Bolt fastening axial force ultrasonic detection method based on differential method

A fastening axial force and ultrasonic testing technology, applied in force/torque/work measuring instruments, measuring torque/torsion force during tightening, measuring devices, etc., can solve poor adaptability, high cost, and unfavorable bolt fastening axial force Ultrasonic testing method engineering application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The specific embodiment of the present invention is described in detail below:

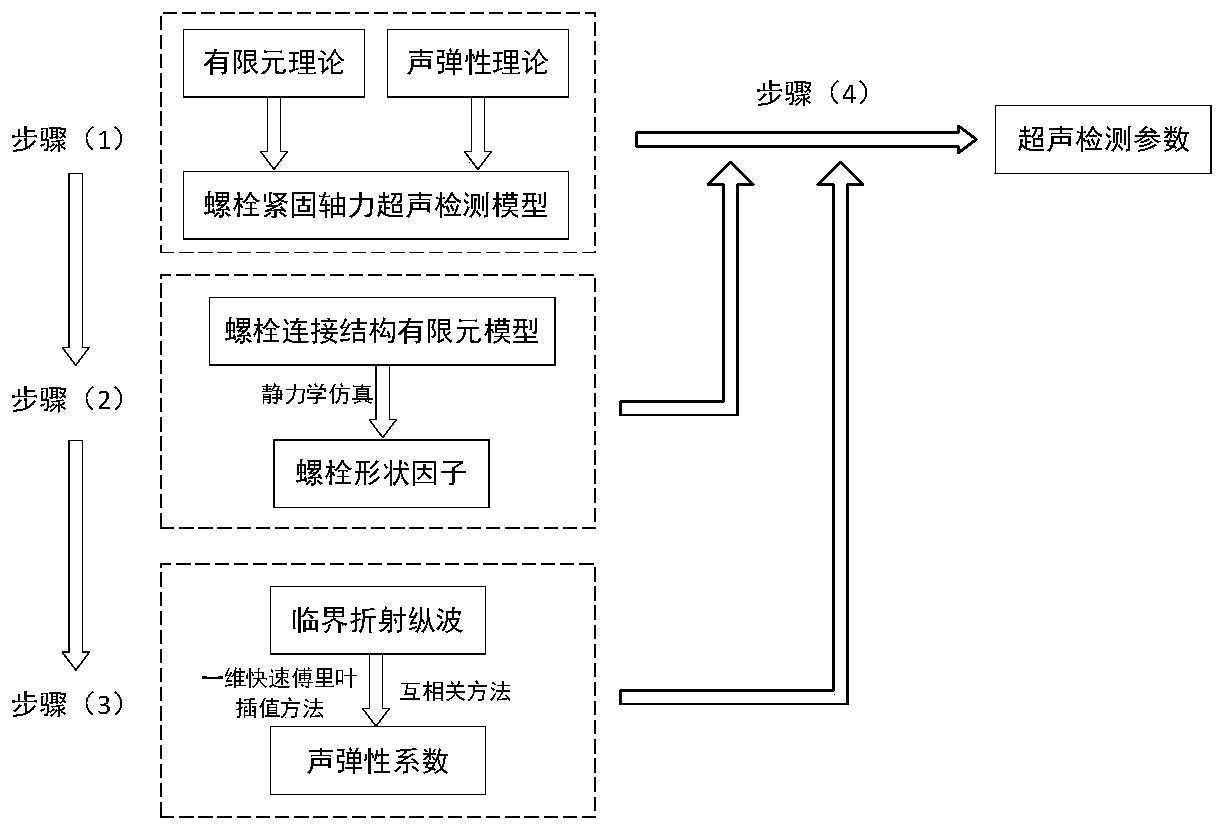

[0075] The invention provides a method for ultrasonic detection of bolt fastening axial force based on a differential method, the method described in the method, such as figure 1 Shown, its implementation steps are as follows:

[0076] Step 1. Establish the principle model of bolt fastening axial force ultrasonic testing

[0077] Based on the finite element theory and acoustic elasticity theory, the mathematical relationship between the bolt fastening axial force and the ultrasonic propagation time difference is established, and the ultrasonic detection principle model of the bolt fastening axial force is established. The specific methods are as follows:

[0078] According to the theory of acoustoelasticity, when an isotropic solid material is subjected to stress in one direction, the sound velocity of ultrasonic longitudinal waves propagating along the stress direction can be deduced as: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com