Remote control maintenance method and device based on human factor simulation analysis

A technology of remote maintenance and simulation analysis, applied in data processing applications, resources, calculations, etc., can solve problems such as serious nuclear pollution and nuclear accidents, unplanned shutdown of devices, and harsh environments, so as to improve work efficiency and operation accuracy, The effect of optimizing factor indicators and optimizing working methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

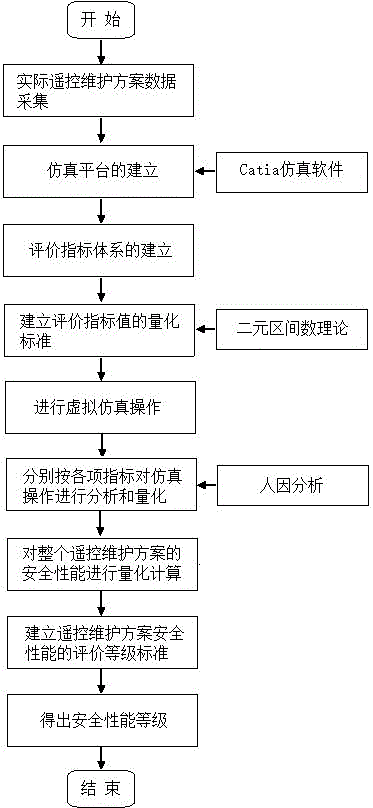

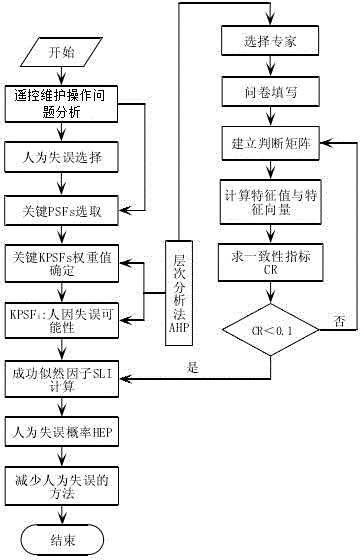

[0030] A remote maintenance method based on human factors simulation analysis, the maintenance method includes the following steps:

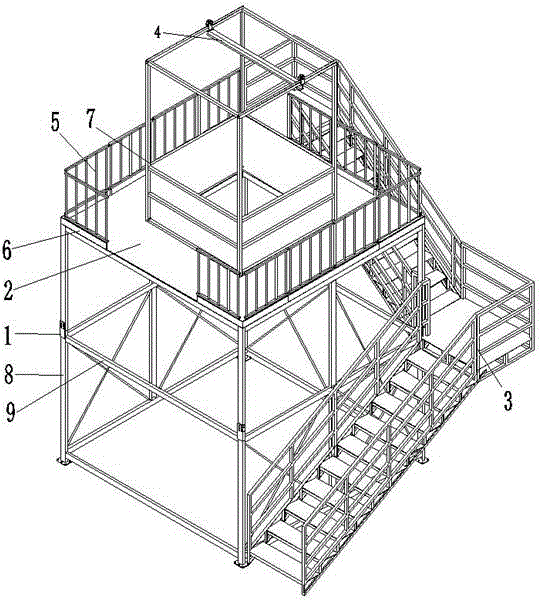

[0031] 1) Establish a remote maintenance device through Catia 3D modeling software, construct a virtual 3D remote maintenance operation environment, and the size ratio of the established virtual 3D remote maintenance operation environment to the actual operation environment is 1:1;

[0032] 2) In the virtual three-dimensional remote maintenance operation environment, establish a virtual human. The virtual human is a human body model at the 50th percentile. The height of the virtual human is 1704.5 mm, and the arm length is 722.261 mm. The simulated movement in the virtual human is analyzed and evaluated through the simulated movement to evaluate the visual accessibility, operational accessibility, physical damage, radiation damage, fatigue, human error probability and psychological cognition index quantification value;

[0033] 3) Assuming that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com