Board drilling equipment

A technology for drilling equipment and plates, which is applied to stone processing equipment, stone processing tools, manufacturing tools, etc., can solve problems such as complex procedures, low processing efficiency, and large positioning errors, so as to overcome complex procedures, improve production efficiency, reduce The effect of small positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

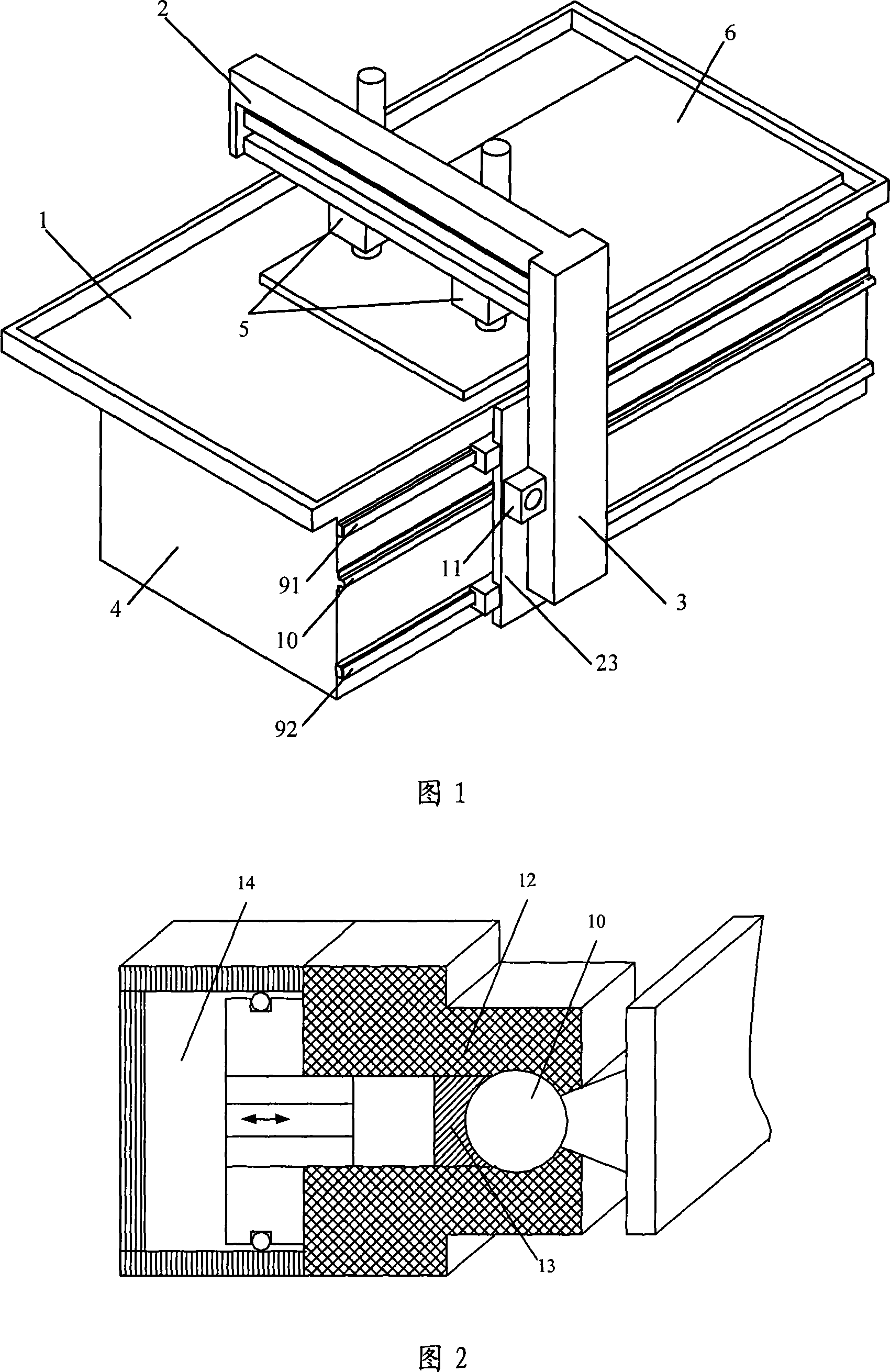

[0027] As shown in Figure 1, it is a structural schematic diagram of a specific embodiment of the plate drilling equipment of the present invention. The equipment of this embodiment includes: a machine bed 4, a workbench 1 arranged on the machine bed 4; connected to the machine bed 4 The frame on the frame is L-shaped and consists of beams 2 and columns 3; two working heads 5 connected to the beams 2 of the frame; The guide rails 91, 92 parallel to the surface of the table 1, the column 3 of the frame and the guide rails 91, 92 are slidingly connected; the machine bed 4 is also provided with a locking guide rail 10 parallel to the guide rails 91, 92, and the locking guide rail 10 is arranged on Between the two guide rails 91, 92, the upright column 3 of the frame is slidably connected with the locking guide rail 10, and a locking device 11 is provided between the upright column 3 and the locking guide rail 10.

[0028] In this embodiment, the frame is composed of a beam 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com