Compositions for electromagnetic shielding composite coatings, coatings and methods thereof

A composite coating and electromagnetic shielding technology, applied in coatings, radiation-absorbing coatings, etc., can solve problems such as secondary electromagnetic pollution, and achieve the effects of low synthesis temperature, simple preparation method, and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the mass ratio of mesoporous carbon: resin = 14:86 (equivalent to mesoporous carbon filling amount of 14wt%), weigh mesoporous carbon CMK-3 and solid methyl methacrylate resin raw materials; dissolve the raw materials in ethyl acetate In the solvent, the total mass of raw materials: ethyl acetate mass = 1:5; after stirring at room temperature, put it into an ultrasonic disperser for ultrasonic dispersion for 6 hours; coat it on an engineering plastic substrate, and dry it in an oven at 40°C for 12 hours , Control the coating thickness after drying to 0.4mm.

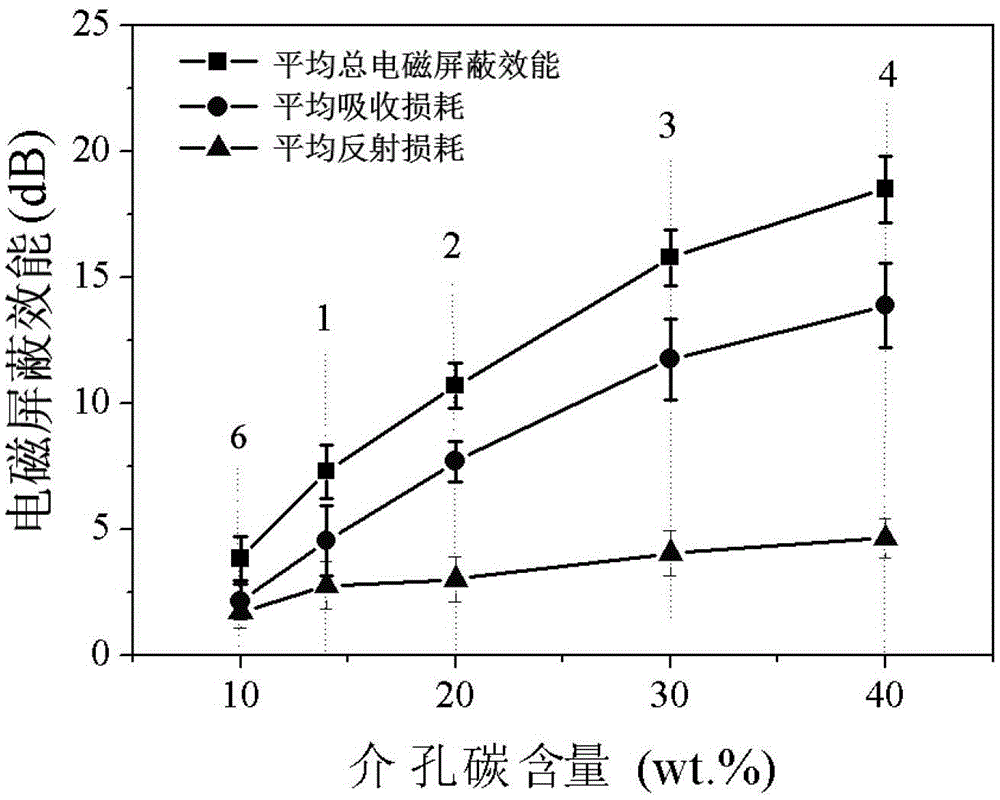

[0021] Such as figure 1 Shown in 1: it is detected that the average electromagnetic shielding effectiveness of the electromagnetic shielding composite coating prepared in embodiment 1 in the X band is 7.29dB, the average absorption loss is 4.53dB, and the average reflection loss is 2.75dB. The reflection effect is low and the absorption loss is high. Such as figure 2 As shown in 1, the prepared ele...

Embodiment 2

[0023] According to the mass ratio of mesoporous carbon: resin = 20:80 (equivalent to 20wt% mesoporous carbon filling), weigh mesoporous carbon CMK-3 and solid methyl methacrylate resin raw materials; dissolve the raw materials in ethyl acetate In the solvent, the total mass of raw materials: ethyl acetate mass = 1:5; after stirring at room temperature, put it into an ultrasonic disperser for ultrasonic dispersion for 6 hours; coat it on an engineering plastic substrate, and dry it in an oven at 40°C for 12 hours , Control the coating thickness after drying to 0.4mm.

[0024] Such as figure 1 Shown in 2: detect that the average electromagnetic shielding effectiveness of the electromagnetic shielding composite coating prepared in embodiment 2 in the X-band is 10.69dB, the average absorption loss is 7.68dB, and the average reflection loss is 3.01dB. The reflection effect is low and the absorption loss is high. Such as figure 2 As shown in 2, the prepared electromagnetic shie...

Embodiment 3

[0026] According to the mass ratio of mesoporous carbon: resin = 30:70 (equivalent to 30wt% mesoporous carbon filling), weigh mesoporous carbon CMK-3 and solid methyl methacrylate resin raw materials; dissolve the raw materials in ethyl acetate In the solvent, the total mass of raw materials: ethyl acetate mass = 1:5; after stirring at room temperature, put it into an ultrasonic disperser for ultrasonic dispersion for 6 hours; coat it on an engineering plastic substrate, and dry it in an oven at 40°C for 12 hours , Control the coating thickness after drying to 0.4mm.

[0027] Such as figure 1 Shown in 3: it is detected that the average electromagnetic shielding effectiveness of the electromagnetic shielding composite coating prepared in embodiment 3 in the X-band is 15.78dB, the average absorption loss is 11.74dB, and the average reflection loss is 4.04dB. The reflection effect is low and the absorption loss is high. Such as figure 2 As shown in 3, the prepared electromagn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com