Method for measuring bubble size, bubble number and bubble movement velocity in gas-liquid two-phase flow

A moving speed and bubble technology, which is used in the measurement of number and moving speed, and the size of bubbles in gas-liquid two-phase flow. The effect of penetrating power and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

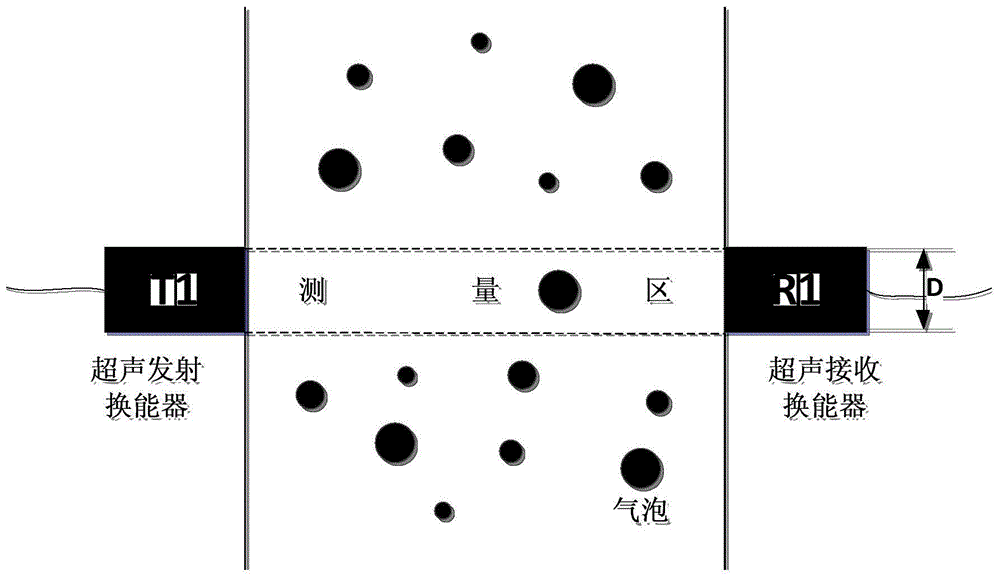

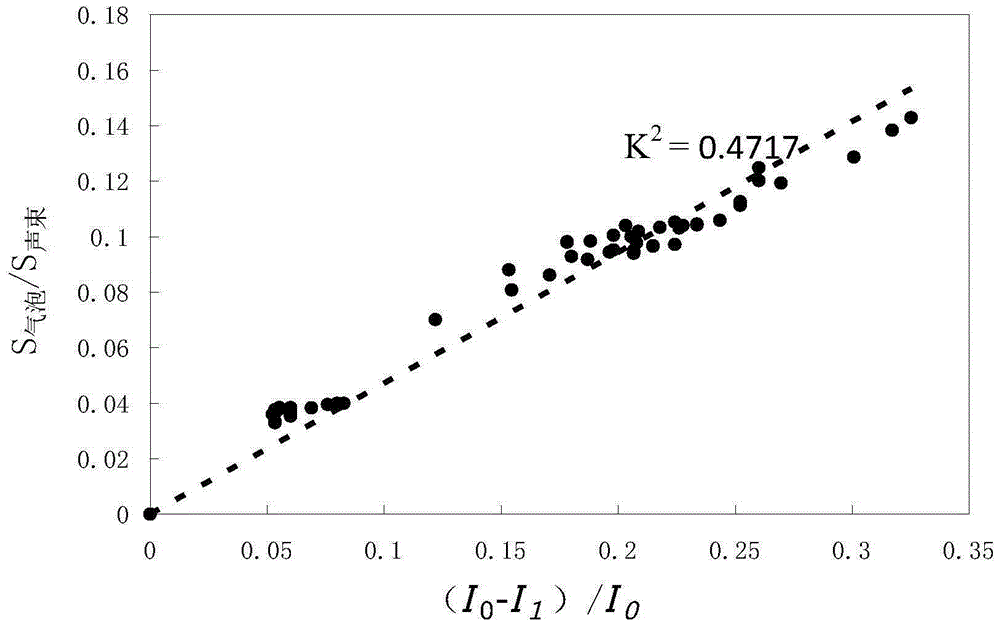

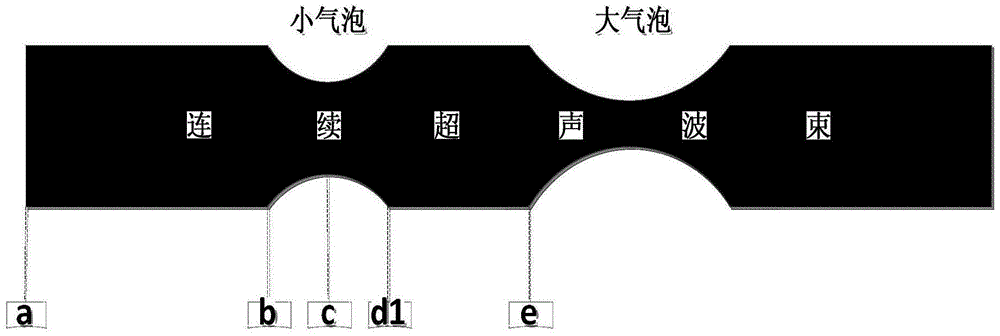

[0028] Ultrasound has the characteristics of high frequency, short wavelength, small diffraction phenomenon, especially good directionality, and can become directional propagation of rays. When ultrasonic waves propagate in liquid, there is no obvious energy attenuation during the propagation process. When propagating in gas-liquid two-phase flow, since the acoustic impedance of gas is much smaller than that of liquid, for example, the ratio of characteristic impedance of water to air is about 3560, which is The difference in acoustic impedance will lead to the reflection of ultrasonic waves on different medium surfaces, resulting in energy loss. The present invention is based on the relationship between the attenuation degree and attenuation time of the ultrasonic wave, the size of the bubble particle size and the moving speed of the bubble, and invented a method for measuring the particle size and moving speed of the bubble. Specifically include the following steps:

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com