Automatic material taking mechanism for material particles

A technology of automatic material retrieving and granulation, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of gunpowder dust toxicity, collision and extrusion, and potential safety hazards, so as to improve the working environment and methods, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

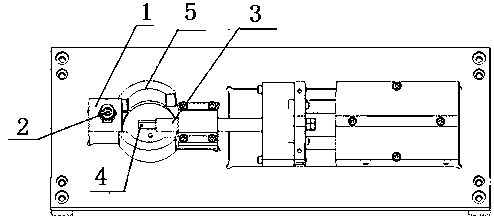

[0024] like figure 1 As shown, the mechanism mainly includes three parts, the feed bin, the discharge funnel and the discharge rod.

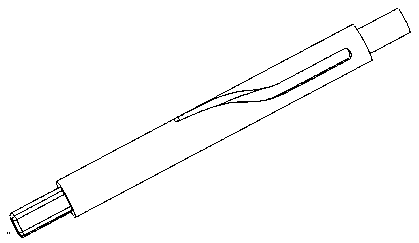

[0025] The feeding bin in the picture consists of two parts, the fixed feeding channel at the lower end and the detachable feeding port at the upper end. In order to better ensure the feeding efficiency, the feeding port adopts an inverted tapered design, that is, a bell mouth The design idea; the lower feeding channel adopts a cylindrical design, and the trumpet-shaped feeding port is set on the feeding channel, and the two can be separated. In order to ensure that the trumpet-shaped feeding port can be fixedly arranged on the feeding channel, threads can be provided on the outer diameter of the trumpet-shaped feeding port, and an effective connection can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com