HVAC fan-powered terminal unit having preset fan CFM

a terminal unit and fan technology, applied in the field of control of fan powered terminal units, can solve the problems of high cost of hvac system setup, inability to easily determine the width of pulses of pwm signal, and terminal units currently using ecm motors must still undergo high-cost air flow balancing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

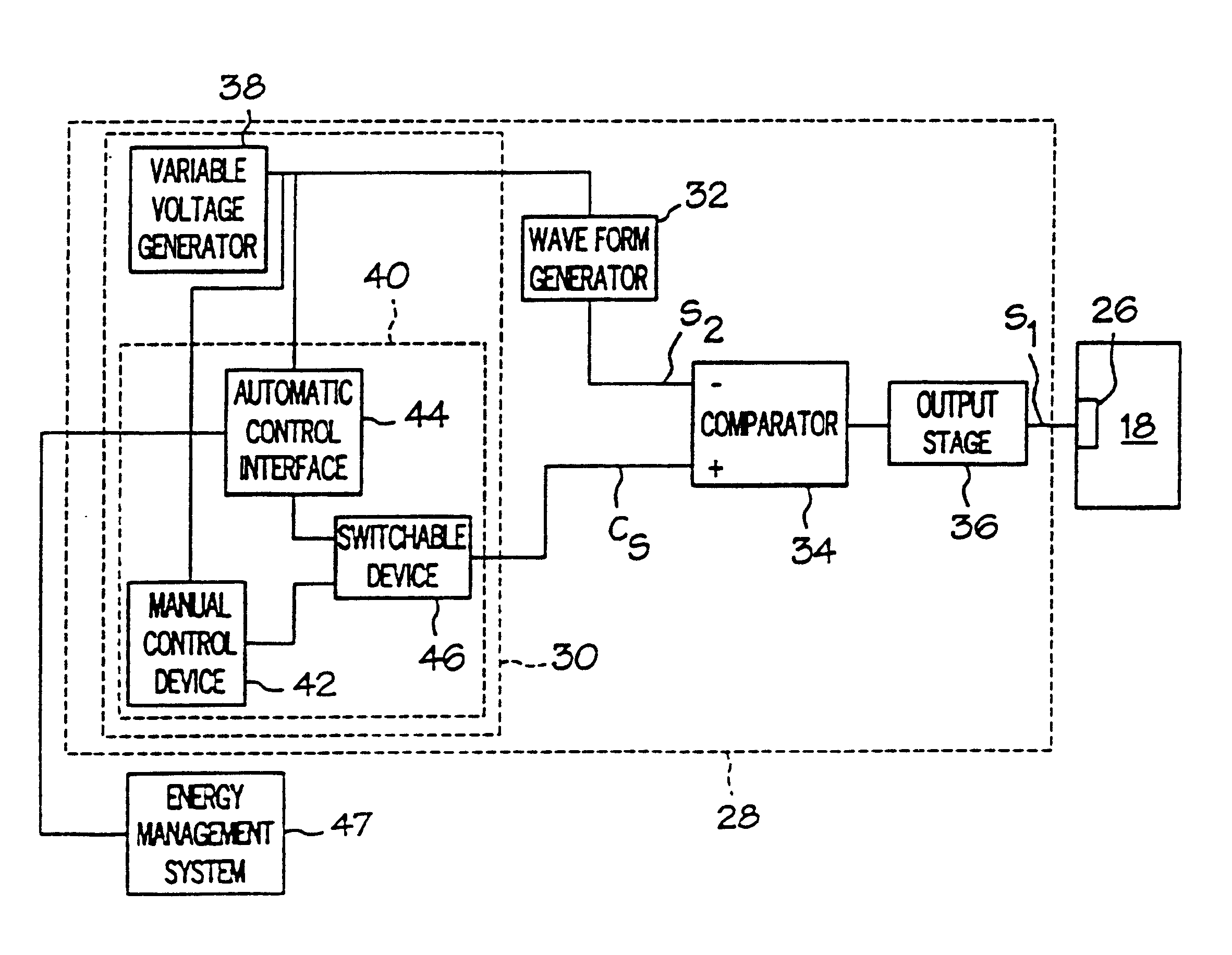

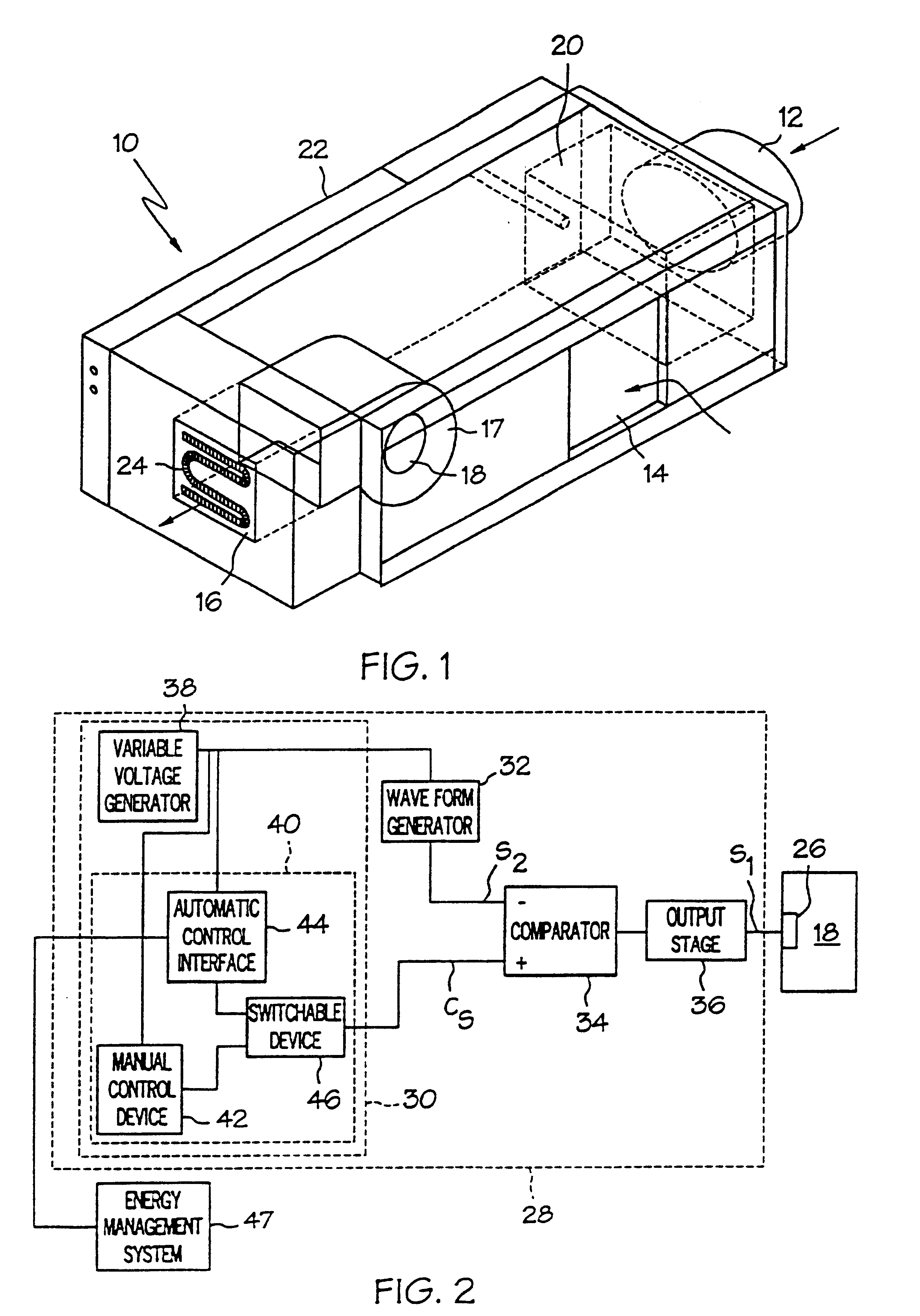

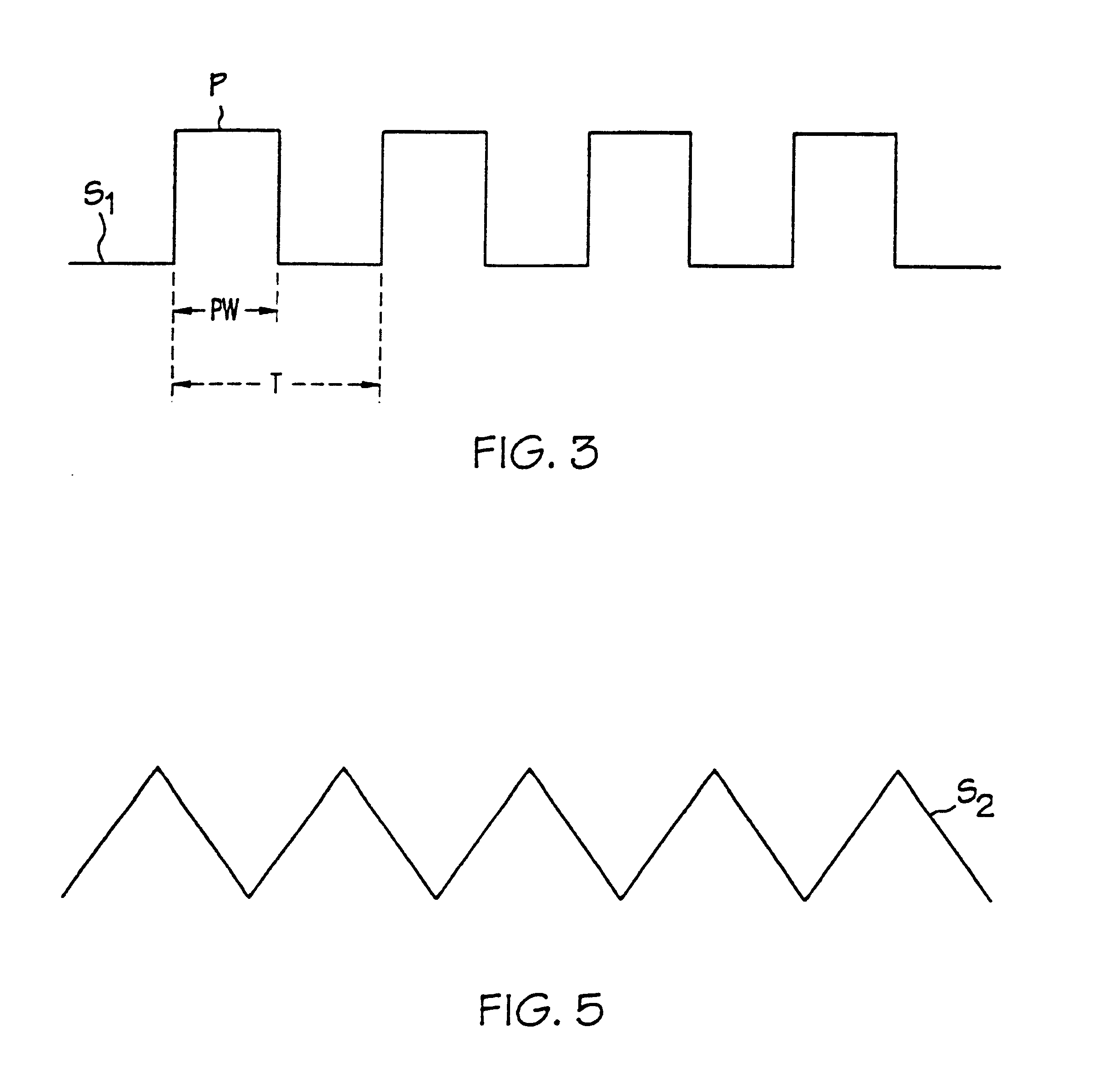

While the present invention is applicable in general to HVAC systems, it will be described herein with reference to a fan-powered terminal unit for use in a commercial building for which it is particularly attractive and in which it is initially being utilized. Referring to FIG. 1, a fan-powered terminal unit 10 is provided having a primary air duct 12, an induced plenum air inlet 14 and a discharge duct 16. The primary air duct 12 receives primary air from the ventilation system (not shown) while the induced plenum air inlet 14 receives warmer plenum air from the building core plenum space (not shown). The warmer plenum air is generated by the free heat derived from people, lighting and other equipment in the building. The primary air duct 12 and the induced plenum air inlet 14 are arranged in series for delivering a desired air flow or cfm to a perimeter zone of a building (not shown) through the discharge duct 16. This type of fan-powered terminal unit 10 is also known as a serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com