High-pressure-gas-coupled ultrasonic detection method for flaw of composite material

A composite material and high-pressure gas technology, which is applied to the analysis of materials, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve contamination, detection is not fully applicable, and time-consuming coupling agent cleaning And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation steps of the present invention are described in detail below:

[0029] 1) Determine the relevant parameters of the composite material workpiece to be tested, including the thickness T of the test piece, the sound velocity C, etc., to ensure that the ultrasonic wave can penetrate the test piece under a certain excitation voltage and gain.

[0030] 2) Determine the selected transmitting and receiving air-coupled ultrasonic probes, both of which have a nominal frequency of 500KHz, a near-field distance of 60mm, and an aperture of 20mm.

[0031] 3) Place the test piece between the transmitting and receiving transducers, adjust the horizontal position of the probes to keep the axes of the two probes consistent, and adjust the distance to maximize the amplitude of the received A-scan waveform.

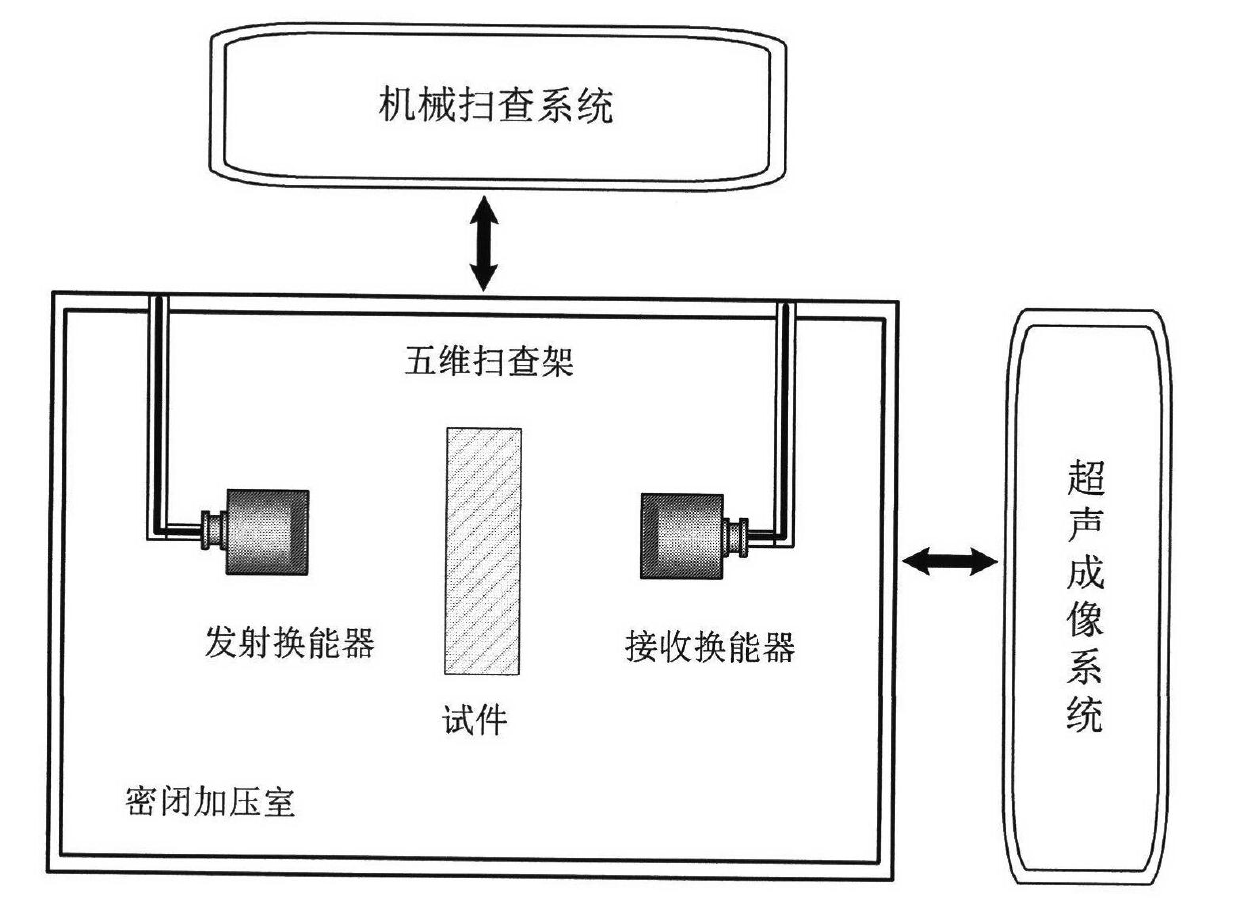

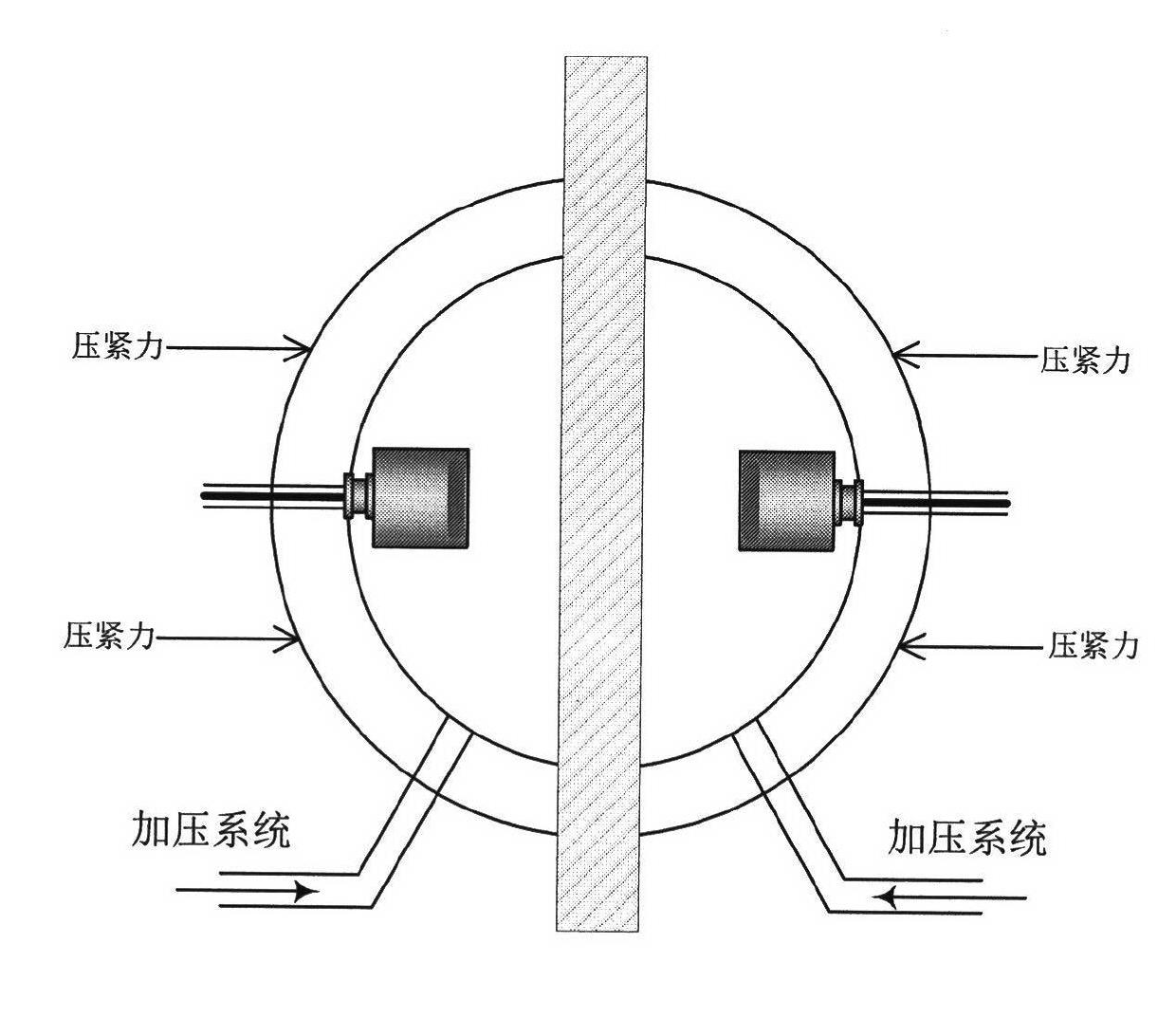

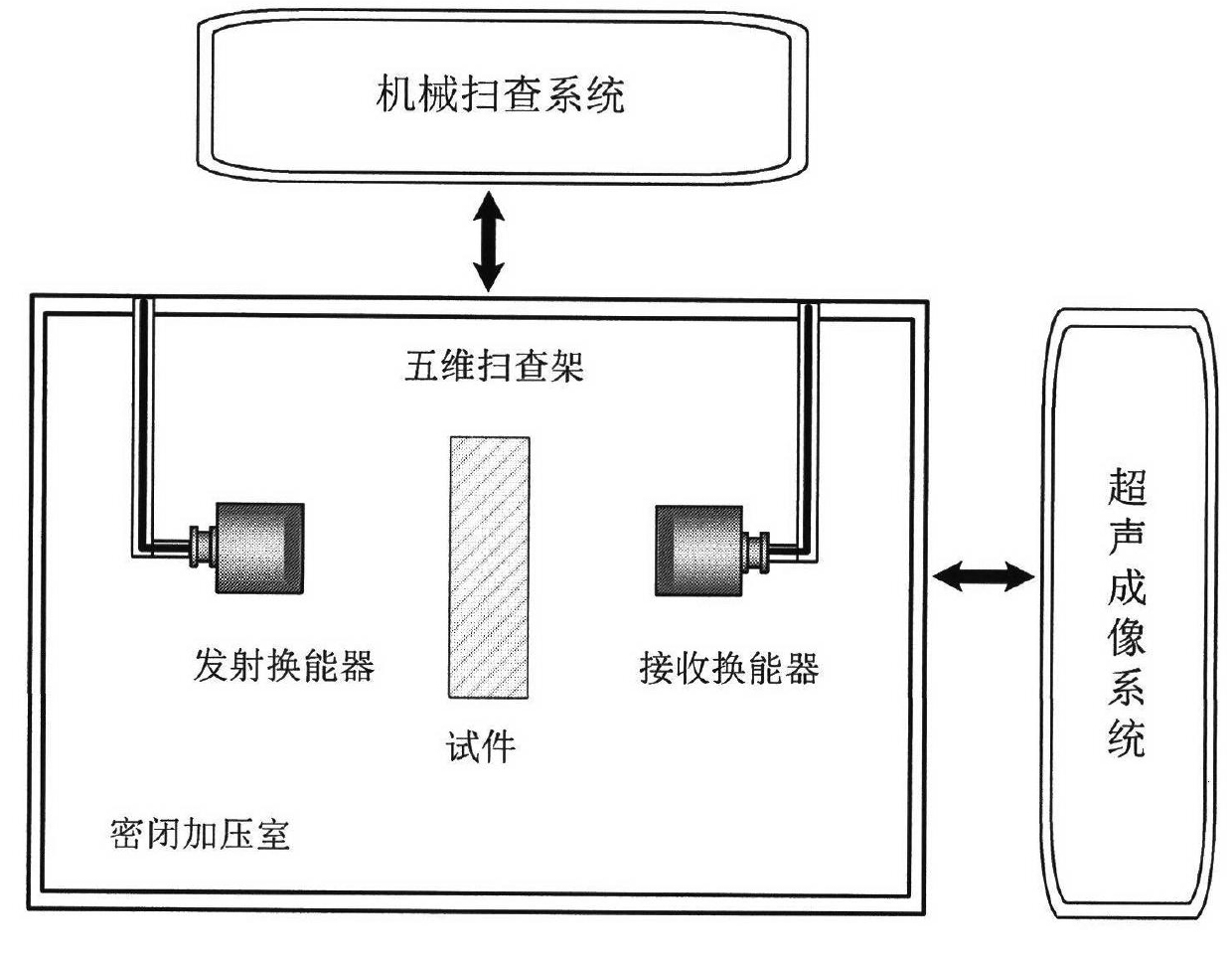

[0032] 4) Place the air-coupled ultrasonic transducer and the test piece in a closed pressurized chamber, observe the received A-scan waveform under standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com