Shorn-pile elastic fabric and manufacturing process

A kind of elastic and shearing technology, applied in textile, fabric, textile and papermaking, etc., can solve the problems of inability to make elastic fabrics, poor fabric softness, easy to peel off, etc. The effect of collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

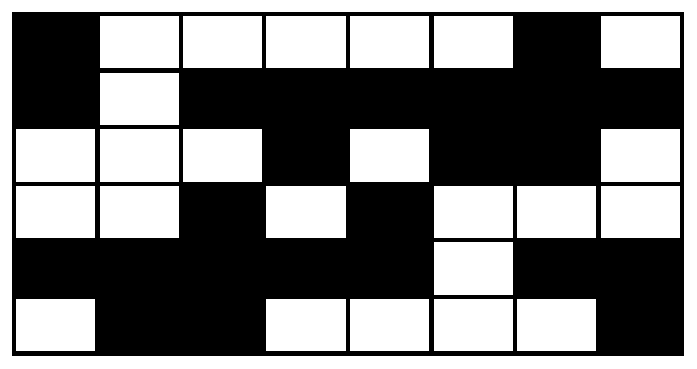

[0028] Such as Figure 1 to Figure 3 As shown, the sheared elastic fabric includes more than two layers of weaving layers, each layer of weaving layers includes weft yarns and warp yarns, and adjacent weaving layers share warp yarns, and the warp yarns are elastic warp yarns; between the adjacent weft yarns of the bottom weaving layer The weft yarns of more than one weave layer adjacent to the underlying weave layer; the weft yarns of the underlying weave are formed with shearling.

[0029] In this embodiment, two braiding layers are provided, which are respectively defined as a surface braiding layer and a bottom braiding layer. The surface braiding layer and the bottom braiding layer share warp yarns, and the warp yarns are empty covered elastic yarns or twisted covered elastic yarns. Of course, other elastic warp yarns can also be used. The weft yarn of the layer uses OER7S air-spun viscose fiber, and of course other various weft yarns can also be used. In order to make th...

Embodiment 2

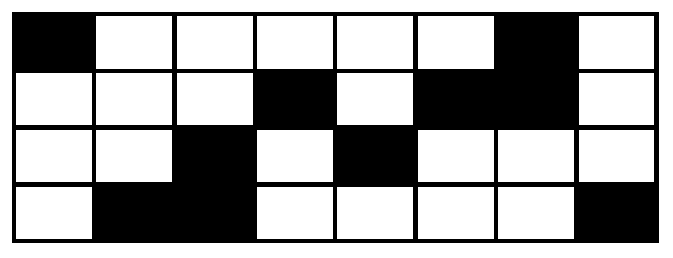

[0043] Such as Figure 4 As shown, the sheared elastic fabric includes more than two layers of weaving layers, each layer of weaving layers includes weft yarns and warp yarns, and adjacent weaving layers share warp yarns, and the warp yarns are elastic warp yarns; between the adjacent weft yarns of the bottom weaving layer The weft yarns of more than one weave layer adjacent to the underlying weave layer; the weft yarns of the underlying weave are formed with shearling.

[0044] In this embodiment, two braiding layers are provided, which are respectively defined as a surface braiding layer and a bottom braiding layer. The surface braiding layer and the bottom braiding layer share warp yarns, and the warp yarns are empty covered elastic yarns or twisted covered elastic yarns. Of course, other elastic warp yarns can also be used. The weft yarn of the layer uses OER7S air-spun viscose fiber, and of course other various weft yarns can also be used. In order to make the pile lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com