Room-temperature cured phenyl silicon resin conformal coating

A phenyl silicone resin, room temperature curing technology, applied in the direction of coating, etc., can solve the problems of low surface hardness, low surface strength and hardness, easy to absorb dust, etc., and achieve the effect of good elasticity, excellent high and low temperature performance, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

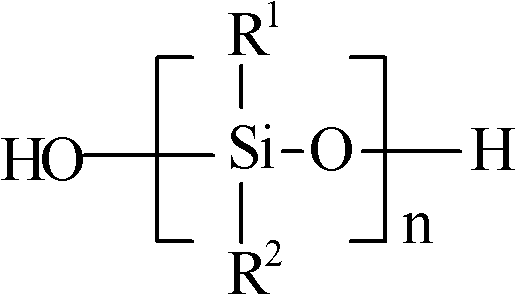

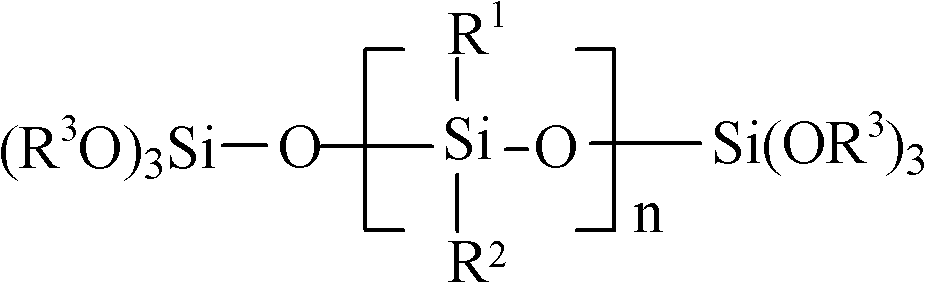

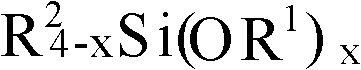

Method used

Image

Examples

Embodiment 1

[0023] Add 300g of phenyltrimethoxysilane and 300g of toluene into a 1L three-necked flask. Add 60g of 0.01% hydrochloric acid aqueous solution dropwise to the flask at room temperature and rapid stirring. The dropping time is controlled at about 20min. The hydrochloric acid aqueous solution is added dropwise. After the completion, the temperature was raised to 75°C and refluxed for 3h. After the reflux reaction, the temperature was reduced to 50°C and 1.06g of hexamethyldisilazane was added and stirred for 0.5h. After that, the reaction was stopped, and the reaction solution was cooled and allowed to stand and then filtered The temperature of the filtered reaction solution was raised to 120° C. The by-product methanol and part of the solvent were distilled out to obtain 352 g of translucent phenyl silicone resin. The solid content of the resin was 60%.

[0024] In a 1L three-necked flask equipped with nitrogen protection and water separator, 190g of the phenyl silicone resin prep...

Embodiment 2

[0027] Add 220g of phenyltrimethoxysilane, 64g of methylphenyldimethoxysilane and 295g of toluene into a 1L three-necked flask, and add 73.3g of 0.01% hydrochloric acid aqueous solution into the flask at room temperature and rapid stirring. The dripping time is controlled at about 20min. After the hydrochloric acid aqueous solution is dripped, the temperature is increased to 75°C and the reaction is refluxed for 4.5h. After the reflux reaction is completed, the temperature is reduced to 50°C and 1.29g of hexamethyldisilazane is added and stirred for 0.5h. After that, the reaction was stopped, the reaction solution was cooled and left to stand and then filtered. The filtered reaction solution was heated to 120-130°C. The by-product methanol and part of the solvent were distilled out at atmospheric pressure to obtain 325g of translucent phenyl silicone resin. The solid content is about 55%.

[0028] Into a 1L three-necked flask equipped with nitrogen protection and water separation...

Embodiment 3

[0031] Using the phenyl silicone resin prepared in Example 1, the hydroxy-terminated polydimethylsiloxane with a viscosity of 80 mpa.s in Example 1 was replaced with a hydroxy-terminated polydimethylsiloxane with a viscosity of 200 mpa.s , And other conditions remain unchanged, the conformal coating III is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com