Elastomer composite material as well as preparation method and application thereof

A composite material and elastomer technology, applied in the field of materials, can solve problems such as lack of processability, high synthesis requirements, and increased material use costs, and achieve excellent processing performance, self-repairing performance, excellent impact resistance, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

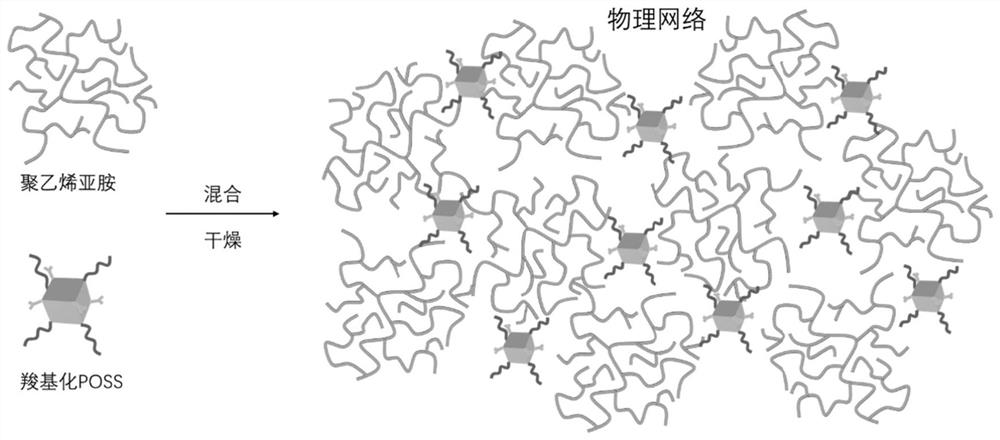

Image

Examples

Embodiment 1

[0065] The preparation steps of the elastomer composite material in this example are as follows:

[0066] 2.7 g of carboxylated POSS was dissolved in tetrahydrofuran to obtain a solution with a concentration of 0.1 mmol / mL, and 0.6 g of polyethyleneimine (Mw=600) was dissolved in water to obtain a solution with a concentration of 0.1 mmol / mL. 10 mL of polyethyleneimine solution was added to a 100 mL round-bottomed flask, and 20 mL of carboxylated POSS solution was slowly added dropwise during stirring. The obtained pale yellow turbid liquid was evaporated under reduced pressure to remove the solvent, and the obtained yellow mucus was put into a vacuum oven for drying for 12 hours to obtain a POSS / PEI elastomer composite material.

Embodiment 2

[0068] The preparation steps of the elastomer composite material in this example are as follows:

[0069] 2.7 g of carboxylated POSS was dissolved in tetrahydrofuran to obtain a solution with a concentration of 0.1 mmol / mL, and 1.8 g of polyethyleneimine (Mw=1800) was dissolved in water to obtain a solution with a concentration of 0.1 mmol / mL. 10 mL of polyethyleneimine solution was added to a 100 mL round-bottomed flask, and 20 mL of carboxylated POSS solution was slowly added dropwise during stirring. The obtained pale yellow turbid liquid was evaporated under reduced pressure to remove the solvent, and the obtained yellow mucus was put into a vacuum oven for drying for 12 hours to obtain a POSS / PEI elastomer composite material.

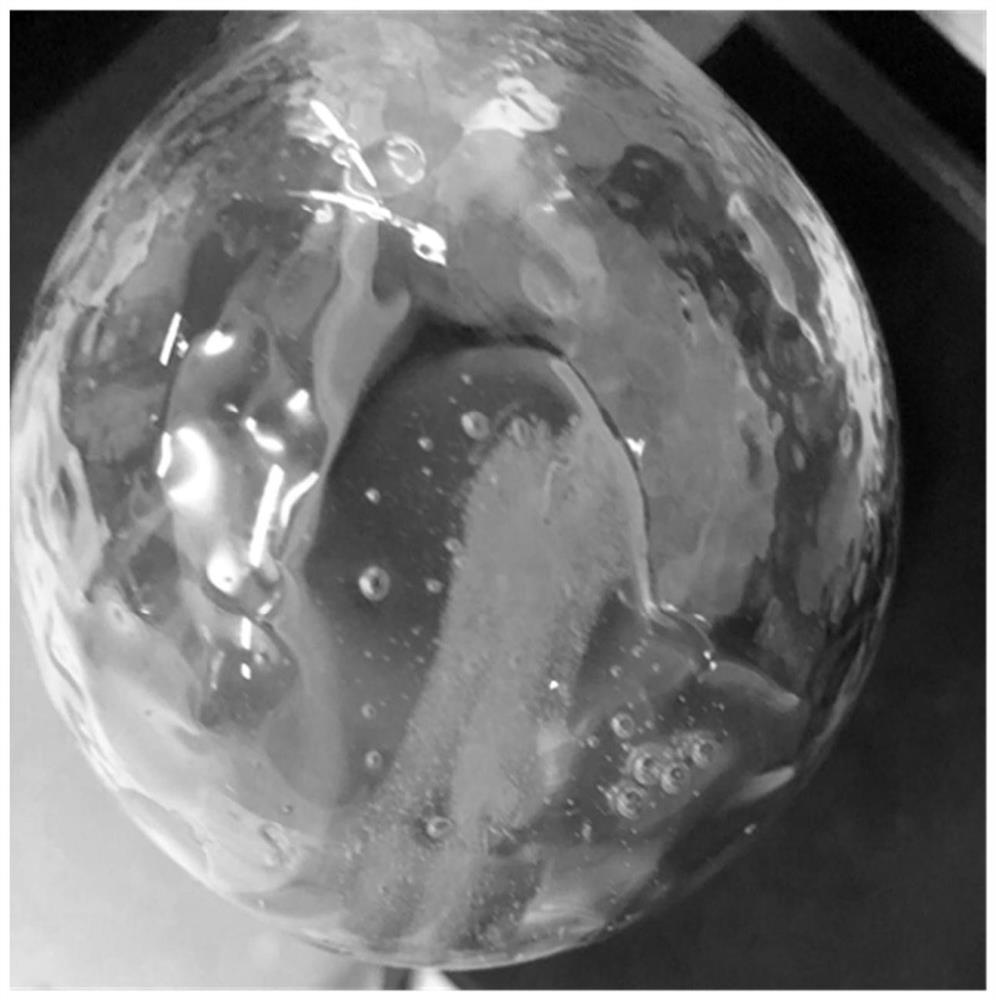

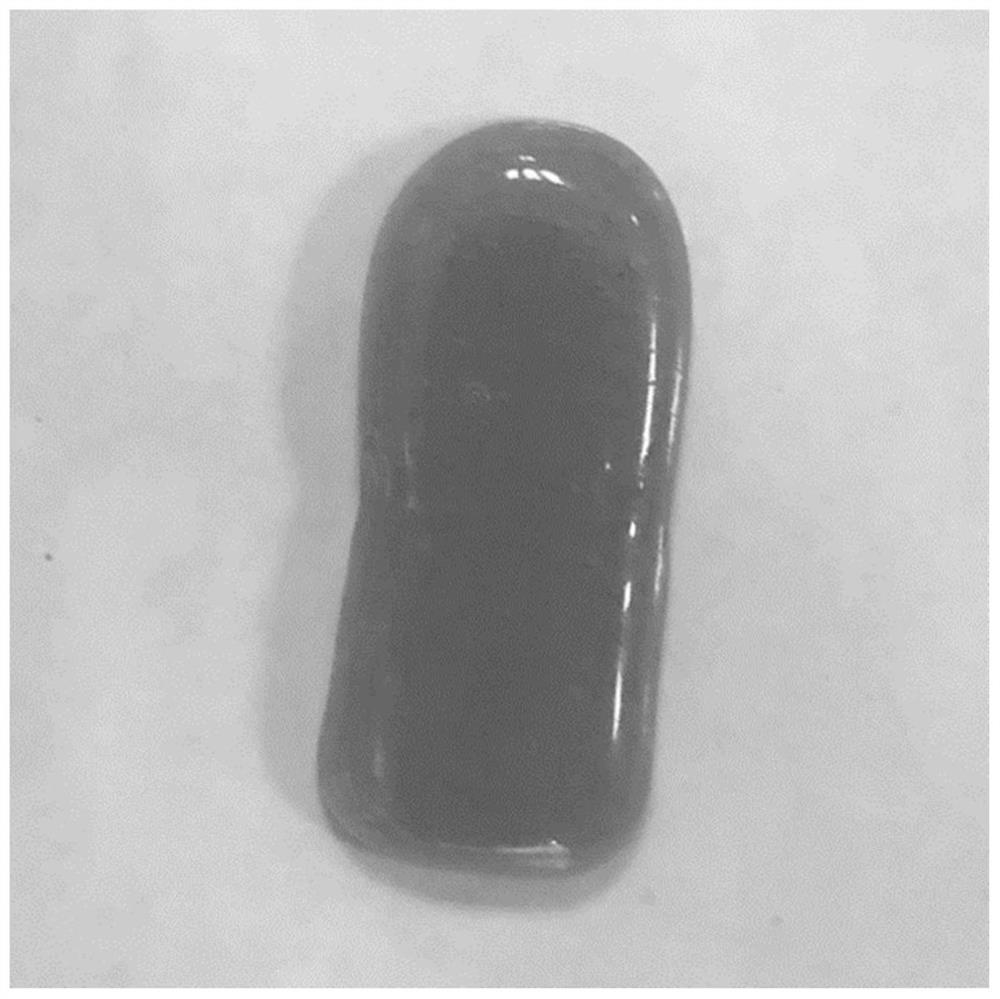

[0070] figure 2 It is a sample diagram after mixing polyethyleneimine and carboxylated POSS in Example 2; image 3 The sample diagram of the elastomer composite material prepared in Example 2; Figure 4 Tensile graph of the elastomer composite ...

Embodiment 3

[0072] The preparation steps of the elastomer composite material in this example are as follows:

[0073] 2.7 g of carboxylated POSS was dissolved in tetrahydrofuran to obtain a solution with a concentration of 0.1 mmol / mL, and 10.0 g of polyethyleneimine (Mw=10000) was dissolved in water to obtain a solution with a concentration of 0.1 mmol / mL. 10 mL of polyethyleneimine solution was added to a 100 mL round-bottomed flask, and 20 mL of carboxylated POSS solution was slowly added dropwise during stirring. The obtained pale yellow turbid liquid was evaporated under reduced pressure to remove the solvent, and the obtained yellow mucus was put into a vacuum oven for drying for 12 hours to obtain a POSS / PEI elastomer composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com