A method and system for loading, unloading and cutting a longitudinal metal plate

A cutting system and cutting method technology, applied in metal processing, metal processing equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex control design of handling and stacking units, tight and cramped factory layout, etc., to ensure the quality of processing and installation , convenient working method and compact system layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

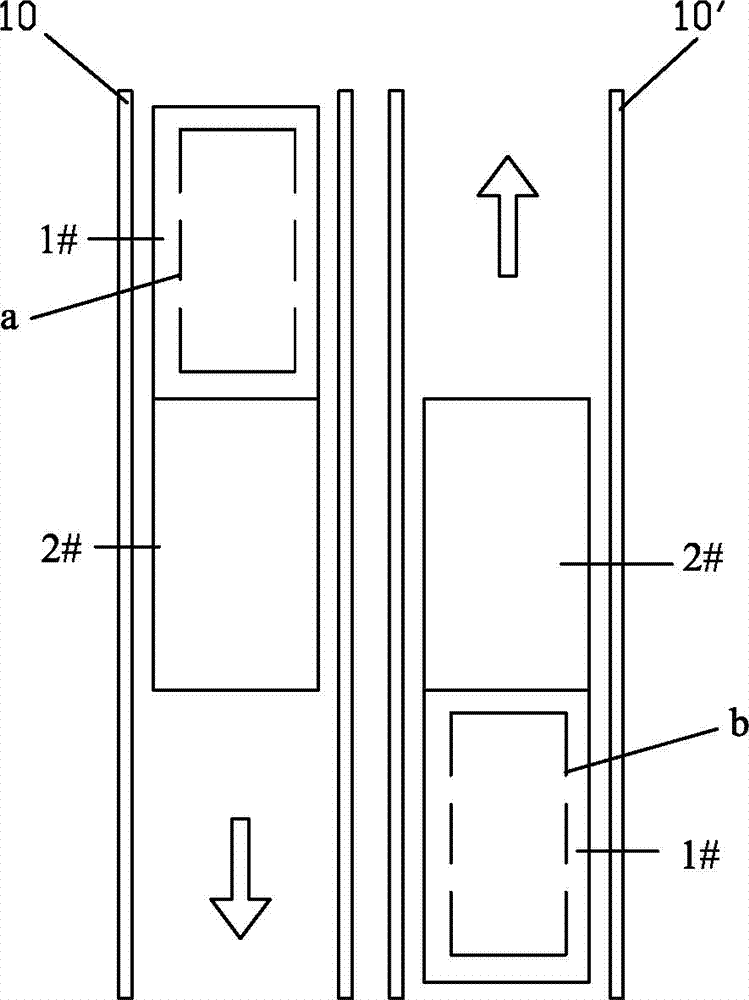

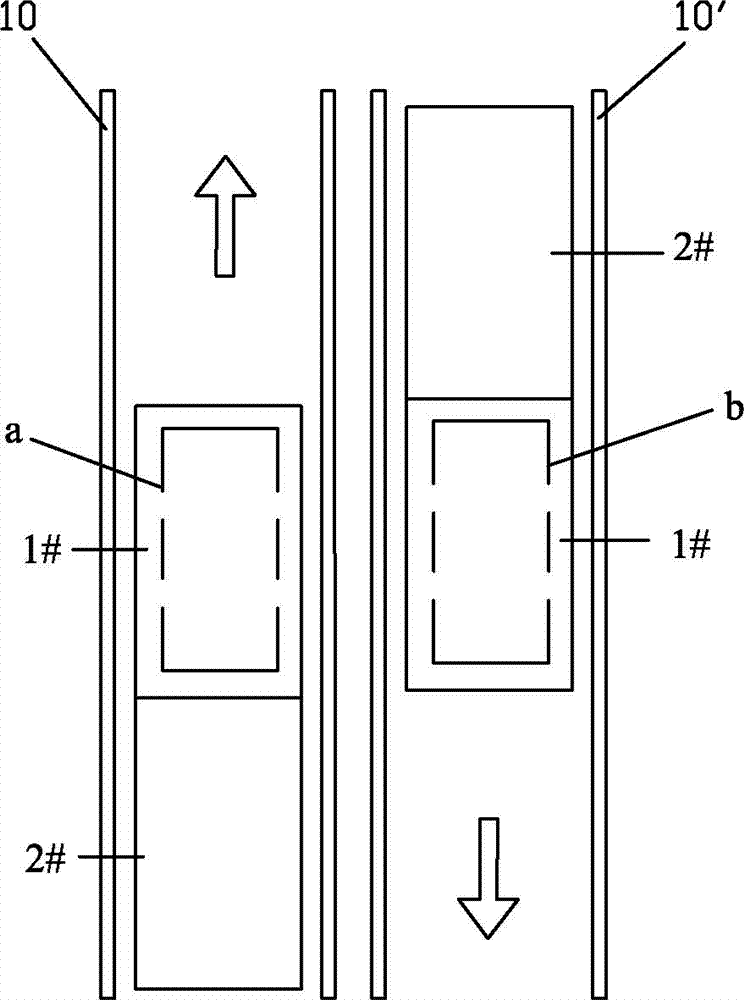

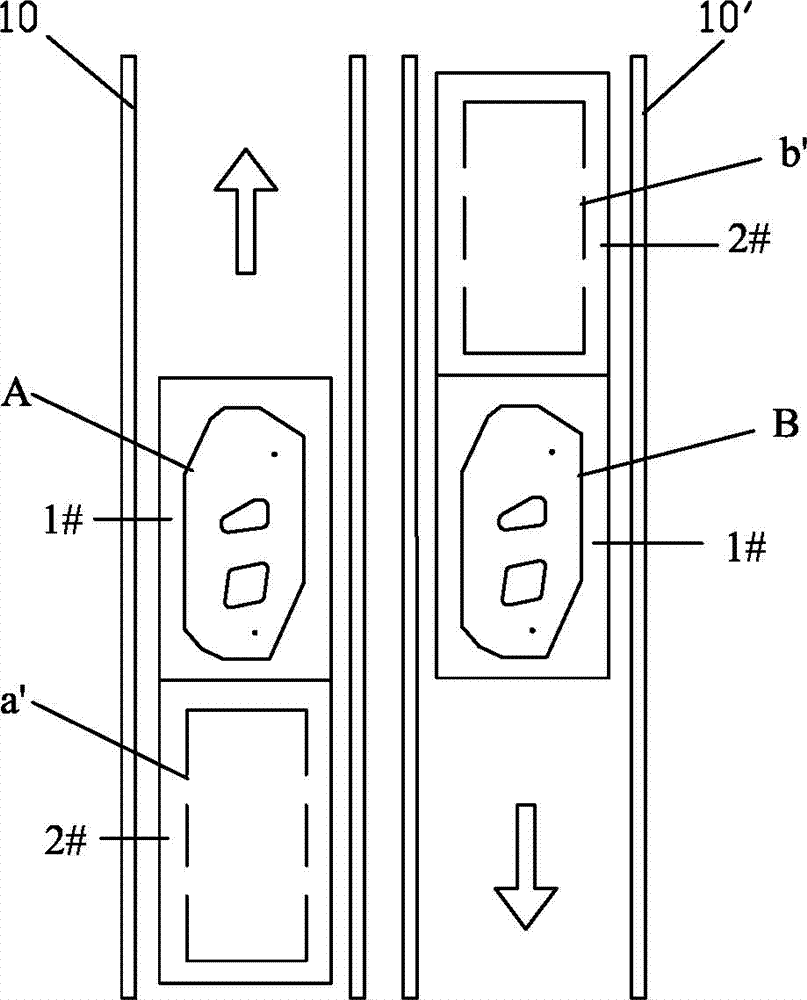

[0025] refer to figure 1 , figure 2 , a metal plate cutting system of the present invention adopts two vertically moving loading and unloading and cutting operation lines A and B arranged in parallel, and each operation line A and B respectively include group material feeding positions 1, 1', cutting workers Positions 2, 2', sheet unloading positions 3, 3', two handling and stacking robots 4, 4' and corresponding external axes 41, 41' set between the two operation lines; two operation lines A , The setting direction of group B material loading level 1, 1' is opposite; said group material loading level 1, 1', sheet material lowering level 3, 3' are respectively set group material trolley 5, 5', and sheet material trolley 6 , 6' and corresponding guide rails 7, 7', 8, 8'; cutting stations 2, 2' are equipped with at least one laser generator and two laser cutting heads 9, 9' and moving group materials, sheet materials in and out The mobile fast table 10, 10' in the cutting are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com