Drainage water quality energy recovery system for thermal equipment and pipelines of thermal power plant

A technology for thermal power plants and thermal equipment, applied in the field of drainage water quality energy recovery system, can solve the problems of thermal drainage energy waste, large pressure difference before and after the trap, and increased heat load of the condenser, etc., so as to prolong the service life, Reduce the degree of scouring wear and reduce the effect of heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

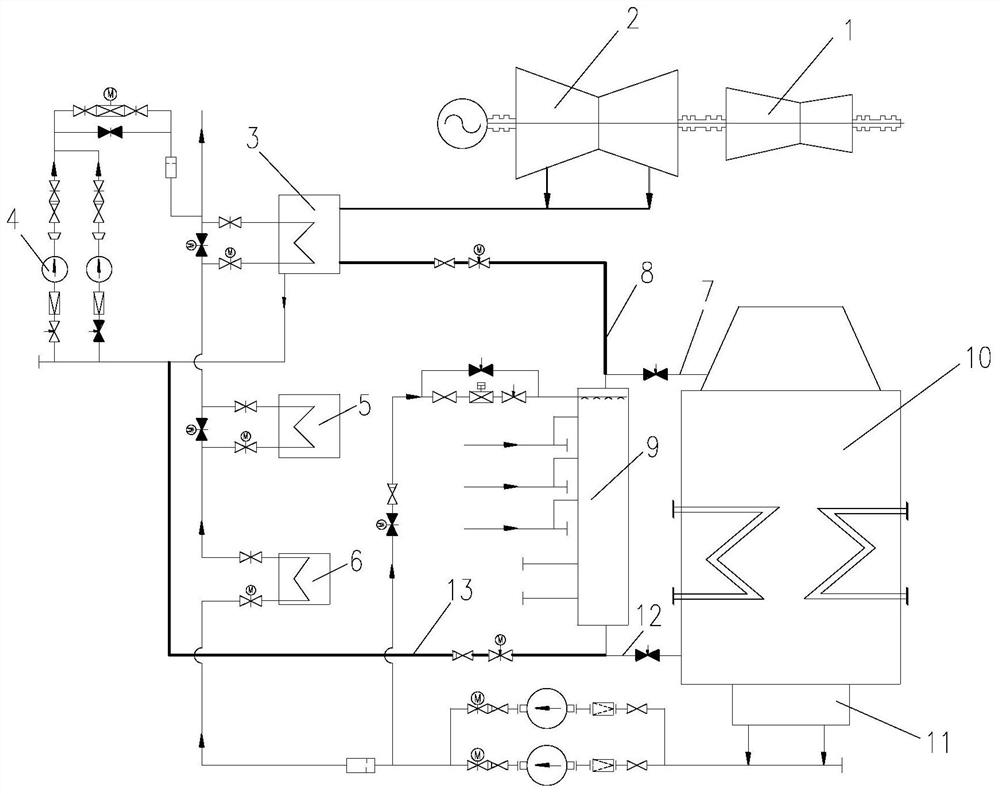

[0017] refer to figure 1 , the present embodiment includes a low pressure drainage pump heat recovery system and a heat engine drainage system. The low pressure steam extraction heat recovery system is connected to the heat engine drainage system. There are drain pump 4, next-end low-pressure heater 3, last-stage low-pressure heater 5 and shaft seal heater 6, drain pump 4 and second-last low-pressure heater 3 are connected in series to form a drain pump branch circuit, and the last-stage low-pressure heater 3. The final low-pressure heater 5 and the shaft seal heater 6 are connected in series to form a heater branch circuit. The heat engine drainage system includes a hydrophobic expansion vessel 9 and a condenser 10. The steam space of the hydrophobic expansion vessel 9 passes through the first exhaust pipe 7 and the condenser. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com