Method for detecting water mist on inner surface of windshield

A technology for windshields and inner surfaces, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., which can solve the problems affecting heat transfer, energy consumption, and difficult process implementation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

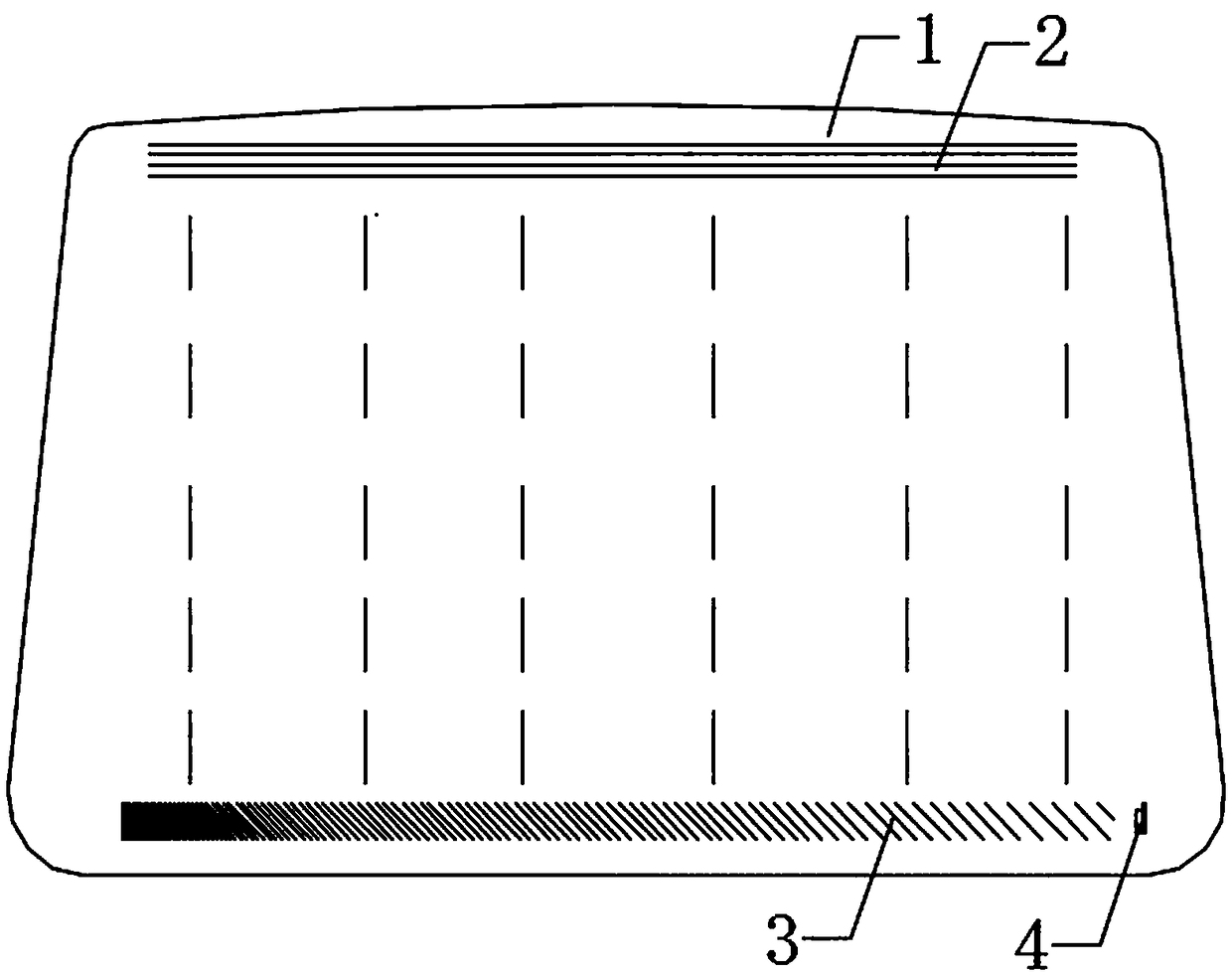

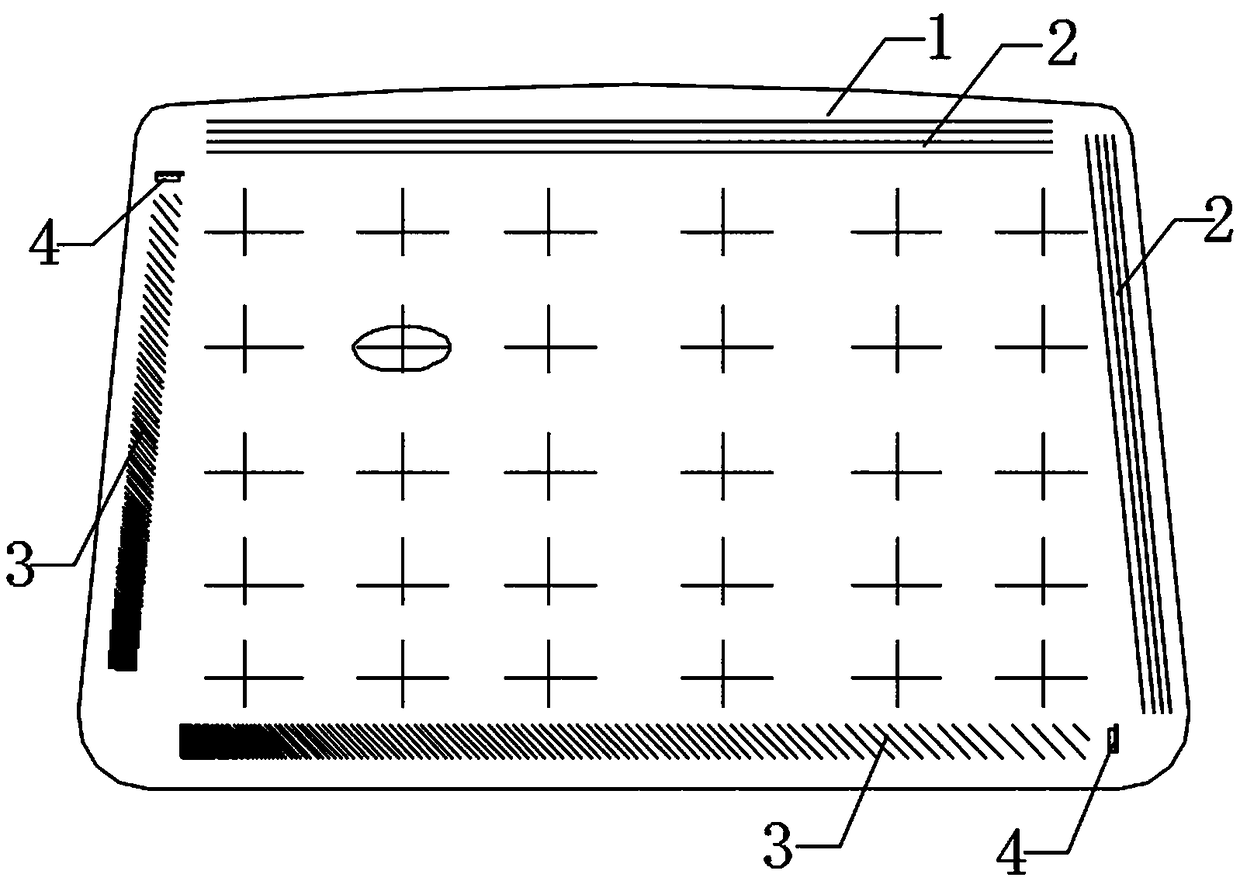

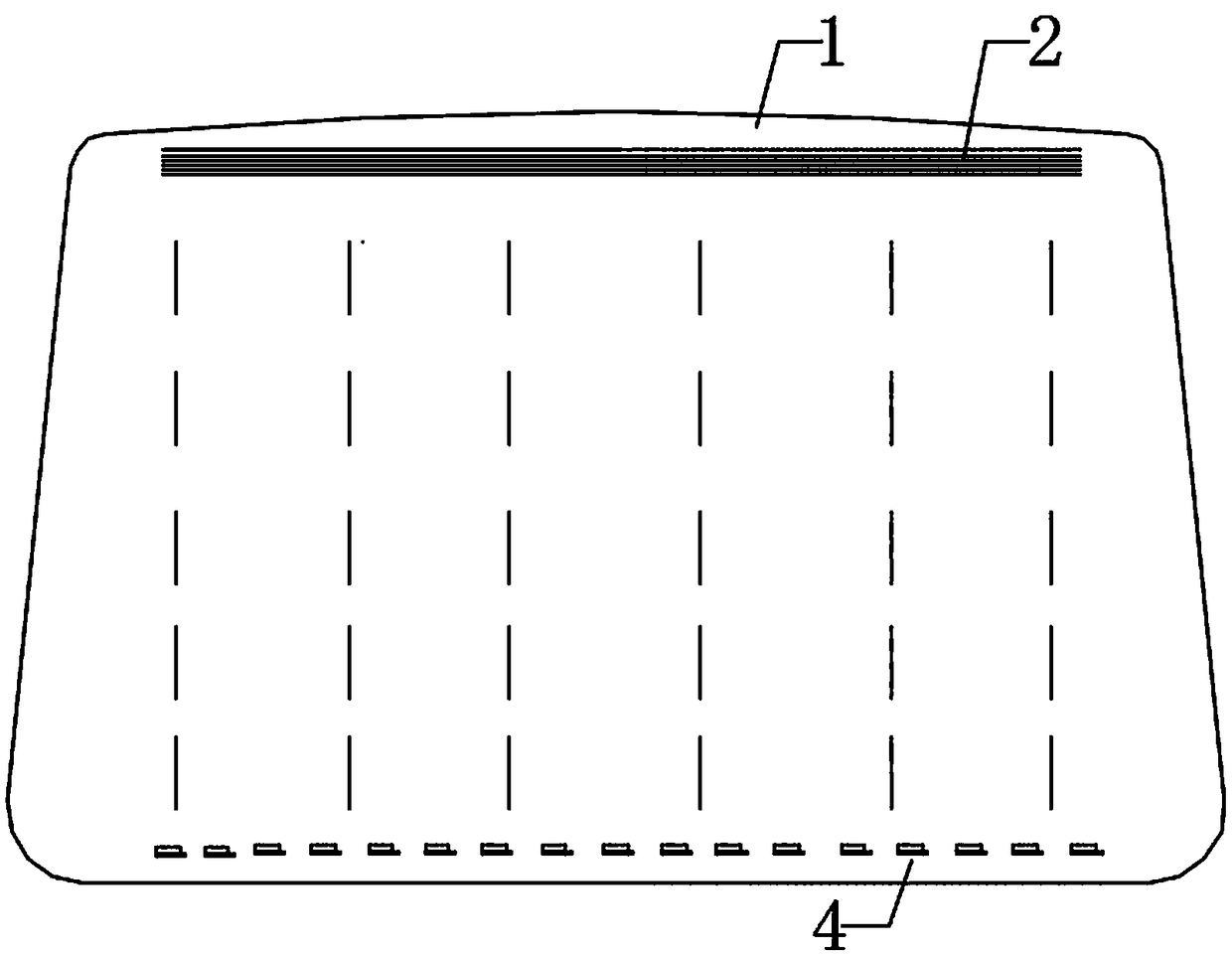

[0057] This embodiment discloses a method for detecting water mist on the inner surface of a windshield, which uses surface ultrasonic waves to detect the water mist on the inner surface 1 of the glass. Specifically, the detection method is as follows: the controller (not shown in the figure) controls the ultrasonic transceiver assembly to form a surface ultrasonic detection area on the inner surface 1 of the glass. When water mist is generated on the inner surface 1 of the glass, the The surface ultrasonic wave is absorbed and attenuated, and the controller determines the position of the water mist on the inner surface 1 of the glass according to the received attenuation signal.

[0058] In this embodiment, the frequency of the surface ultrasonic waves is set to 1.1-10 MHz, which is applicable to windshields of different thicknesses.

Embodiment 2

[0060] This embodiment discloses a method for detecting water mist on the inner surface of a windshield, which uses surface ultrasonic waves to detect the water mist on the inner surface 1 of the glass. Specifically, the detection method is as follows: the controller (not shown in the figure) controls the ultrasonic transceiver assembly to form a surface ultrasonic detection area on the inner surface 1 of the glass. When water mist is generated on the inner surface 1 of the glass, the The surface ultrasonic wave is absorbed and attenuated, and the controller determines the position of the water mist on the inner surface 1 of the glass according to the received attenuation signal.

[0061] In this embodiment, when the attenuation signal received by the controller is higher than the set value, it indicates that the amount of water mist on the inner surface 1 of the glass is relatively large, and it is determined that the amount of water mist on the inner surface 1 of the glass af...

Embodiment 3

[0063] This embodiment discloses a method for detecting water mist on the inner surface of a windshield, which uses surface ultrasonic waves to detect the water mist on the inner surface 1 of the glass. Specifically, the detection method is as follows: the controller (not shown in the figure) controls the ultrasonic transceiver assembly to form a surface ultrasonic detection area on the inner surface 1 of the glass. When water mist is generated on the inner surface 1 of the glass, the The surface ultrasonic wave is absorbed and attenuated, and the controller determines the position of the water mist on the inner surface 1 of the glass according to the received attenuation signal.

[0064] In this embodiment, when the attenuation signal received by the controller is higher than the set value, it indicates that the amount of water mist on the inner surface 1 of the glass is relatively large, and it is determined that the amount of water mist on the inner surface 1 of the glass af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com