Novel process for preparing emulsion paint through waste polystyrene plastic

A polystyrene plastic, waste polystyrene technology, applied in latex paints, rosin coatings, coatings, etc., can solve the problems of poor film-forming properties and adhesion of latex paints, strong irritation, high cost, and achieve good chemical Effects of stability and mechanical properties, low toxicity, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

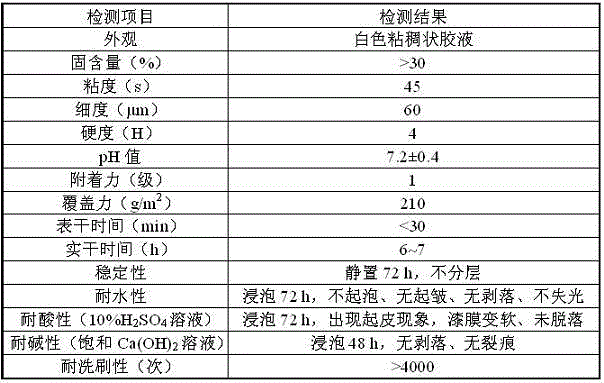

Image

Examples

Embodiment 1

[0026] Example 1 A kind of new technology that utilizes waste polystyrene plastics to prepare latex paint, comprises the following steps:

[0027] (1) Soak the waste polystyrene plastic in lime water with a temperature of 15°C and a mass concentration of 0.10% for 50 minutes, and take it out after mechanical stirring for 8 minutes, and then wash it twice with clean water to remove the stained oil and impurities. Get clean polystyrene plastic.

[0028] (2) Dry the clean polystyrene plastic at a temperature of 35°C or air-dry it and then pulverize it to obtain polystyrene particles with a particle size of 0.3 cm.

[0029] (3) Add 45 g of polystyrene particles to the heavy aromatic oil per 100 mL of heavy aromatic oil, stir and dissolve into a homogeneous phase, and then filter to obtain the filtrate.

[0030] (4) Add 8.5 g of polyvinyl acetate and 3.2 g of rosin to the filtrate successively for every 100 mL of filtrate, and then heat and stir at a temperature of 70°C until...

Embodiment 2

[0037] Example 2 A kind of new technology that utilizes waste polystyrene plastics to prepare latex paint, comprises the following steps:

[0038] (1) Soak the waste polystyrene plastic in lime water with a temperature of 25°C and a mass concentration of 0.10% for 60 minutes, take it out after mechanical stirring for 5 minutes, and then wash it twice with clean water to remove the stained oil and impurities. Clean polystyrene plastic.

[0039](2) Dry the clean polystyrene plastic at a temperature of 25°C or dry it and then pulverize it to obtain polystyrene particles with a particle size of 0.1 cm.

[0040] (3) Add 45 g of polystyrene particles to the heavy aromatic oil per 100 mL of heavy aromatic oil, stir and dissolve into a homogeneous phase, and then filter to obtain the filtrate.

[0041] (4) Add 8.5 g of polyvinyl acetate and 3.2 g of rosin to the filtrate successively for every 100 mL of filtrate, and then heat and stir at a temperature of 50° C. until the react...

Embodiment 3

[0048] Example 3 A kind of new technology that utilizes waste polystyrene plastics to prepare latex paint, comprises the following steps:

[0049] (1) Soak the waste polystyrene plastic in lime water with a temperature of 20°C and a mass concentration of 0.10% for 55 minutes, and take it out after mechanical stirring for 6 minutes, and then wash it twice with clean water to remove the stained oil and impurities. Get clean polystyrene plastic.

[0050] (2) Dry the clean polystyrene plastic at a temperature of 30°C or dry it and then pulverize it to obtain polystyrene particles with a particle size of 0.2 cm.

[0051] (3) Add 45 g of polystyrene particles to the heavy aromatic oil per 100 mL of heavy aromatic oil, stir and dissolve into a homogeneous phase, and then filter to obtain the filtrate.

[0052] (4) Add 8.5 g of polyvinyl acetate and 3.2 g of rosin to the filtrate successively for every 100 mL of filtrate, and then heat and stir at a temperature of 60° C. until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com