High plus emergency drainage and decompression escape steam system

An emergency dredging and steam escape technology, applied in the field of high-pressure heater emergency drainage system, can solve problems such as damage and scouring, and achieve the effect of reducing the degree of scouring and wear, prolonging the service life and improving the tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments should not be construed as limitations of the present invention, but only as examples, while the advantages of the present invention will become clearer and easier to understand.

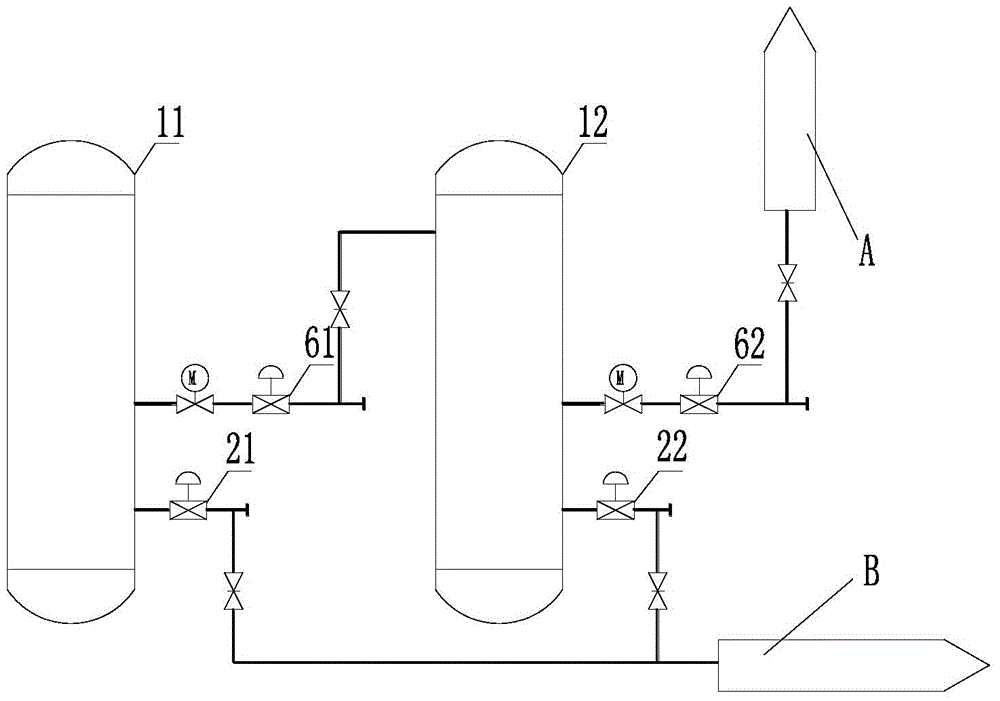

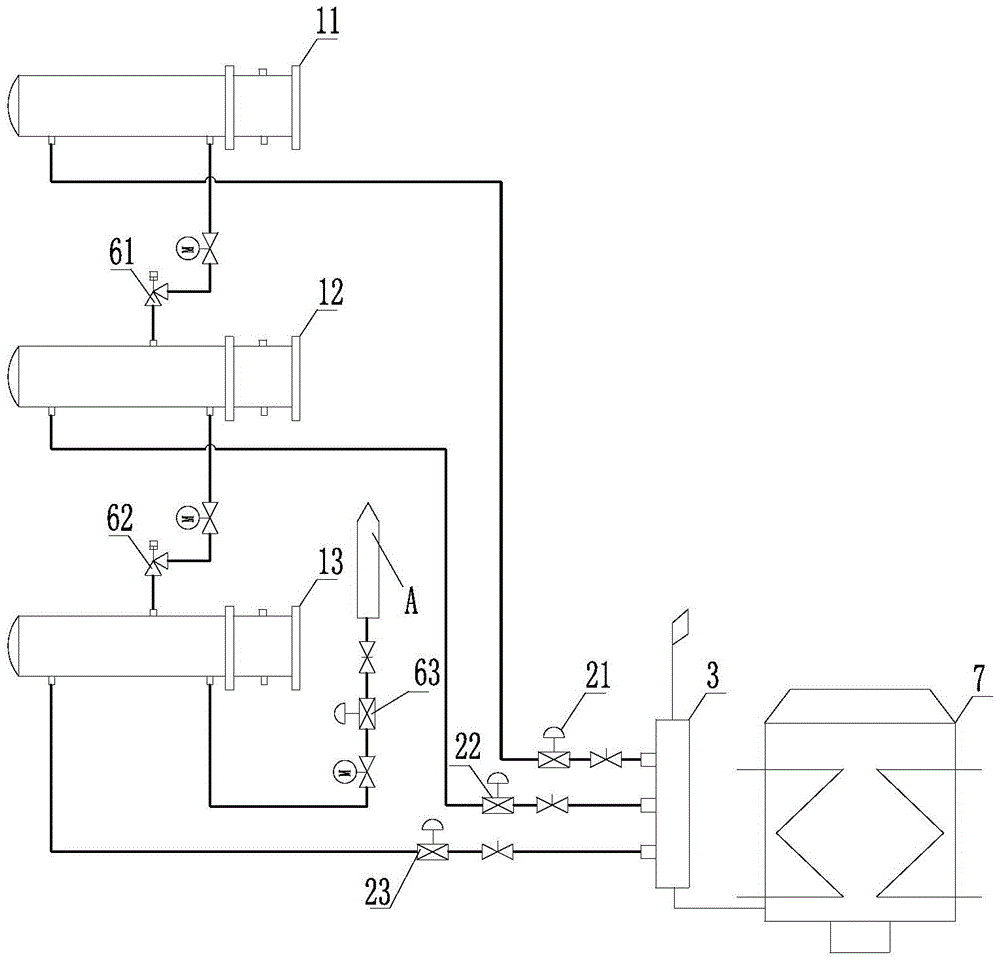

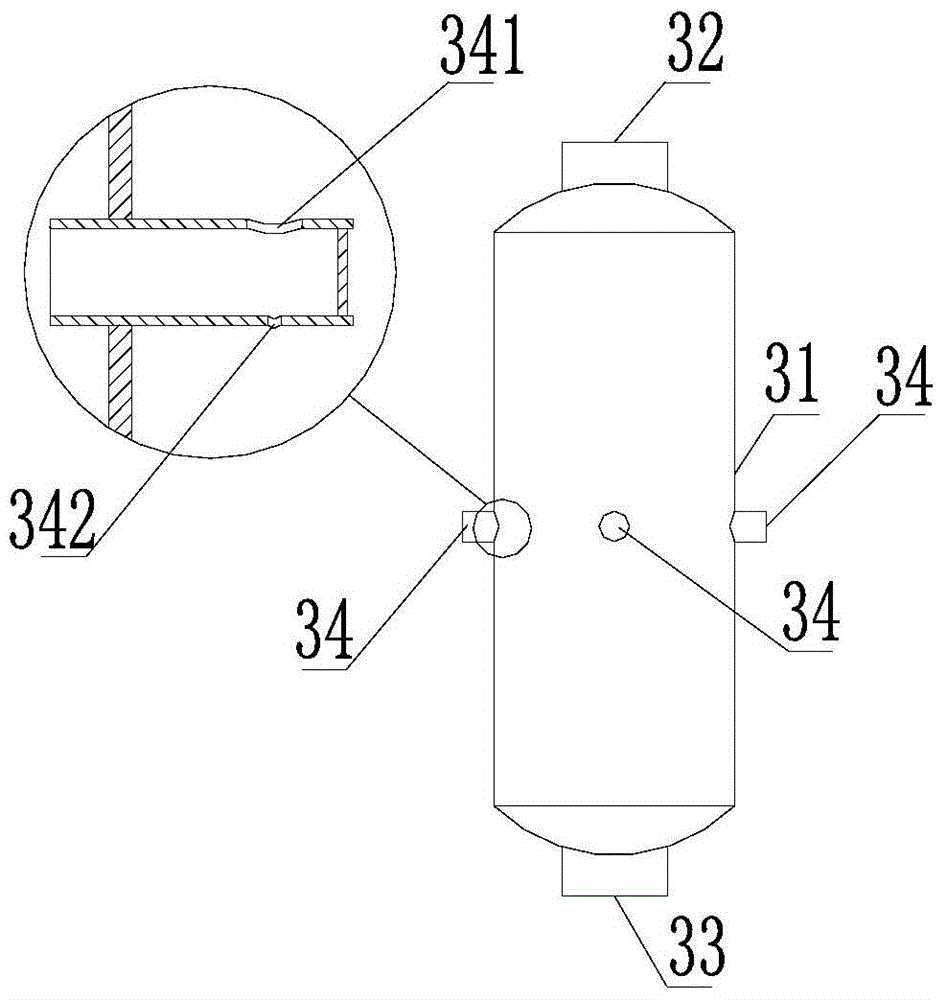

[0026] As shown in the drawings, the high pressure emergency drain pressure reduction steam escape system includes three high pressure heaters, wherein the first high pressure heater 11 is connected to the input end of the second high pressure heater 12 through the first high pressure normal steam trap 61 Connection; the second high-pressure heater 12 is connected to the input end of the third high-pressure heater 13 through the second high-pressure normal steam trap 62; the third high-pressure heater 13 is connected to the normal steam trap through the third high-pressure normal steam trap 63 Road A, connected to deaerator 4 through normal drain li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com