Flexible resistance-type MEMS (micro-electro-mechanical systems) temperature sensor array and preparation method thereof

A temperature sensor and resistive technology, which is applied in the field of medical engineering, can solve the problems of thermal deformation of the base material, failure to work normally, sensor damage, etc., and achieve high ultrasonic propagation speed, low processing cost, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

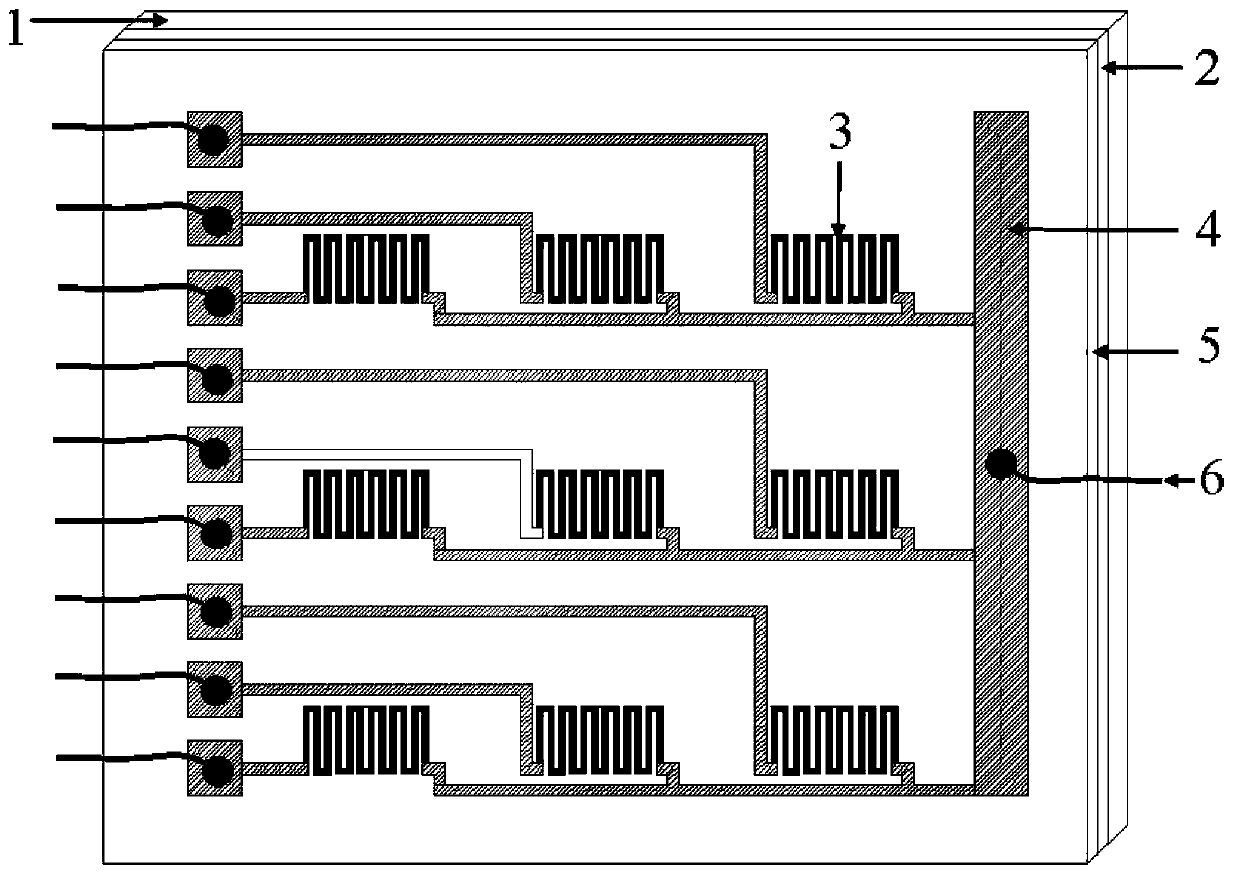

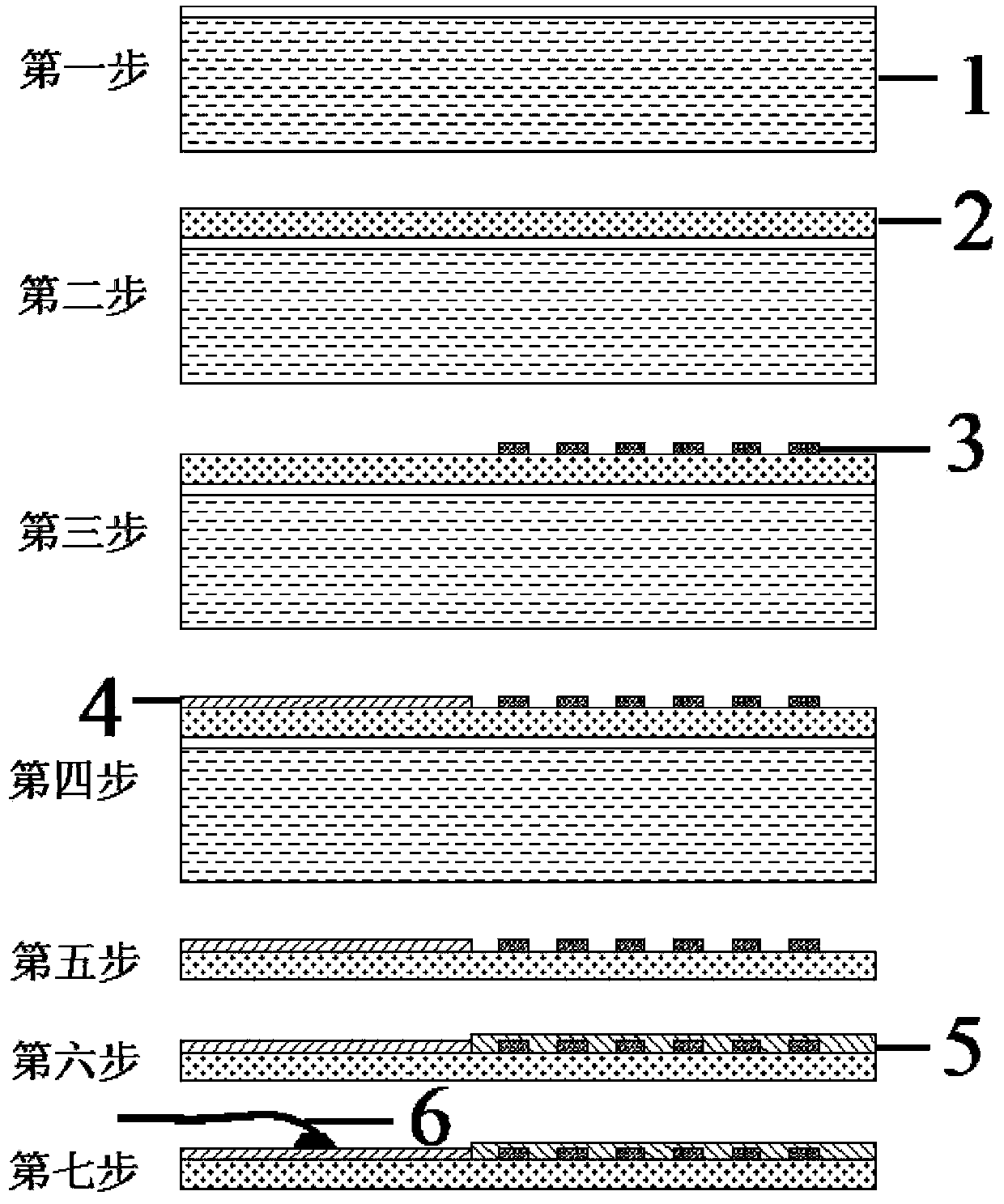

[0040] Such as figure 1 As shown, the present embodiment provides a flexible resistive MEMS temperature sensor array, including a fixed base 1, a flexible base film 2, an array of temperature-sensitive films 3, an electrode array 4, a flexible covering film 5 and electrical leads 6, wherein: flexible The base film 2 is fixed on the fixed base 1, the array of temperature sensitive films 3 is deposited on the flexible base film 2, the electrode array 4 is patterned on the flexible base film 2, and the flexible cover layer film 5 is patterned and covered on the array of temperature sensitive films 3, Electrical leads 6 connect the electrode array 4 .

[0041] In this embodiment, the fixed base 1 is a silicon wafer.

[0042] In this embodiment, the flexible base film 2 is made of PI material with a thickness of 50 μm.

[0043] In this embodiment, the temperature-sensitive thin film 3 is Cr / Pt with a thickness of 200 nm.

[0044] In this embodiment, the electrode array 4 is a Ti...

Embodiment 2

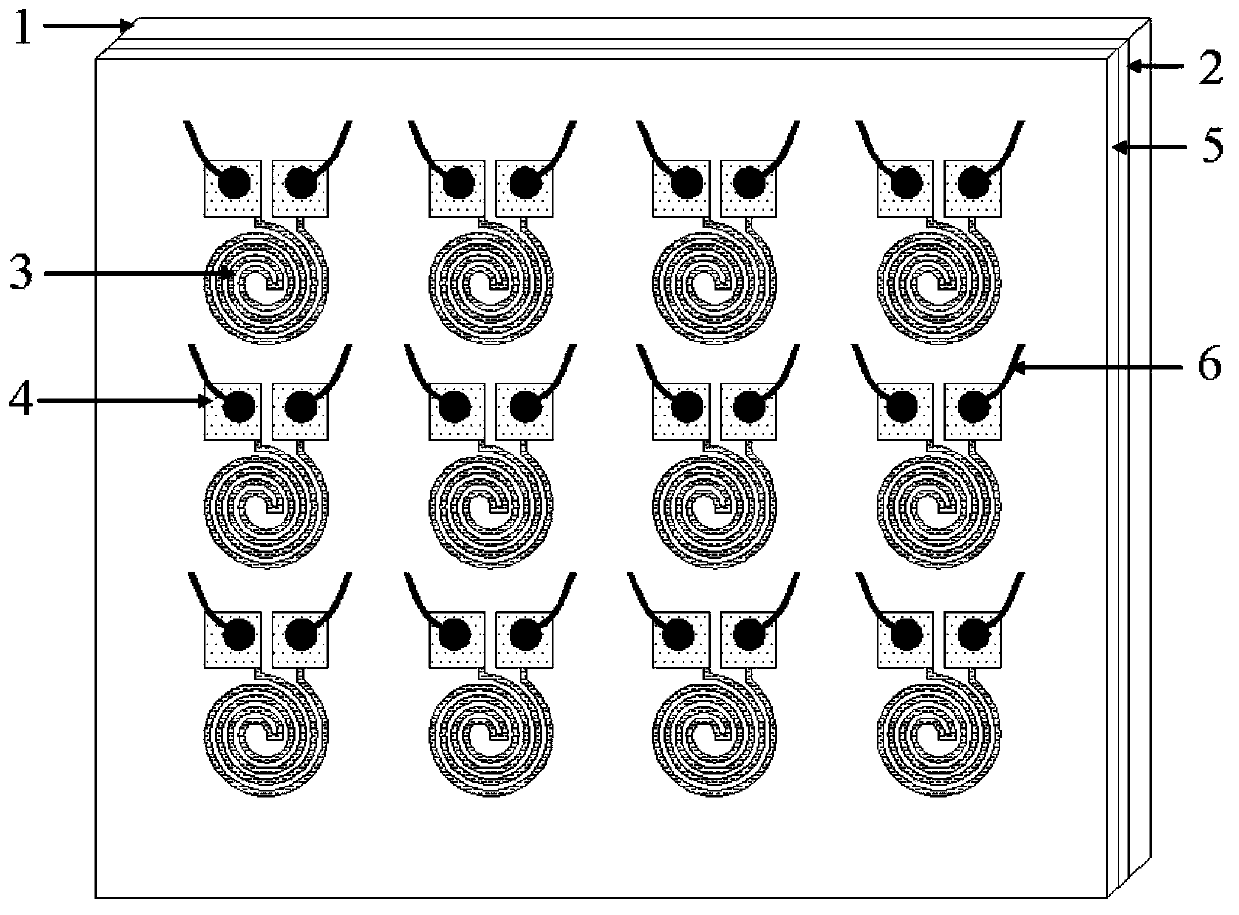

[0062] Such as image 3 As shown, the present embodiment provides a flexible resistive MEMS temperature sensor array, including a fixed base 1, a flexible base film 2, an array of temperature-sensitive films 3, an electrode array 4, a flexible covering film 5 and electrical leads 6, wherein: flexible The base film 2 is fixed on the fixed base 1, the temperature sensitive film 3 is deposited on the flexible base film 2, the electrode array 4 is patterned on the flexible base film 2, the flexible cover layer film 5 is patterned and covered on the temperature sensitive film 3, and the electric wire 6 is connected to the electrode array 4 .

[0063] In this embodiment, the fixed base 1 is glass with a thickness of 500 μm.

[0064] In this embodiment, the flexible base film 2 is made of PI material with a thickness of 10 μm.

[0065] In this embodiment, the temperature-sensitive thin film 3 is Ti / Au with a thickness of 20nm / 200nm.

[0066] In this embodiment, the electrode array...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com