Versatile coating brush

A paint brush and paint technology, applied in the fields of brushing, anti-corrosion, and painting, to achieve the effects of safe and reliable use, good industrialization prospects, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

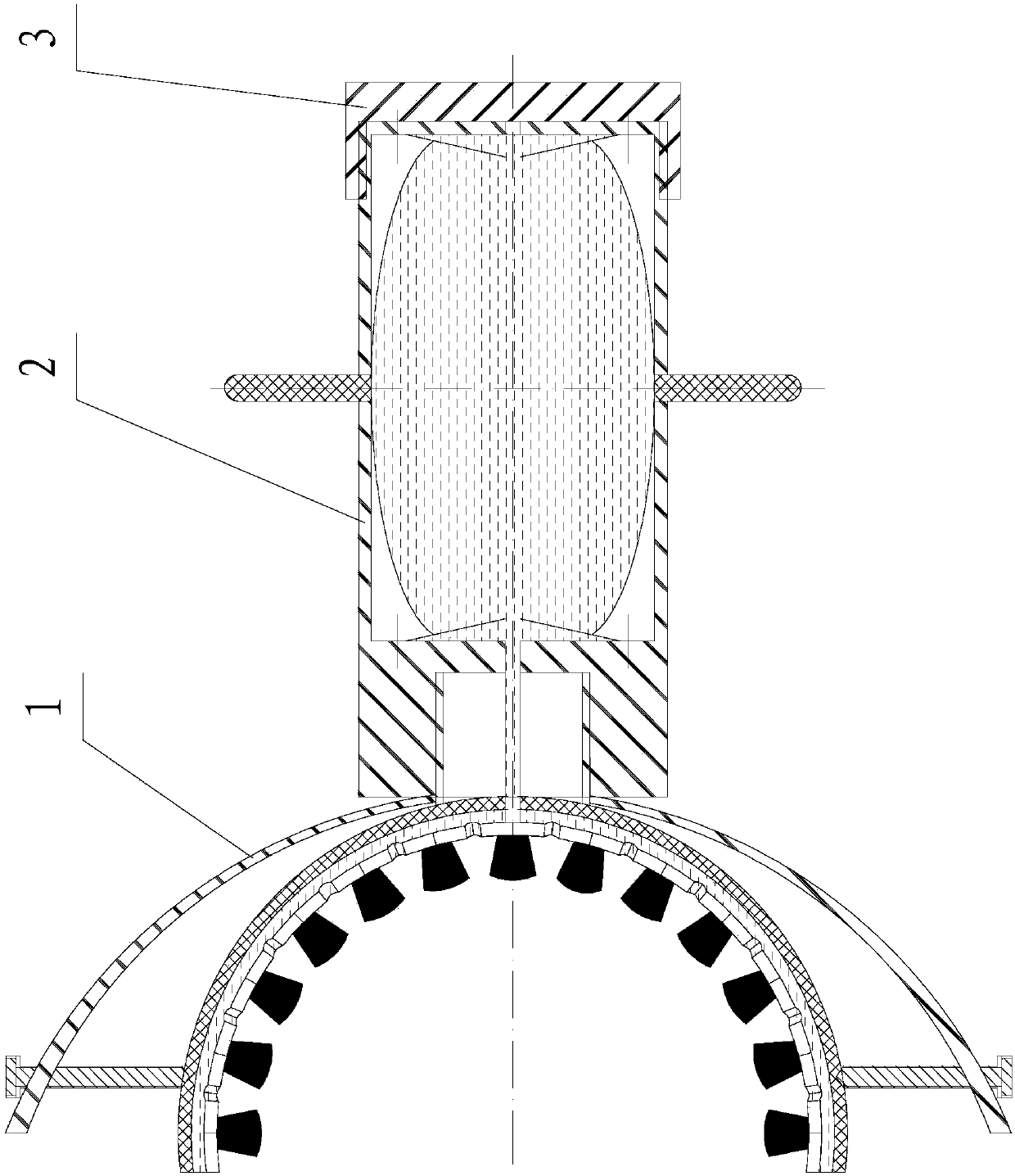

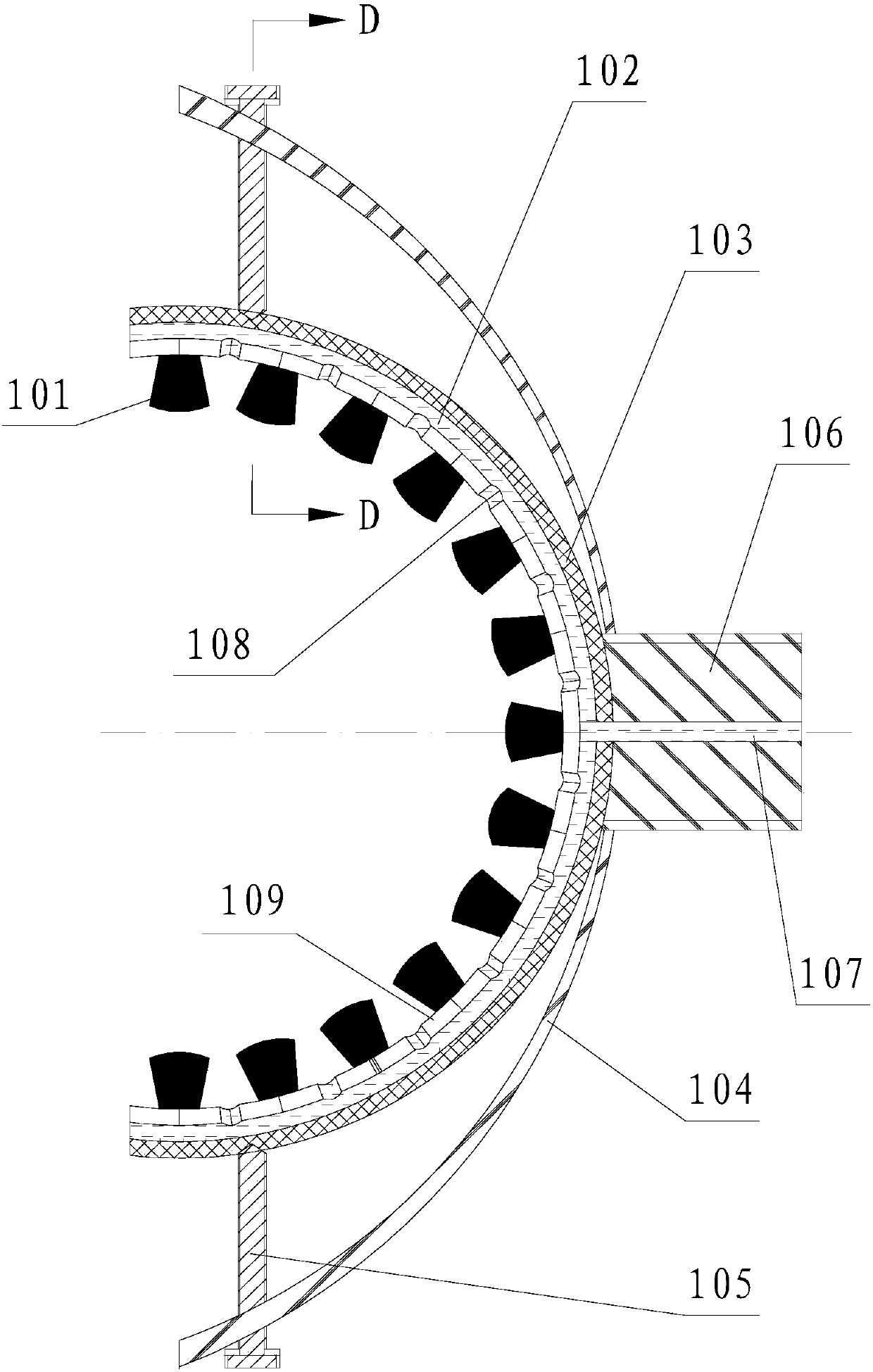

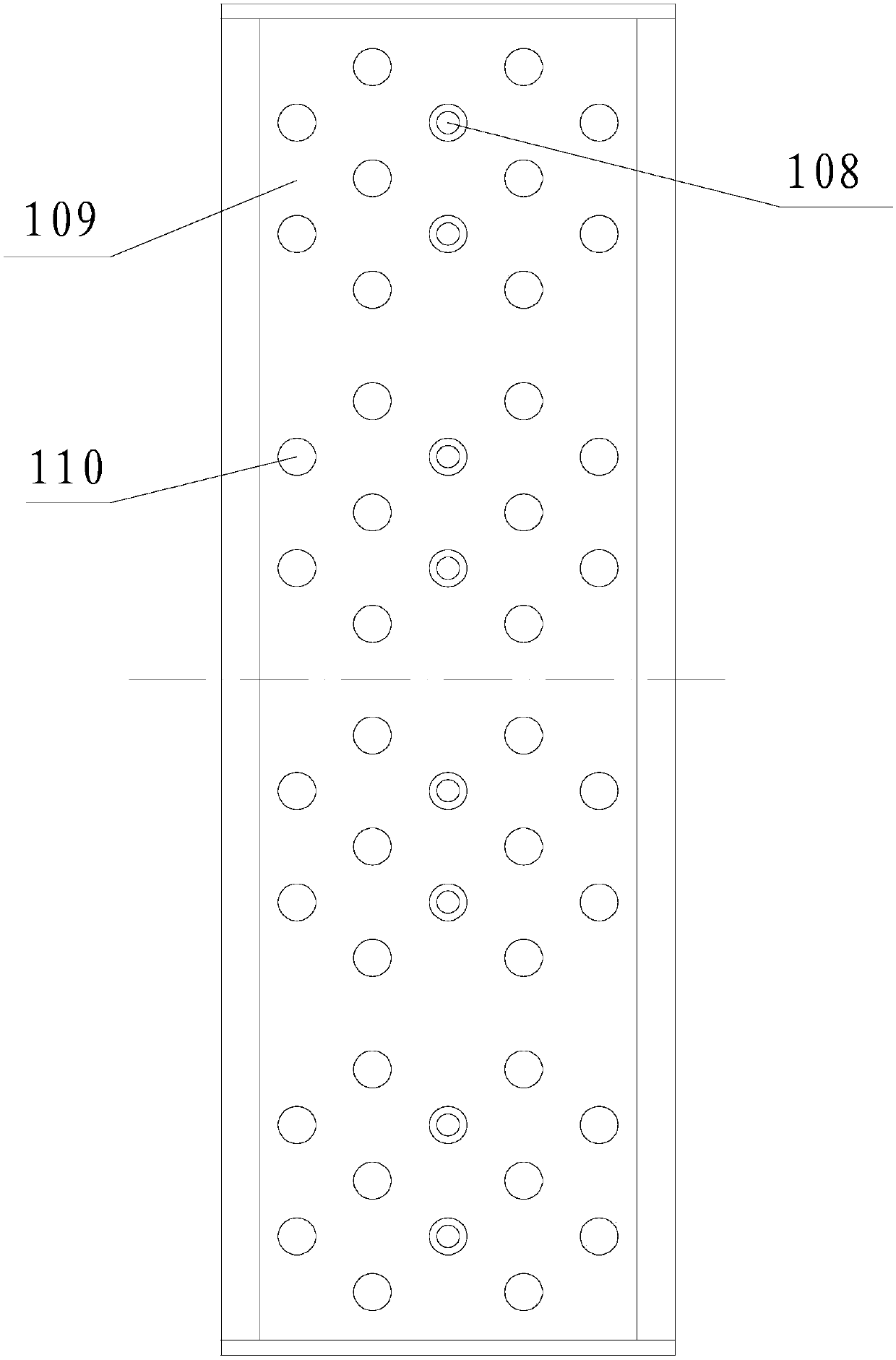

[0033] like figure 1 , Figure 2A-2C , Figure 3A-3B , Figure 4 and Figures 5A-5B As shown, the present invention comprises a brush handle 2 and a brush head 1 and a brush handle cover 3 which are threadedly connected to two ends of the brush handle 2 respectively, wherein the brush head 1 includes a paint storage tube 102, a structural seat 103, a control panel 104, and adjustment positioning bolts 105 and the bristle seat 109, the paint storage tube 102 of the present embodiment, the structure seat 103, the control panel 104 and the bristle seat 109 are arc-shaped, and the paint storage tube 102, the structure seat 103 and the bristle seat 109 are integral. One side of the bristle holder 109 is provided with a plurality of paint outlets 108 and a plurality of bristle placement holes 110 arranged on the periphery of each paint outlet 108, and each bristle placement hole 110 has a bristle 101 planted therein. The other side of the bristle seat 109 abuts against the insid...

Embodiment 2

[0047] like Figure 7 As shown, the difference between the present embodiment and the first embodiment is that the paint storage pipe 102, the structural seat 103, the control panel 104 and the bristle seat 109 of the present embodiment are all provided with openings, and the two ends of the openings are connected with connecting flanges 4 , the paint storage tube 102, structure seat 103, control panel 104 and bristle seat 109 adjust the respective internal diameters through the opening, and connect the connecting flanges 4 at both ends by bolts 5 after adjustment, the result is that the bristle seat 109, the paint storage tube 102 , the structural seat 103 and the control board 104 are all round in shape, that is, the round brush head 1 . All the other structures are identical to Embodiment 1.

[0048] The difference between the working principle of the present embodiment and the first embodiment is that the brush head 1 of the present embodiment is circular. When attaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com