Method for detecting corrosion condition inside lithium ion battery with flexible package

A lithium-ion battery and internal corrosion technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as battery leakage, safety hazards, accelerated electrochemical corrosion, etc., to reduce production costs and improve production Effects on efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

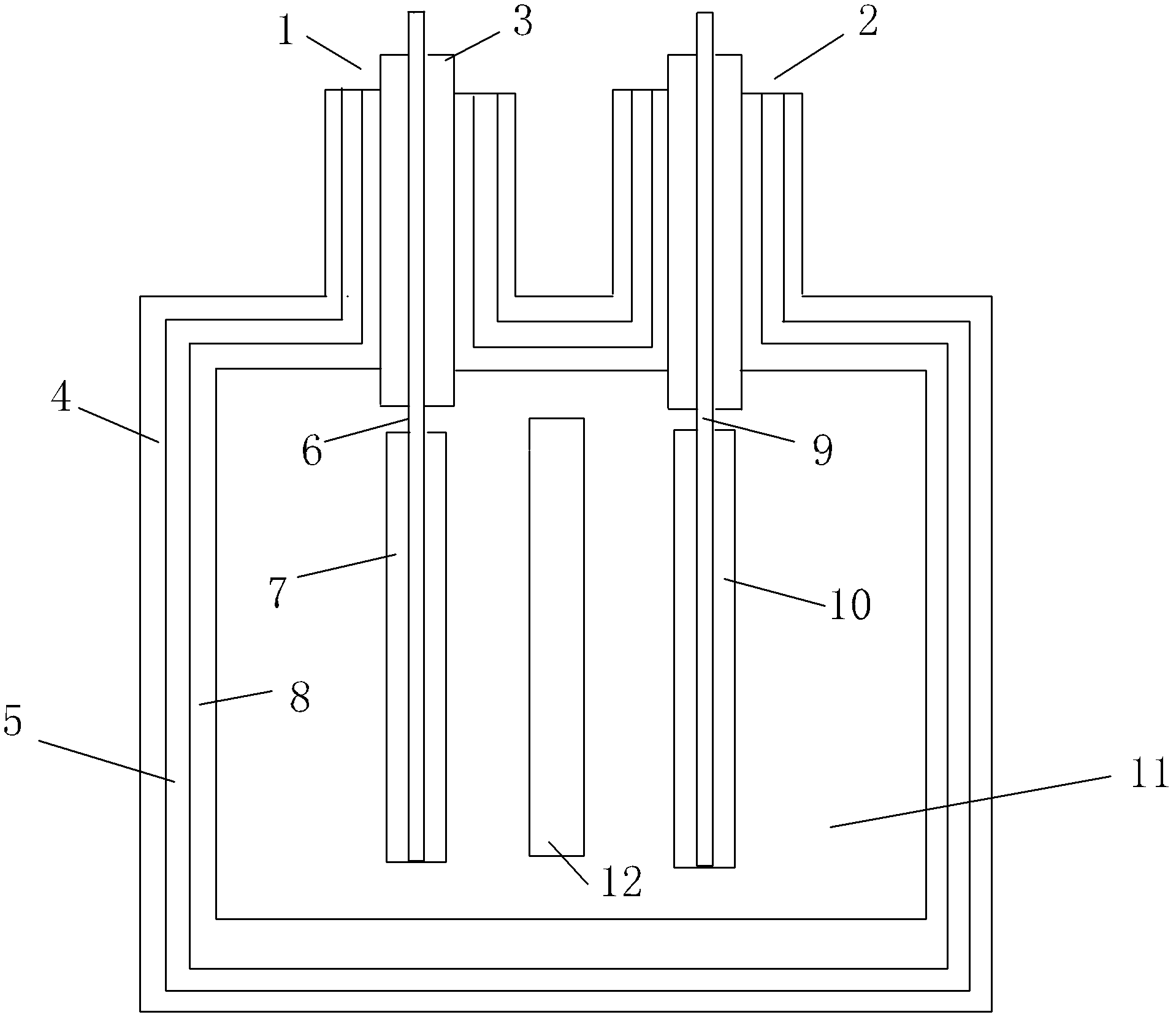

[0016] as attached figure 1 As shown, 1 is the positive electrode of the battery, 2 is the negative electrode of the battery, 3 is the ear glue of the battery, 4 is the nylon layer, 5 is the aluminum layer, 6 is the aluminum foil, 7 is the positive electrode material layer, 8 is the cpp film, and 9 is copper Foil, 10 is a graphite layer, 11 is an electrolyte, and 12 is a diaphragm, which together form the flexible lithium-ion battery.

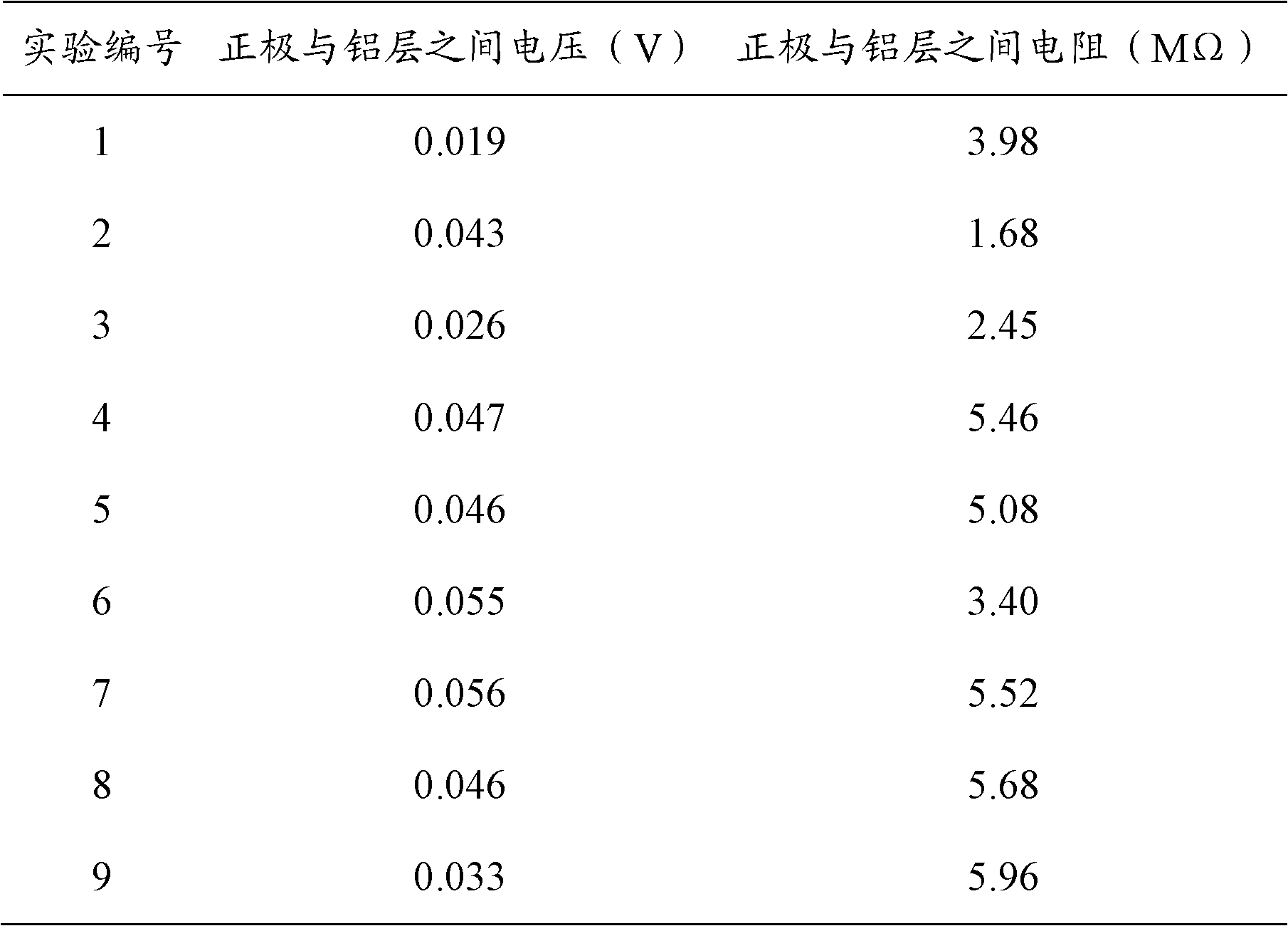

[0017] The principle of judging whether the internal corrosion of the soft-packed lithium-ion battery according to the voltage is that, according to the metal aluminum has a certain ability to intercalate lithium, when the aluminum layer contacts the electrolyte, lithium ions will deintercalate from the negative electrode of the battery into the aluminum, forming an intercalation. For lithium composite materials, its potential is close to that of metal lithium, that is, relative to the positive electrode of the battery, the potential of the alu...

Embodiment 2

[0029] The method for detecting internal corrosion of a soft-packaged lithium-ion battery comprises the steps of preparing a soft-packaged lithium-ion battery and a multimeter, using the multimeter to measure the resistance R between the positive ear of the soft-packaged lithium-ion battery and the aluminum layer of the aluminum-plastic film, and comparing the size of R , if R<100Ω, the lithium-ion battery must undergo internal corrosion, and this method has no requirements for the battery state of charge and storage time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com