Residual heat reclaiming apparatus for boiler vent gas

A waste heat recovery device and tail gas technology, applied in steam separation devices, indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of low heat recovery and utilization rate of flue gas and tail gas, and achieve small flow resistance, compact equipment structure, The effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

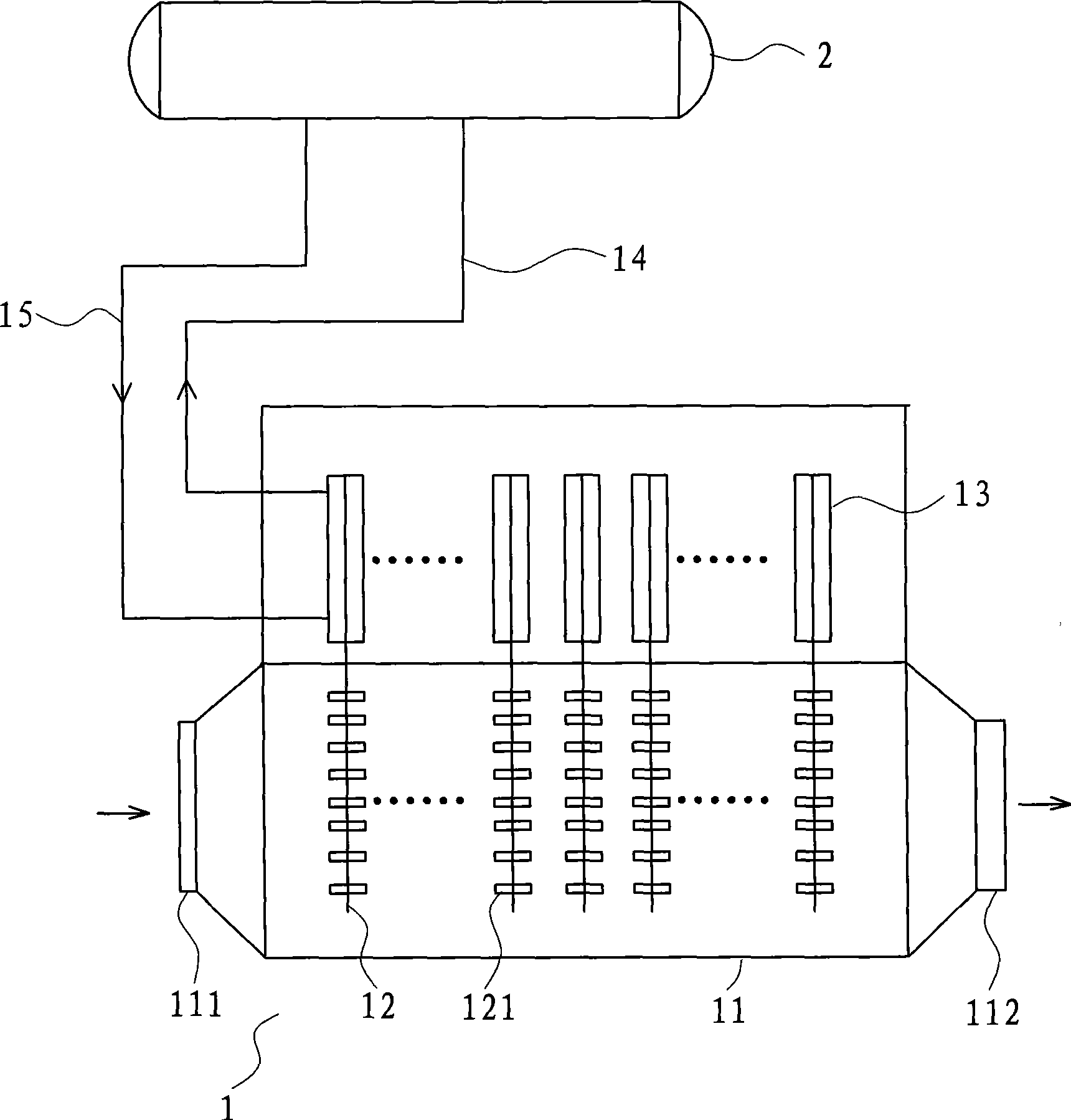

[0008] The boiler tail gas waste heat recovery device uses the evaporation and condensation of the working fluid to transfer heat, pumps the inner side of the heat pipe to a higher degree of vacuum and fills it with an appropriate amount of working fluid such as liquid metal, so that the capillary porous material of the liquid-absorbing core close to the inner wall of the heat pipe Sealed after being filled with liquid. The whole device consists of two parts: heat pipe steam generator and steam-water separation device (steam drum).

[0009] Among them, the high-temperature heat pipe uses liquid metal (sodium, potassium, etc.) as the working medium. Because liquid metal has good thermal stability and very low saturated vapor pressure, such as sodium at 800 ° C, the saturated vapor pressure is only 0.047MPa; so Under high temperature conditions, the liquid metal high temperature heat pipe hardly withstands internal pressure and can work safely under high temperature conditions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com