Processing process for artificial fur weaving blended yarns

A processing technology, a technology for blending yarns, applied in textiles, papermaking, yarns, etc., can solve problems such as no technical disclosure, and achieve the effects of easy cutting and brushing, cost reduction, and realistic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be further described in conjunction with the embodiments.

[0033] 1. Product design

[0034] The blended yarn is made of mercerized Australian wool, expanded acrylic and ordinary acrylic.

[0035] 2. Process flow

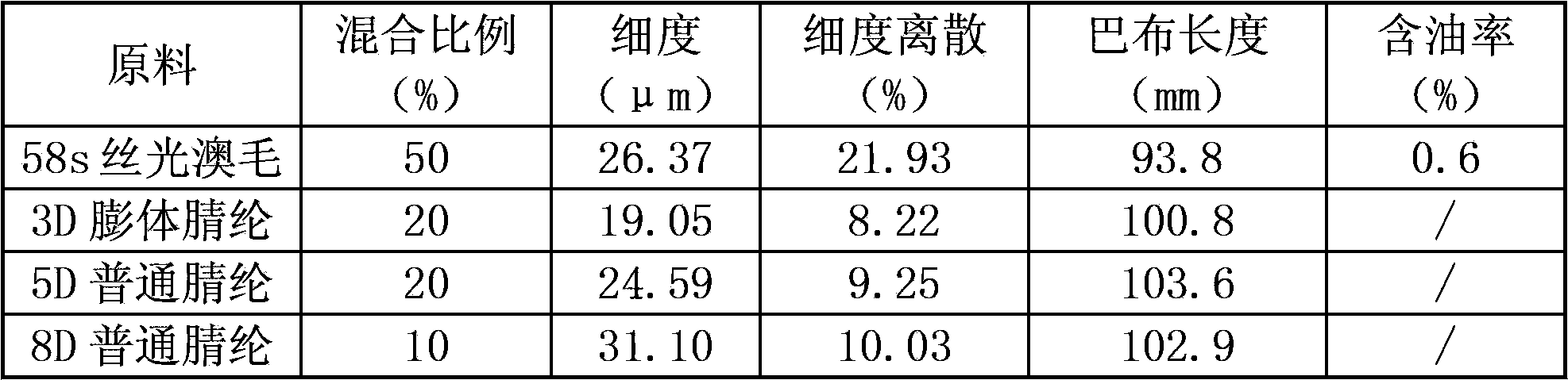

[0036] 1. Raw material preparation

[0037]

[0038] 2. SA50-628Nm / 2 blended yarn (including expanded acrylic) process flow

[0039] ⑴、Front spinning process

[0040] One-time blending: equipment model B412, combined root number 10 (5 hairs, 2 3D expanded acrylic fibers, 2 3D ordinary acrylic fibers, 1 8D ordinary acrylic fibers), draft ratio 10, and off-machine weight 20±1g; 24h pre-moisture after mixing;

[0041] Secondary mixing: equipment model GN6-17, combined roots 8, drafting multiples of 10, off-machine weight 16±0.5g, oiling volume 50ml / min;

[0042] One needle comb: equipment model GN6-17R, combined roots 8, drafting multiples of 9.6, off-machine weight 13.3±0.5g;

[0043] Two-pass needle comb: equipment model GN6-26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com