Paint storage type paint brushing roller capable of automatically adjusting paint outlet amount

A self-adjusting and painting technology, applied in the direction of architecture and building structure, can solve the problems of delayed painting time, layering of paint surface, and low painting efficiency, so as to reduce the time of back-and-forth dipping and facilitate the use of painting. , Improve the effect of painting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

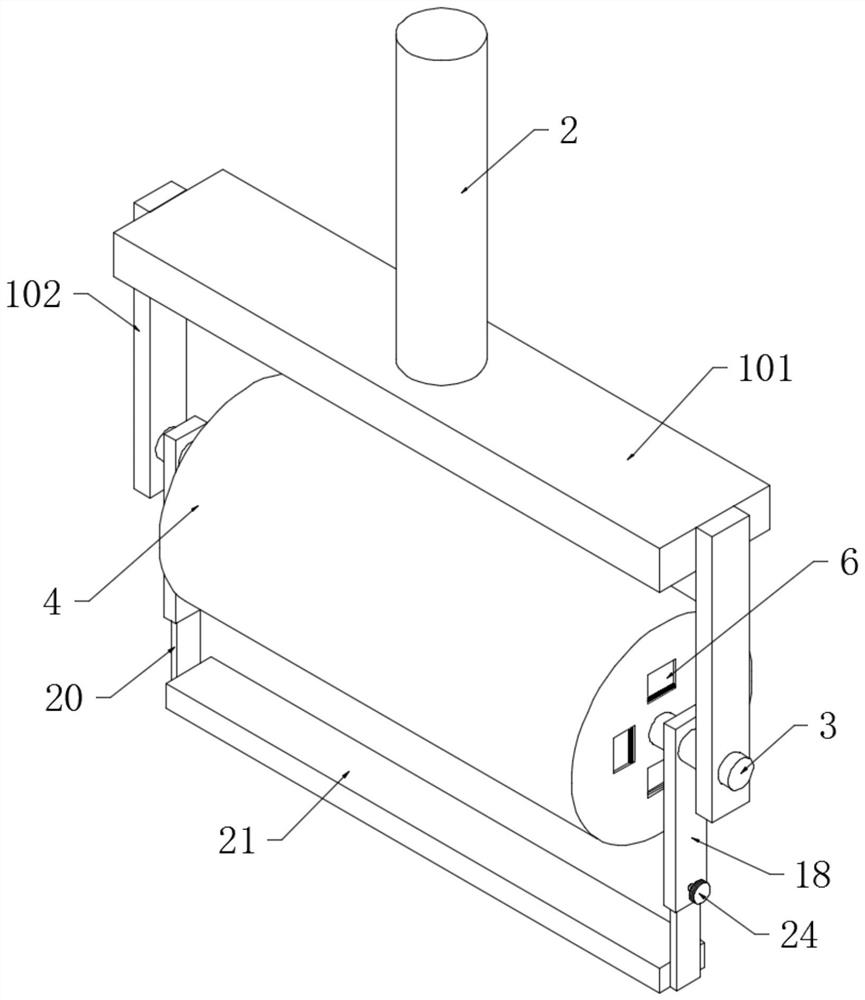

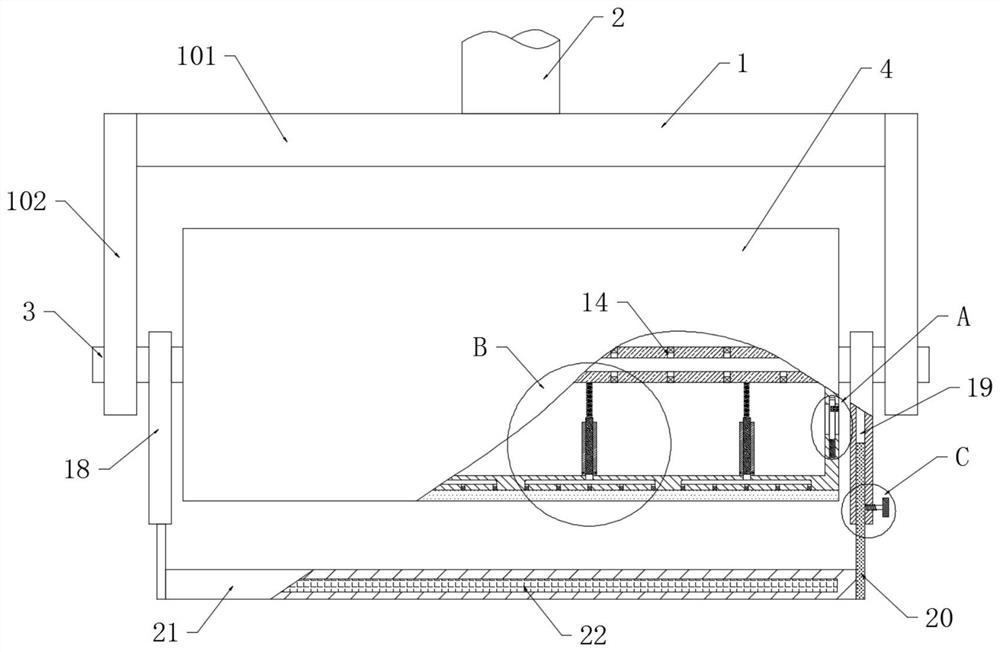

[0024] refer to Figure 1-6 , a self-adjusting paint storage type paint roller, including a U-shaped roller frame 1, the roller frame 1 is formed by connecting a fixed plate 101 and two support plates 102, and the two ends of the fixed plate 101 are respectively It is vertically fixedly connected with two support plates 102, and one end of the two support plates 102 away from the fixed plate 101 is rotatably connected with a hollow rotating shaft 3 through a bearing, and a hollow paint roller 4 is coaxially fixedly connected to the rotating shaft 3, and the paint roller The outer ring surface of 4 is connected with a circle of roller felt 5, and the painting roller 4 is provided with a paint-in-out device.

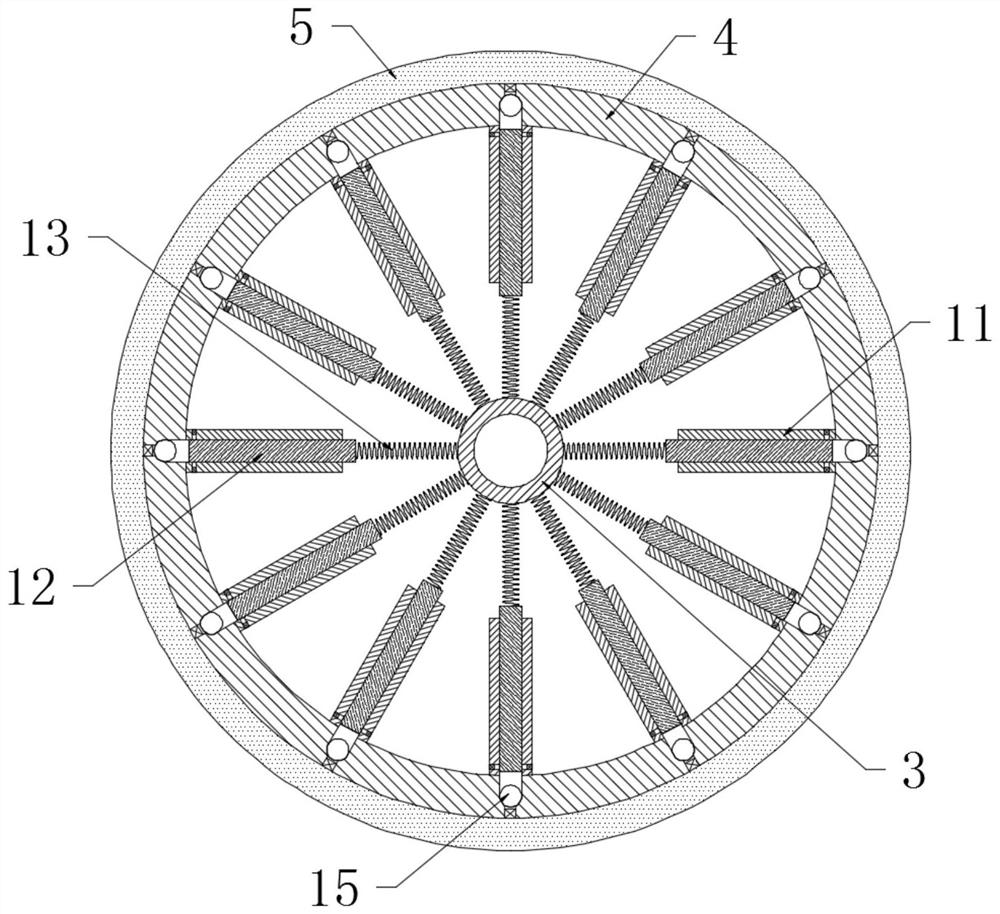

[0025] The paint inlet and outlet device includes a plurality of piston rods 12, and a rotating shaft on the inner wall of the paint roller 4 is distributed with a plurality of cylinders 11 in a circular array at the center, and the connection between each cylinder 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com