Scraping plate error correcting tool

An error correction and scraper technology, applied in the field of fixtures, can solve problems such as low efficiency and complicated operation, and achieve the effect of saving error adjustment steps and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

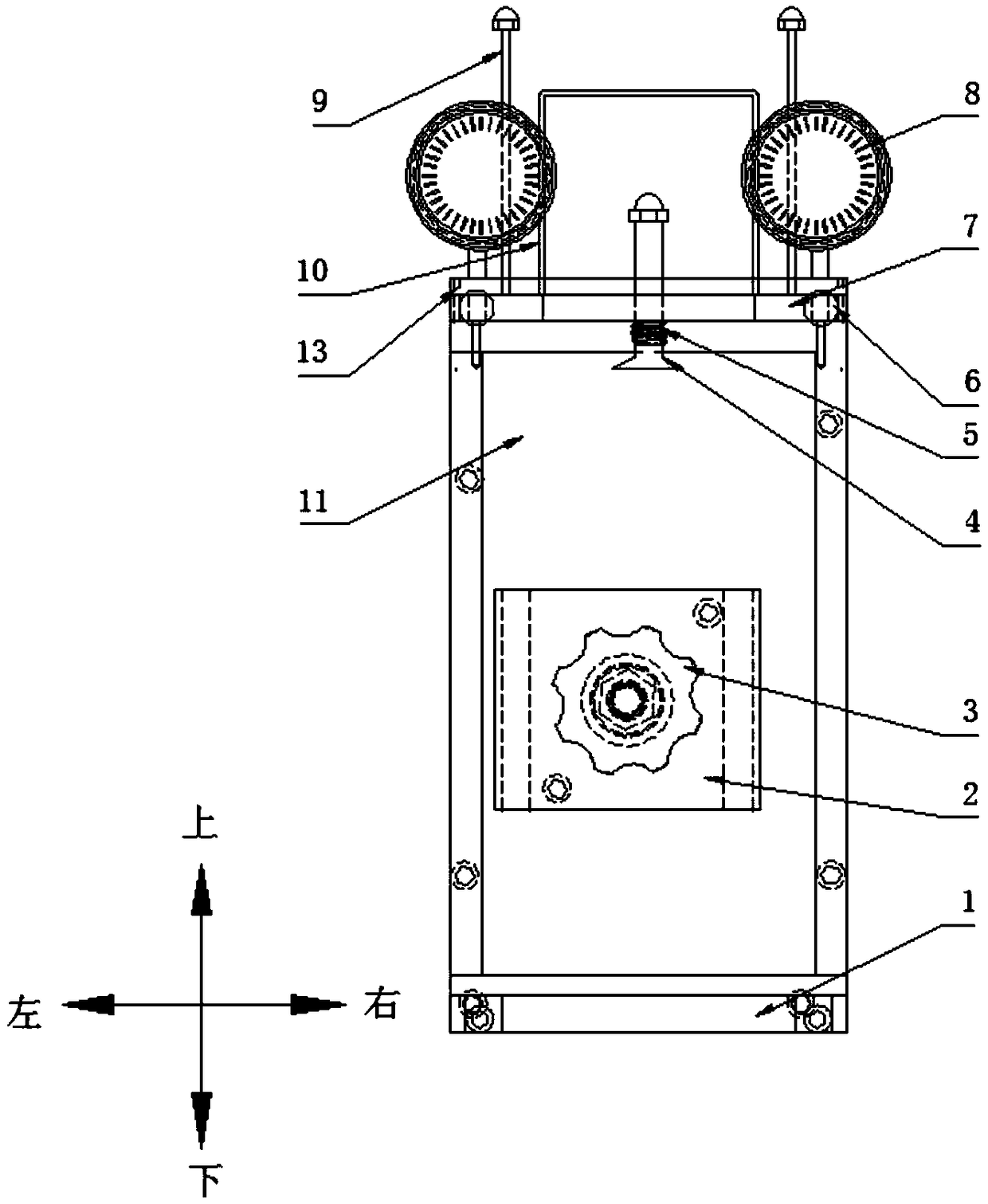

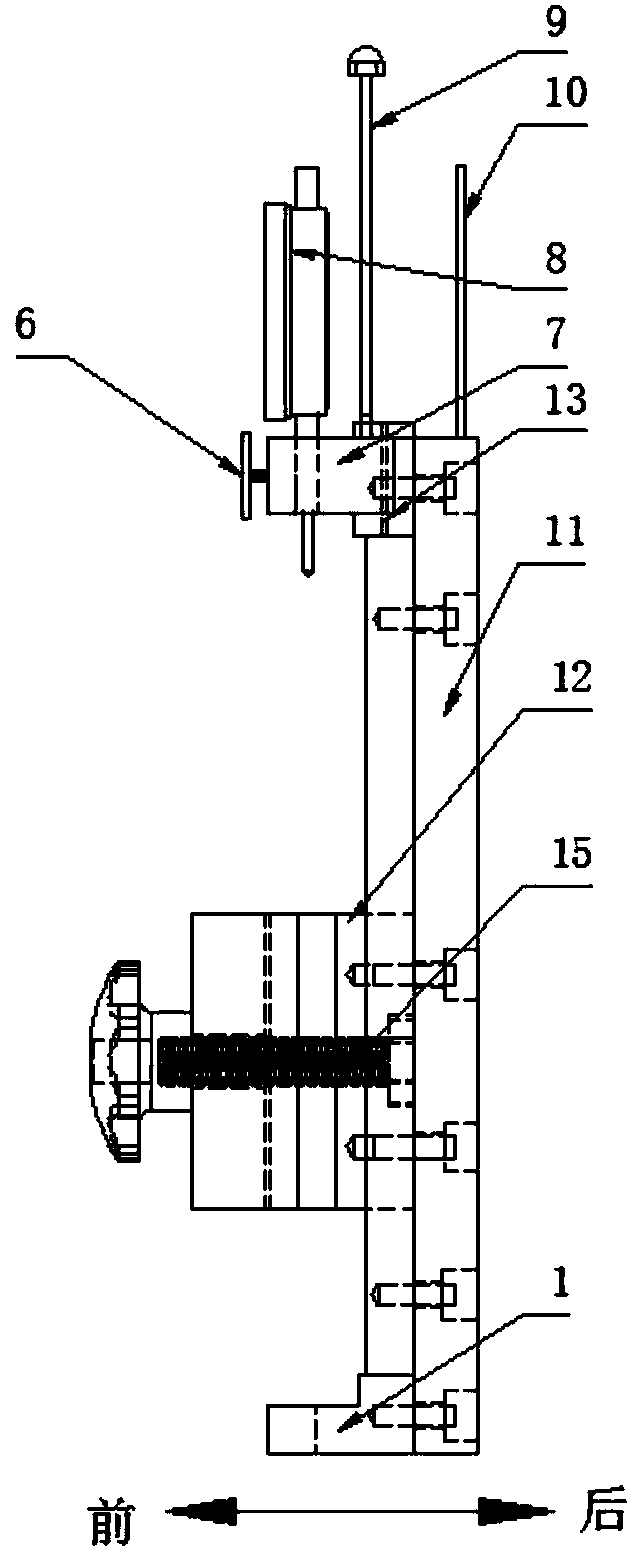

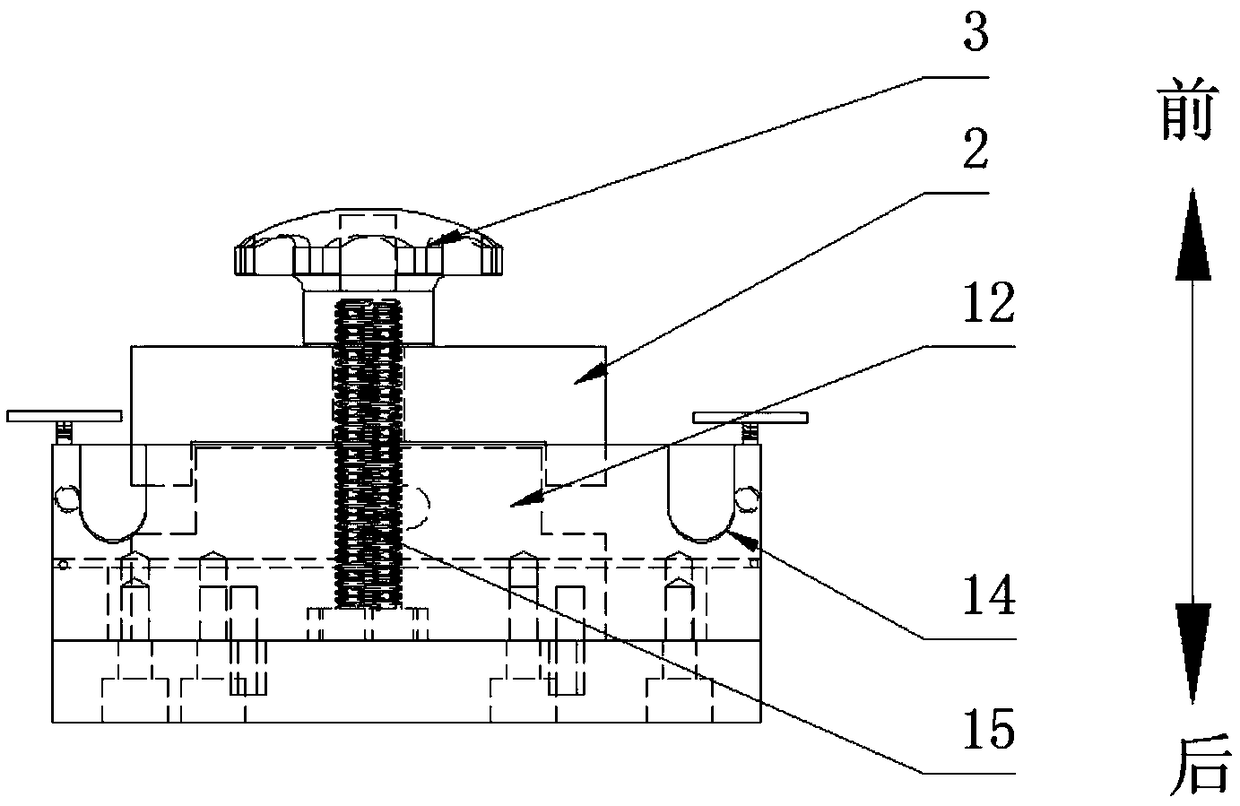

[0045] like Figure 1-Figure 8 As shown, a scraper error correction tool includes a scraper positioning assembly, a base 11, two dial indicator fixing blocks 7 and two dial indicators 8, and the scraper positioning assembly is in phase with the base 11. The scraper positioning assembly has two grooves 14 for accommodating an outer micrometer anvil or a micrometer screw. The two dial indicator fixing blocks 7 are rotatably connected to the base 11, and the two The dial indicator 8 and the two dial indicator fixing blocks 7 are arranged in a one-to-one correspondence and are penetrated in the dial indicator fixing block 7, and the groove 14 is one with the dial indicator 8. A corresponding arrangement, the dial indicator 8 is in contact with or separated from the scraper with the change of the relative position of the dial indicator fixing block 7 and the base 11 .

[0046] Specifically, as Figure 1-Figure 8 As shown, the dial indicator fixing block 7 has a through hole, and ...

Embodiment 2

[0069] On the basis of the first embodiment, the rotational connection between the dial gauge fixing block 7 and the base 11 is replaced by a sliding connection.

[0070] like Figure 9 and Figure 10 As shown, it includes two locking and positioning rods 17, and the base 11 is provided with two horizontal slide grooves, and the dial gauge fixing block 7 is embedded in the slide grooves and slides relative to the slide grooves. , the side wall of the chute has two locking holes perpendicular to the chute, the locking holes are set in one-to-one correspondence with the dial gauge fixing block 7, and the locking positioning rod 17 and the The locking holes are connected one by one and abut against the dial gauge fixing block 7 .

[0071] like Figure 9 As shown, in the process of adjusting the scraper, unscrew the left and right dial indicator lock nuts 6, adjust the position of the dial indicator 8 up and down, so that the contact of the dial indicator 8 is in contact with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com