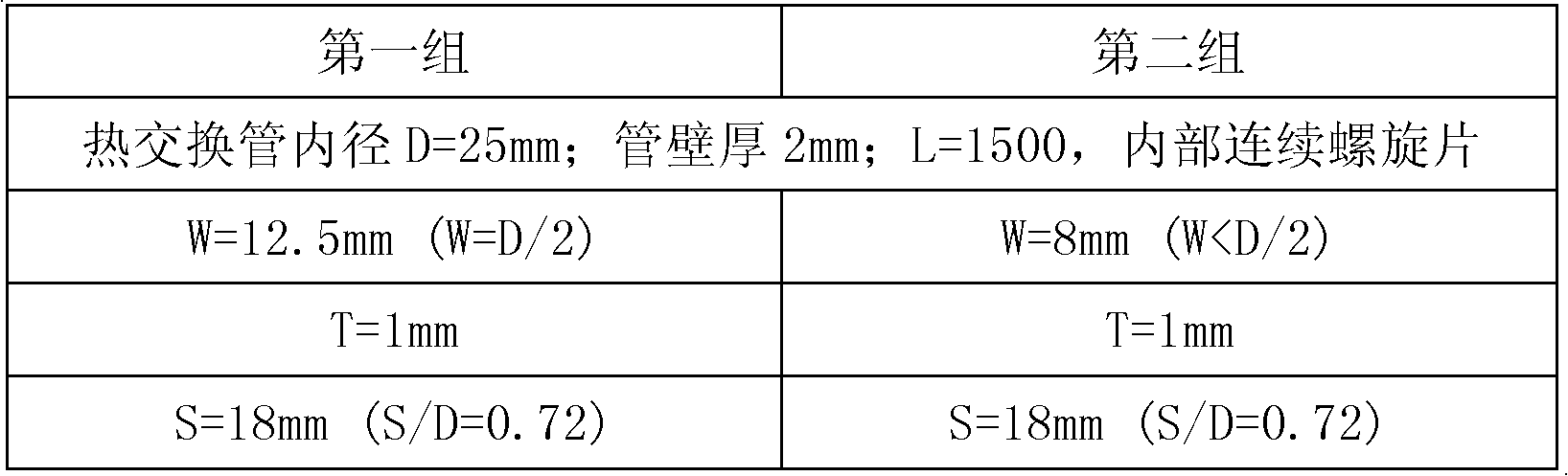

Heat exchange tube internally provided with spiral fins and application thereof

A heat exchange tube and spiral fin technology is applied in the field of energy and chemical industry, which can solve the problems of difficulty in processing and casting, low heat transfer efficiency, and tube wall scouring, and achieve the effects of reducing production capacity consumption, improving heat transfer efficiency, and reducing scouring wear.

Inactive Publication Date: 2011-06-15

EAST CHINA UNIV OF SCI & TECH

View PDF6 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the existing problems in the past, the purpose of the present invention is to provide a heat exchange tube with built-in spiral fins to overcome the low heat transfer efficiency of the traditional ethylene cracking furnace tube, easy coking, serious erosion of the tube wall by high-speed fluid, difficulty in processing and casting, etc. Defects, one or more spiral fins are manufactured inside the heat exchange tube to enhance heat transfer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

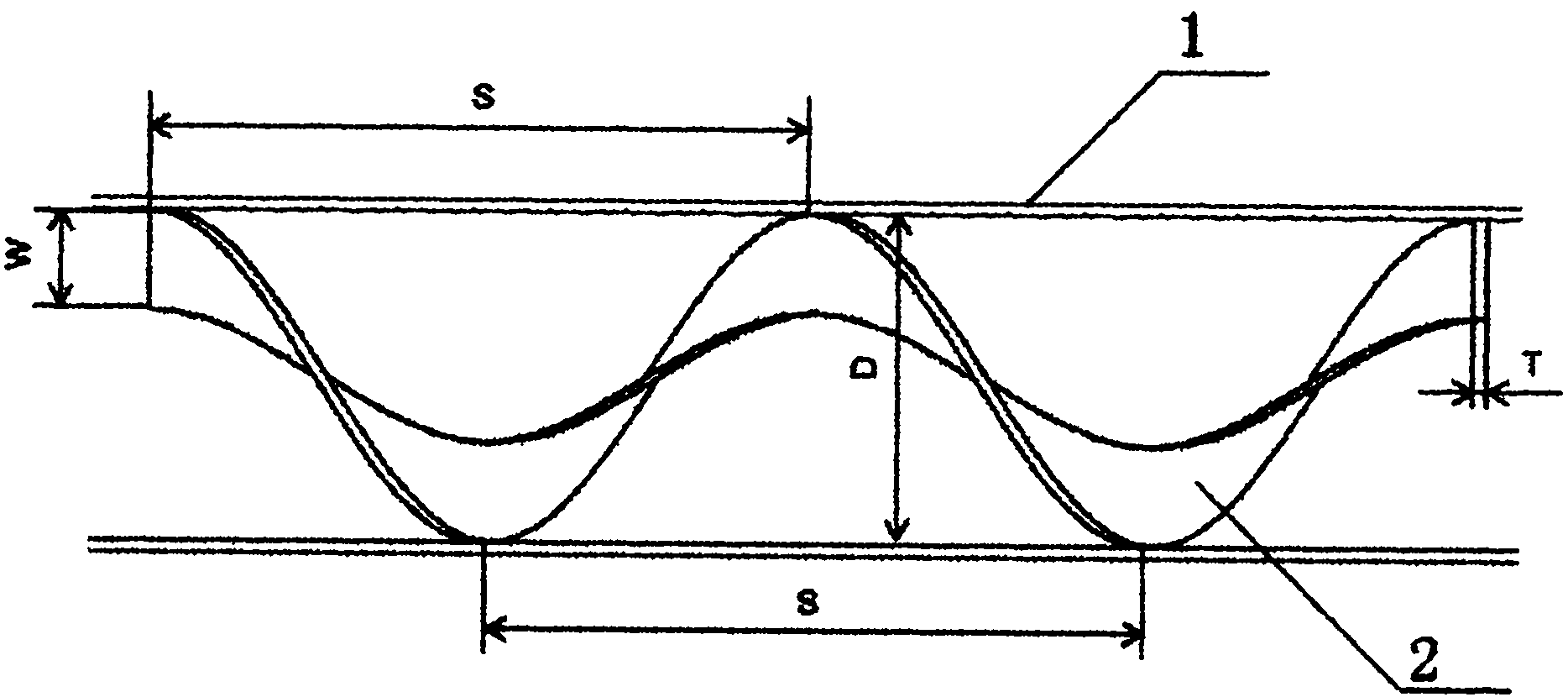

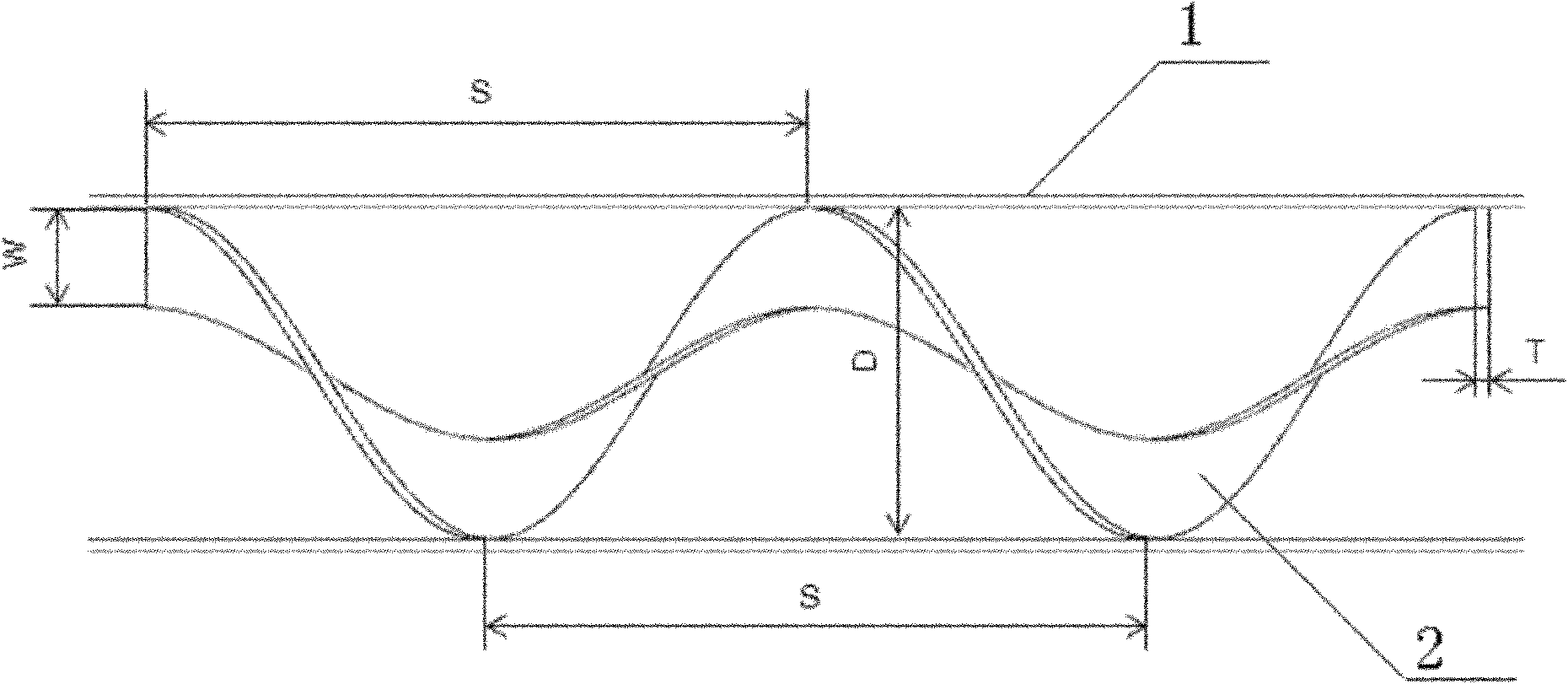

The invention relates to a heat exchange tube internally provided with spiral fins and application thereof. The heat exchange tube internally provided with the spiral fins comprises a heat exchange tube (1) and is characterized in that the heat exchange tube (1) is internally provided with the spiral fins (2) which are spiral; and the spiral fins (2) are distributed in the form of one or more sections along the axial direction at the inner side in the heat exchange tube (1). Meanwhile, the heat exchange tube internally provided with the spiral fins can be arranged in a radiation section furnace tube of an ethylene cracking furnace and can also be arranged in other heat exchangers, such as a shell-and-tube heat exchanger. The heat exchange tube achieves the purposes of increasing the heat transfer efficiency, strengthening the heat transfer effect, reducing coking, reducing the capacity consumption and increasing the life cycle of the equipment. Meanwhile, the spiral design also reduces the washing and abrading phenomena of high-speed fluid in the heat exchange tube to the interior of the tube body, thereby the heat transfer effect is further strengthened.

Description

A heat exchange tube with built-in spiral fins and its application technical field The invention relates to a heat exchange tube and its application. More specifically, the invention relates to a heat exchange tube with built-in spiral fins and its application in an enhanced heat transfer furnace tube of an ethylene cracking furnace, which belongs to the field of energy and chemical industry. Background technique Ethylene cracking furnace is an important equipment in petrochemical industry, mainly used for heating cracking raw materials to realize cracking reaction. The cracking reaction of high temperature, short residence time and low hydrocarbon partial pressure is the key to improving the cracking selectivity and cracking depth, and then improving the yield of key chemical products such as ethylene and propylene. Therefore, the cracking reaction process requires a lot of heat, making cracking Furnace is a major energy consumer of ethylene plant, and its energy consumpt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F28F13/06F28F13/02C10G9/20

Inventor 倪志宇王学生黄志荣蒋晓东李培宁代晶晶

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com