Shell-and-tube heat exchanger with combined type one-shell-pass continuous spiral baffles

A shell-and-tube heat exchanger and helical baffle technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. Reduce heat transfer efficiency and other issues to achieve the effect of improving overall heat transfer performance, improving surface heat transfer coefficient, and increasing fluid mass flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

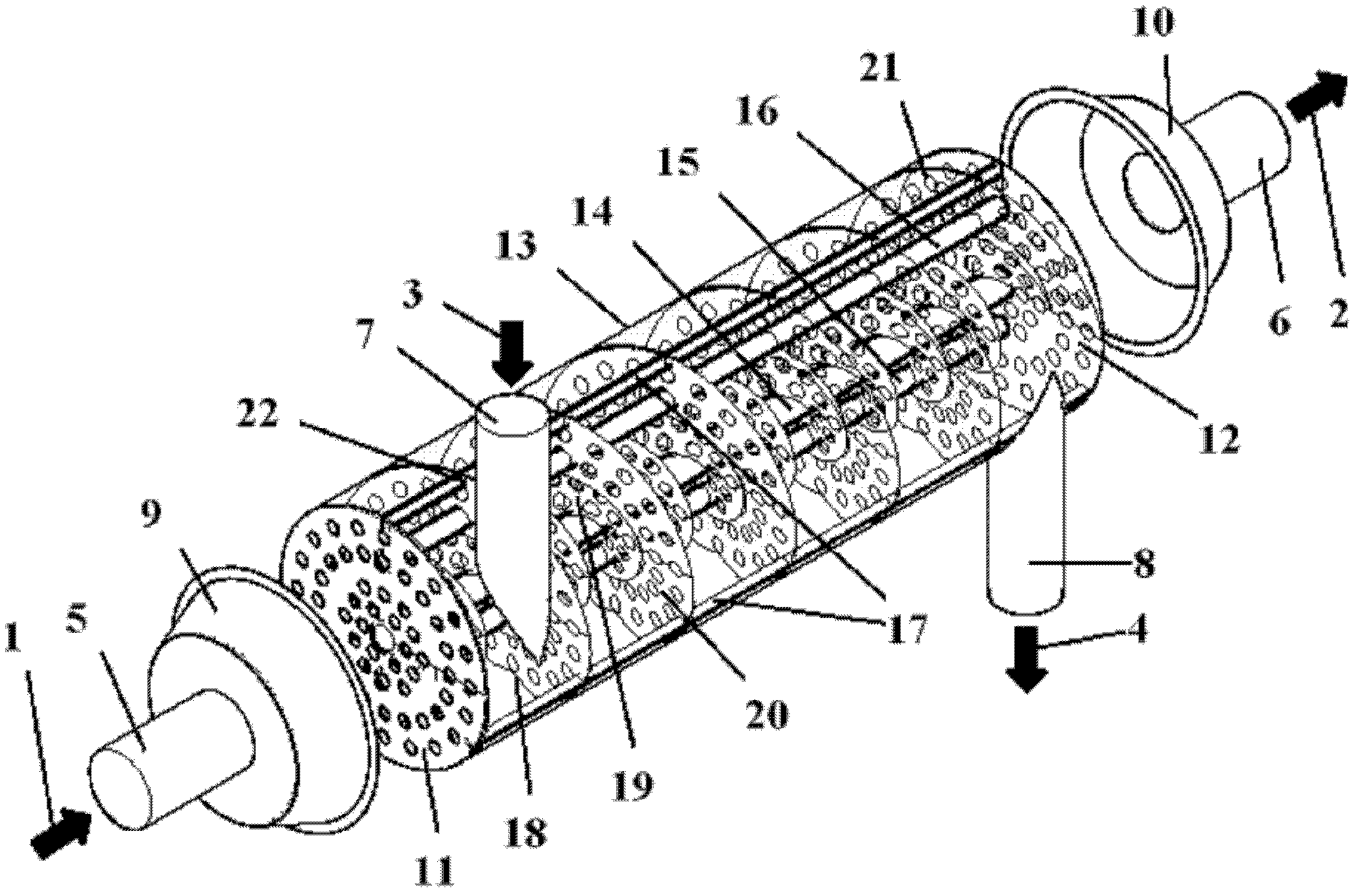

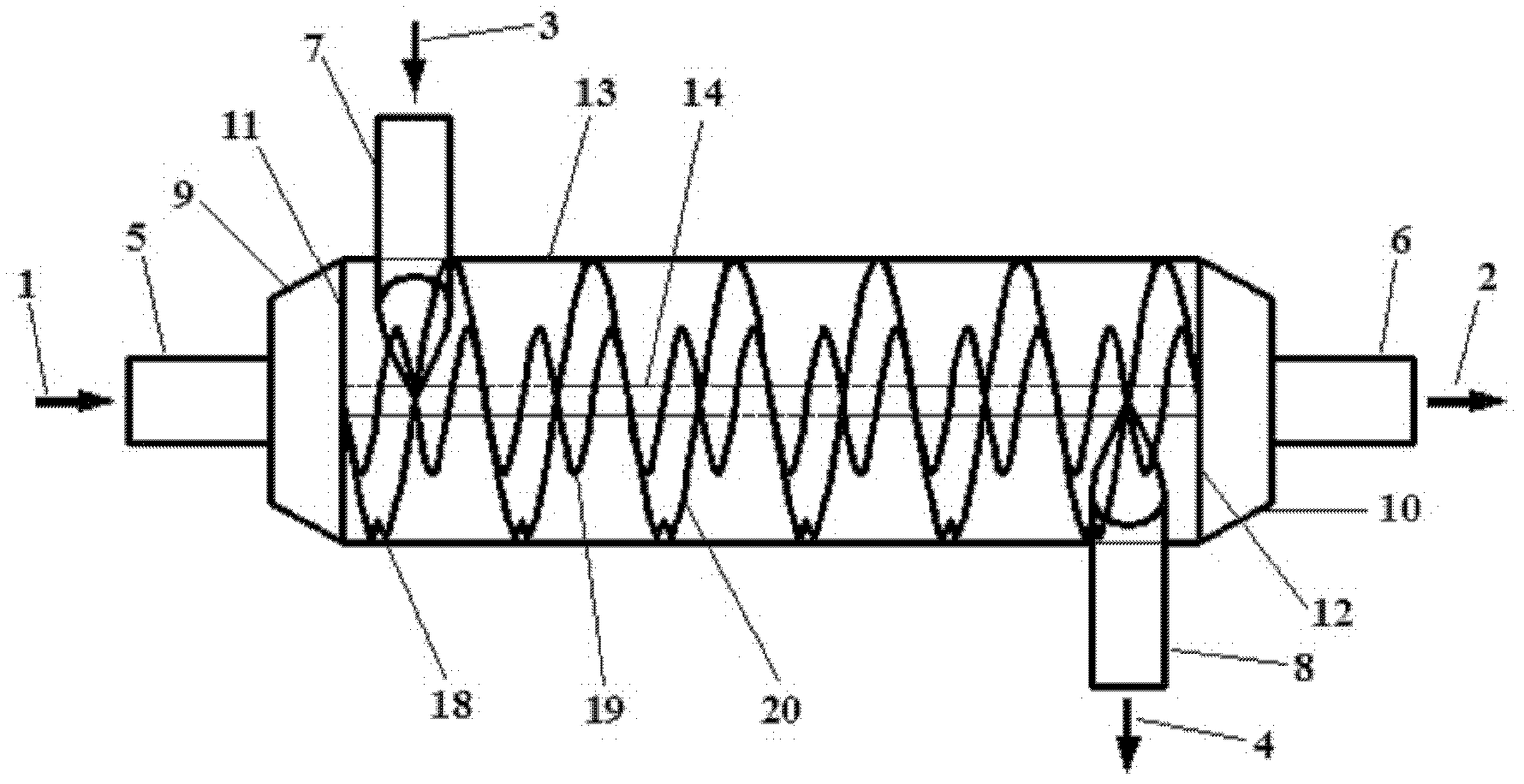

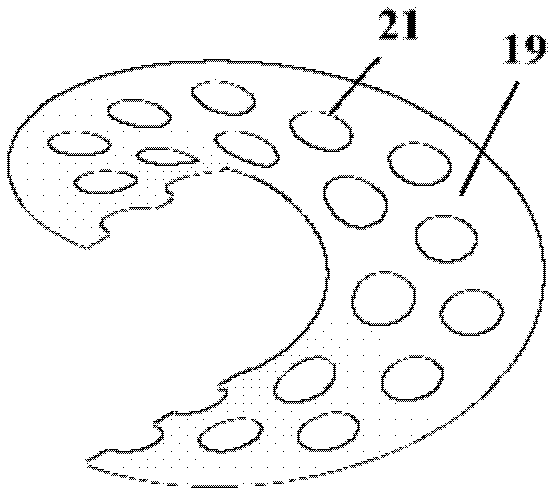

[0049] Referring to Fig. 1 (a, b), a combined single-shell pass continuous spiral baffle shell-and-tube heat exchanger includes: a shell 13, a central tube 14 located in the center of the shell 13, and a central tube 14 located in the shell The tube sheet 11 and the tube sheet 12 at both ends of the body 13, the tube sheet 11 is connected to the first head 9, and the tube sheet 12 is connected to the second head 10, wherein the first head is provided with a tube-side inlet pipe 5, and the second head A pipe-side outlet pipe 6 is provided on it. Between the two tube sheets 11 and 12, there are heat exchange tube bundles 15 (there are many, and only a representative one is shown in Fig. , 20), fixed distance belt 17 (mainly plays the role of fixing outer spiral baffle 20 and reducing side flow) and spiral baffle, and the spiral baffle is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com