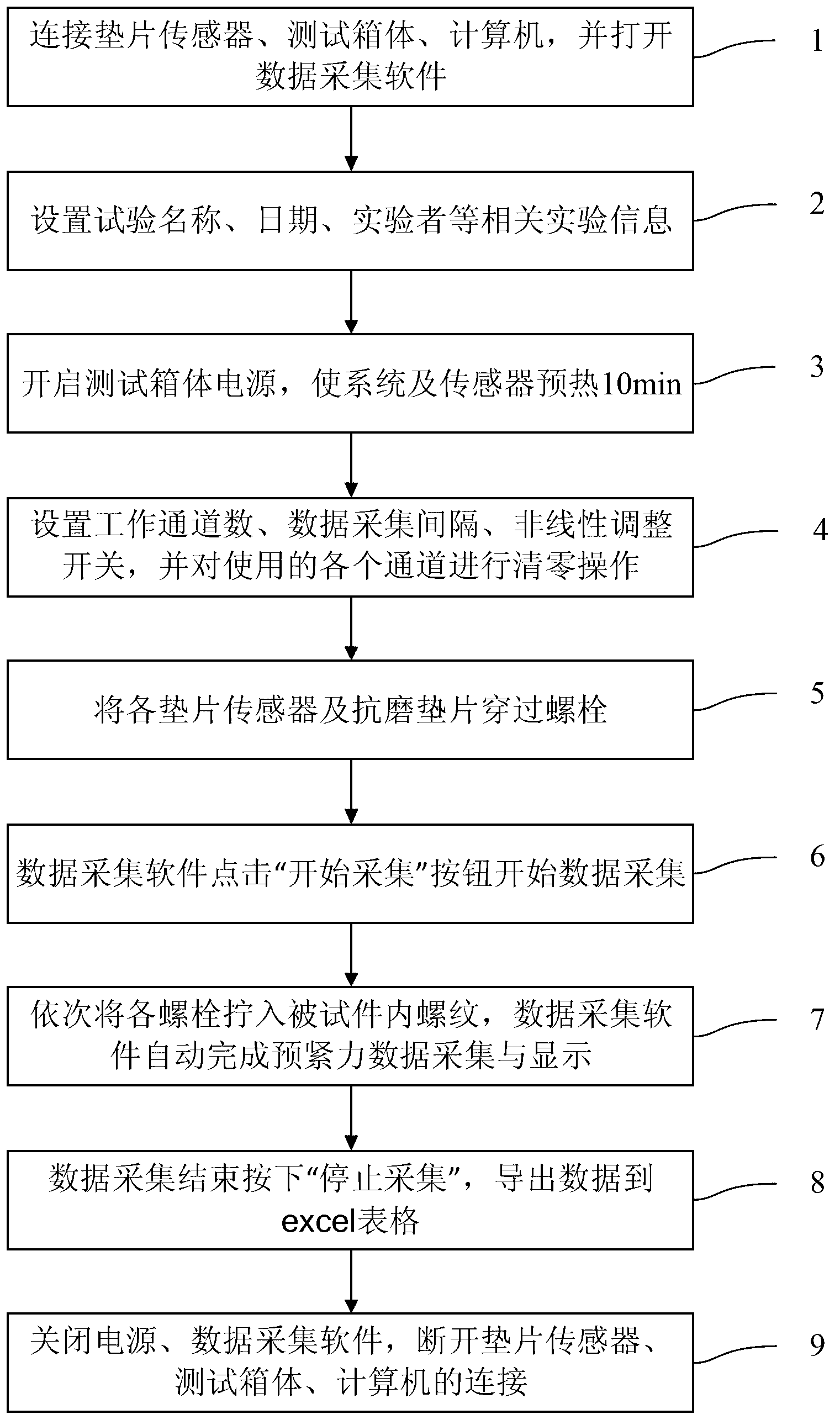

[0048] Such as figure 1 , 2 Shown in and 4, the embodiment of the present invention provides a kind of pretightening force measuring system that bolt group connects, comprises: gasket type force sensor 1; The test box body 2 that is connected with gasket type force sensor 1; And with described The processing equipment 3 connected to the test box 2; wherein, the gasket type force sensor 1 has a through hole for the bolt to pass through, and transmits the pre-tightening force signal obtained when the bolt is tightened to the test box 2 , and the test box 2 performs signal conditioning on the pre-tightening force signal, and transmits the conditioned pre-tightening force signal to the processing device 3 for processing.

[0049] Among them, such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com