Low-position heat energy spray evaporation-multiple-effect distillation seawater desalination method and device

A technology of spray evaporation and multi-effect distillation, which is applied in chemical instruments and methods, seawater treatment, heating water/sewage treatment, etc., can solve the problems of popularization restrictions, achieve wide application prospects, increase fresh water production, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

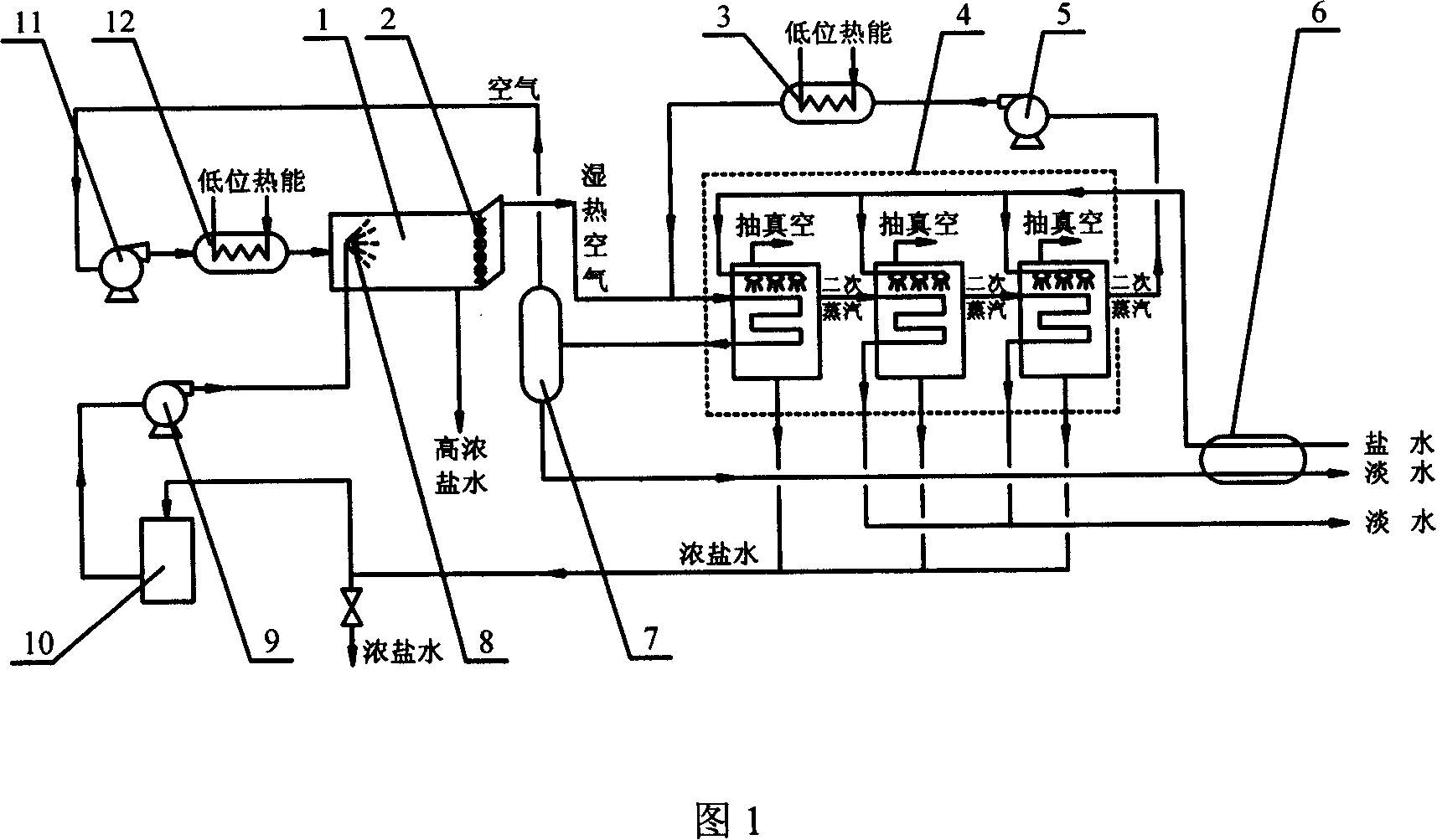

[0039] a) The air is transported by the fan 11 to the heater 12, and enters the spray evaporation chamber 1 after being heated to 100°C; at the same time, the concentrated brine in the brine storage tank 10 is transported to the nozzle 8 by the pump 9, and then sprayed in the spray evaporation chamber in the form of mist In the inner cavity of chamber 1, it is in contact with the hot air flow and vaporized;

[0040] b) The water vapor obtained from the vaporization of salt water droplets is mixed with air, and the hot and humid air formed passes through the demister 2 and then discharged out of the spray evaporation chamber 1; the remaining salt water droplets after vaporization are concentrated at the bottom of the spray evaporation chamber 1 and condensed into high-concentration salt water , and discharged from the outlet at the bottom of the spray evaporation chamber 1; the high-concentration brine is used for salt production and the extraction of chemical elements such as p...

Embodiment 2

[0051] Device and working process are identical with embodiment 1, and difference is that the air flow that fan 11 produces is 139kg 干空气 / h, the heating temperature of the air in the heater 12 is 95°C, the temperature of the normal pressure hot and humid air produced by the spray evaporation chamber 1 is 70°C, and the water content is 0.27kg 水 / kg 干空气 , the fresh water output provided by the condensation of hot and humid air is 32.4kg / h. In this embodiment, the feed seawater flow rate of the multi-effect distillation device 4 is 221.1 kg / h, the fresh water output is 100.5 kg / h, and the salt content of the fresh water is 4.6 mg / L. The spray evaporation-multi-effect distillation process described in this embodiment increases the fresh water production by 32.24% on the basis of the common multiple-effect distillation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com