An h-type finned tube economizer based on longitudinal vortex

A technology of finned tube and economizer, applied in the field of H-type finned tube economizer, can solve the problems of ineffectiveness, exceeding the reaction temperature of out-of-stock catalyst, and high smoke temperature, so as to reduce ash accumulation, achieve remarkable energy-saving effect, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

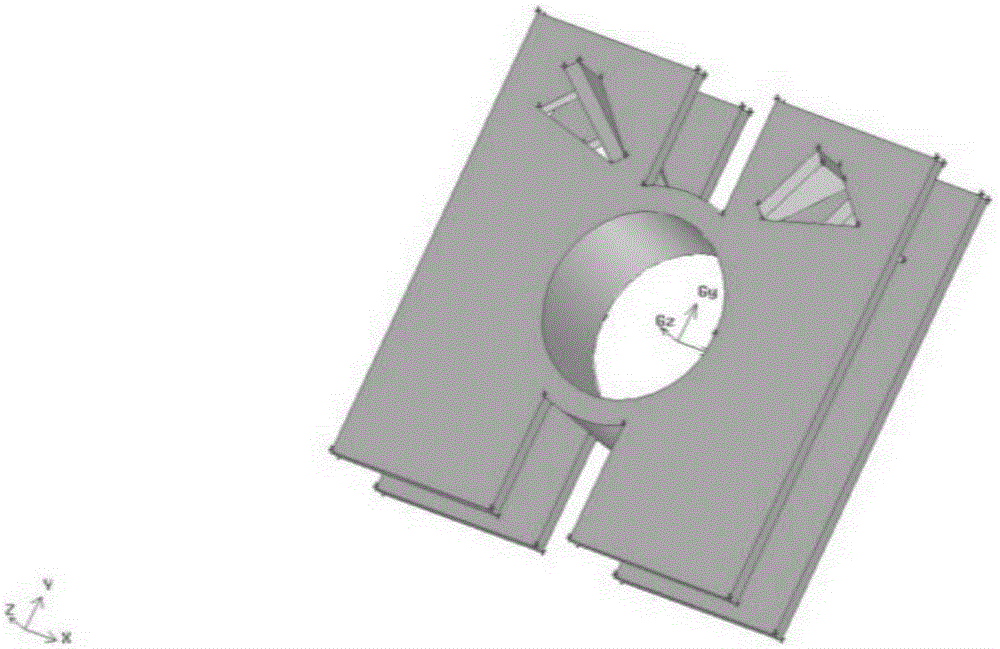

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: At least two of the fins are respectively distributed in the upper left corner and the upper right corner of the H-shaped fin.

Embodiment 2

[0034] Embodiment 2: At least two of the fins are respectively distributed in the upper left corner and the lower right corner of the H-shaped fin.

Embodiment 3

[0035] Embodiment 3: At least two of the fins are respectively distributed in the lower left corner and the upper right corner of the H-shaped fin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com