Pipe shell type heat-exchanger

A shell-and-tube heat exchanger, heat exchange tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc. The effect of low management cost, simple structure and good structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

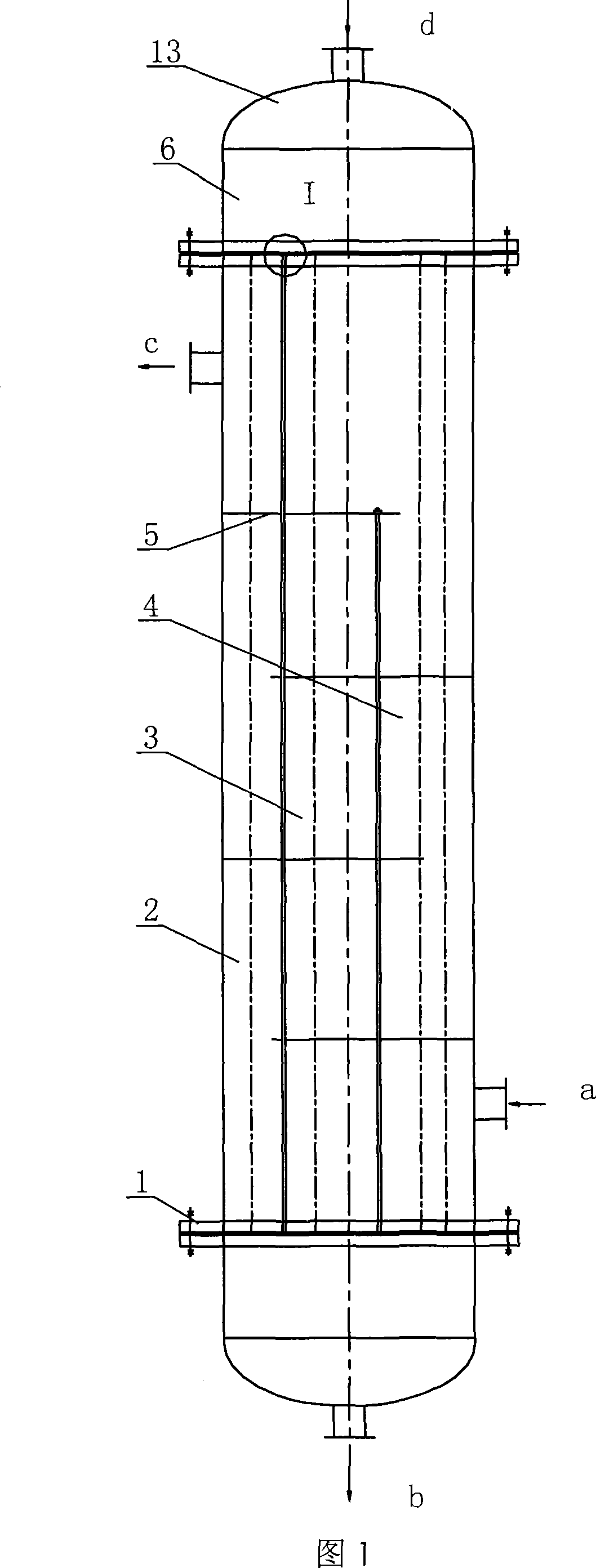

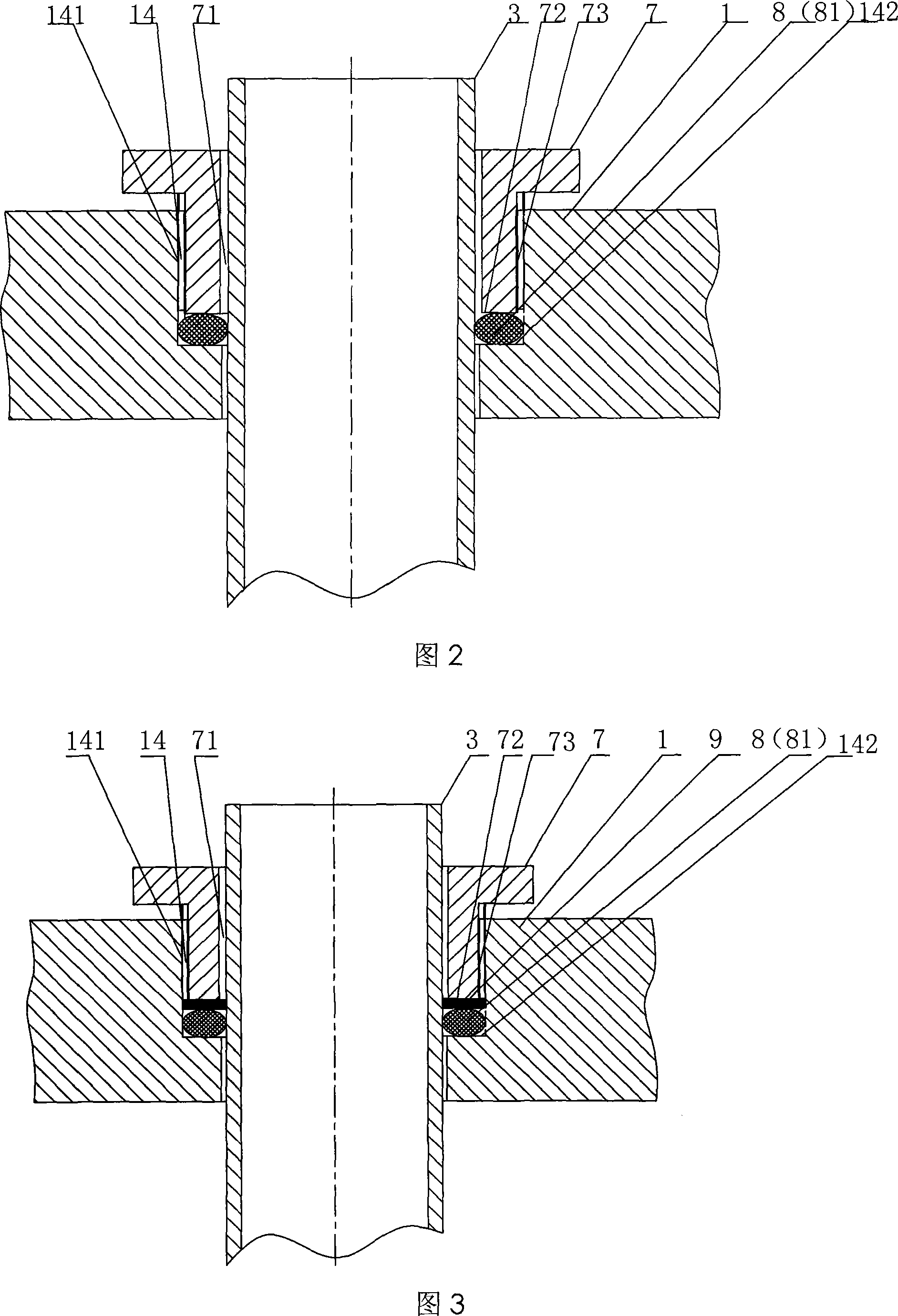

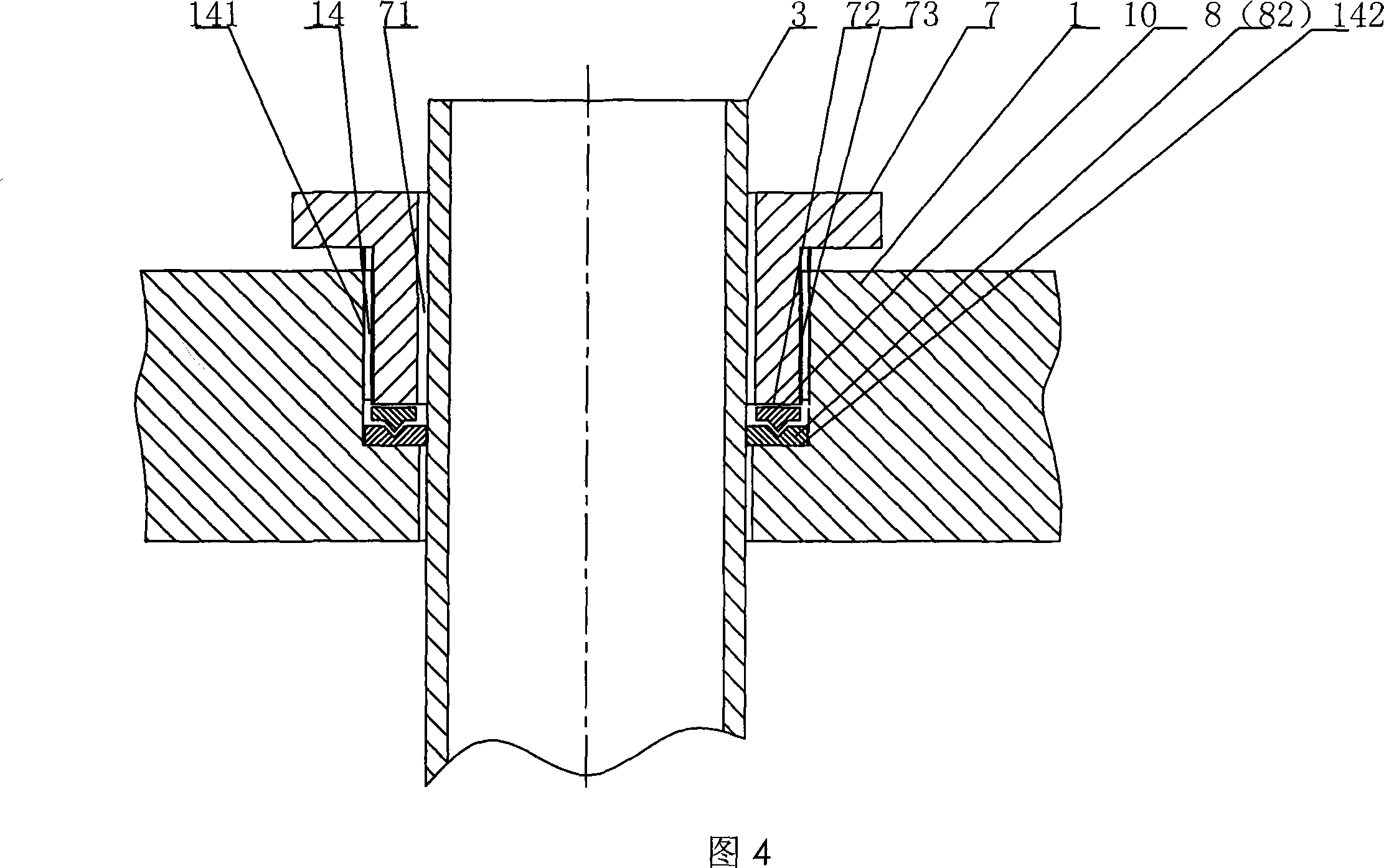

[0017] A shell-and-tube heat exchanger designed by the present invention (hereinafter referred to as heat exchanger, see Fig. 1-4) is a shell-and-tube heat exchanger widely used in industrial production at present, mainly composed of tube plate 1, shell 2 and The inlet a and outlet c of one material on it (see Figure 1), the two symmetrical heads 13 and the inlet d and outlet b of another material on the two heads 13 respectively (see Figure 1) , heat exchange tubes 3, pull rods 4, baffles 5 and two symmetrical tube boxes 6 and other components are assembled according to conventional quantities and methods, and are characterized in that a stepped circular hole 14 is opened in the center of the tube plate 1 , the large diameter of the stepped circular hole 14 has an internal thread 141, and the small diameter matches the diameter of the heat exchange tube 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com