Shelling-out and coating device

A painting and brushing technology, applied in the fields of painting, anti-corrosion, and painting, can solve the problems affecting production safety, limited brushing area, limited painting tools and coatings, etc., to achieve safe and reliable use, saving raw materials, and assembling flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

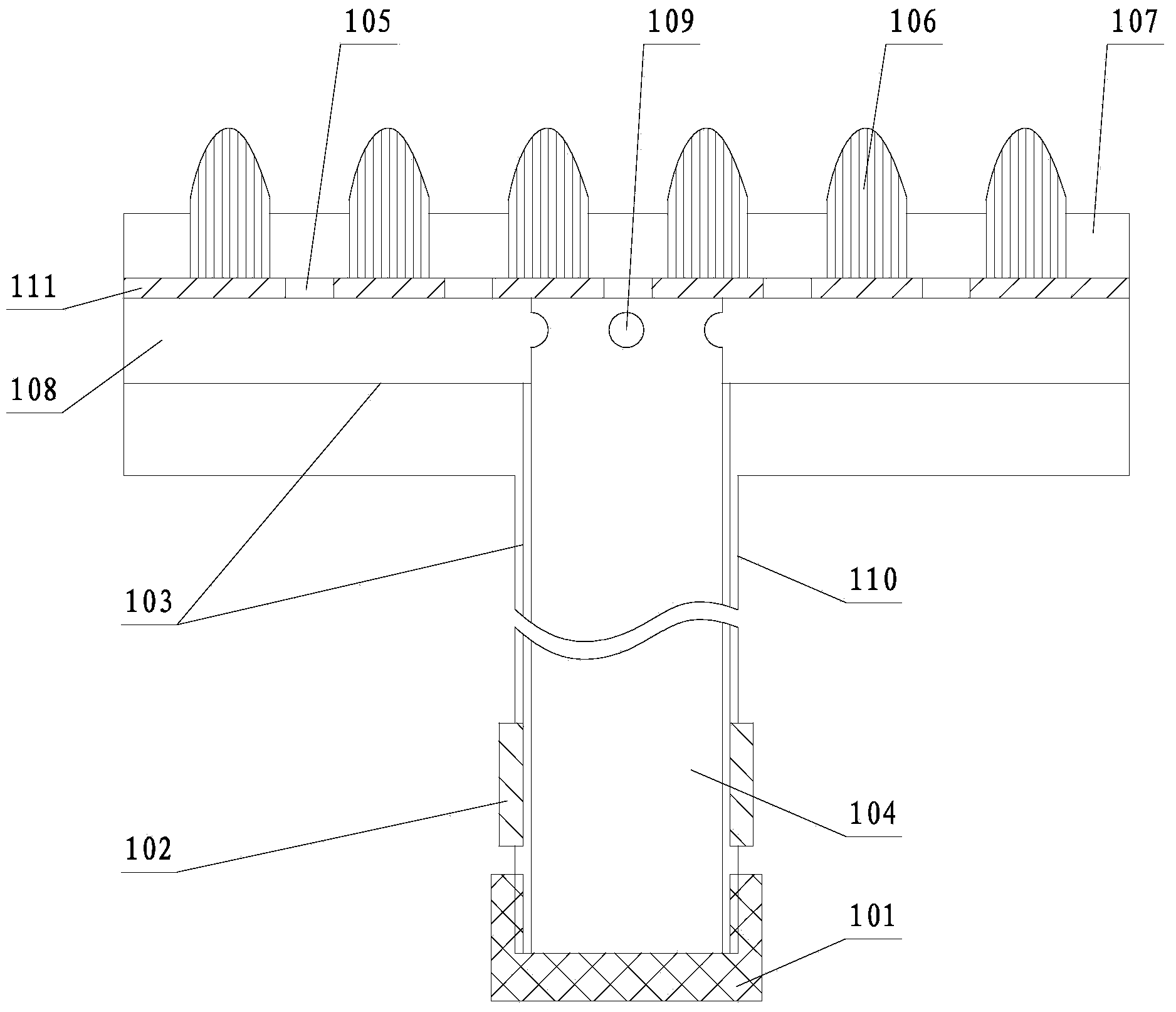

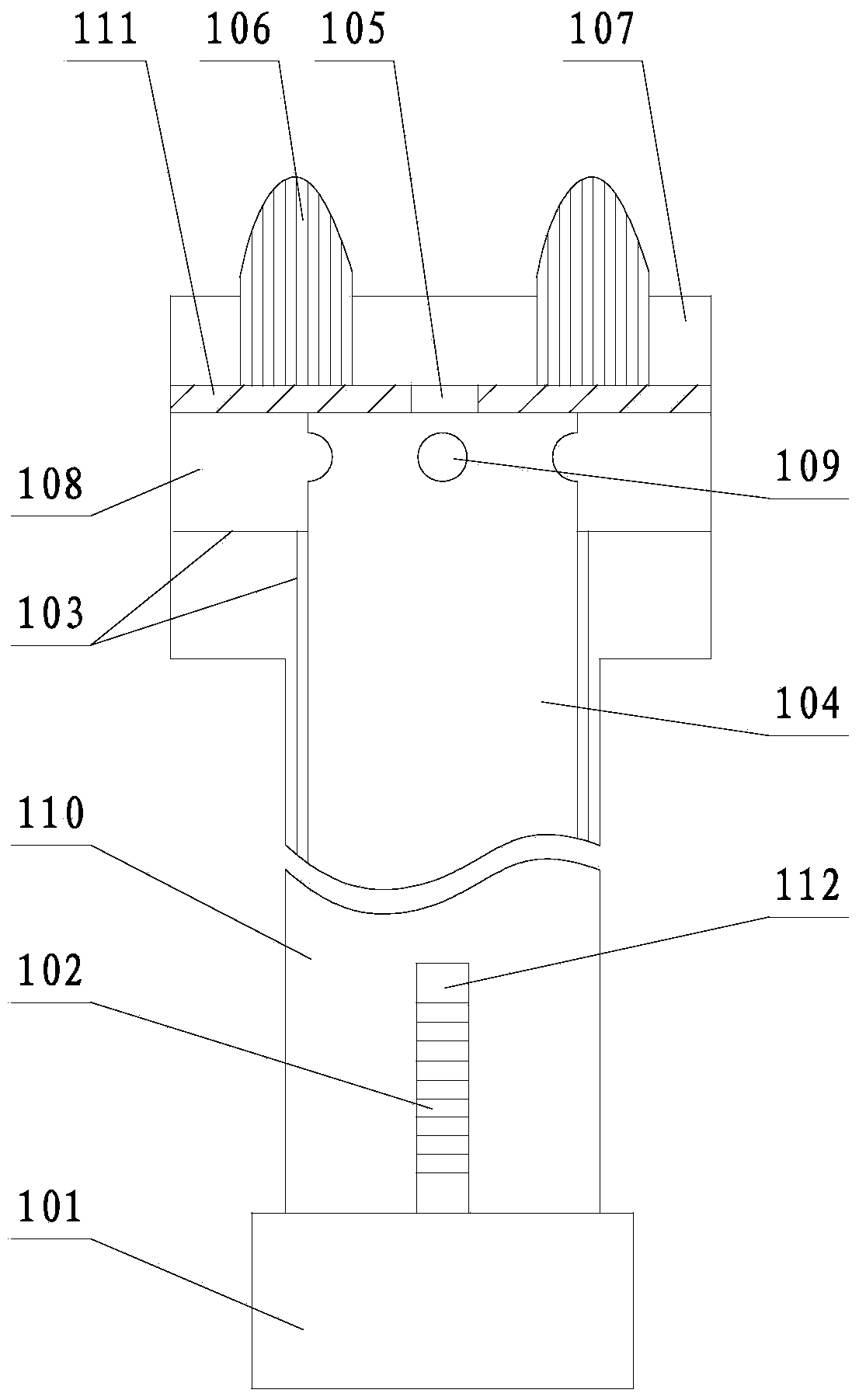

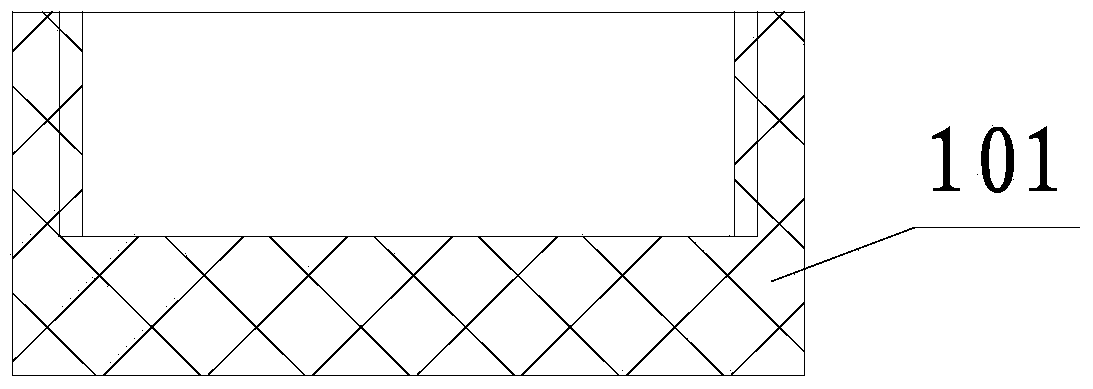

[0026] Such as Figure 1~3 As shown, the painting device of the present embodiment is a paint brush 1, which includes a brush handle cover 101, a brush handle 110, a brush head seat, an elastic tube 104, a push button 102 and a push button 103, wherein the brush The inner wall of the opening end of the handle cover 101 is provided with an internal thread, which is threadedly connected to one end (lower end) of the brush handle 110, and the brush head seat is connected to the other end (upper end) of the brush handle 110; A plurality of bristles 106 are evenly distributed on the top plate 111 of the brush head seat, and a plurality of paint outlet holes 105 respectively communicated with the storage chamber 108 are arranged on the top plate 111, and each paint outlet hole 105 is opened between each bristle 106; The top plate 111 of the brush head seat is provided with a leak-proof baffle 107 around, and the height of the leak-proof baffle 107 is lower than the height of the bri...

Embodiment 2

[0029] Such as Figure 4~6 As shown, the difference between this embodiment and Embodiment 1 is that the brush handle cover 101 of this embodiment is a brush handle adapter cover, that is, the brush handle cover 101 of the paint brush 1 of this embodiment passes through the delivery pipe 2 and is equipped with paint. The storage tank 3 is connected. The bottom surface of the brush handle cover 101 is provided with a first through hole 1014 for inserting the feeding pipe 2, and first screw holes 1011 are evenly distributed around the first through hole 1014, and one end of the feeding pipe 2 is connected by the first through hole 1014. The hole 1014 is inserted, and the end is turned outwards and fixedly connected to the brush handle cover 101 by the first screw 1013 threaded into the first screw hole 1011; . A first watertight gasket 1012 is provided between the first screw 1013 and the conveying material pipe 2 , and the first screw 1013 passes through the first watertight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com