Patents

Literature

65results about How to "Easy to brush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

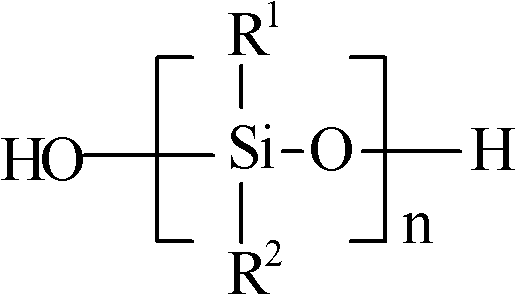

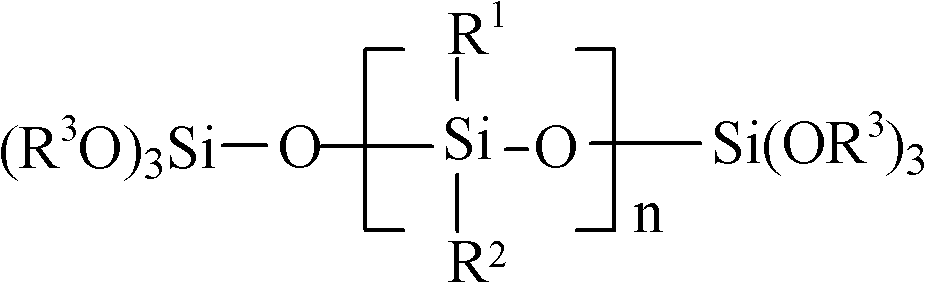

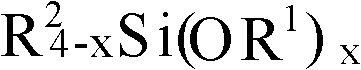

Room-temperature cured phenyl silicon resin conformal coating

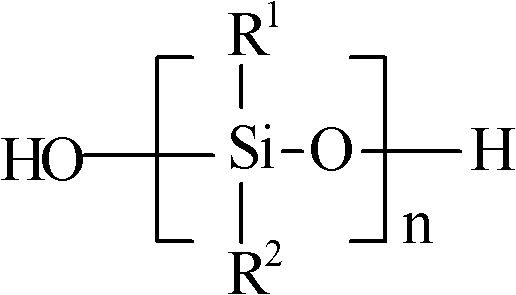

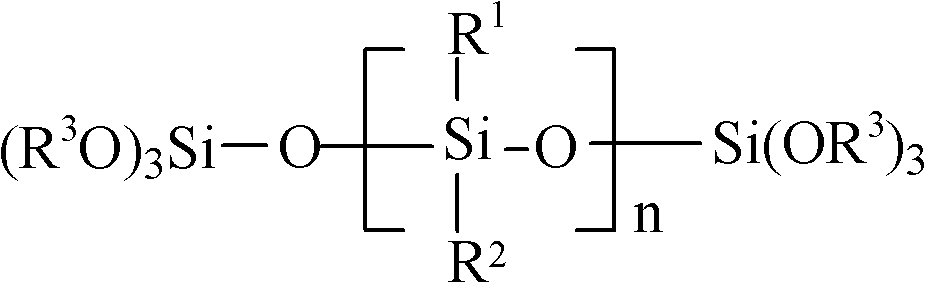

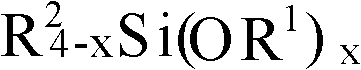

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Poly fleece textile using polypropylene glycol terephthalate as material and its production method

InactiveCN1730758ABeneficial to stand uprightConsistent grain sizeWeft knittingDyeing processYarnPolytrimethylene terephthalate

The present invention discloses one kind of polyester polar fleece fabric with polypropanediol terephthalate as material and its production process. The polyester polar fleece fabric has facing material of polypropanediol terephthalate yarn or filament and foundation material of other natural or synthetic fiber yarn or filament, and knitted. The polyester polar fleece fabric with polypropanediol terephthalate has soft hand feeling, high loft and elasticity, high dirt resistance, good fuzz resistance and excellent antistatic performance.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Sound-absorbing radiation protective paint and preparation method thereof

ActiveCN101831211AImprove sound absorptionGood radiation protectionRadiation-absorbing paintsLow speedHydroxyethyl cellulose

The invention relates to a sound-absorbing radiation protective paint, which comprises the following components in percentage by weight: 30 to 38 percent of porous modified starch, 5.0 to 9.5 percent of styrene-acrylic latex emulsion, 33 to 41 percent of barite, 0.5 to 1 percent of iron oxide, 0.25 to 1 percent of sodium polycarboxylate dispersant, 0.01 to 1 percent of brightening agent, 1.0 to 6 percent of titanium white, 0.5 to 1 percent of defoamer, 0.01 to 1 percent of mildew preventive, 13 to 18 percent of water, 0.4 to 1 percent of ethylene glycol, 0.3 to 1 percent of film-forming auxiliary agent, 0.005 to 1 percent of anti-freeze agent, 0.5 to 1 percent of graphite, 1 to 3 percent of hydroxyethyl cellulose and 0.20 to 1 percent of thickening agent. A preparation method of the sound-absorbing radiation protective paint comprises the steps of: (a) premixing, namely stirring 1 / 2 water, the sodium polycarboxylate dispersant, 1 / 2 defoamer, the mildew preventive, the thickening agent, the hydroxyethyl cellulose and the brightening agent at low speed to form colloidal solution; (b) dispersing and grinding, namely adding the titanium white, the barite, the graphite and the iron oxide into the colloidal solution and stirring the solution at high speed to prepare uniform sizing agent; (c) paint mixing, namely adding crylic acid emulsion, the film-forming auxiliary agent and the anti-freeze agent into the sizing agent, uniformly stirring the sizing agent, then dividing the porous modified starch into 1 to 5 parts, and adding the porous modified starch by 1 to 5 times into the mixture for low-speed and uniformly stirring the mixture; and (d) packaging the resulting product.

Owner:谢绍何

Paste solder for hard soldering of SiCp/Al composite material and preparation method and use method thereof

InactiveCN103100800AReduce in quantityImprove automationWelding/cutting media/materialsSoldering mediaAdhesiveTubing types

The invention relates to a paste solder for the hard soldering of a SiCp / Al composite material and a preparation method and use method thereof, and relates to a solder for the hard soldering of the SiCp / Al composite material and a preparation method and use method thereof. The paste solder for the hard soldering of the SiCp / Al composite material aims at the problem that the traditional strip-shaped solder or foil-shaped solder is adverse to the automation in a hard soldering process and is not suitable to weld an irregular, small-sized or geometrical complicated part. The paste solder for the hard soldering of the SiCp / Al composite material is prepared by mixing solder alloy powder, a soldering flux and an adhesive. The preparation method comprises the following steps of: 1, preparing the solder alloy powder; 2, preparing the soldering flux; 3, preparing the adhesive; and 4, mixing to prepare the hard soldering of the paste solder for the SiCp / Al composite material. The use method comprises the following steps of: adopting coating type cloth or needle tube type cloth; and then carrying out vacuum heating treatment so as to complete welding. The preparation method disclosed by the invention is mainly used for preparing the paste solder for the hard soldering of the SiCp / Al composite material.

Owner:HENAN POLYTECHNIC UNIV +2

Antirust pigment for improving antirust property of antirust paint

InactiveCN1504516AReasonable priceImprove rust resistancePigmenting treatmentAnti-corrosive paintsNano siliconVanadium oxide

The invention discloses a composite ferrum-titanium powder, a rust-preventive pigment for improving the tarnish proofness for anti-corrosive paint, characterized in that, the composite ferrum-titanium powder uses natural or artificially synthesized ferriferrous oxide having a fineness of 200-1200 sieve number as carrying agent, to be added by nano silicon oxide, titanium oxide, vanadium oxide, yttrium oxide, zinc oxide, ferric oxide and calcium carbonate.

Owner:万达科技(无锡)有限公司

High-strength anti-corrosion coating as well as preparation method and application thereof

ActiveCN107141863AImprove bindingHigh strengthAnti-corrosive paintsPolyurea/polyurethane coatingsFilm-forming agentSurface modification

The invention discloses a high-strength anti-corrosion coating as well as a preparation method and application thereof. The high-strength anti-corrosion coating contains an anti-corrosion processing agent, a reinforcing agent, a difunctional dispersing agent, a flatting agent, a film forming agent and a solvent, wherein the surface of the reinforcing agent is provided with active groups, and the mass ratio of the anti-corrosion processing agent to the reinforcing agent to the difunctional dispersing agent to the flatting agent to the film forming agent is 1 to (0.005-0.5) to (0.002-0.6) to (0.002-0.4) to (0.002-0.3), and the mass ratio of the solvent to the anti-corrosion processing agent is 100 to (0.01-50). The reinforcing agent is subjected to surface modification and is provided with active functional groups such as -OH and -NH3, so that the bonding force of a coating layer and a base material is enhanced, and the strength and scraping resistance of the coating layer can be substantially enhanced; the brush-coated, sprayed or dipped base material has excellent corrosion resistance, knock resistance and durability and high hardness and adhesive force; and a process of the preparation method is mature, the production cost is low, and the production process is environmentally friendly and pollution-free, so that the preparation method is suitable for large-scale popularization and application.

Owner:嘉兴浩然科技有限责任公司

New process for electroplating non-metal material surface and its special conductive paint

InactiveCN1944718ATo achieve the purpose of metallizationThe purpose of metallization is wideElectrically-conductive paintsCopper platingMetallic materials

The simplified process for electroplating non-metal material surface includes the steps of chemically deoiling the surface of non-metal material, spraying conducting paint for metallizing the non-metal material, and final electroplating copper, nickel or chromium. The conducting paint consists of filming resin 20-40 wt% , flaky conducting metal powder 28-40 wt%, coupler 0.5-2 wt%, orientating arranging agent 1-1.25 wt%, mixed diluent 20-40 wt% and assistant 0.5-2 wt%. The process is simple, low in production cost, high in work efficiency and environment friendship, and may be used in matallizing various non-metal material with complicated shape.

Owner:昆明亘宏源科技有限公司

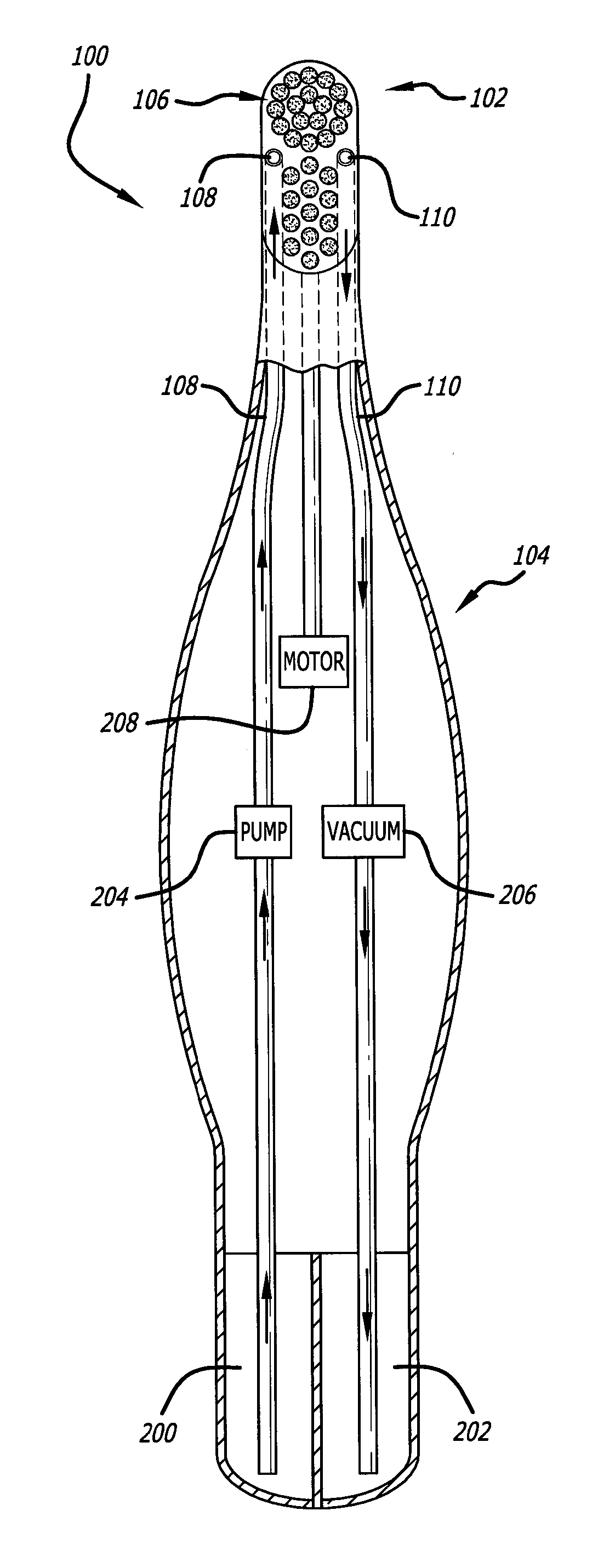

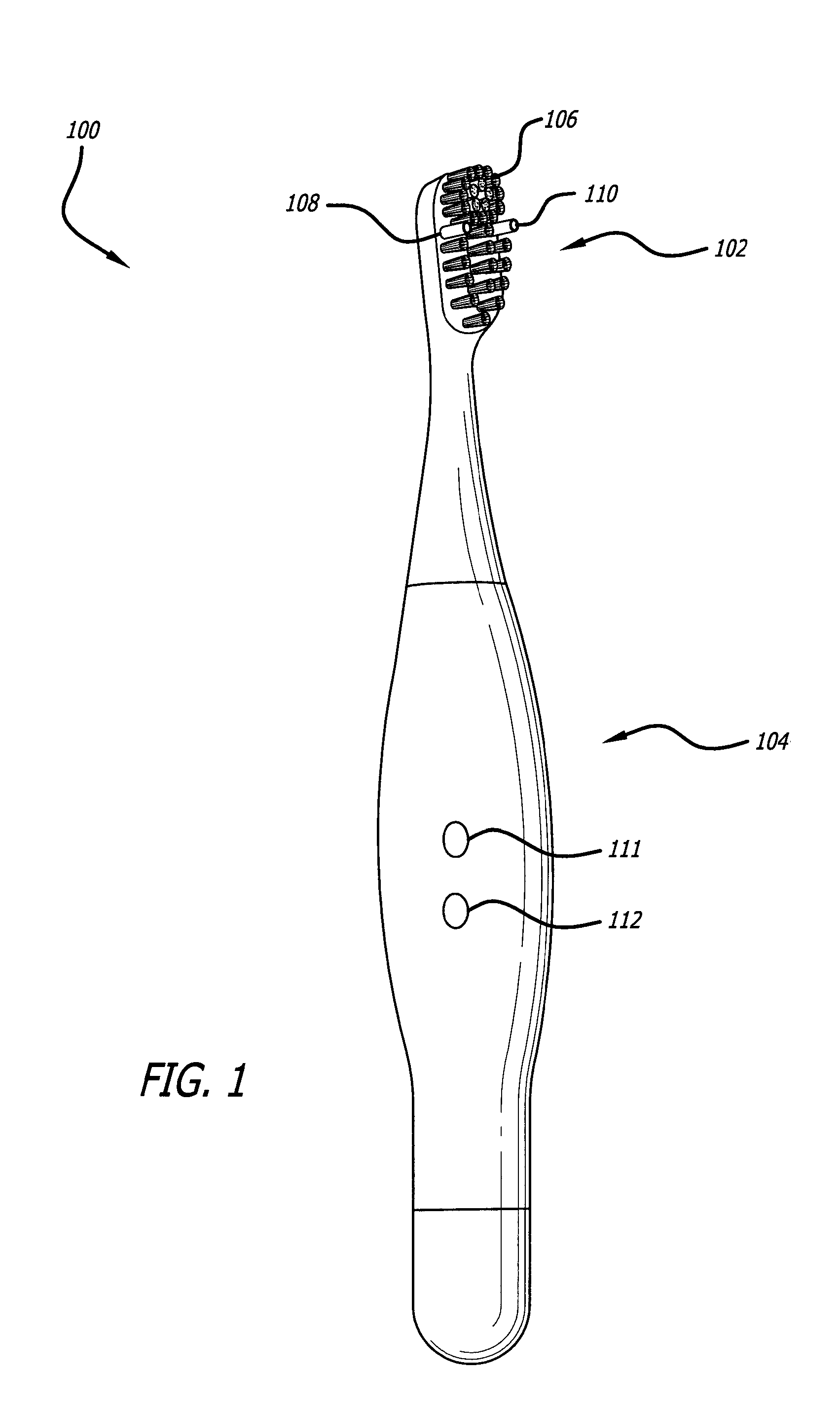

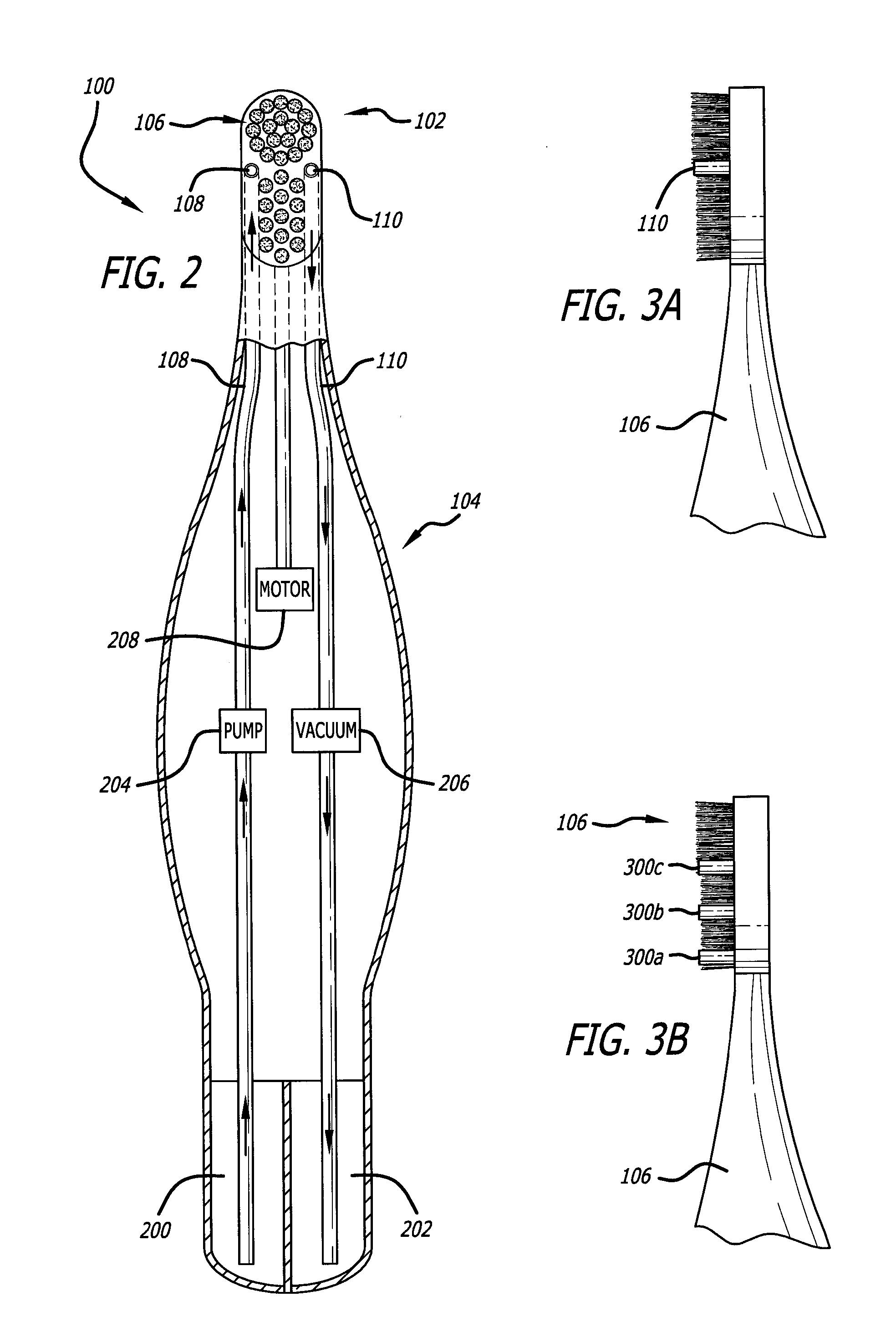

Portable Toothbrush For Delivering And Removing Fluid

InactiveUS20120288320A1Easily brush his or her teethEasy to brushCarpet cleanersFloor cleanersOral healthHand held

A hand-held portable electric or manual toothbrush that is capable of delivering and removing fluid while the toothbrush is being used. A fluid delivery tube delivers fluid from a clean fluid repository to the head of the toothbrush. A fluid removal tube removes used fluid from the user's mouth. The clean fluid is delivered via a pump positioned within a cavity of the toothbrush. The used fluid is removed via a vacuum positioned within the cavity of the toothbrush. This invention enables everyone, including the young, elderly, busy, healthy, sick, disabled, handicapped, and immobile, to brush anytime and anywhere. As a result, this invention would greatly improve the oral health of the general population.

Owner:BARKHORDAR AFSOON

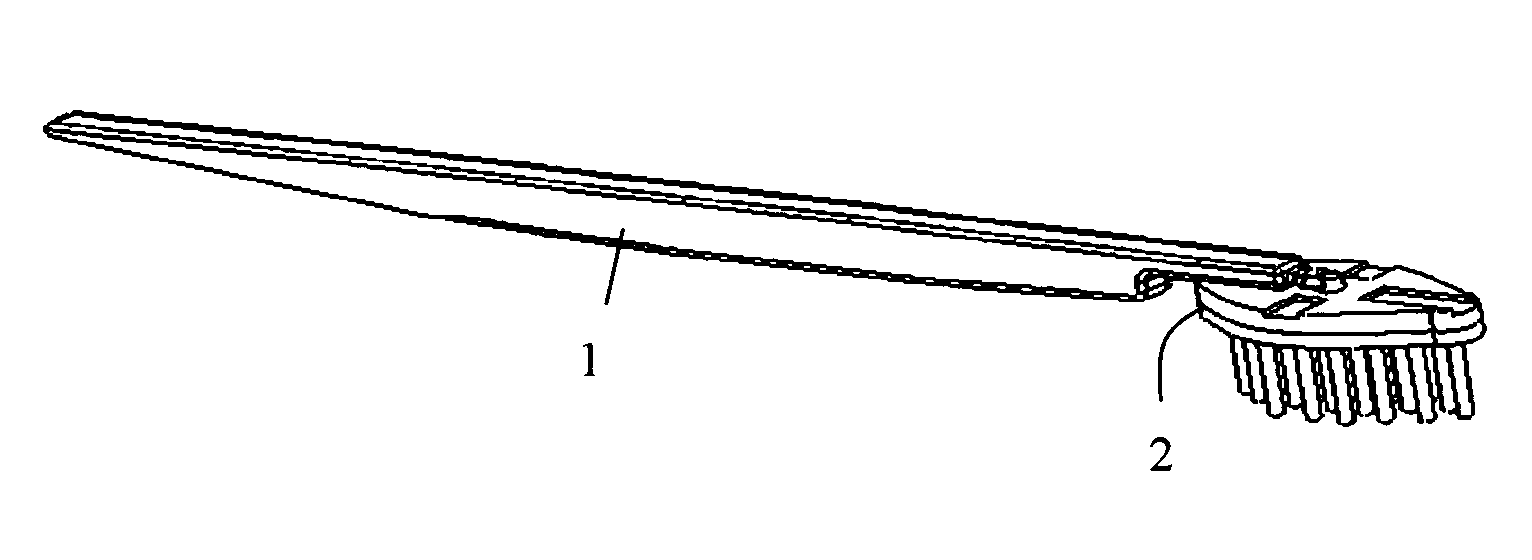

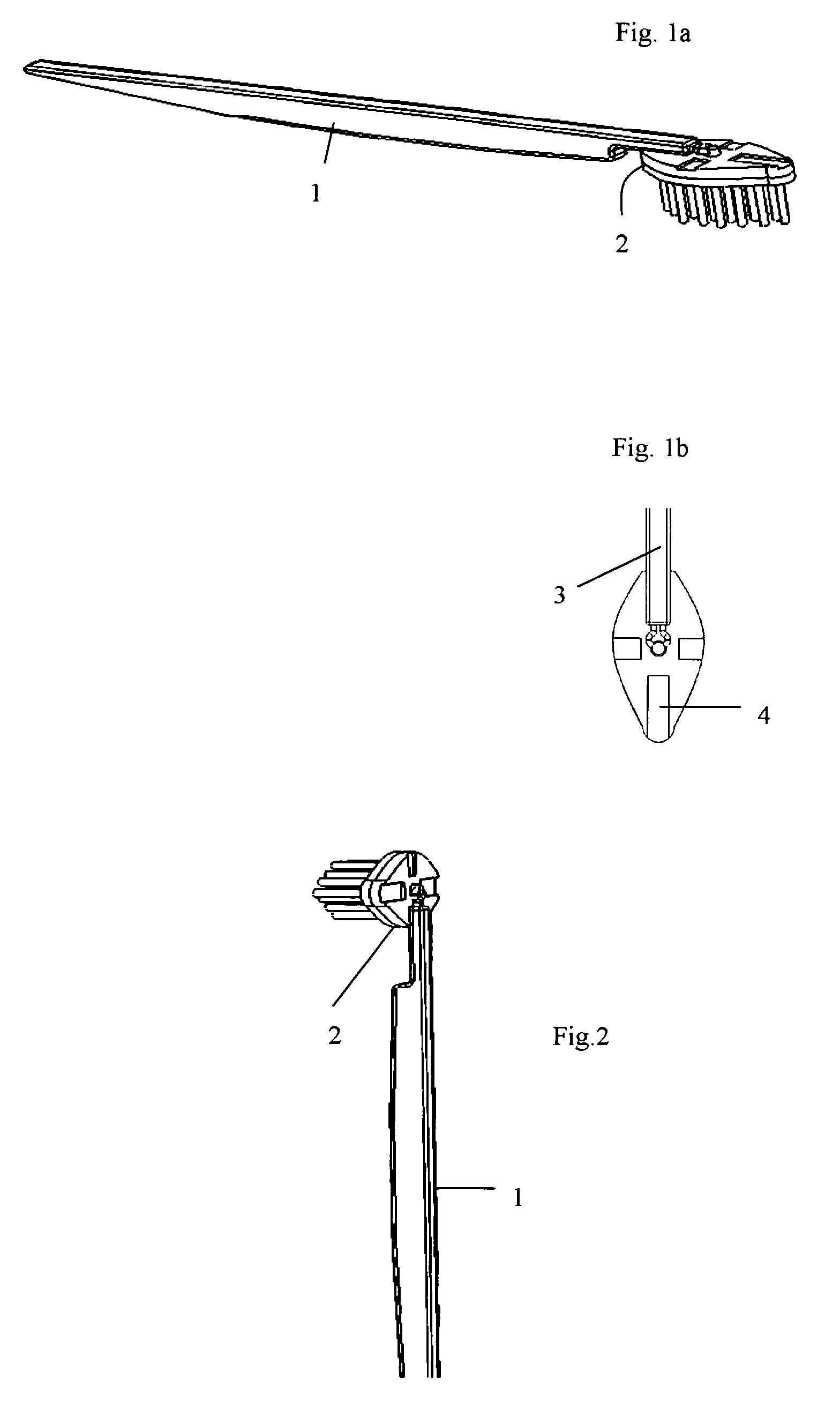

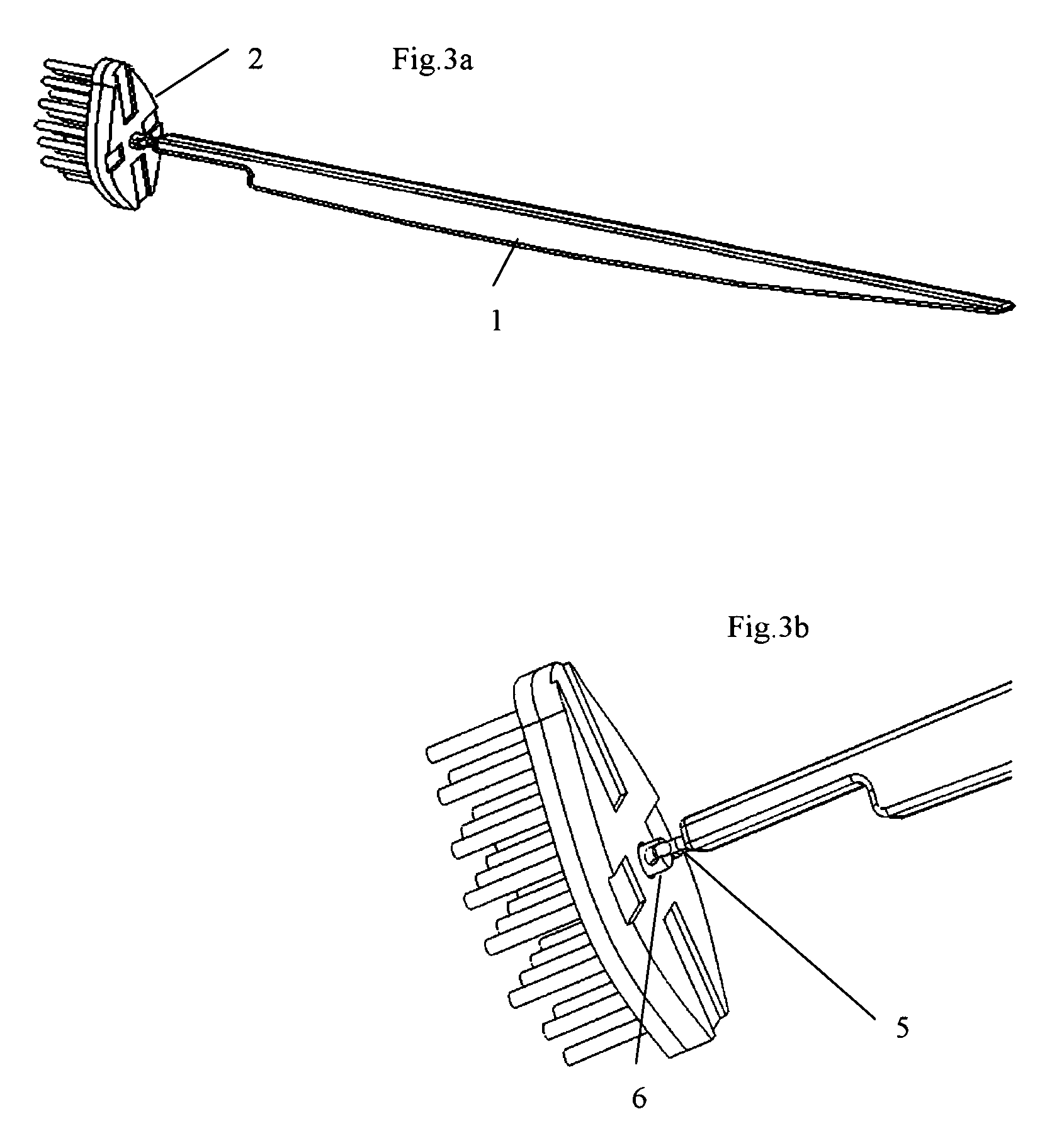

Rotational toothbrush

InactiveUS7913347B2Hard to getBrush the residue at our teeth out more easilyCarpet cleanersBrush bodiesEngineeringMechanical engineering

A toothbrush which head can be rotated to form different angle with the handle. This action of rotation can be done while brushing the teeth, once the handle leaves out the slot at the head, the handle can be moved to another slot, the angle of the head and the handle is changed from 180 degree to 90 degree and then from 90 to 180 degree again. The handle also can be free rotated without fixing to the slot at the head. A T-shape shaft is inserted between two covers at the head of the toothbrush, a connector is connected between the T-shape shaft and the handle of the toothbrush, so that the head and handle can be rotated freely.

Owner:WONG HING WING

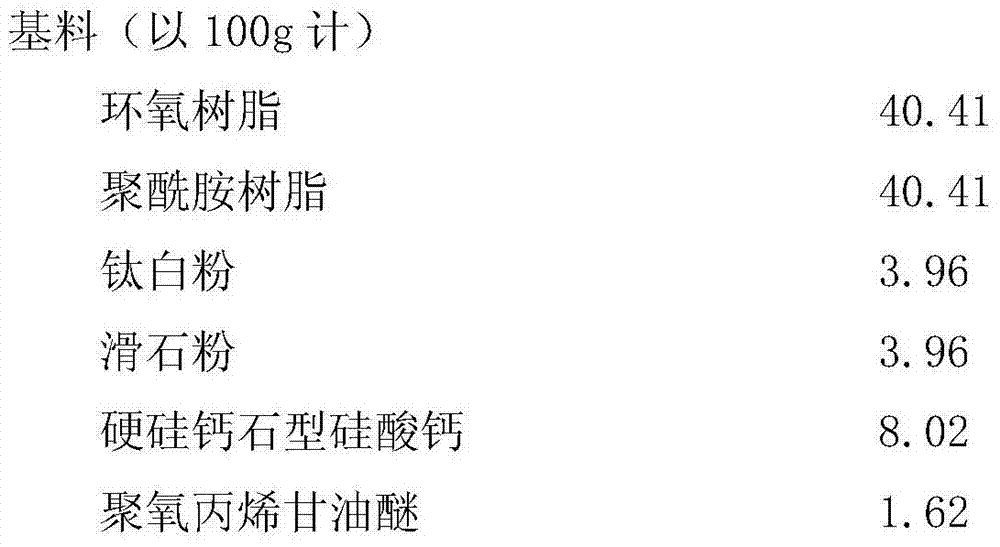

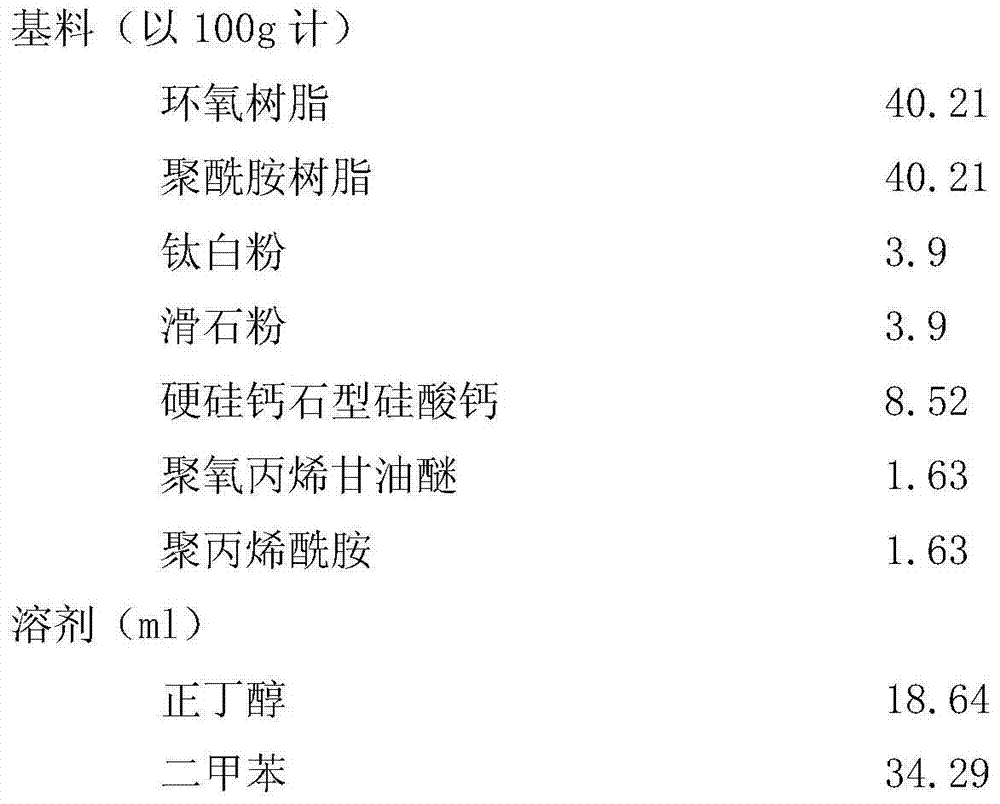

Anticorrosion heat-insulation paint and preparation method thereof

ActiveCN104774528AAddress impact resistanceSolve the strength problemAnti-corrosive paintsPolyamide coatingsCalcium silicateEpoxy

The invention discloses an anticorrosion heat-insulation paint and a preparation method thereof. The paint comprises a base material and a solvent. The base material comprises an expoxy heat-insulation paint, auxiliary pigment and filling materials, a heat-insulation filling material, an antifoaming agent and a dispersant. The expoxy heat-insulation paint is composed of the following components in parts by weight: 40.21 to 40.61 parts of epoxy resin (the membrane), 40.21 to 40.61 parts of polyamide resin (curing agent), 3.76 to 4.16 parts of titanium dioxide, 3.76 to 4.16 parts of talcum powder, 7.52 to 8.52 parts of xonotlite-type calcium silicate (heat-insulation filling material), 1.61 to 1.63 parts of polyoxypropylene glycerol ether (antifoaming agent), 1.61 to 1.63 parts of polyacrylamide (dispersant), 11.86 to 15.1 parts of n-butanol, and 26.05 to 29.49 parts of xylene. After curing, the paint forms an enclosed micro-porous and netted fiber structure on the substrate, has the characteristics of good anticorrosion performance, strong adhesive force, and high compressive strength, and thus solves the problems of bad impact-resistant performance and low adhesive force on wall of conventional barrier heat-insulation paints. Moreover, the paint is convenient for construction, can be painted or brushed, and has strong plasticity.

Owner:锌盾化工无锡有限公司

Neutral white pigment preparation used for ancient and famous trees and preparation thereof

ActiveCN105053006AExtension of timeLow priceBiocidePlant growth regulatorsInsect diseasePolyvinyl alcohol

The invention provides a neutral white pigment preparation used for ancient and famous trees and preparation thereof, which can solve the problem of soil acidity-alkalinity destroy in the current white pigment preparation. The method for preparing the white pigment preparation comprises the following steps: adding polyvinyl alcohol 1788 powder, white pigment powder, a magnesium aluminosilicate suspension auxiliary agent and 80% of water in a stirring cylinder, stirring by a mixer to an uniform state; adding hollow glass bead powder, stirring to the uniform state; cleaning the wall of the stirring cylinder by the rest of water and a rotating shaft, and using the mixer for stirring to the uniform state. The white pigment preparation has the beneficial effect that insect disease of tree, sunburn and frostbite can be prevented, and soil environment after tree brushing can not be influenced.

Owner:CHONGQING LANDSCAPE & GARDENING RES INST

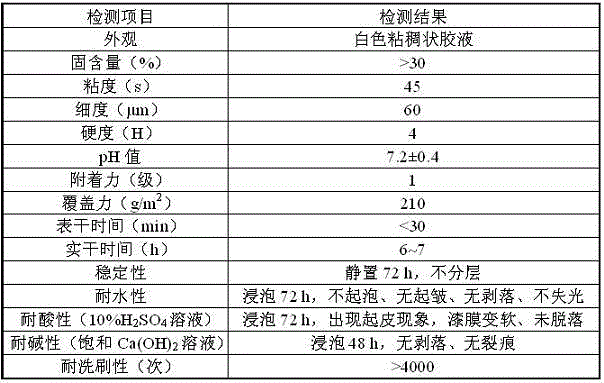

Low-cost silicasol-type interior wall coating

The invention discloses a low-cost silicasol-type interior wall coating. The low-cost silicasol-type interior wall coating consists of the following components in percentage by weight: 6 to 8 percent of styrene-acrylic emulsion, 10 to 14 percent of silicasol, 2 to 6 percent of bentonite, 35 to 45 percent of titanium dioxide and wollastonite powder, 6 to 8 percent of hydroxyethyl cellulose, 6 to 8 percent of dispersing agent, 3 to 5 percent of defoaming agent, 0.05 to 0.1 percent of multi-functional aid, 3 to 8 percent of Texanol lipidol, 0.15 to 0.25 percent of antiseptic and antimildew agent, 1 to 2 percent of thickening agent and 15 to 25 percent of water. The coating provided by the invention has the hardness of inorganic coatings and certain flexibility, keeps the quick dryness and easy painting performance of organic coatings, displays the advantages of inorganic coatings and organic coatings and contributes to the performance improvement of coatings as well as cost reduction.

Owner:顾欣锋

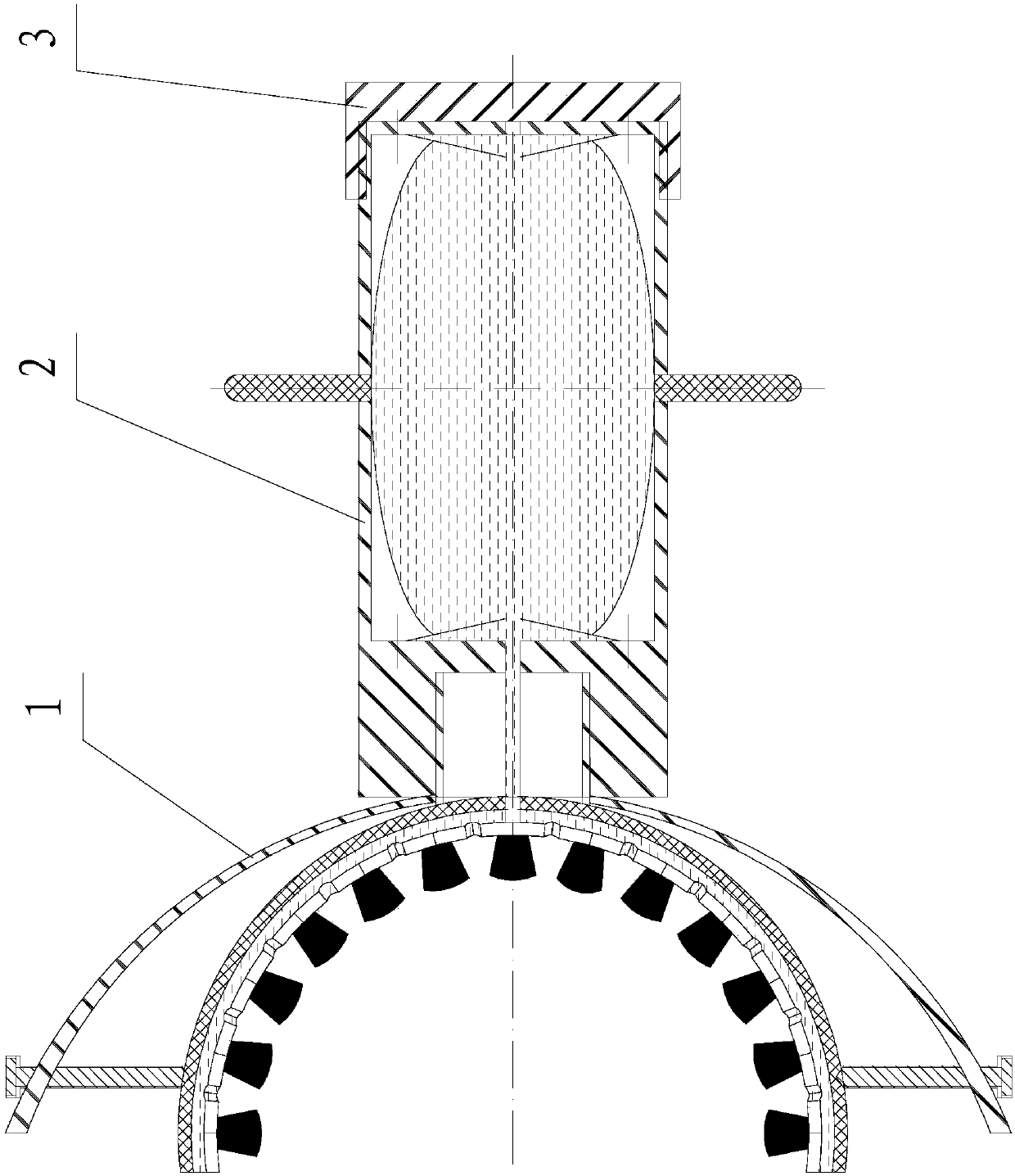

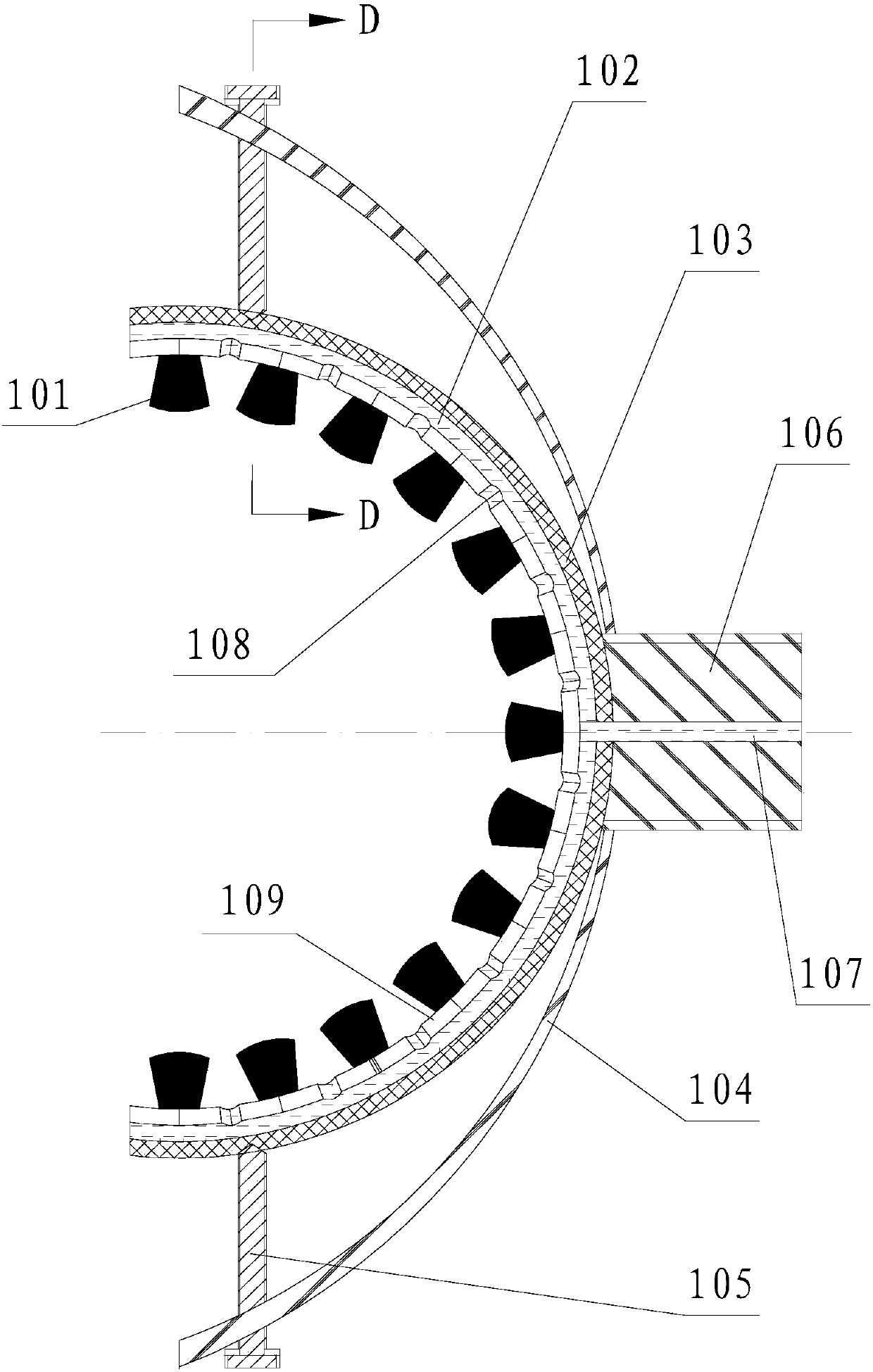

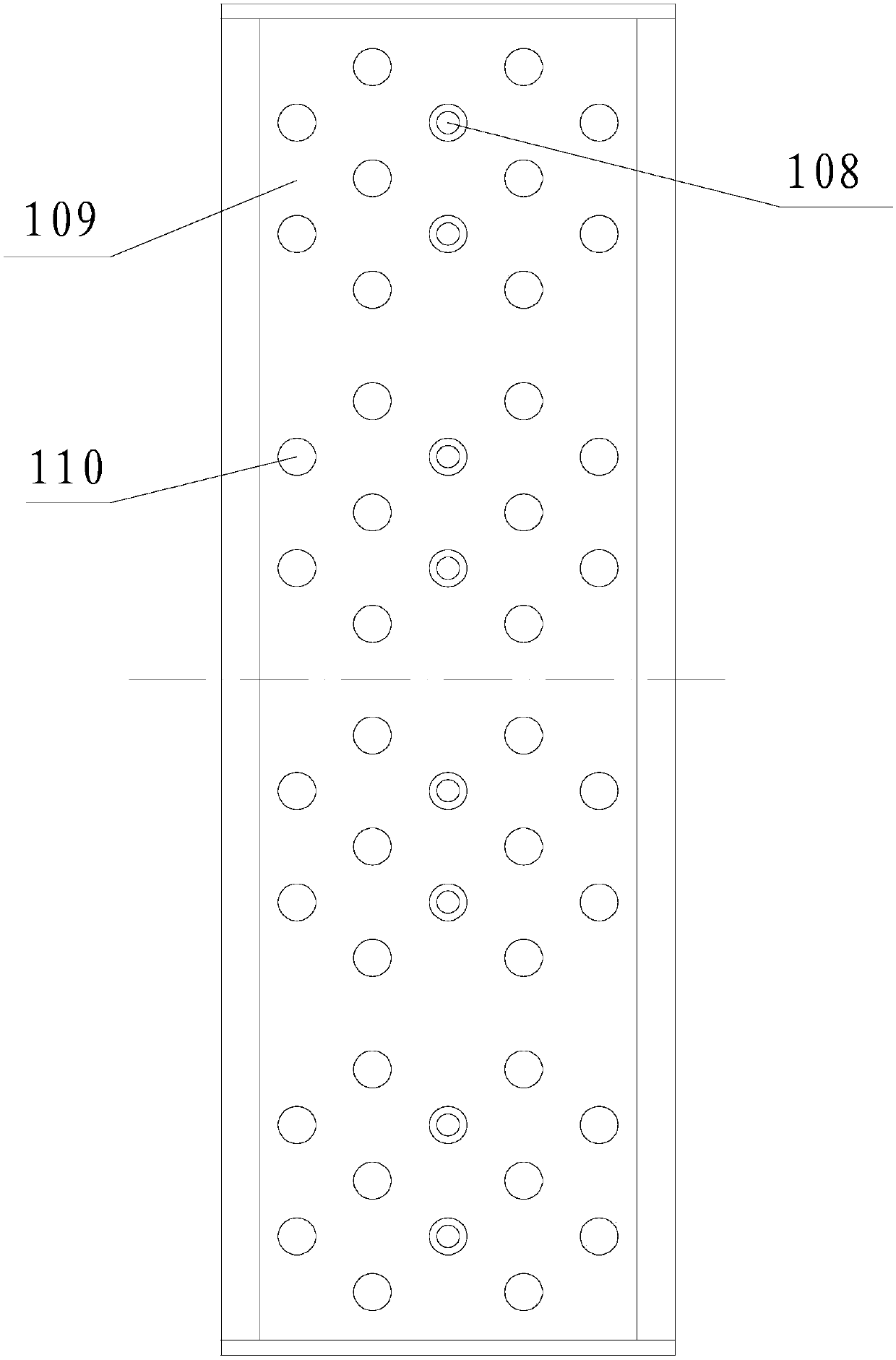

Versatile coating brush

The invention relates to the field of painting, coating and corrosion resisting, in particular to a versatile coating brush. The versatile coating brush comprises a brush handle, a brush head and a brush handle cover, wherein the brush head and the brush handle cover are connected to the two ends of the brush handle respectively. The brush head can be in an arc shape or a circular shape, and the radian of the arc-shaped brush head can be controlled, so that bristles are attached to the surface of a painted (coated) column; the containing angle of the brush head ranges from 0 degree to 120 degrees, the reference is the fact the bristles are tightly attached to the surface of the painted column, outer-gap leakage flowing and splattered painting which are generated when the column is paintedwith a flat plate brush are solved, a coating is saved, and the environment is prevented from being polluted. A coating storage cavity is formed inside the brush handle, so that coating dripping in the coating dipping process is reduced, labor intensity is reduced, and it may be said that materials, time and labor are saved. The versatile coating brush can also be externally connected with an automatic coating conveying device, the coating can be charged while being used, and a quiet convenient effect is achieved when on-site continuous large-area construction and the use quantity of the coating is large. The versatile coating brush is easy and convenient to install and operate, safe, flexible and reliable, raw materials are saved, and the environment is not polluted; economic benefits arehigh, the application range is wide, and industrialization prospects are good.

Owner:青岛迪恩特新材料科技有限公司

Novel process for preparing emulsion paint through waste polystyrene plastic

ActiveCN104449090AEfficient use ofLow toxicityRosin coatingsEmulsion paintsCalcium silicatePolymer science

The invention relates to a novel process for preparing emulsion paint through waste polystyrene plastic. The process includes the following steps that (1) the waste polystyrene plastic is put into lime water to be soaked, stirred mechanically and taken out, then the treated waste polystyrene plastic is stirred and cleaned two times with clean water, and clean polystyrene plastic is obtained; (2) the clean polystyrene plastic is dried or aired and then smashed, and polystyrene particles are obtained; (3) the polystyrene particles are added to heavy aromatic oil to be stirred and dissolved to homogeneous phase and filtered, and filtering liquid is obtained; (4) polyvinyl acetate and rosin are sequentially added to the filtering liquid, then the mixture is heated and stirred till the reaction is completely finished, and base materials are obtained; (5) compound emulsifiers are added to deionized water, the mixture is fully and evenly stirred, modified nano SiO2, dibutyl phthalate, titanium dioxide and calcium silicate are sequentially added and stirred to be pasty, and color paste is obtained; (6) the base materials are injected into the color paste, the mixture is stirred, then grinding and filtering are conducted, and the white sticky emulsion paint is obtained. The novel process is simple in operation and excellent in performance of obtained products.

Owner:EASTERN GANSU UNIVERSITY

Oil flow formula of high speed wind tunnel oil flow experiment clearly demarcating Mach number range

InactiveCN108760225AEasy to buyGuaranteed performanceAerodynamic testingChemistryOleic Acid Triglyceride

The invention relates to an oil flow formula of a high speed wind tunnel oil flow experiment clearly demarcating the Mach number range, and particularly relates to an oil flow formula suitable for theoil flow experiment of which the Mach number range is 0.5-0.9. Use of the trace particle-powdery titanium dioxide, the carrier oil-silicone oil and the diluent-oleic acid is determined through a series of experiments and the mass percent relationship of the three components is determined. A large number of oil flow display experiments are completed and indicate that the oil flow formula can acquire the high-quality oil flow test image for analyzing the model surface air flow pattern so as to achieve the effect of flow visualization.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

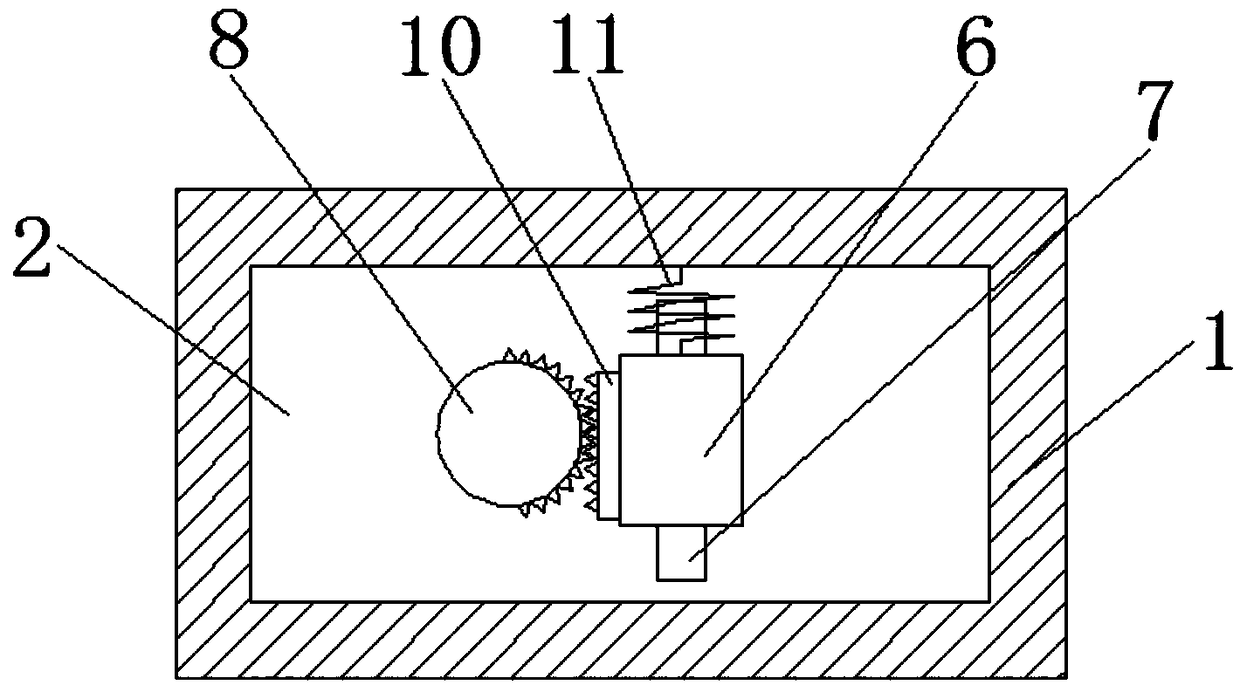

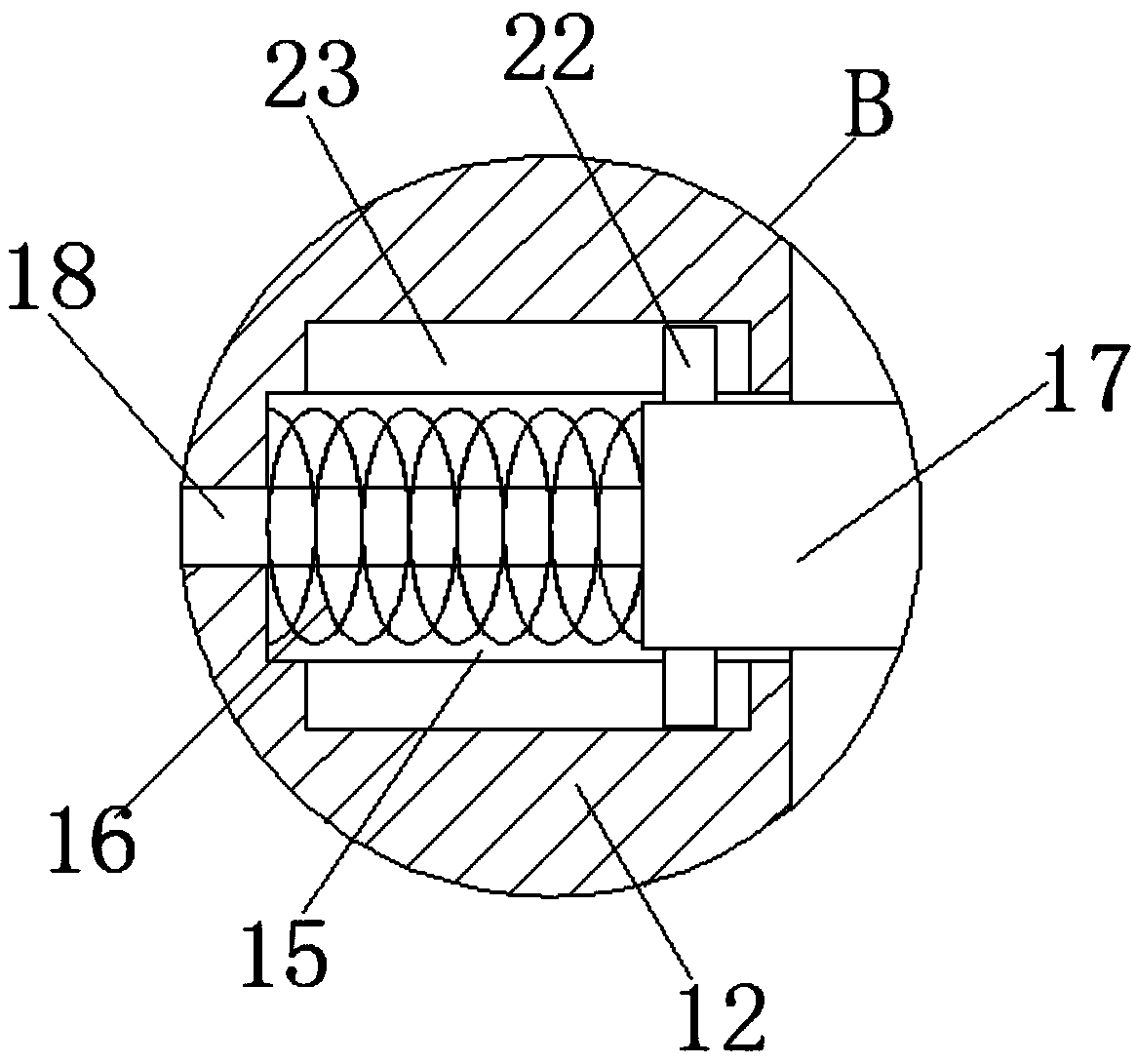

Brush device used for donkey breeding

The invention discloses a brush device used for donkey breeding. The device includes a base, a cavity is formed in the base, the top of the cavity is symmetrically provided with moving tracks, the moving tracks are internally and slidably connected with moving rods, the lower ends of the two moving rods pass through the corresponding tracks, extend to the inside of the cavity and are fixedly connected with a support plate, the center of the lower end of the support plate is fixedly connected with a moving plate, a moving groove is formed in the cavity, the lower end of the moving plate is slidably connected with the inside of the moving groove, the bottom in the cavity is fixedly connected with a drive motor, the output end of the drive motor is connected with a special-shaped gear througha coupler, the side, near the drive motor, of the moving plate is fixedly connected with a rack meshed with the special-shaped gear, and the vertical side wall of one side of the moving plate is fixedly connected with a tension spring. The device is used for brushing the donkey's body surface repeatedly, saves time and labor, has a good brushing effect, is convenient to use and is convenient forbrushing donkeys of different body types.

Owner:兴仁县欣源生态种养殖有限公司

Dispensing viscosity adjustable neutral potent water-soluble paint stripper

The invention discloses a dispensing viscosity adjustable neutral potent water-soluble paint stripper, which is characterized by comprising the following raw materials based on the mass of 1 kilogram: 100 to 600 milliliters of methylene dichloride, 100 to 600 milliliters of phenol, 50 to 400 milliliters of weakly alkaline deionized water solution, 1 to 10 grams of industrial paraffin, 1 to 15 milliliters of surfactant and 1 to 50 grams of thickening agent, wherein the raw materials can be used by uniform mixing. The dispensing viscosity adjustable neutral potent water-soluble paint stripper has the technical effects that the neutral potent water-soluble paint stripper for stripping an airplane coat is particularly suitable for stripping a high-crossed solvent type epoxy or polyurethane or fluorinated polyurethane coat, and can be directly coated on the surface of a common composite materials of metal material, anodized aluminium, metal plating layer and glass fiber reinforced plastics, carbon fiber and the like for airplanes; and the paint stripping surface after using the paint stripper can be directly recoated after cleaning with a proper solvent and drying, the paint film bonding force is not affected, the repair process is simplified, and the repair cost is saved.

Owner:NANCHANG HANGKONG UNIVERSITY

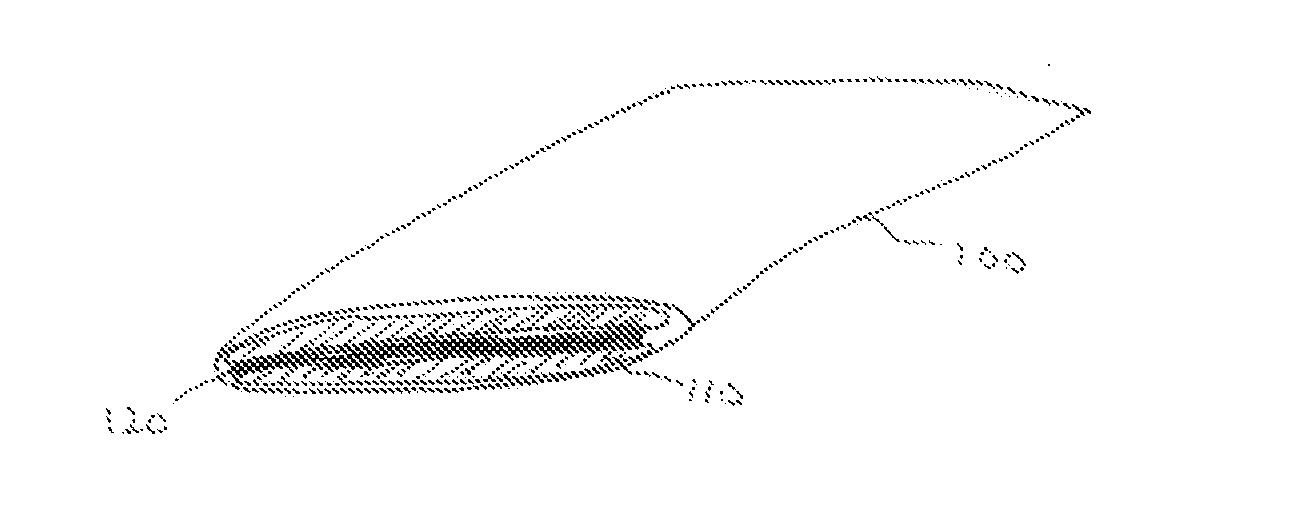

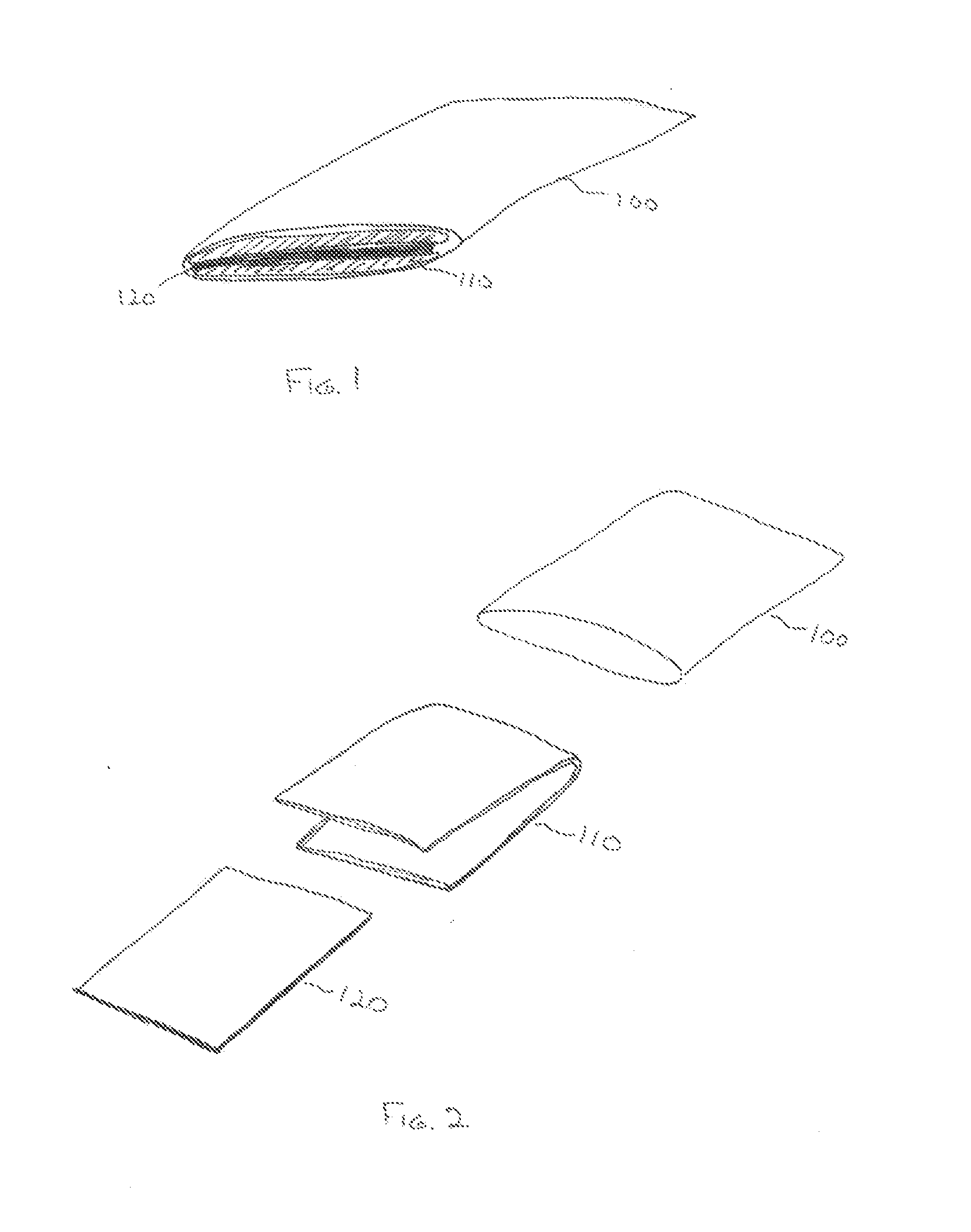

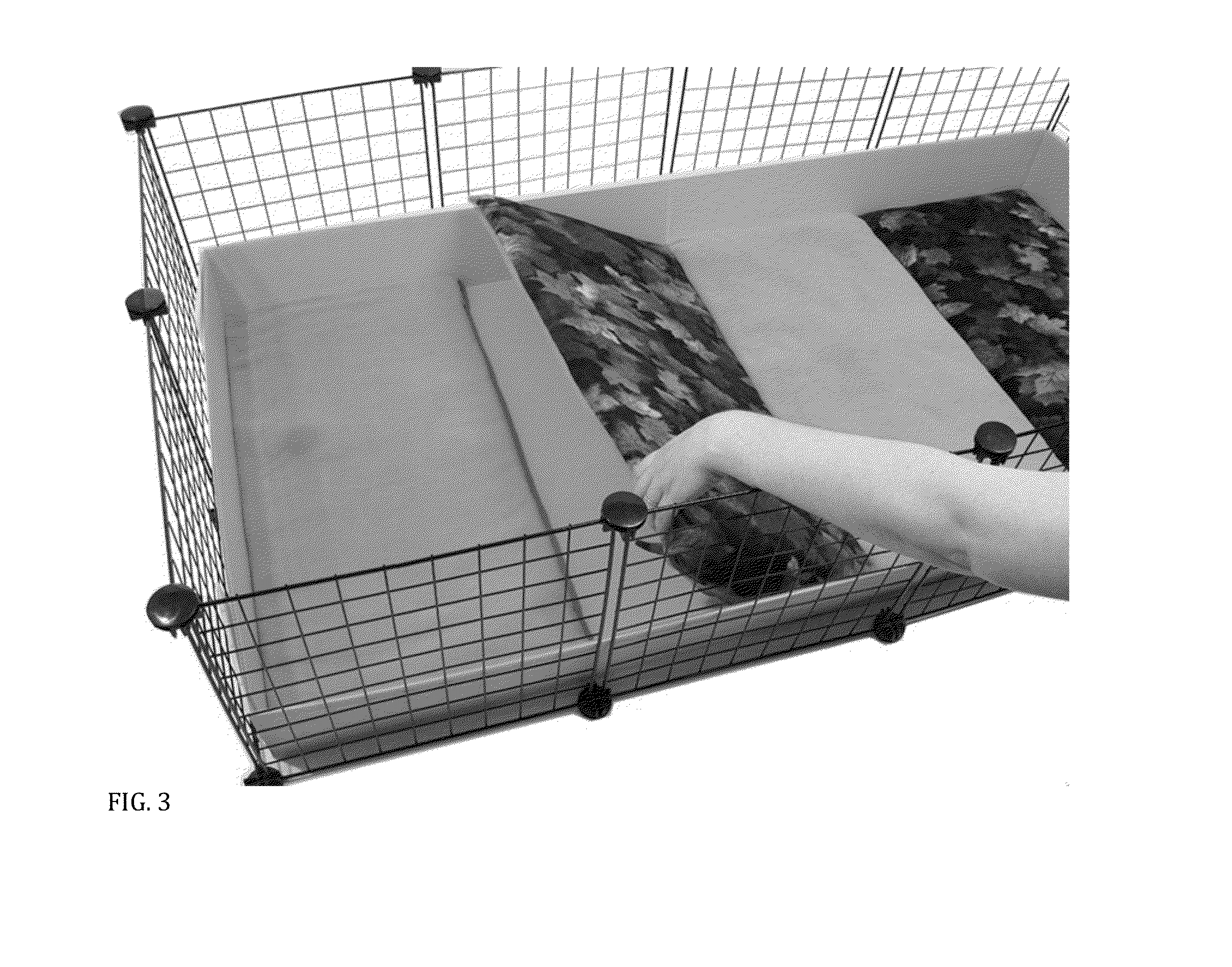

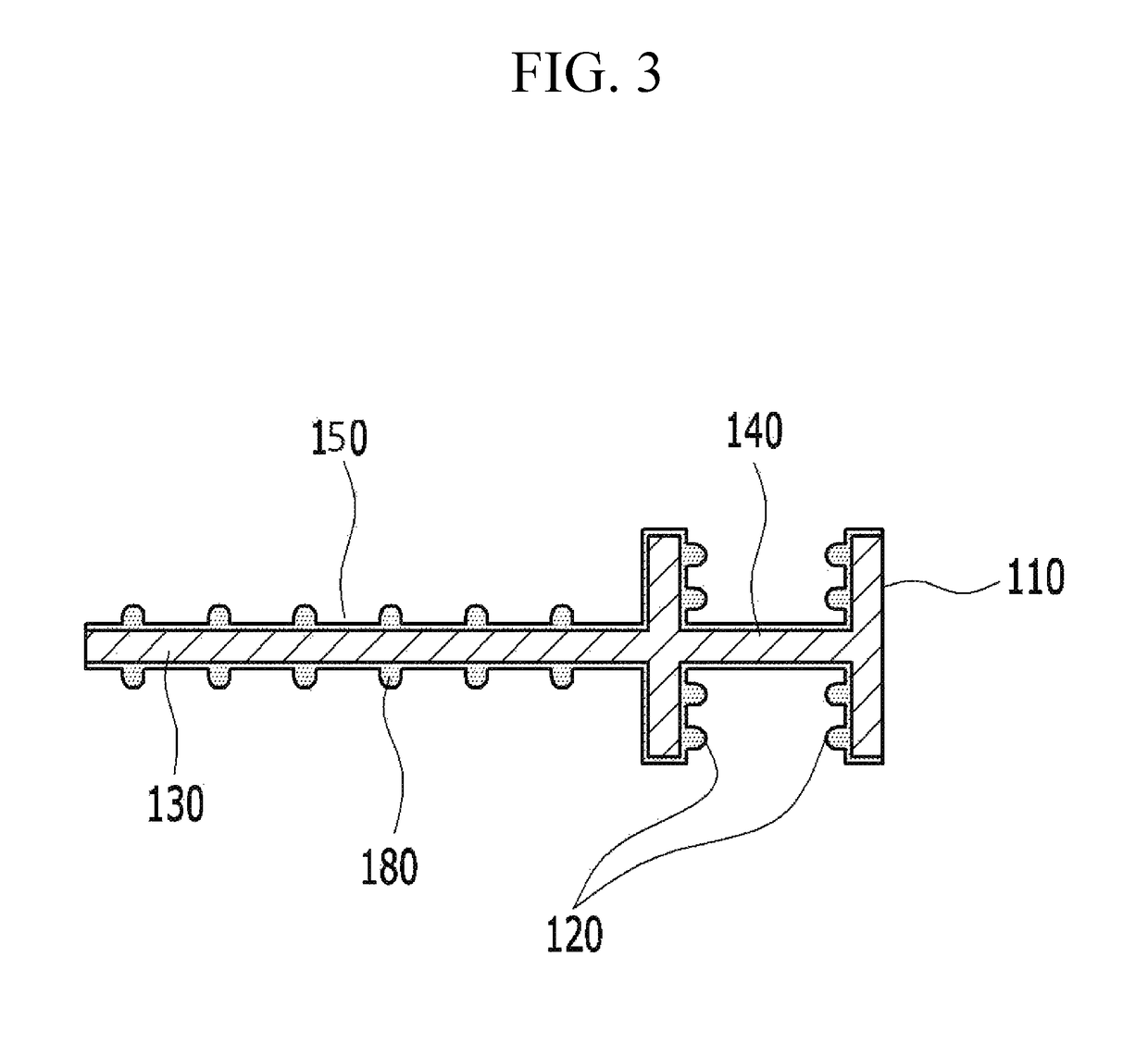

Modular Rigid Small Animal Cage Liner

InactiveUS20150101538A1Easy to replaceEasy to brushAnimal housingOther apparatusSmall animalModularity

A modular bedding system for small animal cages, comprising a plurality of typically washable, absorbent, rigid panels that are safe and appealing to the animal while insulating it from absorbed liquids. Each panel comprises a washable and soft outer layer, an absorbent inner layer, and a rigid central insert. In the preferred embodiment, the panel is symmetrical in that the absorbent inner layer is present on both sides of the rigid insert. The outer layer and the inner absorbent layer(s) can be taken apart and washed separately. The panels may be moved around or flipped, depending on the animal's toilet habits and / or the owner's decor and cage maintenance preferences. The panels may also comprise other features that may be pleasant to an animal, such as extra bedding, a hill, a pocket for burrowing, or other features.

Owner:MURPHY TERESA

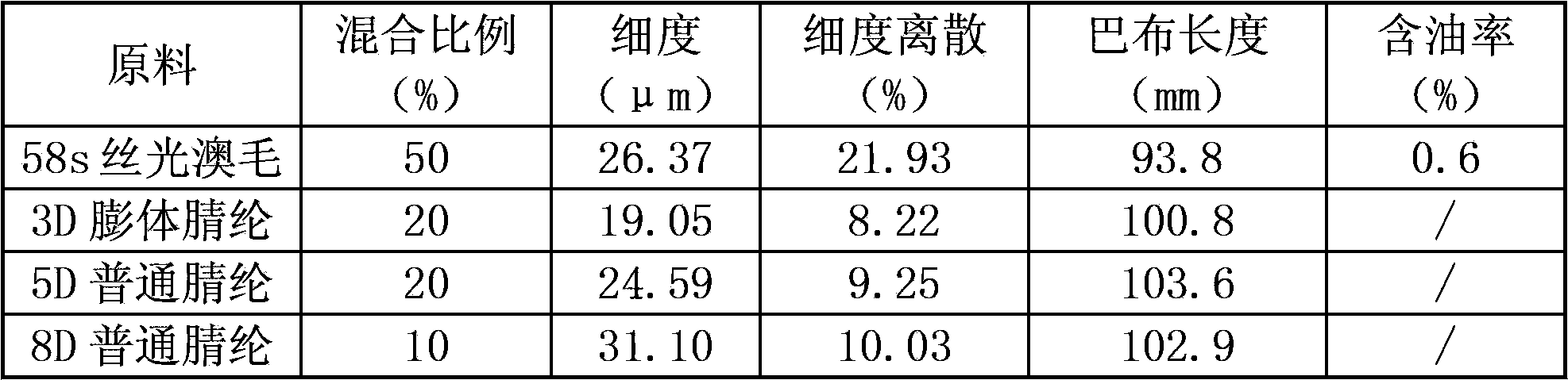

Processing process for artificial fur weaving blended yarns

The invention discloses a processing process for artificial fur weaving blended yarns. The blended yarns are spun from mercerized Australian wool, bulky acrylic and ordinary acrylic. Special treatment methods are adopted for steps of fore-spinning, spinning, post-spinning and the like of the processing process. The processing process has the beneficial effects that the characteristic of fineness controllability of chemical fibers is fully utilized, and acrylic with different finenesses of 3D, 5D and 8D is blended, so that a simulation effect of great fineness variation of natural fur is achieved; in addition, the bulky acrylic is added, and hairiness is produced by yarn expansion treatment after spinning, so that the bulkiness of the yarns is improved, and velvet cutting and brushing are facilitated; an artificial fur fabric woven from the blended yarns has lifelike effects, the cost is greatly lowered, a fur product can be suitable for various consumer groups, particularly for the salaried class.

Owner:天津天纺投资控股有限公司抵羊纺织分公司

Shelling-out and coating device

The invention belongs to the field of shelling-out, coating and corrosion prevention, and particularly provides a shelling-out and coating device which comprises a brush holder cover, a brush holder, a brush head base, an elastic pipe, a push button and a push-press piece. The brush holder cover and the brush head base are connected to the two ends of the brush holder respectively. A storage cavity is formed in the brush head base. A top plate of the brush head base is evenly provided with a plurality of brush hairs and is provided with a plurality of paint outlet holes communicated with the storage cavity respectively. The elastic pipe is located in the brush holder, one end of the brush holder is inserted into the storage cavity and is connected with the top plate, the other end of the brush holder is a free end, and one end of the elastic pipe is evenly provided with a plurality of discharge holes in the circumferential direction. The push button capable of vertically moving and being pushed inwards is arranged on the brush holder, and the push-press piece is arranged on the push button, wherein the push-press piece is used for pushing and pressing the elastic pipe and pushing and pressing the paint in the storage cavity out of the paint outlet holes. The shelling-out and coating device is flexible to assemble, easy and convenient to operate, safe and reliable to use, capable of saving raw materials, and free of polluting the environment.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

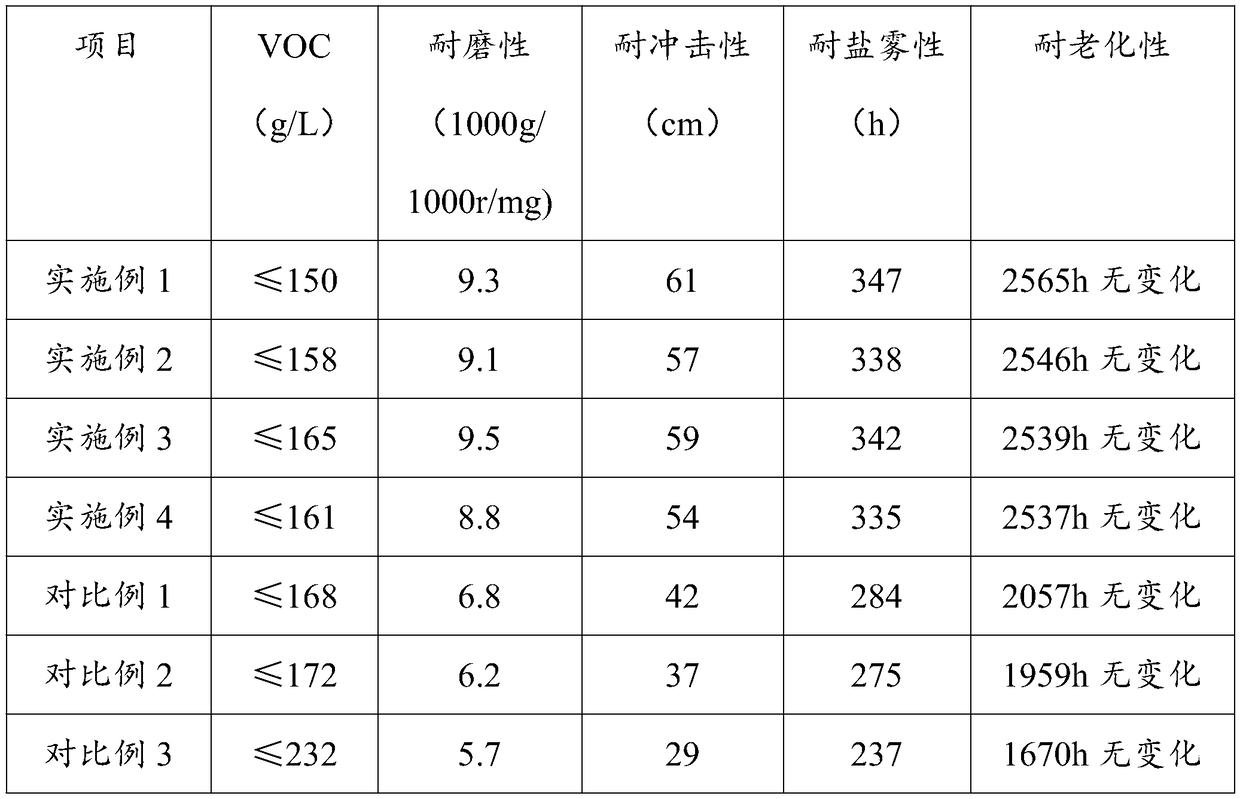

Environmentally-friendly epoxy resin coating for buildings

The invention discloses an environmentally-friendly epoxy resin coating for buildings. The water-based environmentally-friendly coating which is prepared from bisphenol A type epoxy resin modified byhigh-temperature glass flakes used as a base material, environmentally-friendly silica gel filler, a toughening agent and other multiple filler or addition agents are free of residual solvents; raw materials of the environmentally-friendly epoxy resin coating are environmentally-friendly and have low toxicity; the filler can be evenly dispersed; and the environmentally-friendly epoxy resin coatingcomprises the following raw materials in parts by weight: 60 to 90 parts of modified epoxy resin matrix material, 12 to 18 parts of environmentally-friendly silica gel filler, 6 to 15 parts of epoxyreactive diluent, 8 to 13 parts of core-shell structure toughening agent, 4 to 8 parts of sodium methylene bis-naphthalene sulfonate, 2 to 6 parts of carbon black-SiO2 double nanofiller, 3 to 8 partsof polydimethylsiloxane and 32-58 parts of deionized water. A preparation method of the environmentally-friendly epoxy resin coating comprises the following steps of: preparing nanometer slurry, preparing a component A and oscillating a mixed material. The environmentally-friendly epoxy resin coating for buildings has good weather resistance, salt spray resistance and wear resistance, and is suitable as building exterior wall or interior wall coating.

Owner:GANZHOU BENNIU WATERPROOF BUILDING MATERIAL CO LTD

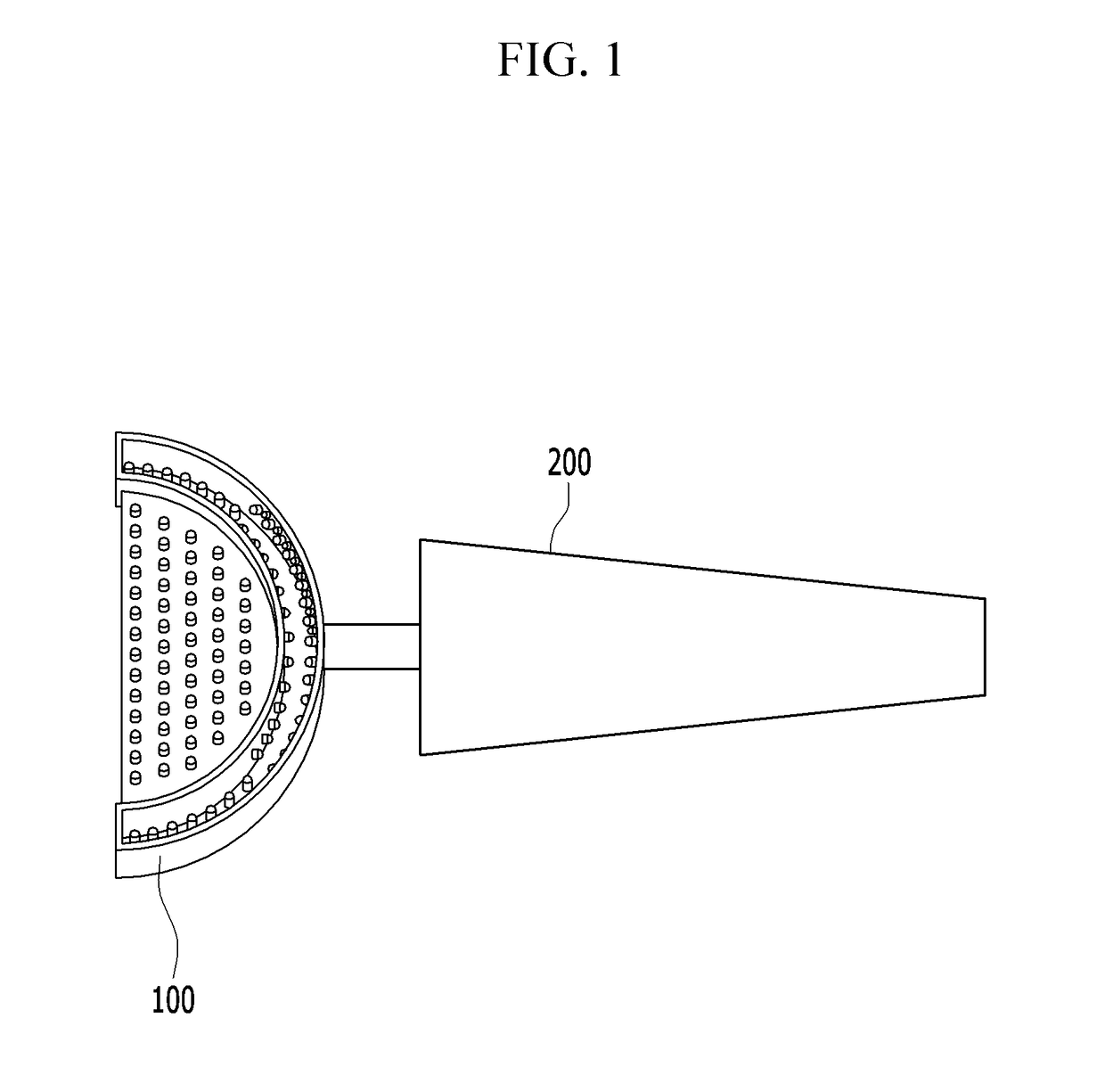

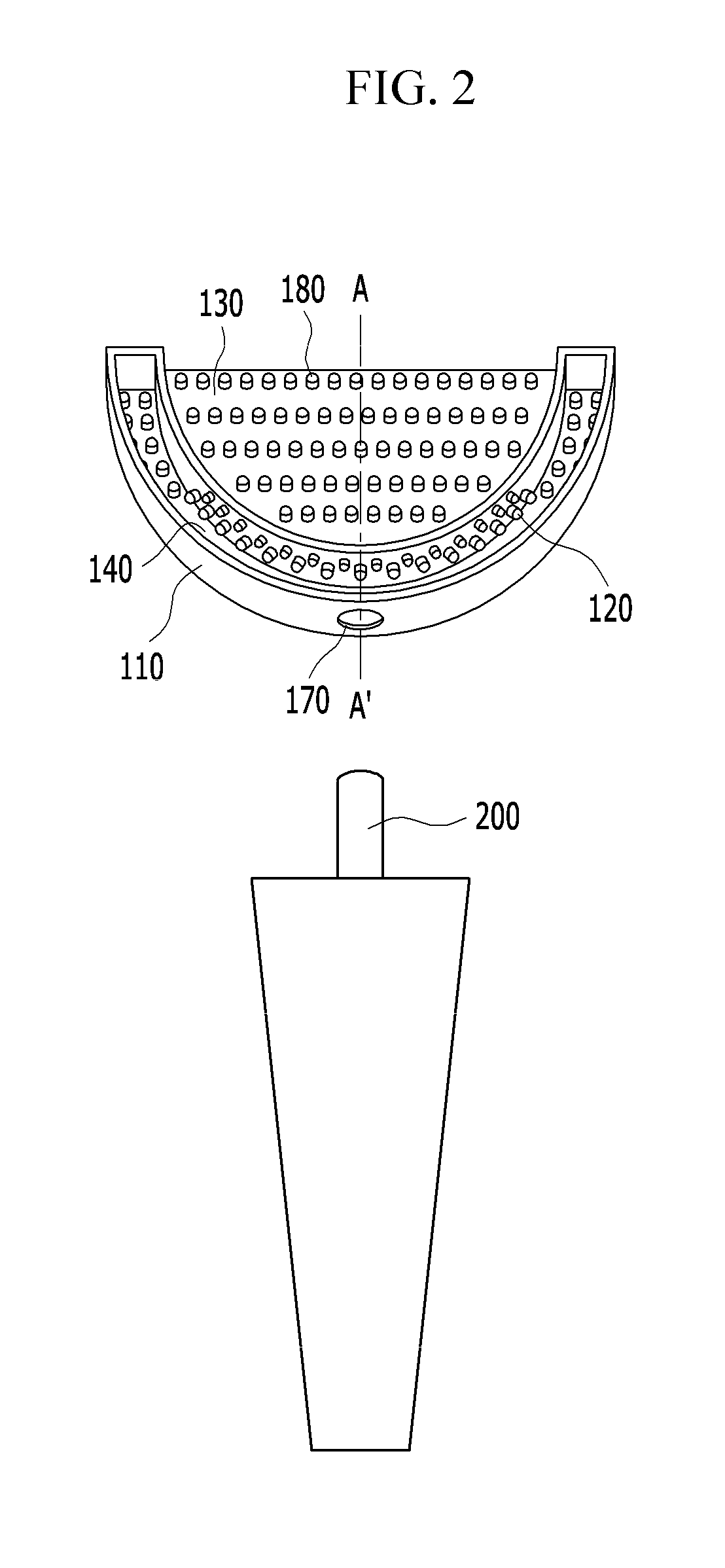

Mouthpiece type of electric toothbrush

InactiveUS10143296B2Simple structureReduce manufacturing costBristleTooth cleaningToothpasteEngineering

A mouthpiece type of electric toothbrush is disclosed. The mouthpiece type of electric toothbrush includes: a toothbrush head that includes a mouthpiece-shaped housing which is provided with upper and lower openings and a blocked intermediate portion, wherein a plurality of first silicone protrusions may be arranged to be spaced apart from each other by a predetermined interval along an inner wall surface of the housing in the upper and lower openings; and a main body that is detachable from the toothbrush head and transmits a vibration to the toothbrush head. The toothbrush head may further include a water-containing pad and an air layer provided at a lower portion of a silicone layer thereof, thus it is possible to easily spread toothpaste through the water-containing pad and to correspond to a size of a user's mouth or oral cavity by adjusting an air amount of the air layer.

Owner:YUSUNG SEMICON CO LTD

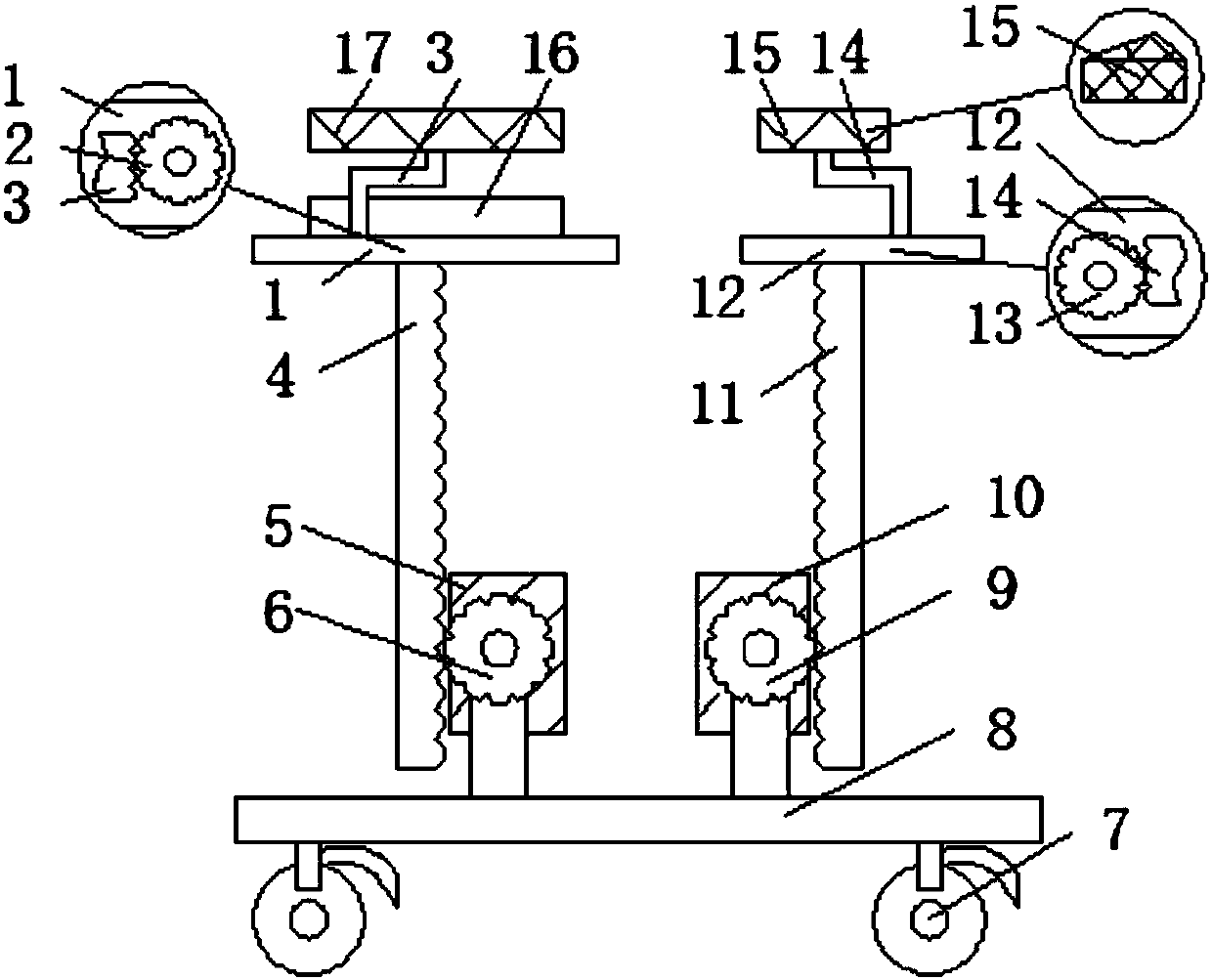

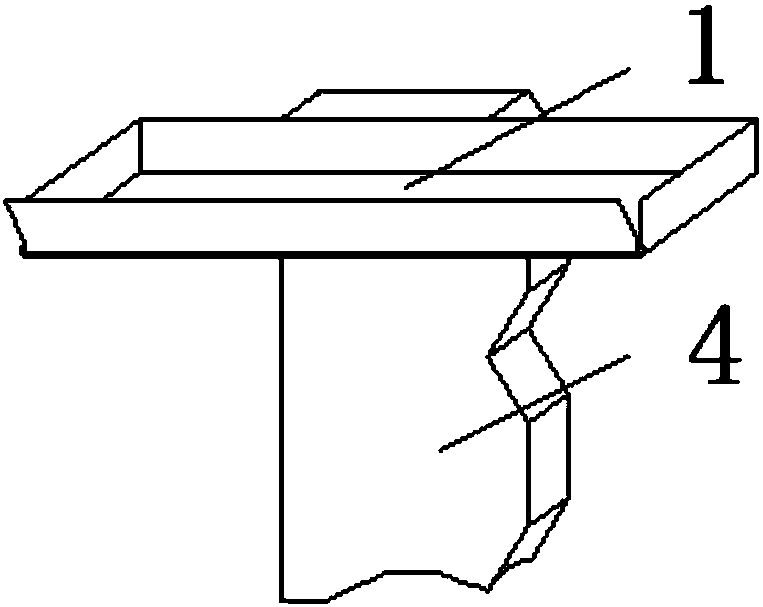

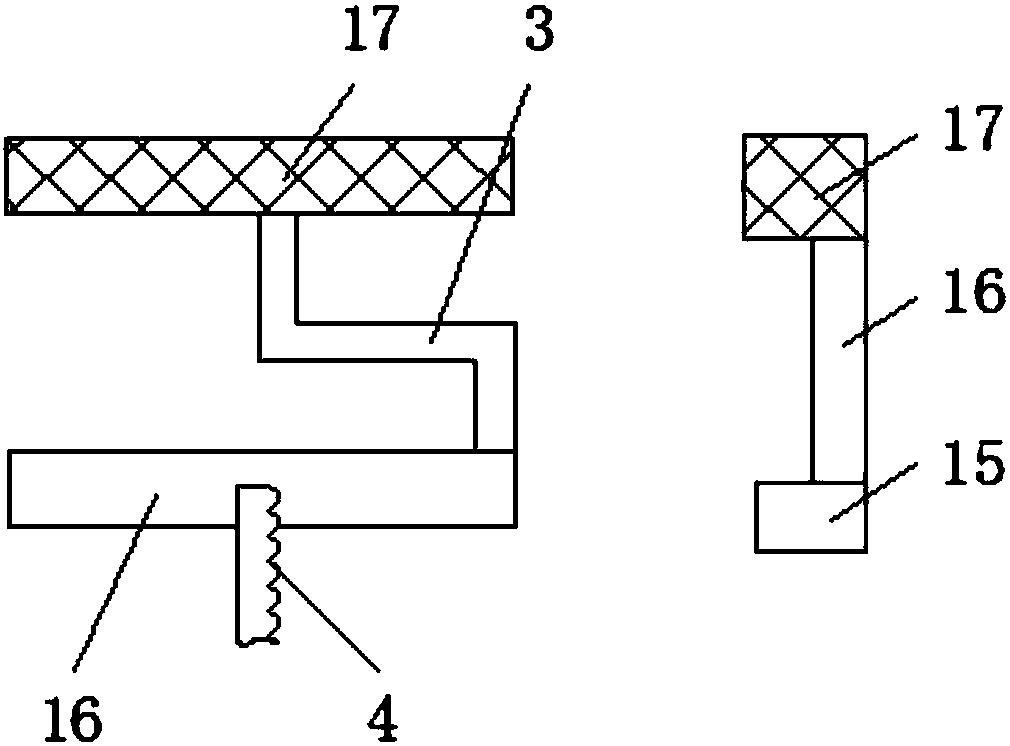

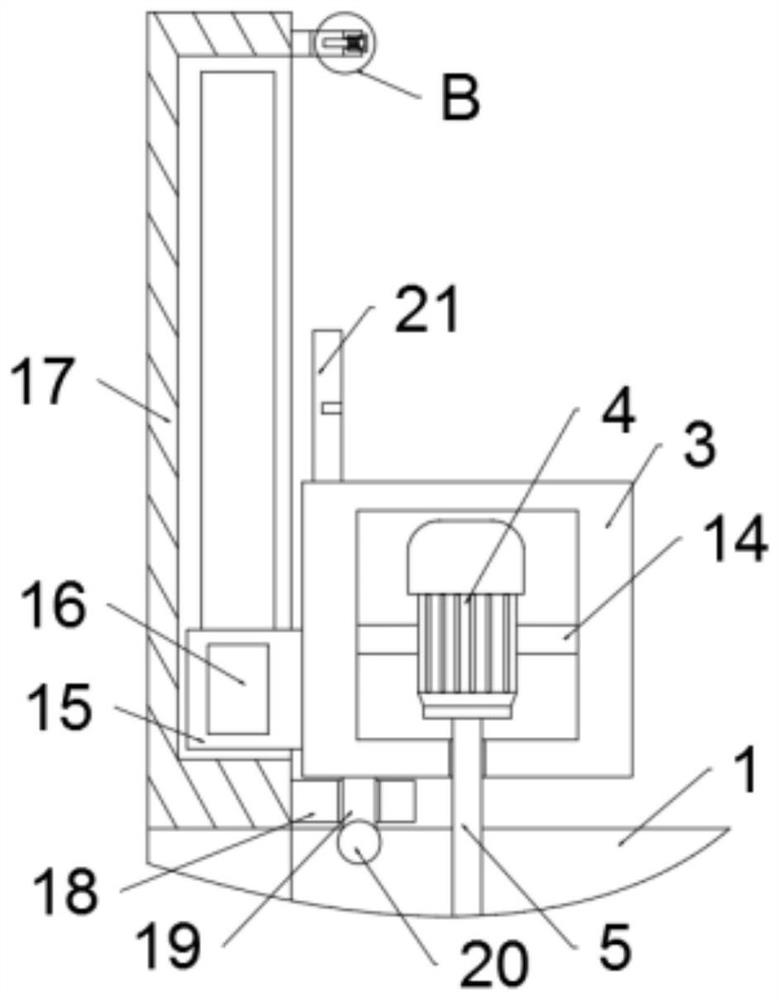

Wall surface brushing device for decoration

The invention discloses a wall surface brushing device for decoration, which includes a triangular roller and a roller. The bottom of the bottom plate is provided with universal wheels, and the top of the bottom plate is connected with a second gear through a connecting column. The second gear Connected to the first bidirectional drive motor through the rotating shaft, one side of the second gear is meshed with the first rack, and a paint collecting plate is arranged at the upper end of one side of the first rack, and the first rack A first paint placement box is provided at the upper end position on the other side, and a first gear is arranged inside the first paint placement box. In the present invention, a paint collecting plate is arranged at the lower position of the roller, and the paint collecting plate is smaller than the width of the roller. When the roller brushes the wall surface, the paint dripped on the roller can just be collected by the paint collecting plate. The roller can reuse the paint collected on the paint collecting plate by rotating to make full use of the paint and save resources.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

Shorn-pile elastic fabric and manufacturing process

ActiveCN110359166APrevent peelingEasy to brushWoven fabricsArchitectural engineeringStructural engineering

The invention discloses a shorn-pile elastic fabric and a manufacturing process. The fabric comprises more than two woven layers, and each woven layer comprises wefts and warps, and adjacent woven layers share the warps which are elastic warps. More than one weft of an adjacent woven layer of a bottom woven layer is positioned among adjacent wefts of the bottom woven layer, and the wefts of the bottom layer are provided with shorn pile. The process includes: (1) beating the warps, and stretching the warps; (2) beating the wefts according to weft knitting requirements; (3) after knitting is finished, enabling the adjacent wefts except for the wefts of the bottom layer to get close under the elastic force of the warps; (4) fleecing the wefts of the bottom layer; (5) cutting to form the shorn-pile elastic fabric. The shorn-pile elastic fabric and the manufacturing process have advantages that a shorn-pile layer and a surface woven layer are knitted into a whole in a knitting process and less prone to stripping, and the fabric is high in softness and elasticity.

Owner:广州天思品汇实业有限公司

Cheese egg tarts and making method thereof

InactiveCN105432754AImprove health factorKeep the sweetnessDough treatmentBakery productsBiotechnologySweetness

The invention provides cheese egg tarts. The cheese egg tarts are made from, by weight, 2-10 parts of cheese, 1-5 parts of cream cheese, 5-20 parts of liquorice, 0.5-2 parts of butter, 0.5-2 parts of plain milk, 0.3-1.5 parts of custard MPCN, 1-5 parts of yellow butter, 0.1-1 part of evaporated milk and 3-8 parts of flour. White granulated sugar or other sugar is not used in the cheese egg tarts, liquorice is adopted instead, so that sweet taste is preserved and sugar content is reduced, and then the health factor is increased after consumers eat the cheese egg tarts.

Owner:MILLION HARVEST DONGGUAN COMPANY

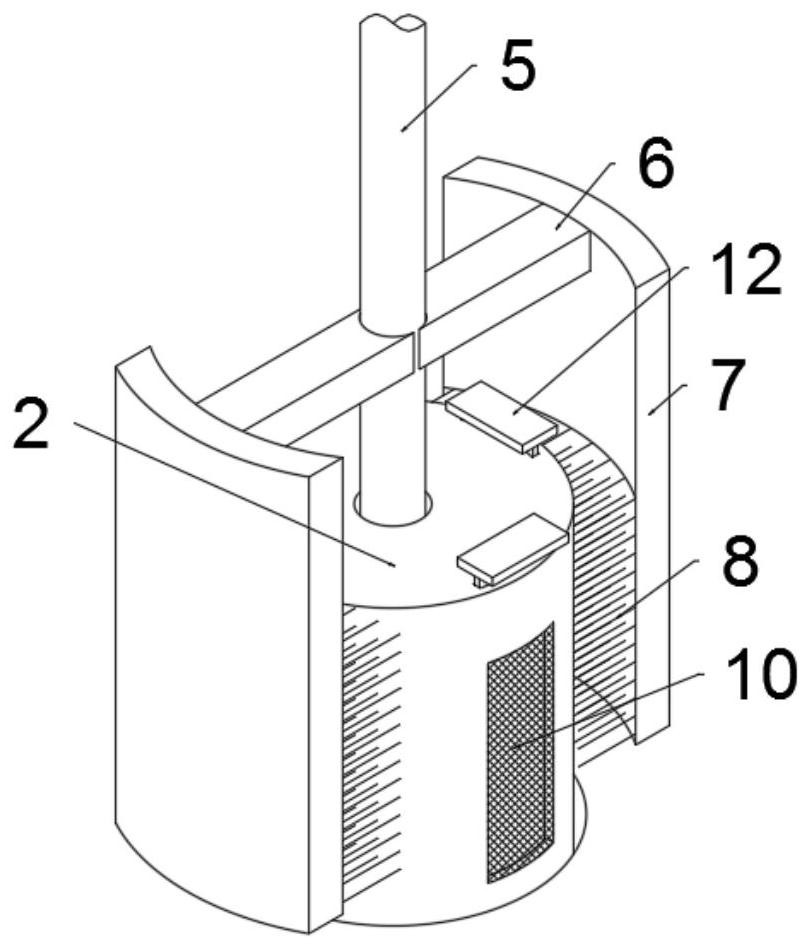

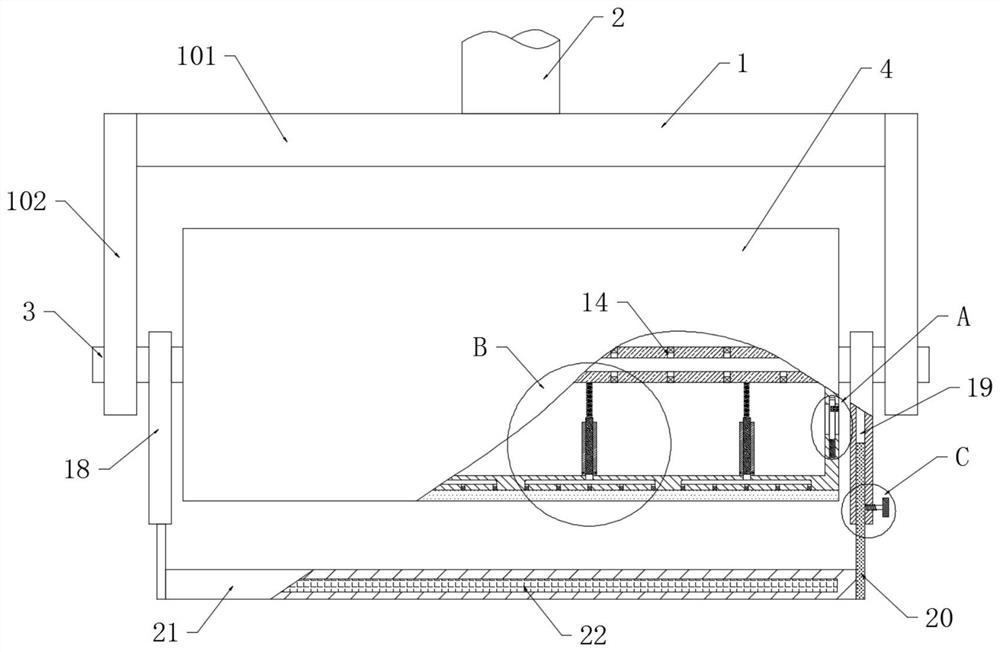

Cleaning device for fish and shrimp culture pond and cleaning method thereof

PendingCN113711979AImprove work efficiencyPrevent spoilagePisciculture and aquariaStationary filtering element filtersElectric machineryInternal cavity

The invention discloses a cleaning device for a fish and shrimp culture pond and a cleaning method thereof. The cleaning device is characterized in that a mounting groove is formed in the bottom end of the inner wall of a pond body, a main drainage pipe is fixedly connected to an inner cavity of the mounting groove in a penetrating mode, a mounting box is arranged over the main drainage pipe and provided with a motor, and the output end of the motor is in transmission connection with a rotating shaft; connecting blocks are fixedly connected to the two sides of the outer wall of the rotating shaft, an annular block is fixedly connected to one side of each connecting block, a plurality of bristles are distributed and embedded in one side of the inner wall of each annular block, a rubber block is fixedly connected to one side of the inner wall of each annular block, and a filter screen is embedded in an inner cavity of a drainage groove. According to the device, the motor, the rotating shaft, the connecting blocks, the annular blocks, the bristles and the rubber blocks are matched, so that the surface of the filter screen is brushed and scraped, impurities on the filter screen are removed conveniently, blockage of the filter screen is prevented conveniently, drainage of the pond body is facilitated, and the working efficiency is improved conveniently.

Owner:谈启龙

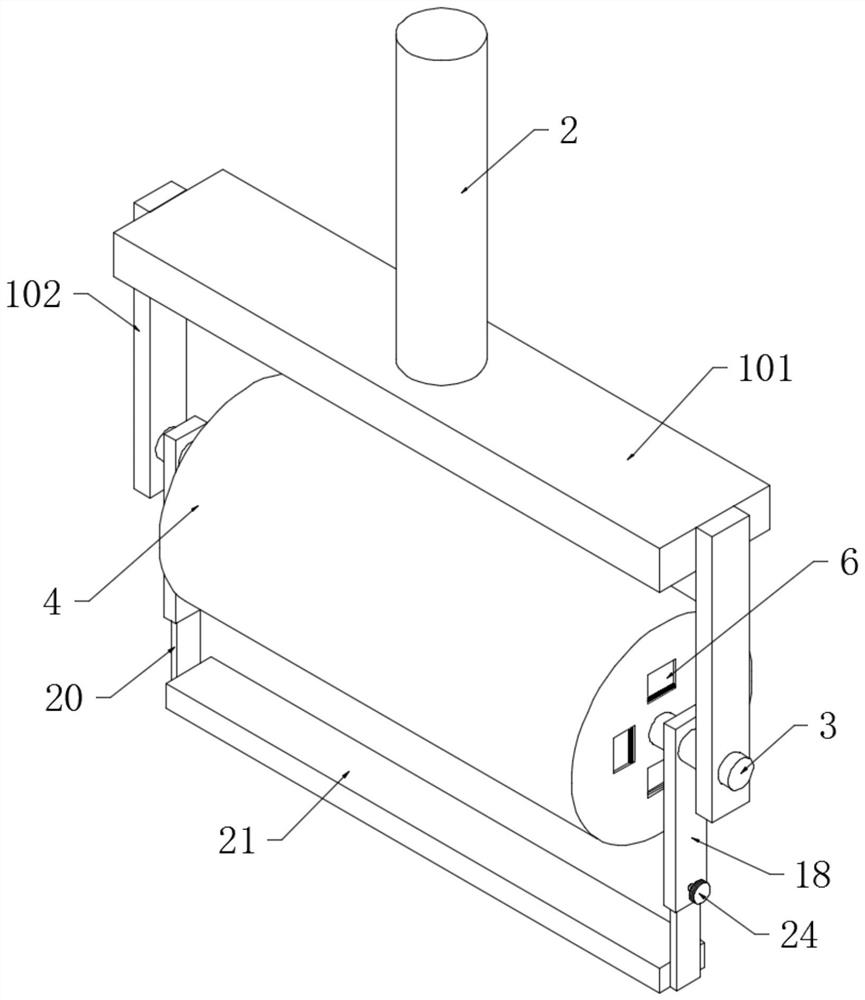

Paint storage type paint brushing roller capable of automatically adjusting paint outlet amount

The invention discloses a paint storage type paint brushing roller capable of automatically adjusting the paint output amount. The paint storage type paint brushing roller comprises a U-shaped roller frame, the roller frame is formed by connecting a fixing plate and two supporting plates, the two ends of the fixing plate are respectively, vertically and fixedly connected with the two supporting plates, the ends, away from the fixing plate, of the two supporting plates are rotationally connected with a hollow rotating shaft through bearings, the rotating shaft is coaxially and fixedly connected with a hollow paint brushing roller, and the outer ring face of the paint brushing roller is connected with a circle of roller felt. The paint brushing roller has the advantages that in the paint brushing process, when the paint brushing roller rolls on a wall surface, cylinders in the paint brushing roller can sequentially pass through the lowest point of the paint brushing roller, piston rods in the cylinders slide in the direction of the rotating shaft through magnetism generated by magnetic strips in gravity plates, paint suction is completed under the action of a one-way valves, after the paint is far away from the magnetic strip, paint is pressed into the roller felt through the elastic force of a second spring, so that the paint brushing roller can brush the wall surface all the time, and the paint brushing efficiency is greatly improved.

Owner:湖州力卓机械设备技术开发有限公司

Water soluble paint remover

InactiveCN105295513AImprove water retentionGood storage stabilityChemical paints/ink removersParaffin waxParaffin oils

The invention provides a water soluble paint remover. The water soluble paint remover is characterized in that 1kg of the water soluble paint remover is prepared from the following raw materials: 300-400ml dichloromethane, 200-300ml phenol, 300-400ml weakly alkaline deionized water solution, 15-20g of industrial paraffin, 20-25ml surfactant and 1-20g of a thickening agent. The water soluble paint remover has the technical effects that coating can be directly carried out again after appropriate solvent cleaning and drying are carried out, a binding force of a paint film is not influenced, a repairing process is simplified, and the repairing cost is reduced.

Owner:关勇河

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

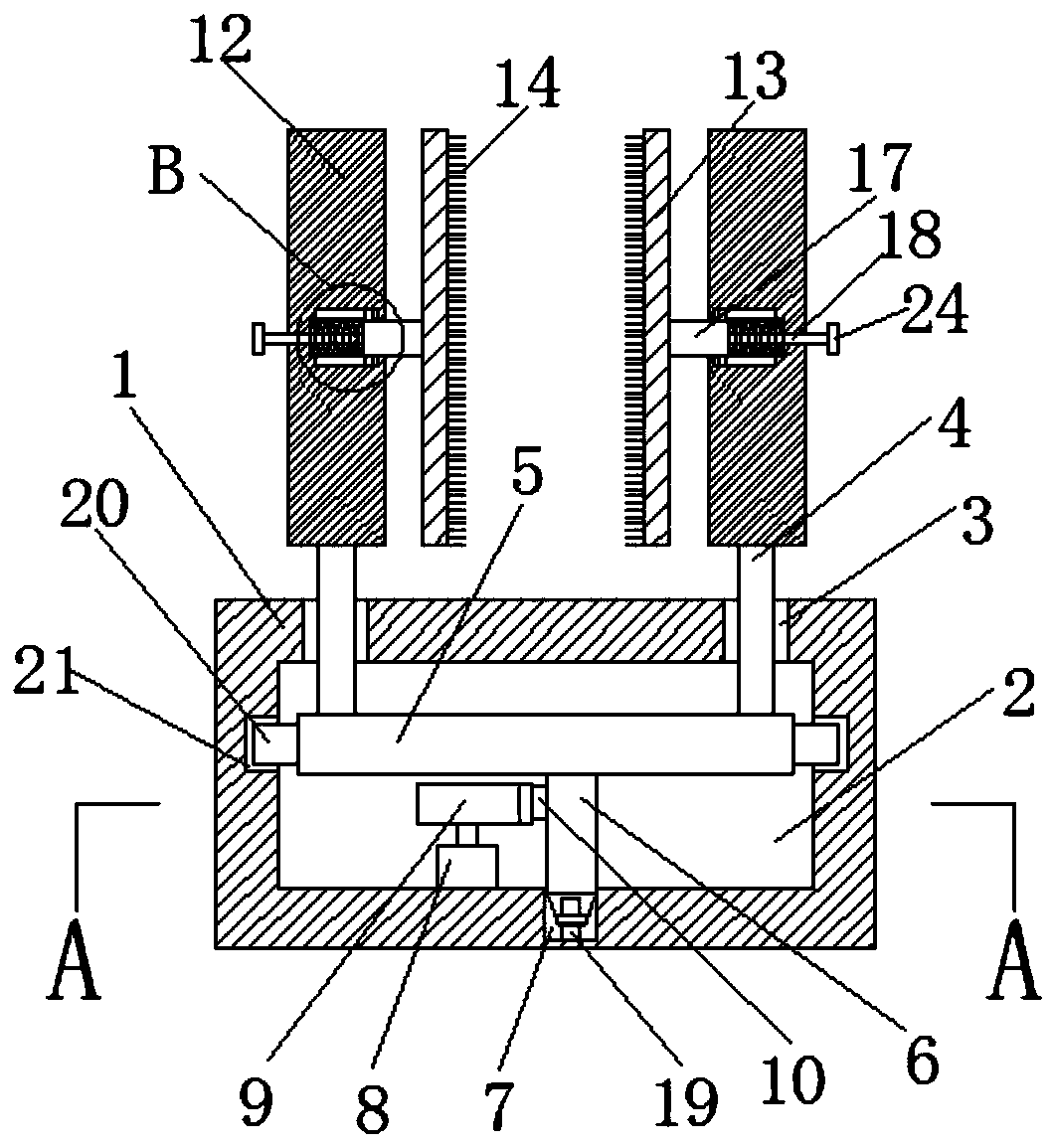

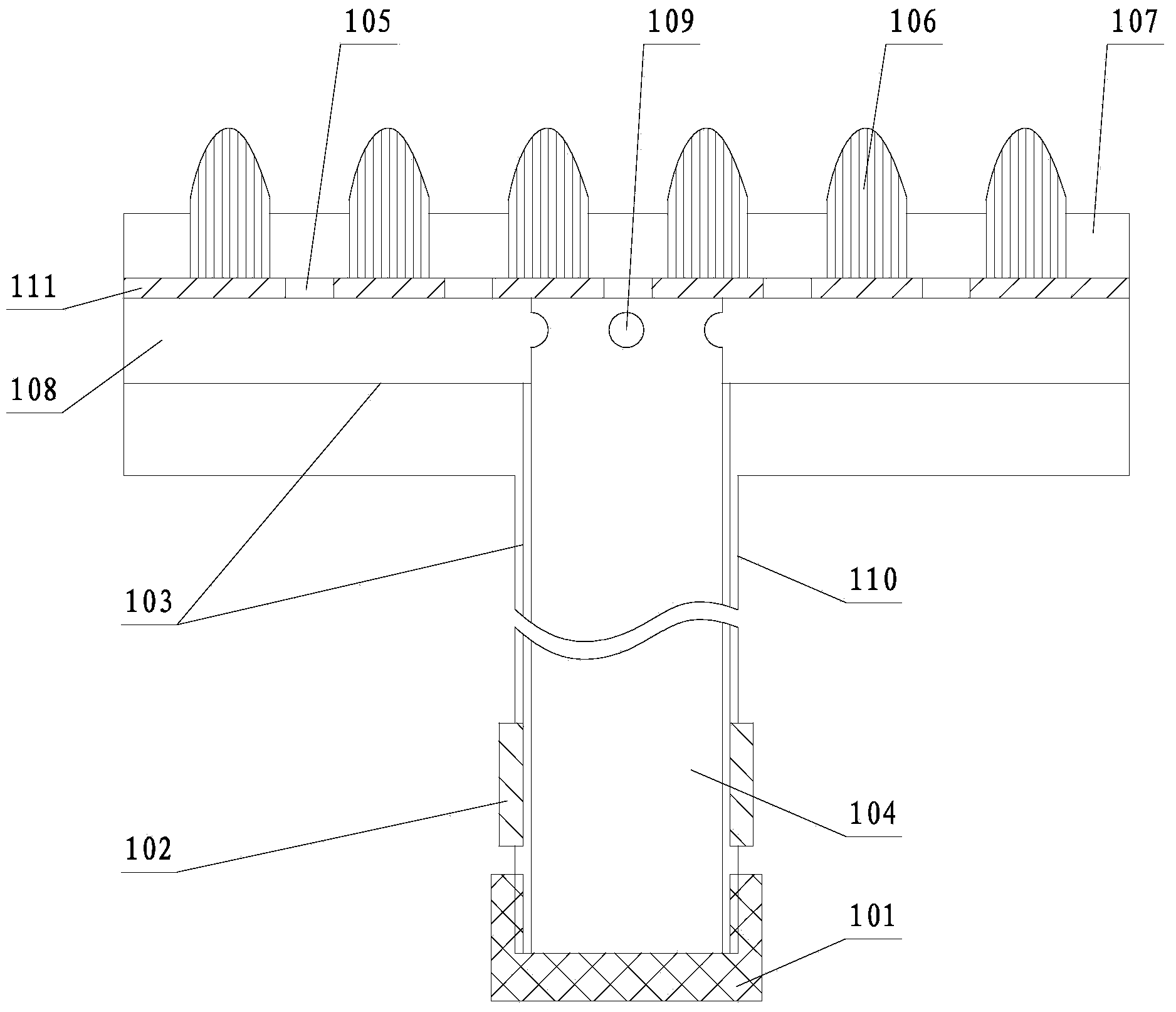

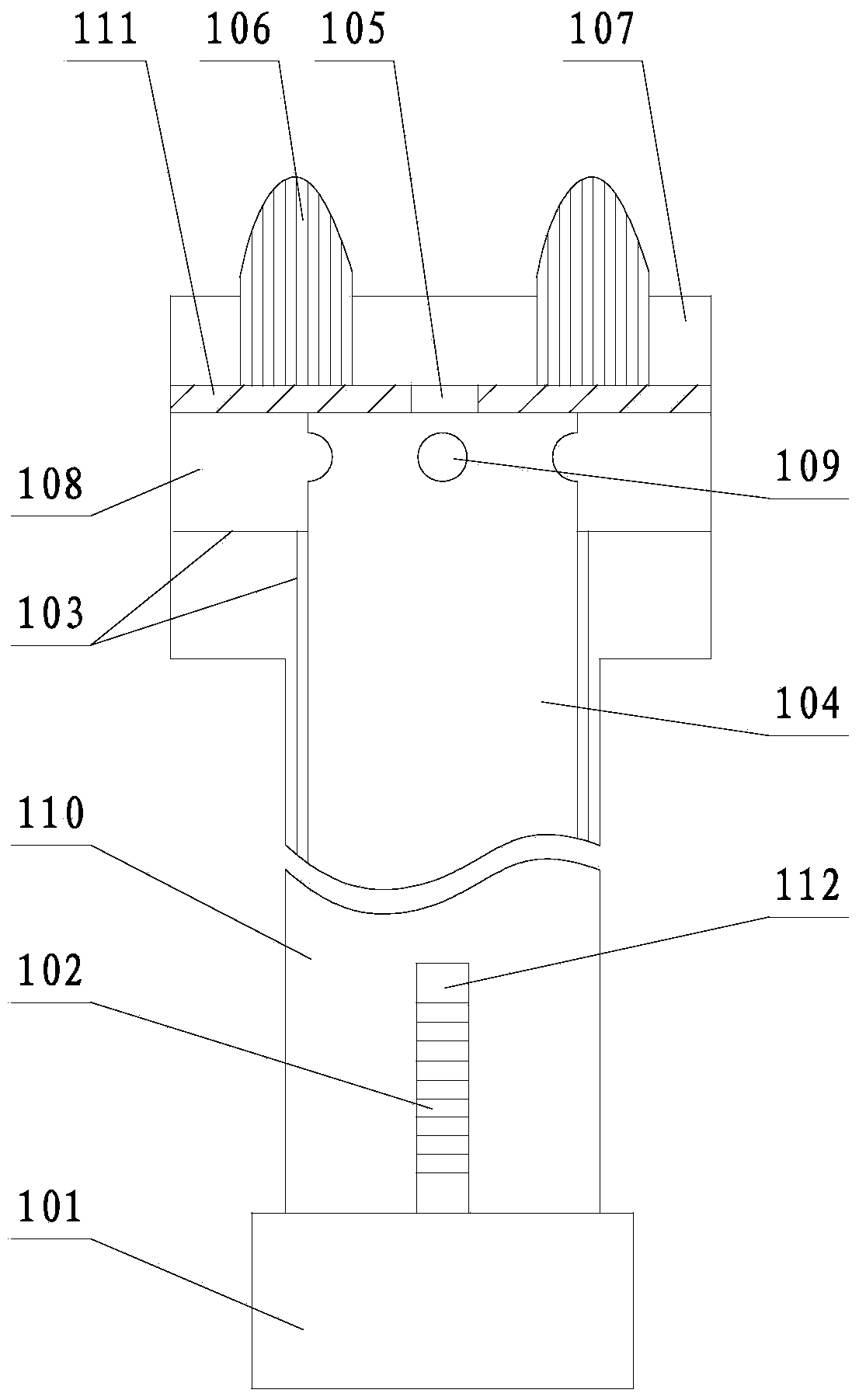

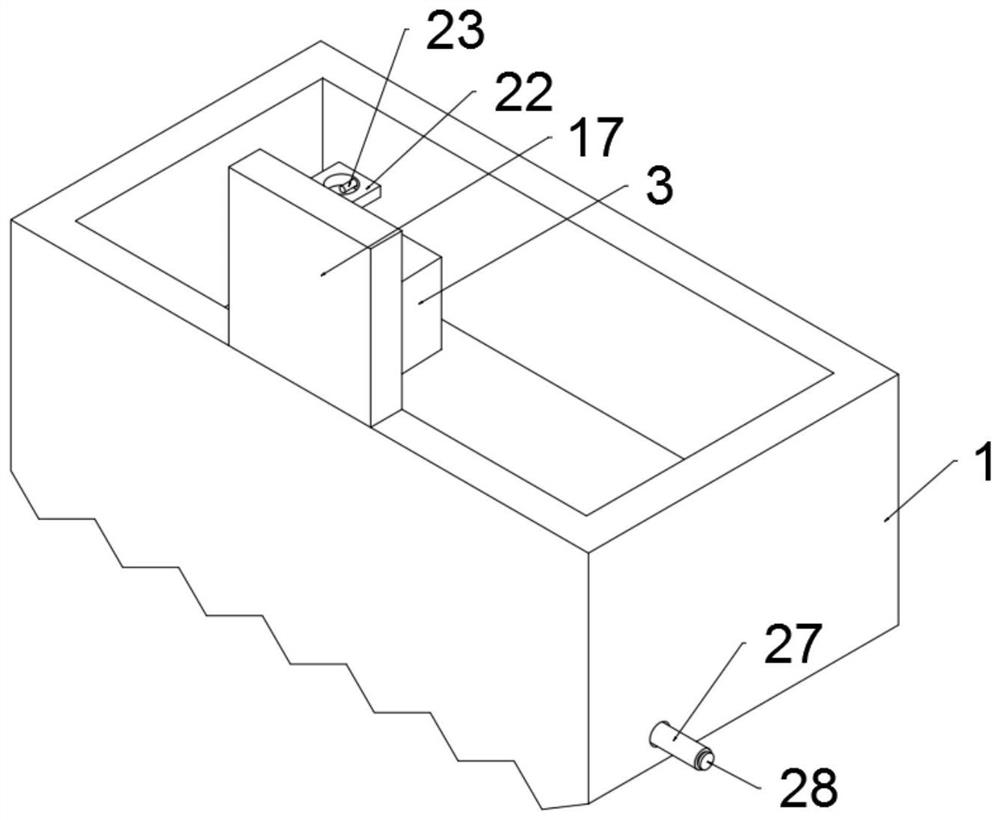

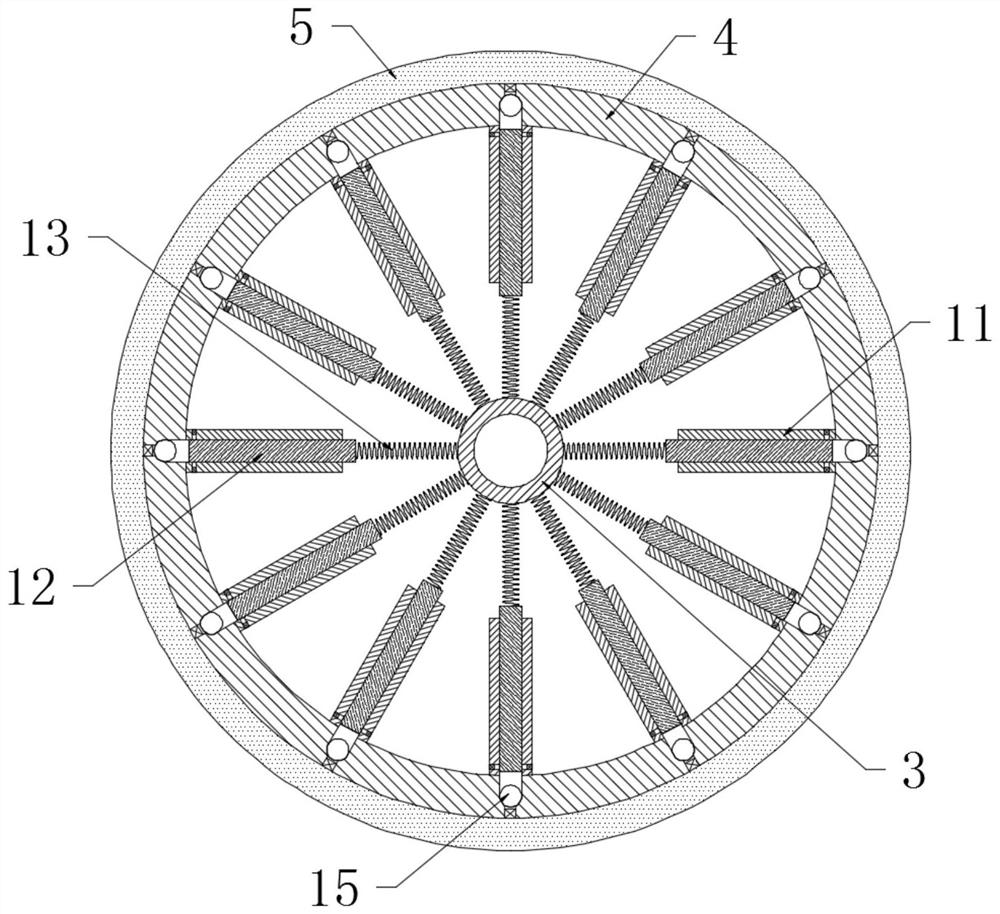

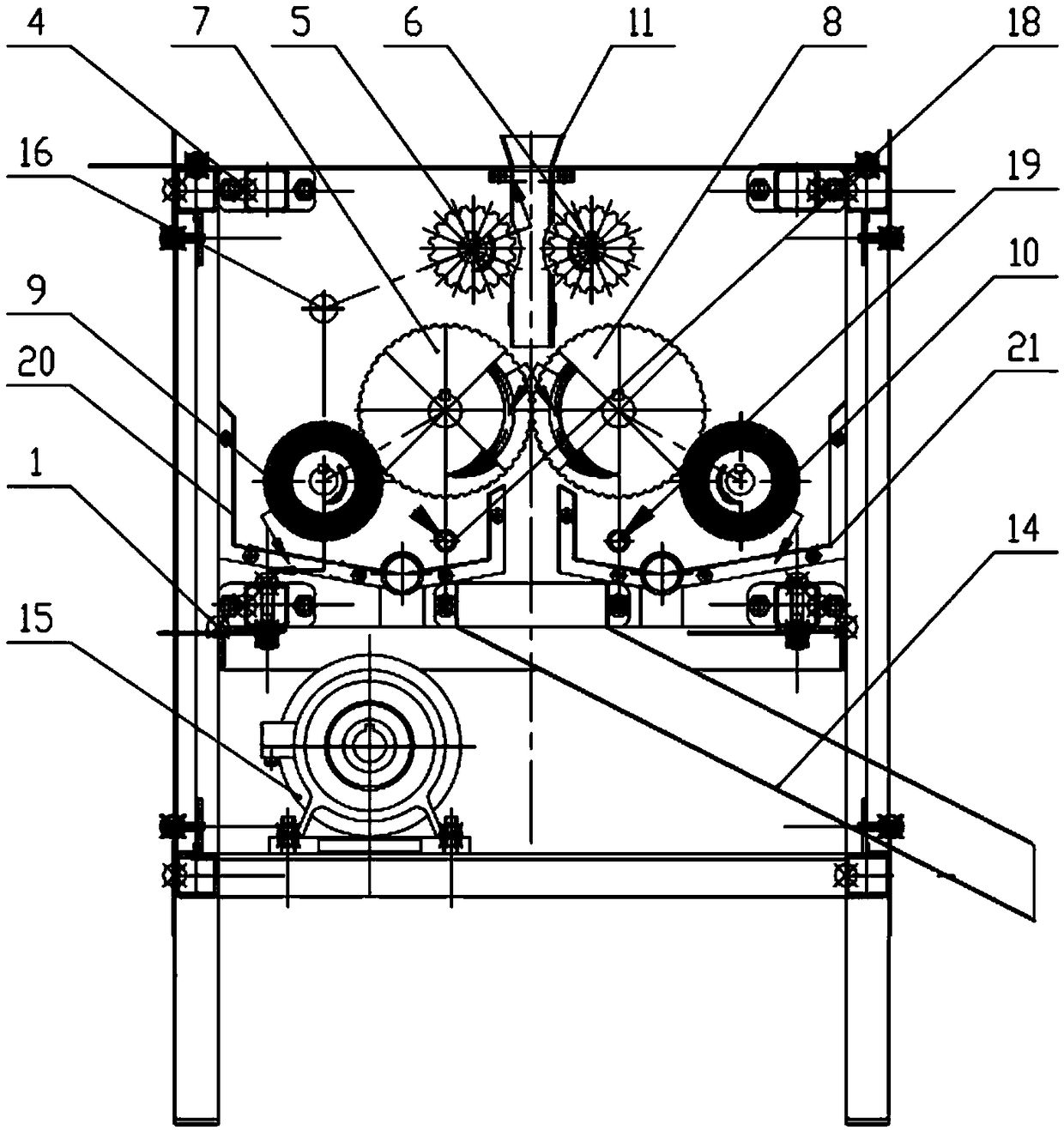

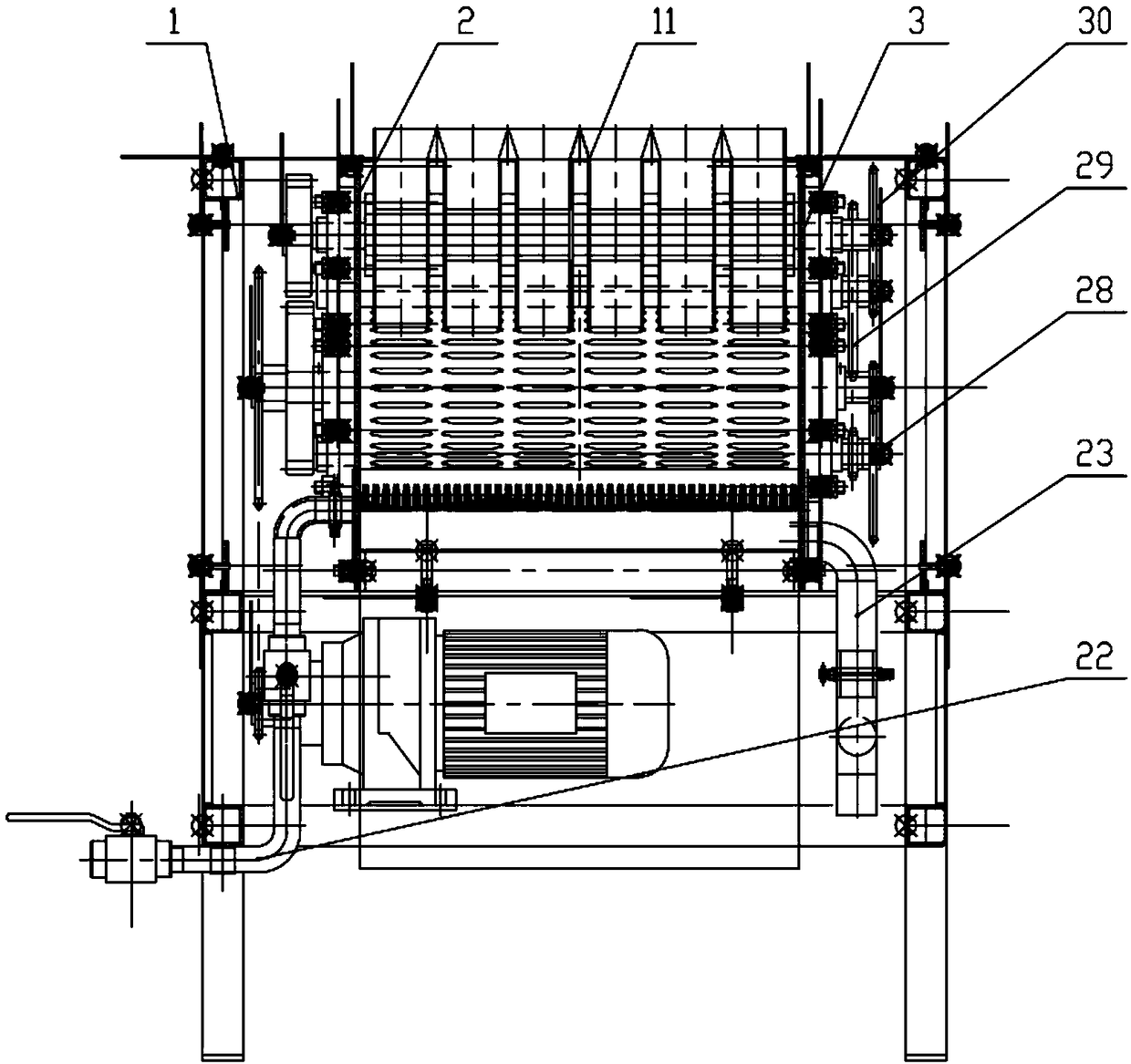

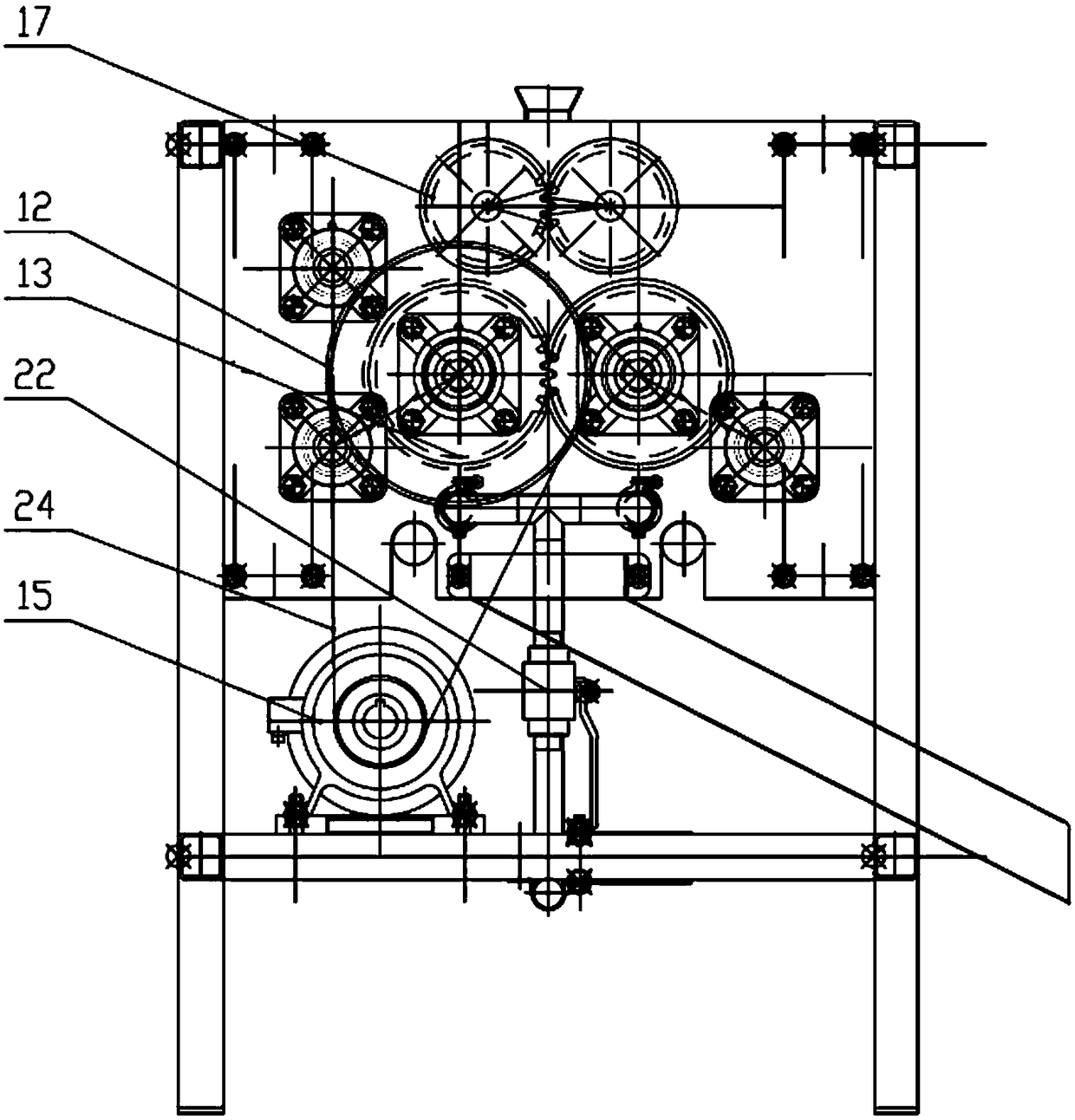

Potato product shaping equipment

PendingCN108813476AAvoid breakingEasy to cleanCleaning using toolsCleaning using liquidsEngineeringMechanical engineering

The invention provides shaping equipment of potato products namely fish-shaped potato noodles. The shaping equipment comprises a machine frame (1), a mold pressing cavity front side plate (2), a moldpressing cavity rear side plate (3), side plate coupling rods (4), a mold pressing forming component and a feeding hopper (11), wherein the mold pressing forming component is fixed to the machine frame (1), and comprises a left pressing mold roller (7), a right pressing mold roller (8), a left feeding roller (5), a right feeding roller (6), a left brush roller (9) and a right brush roller (10); the left pressing mold roller (7), the right pressing mold roller (8), the left feeding roller (5), the right feeding roller (6), the left brush roller (9) and the right brush roller (10) are respectively driven by a driving component through chain transmission and gear transmission, and are fixed to the mold pressing cavity front side plate (2) and the mold pressing cavity rear side plate (3) through spherical surface bearing seats; the mold pressing cavity front side plate (2) and the mold pressing cavity rear side plate (3) are assembled through the side plate coupling rods (4) to be fixed onthe machine frame (1); the left feeding roller (5) and the right feeding roller (6) are arranged above the left pressing mold roller (7) and the right pressing mold roller (8), synchronously rotate in the opposite directions at a certain distance, and are made from polytetrafluoroethylene materials; and smooth grooves are milled on each cylindrical surface.

Owner:SINOMACH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com