Automatic balance adjusting system of mechanical arms

A technology of automatic balancing and adjustment system, applied in the direction of fluid pressure actuation system components, mechanically driven excavators/dredgers, mechanical equipment, etc. structure, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

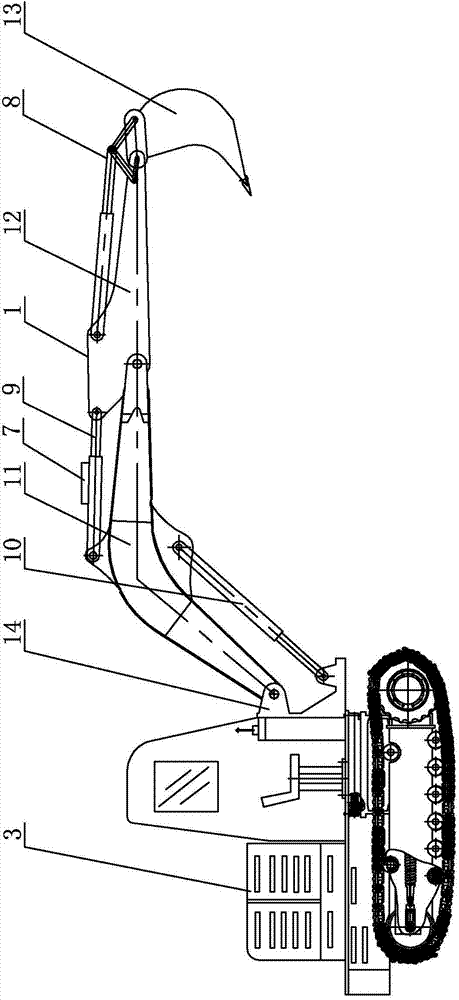

[0022] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Describe this embodiment, in this embodiment it includes at least one mechanical arm 1, at least one hydraulic cylinder assembly 2, hydraulic drive system 3, intelligent control system and a plurality of accumulators 7, the signal output terminal of the intelligent control system sends out the control signal For the hydraulic drive system 3, the hydraulic drive system 3 controls the movement of at least one hydraulic cylinder 2, and each mechanical arm 1 is equipped with a hydraulic cylinder assembly 2, the movement of the hydraulic cylinder assembly 2 drives the movement of the mechanical arm 1, and at least one hydraulic cylinder assembly 2 A plurality of energy accumulators 7 are installed above the upper part, and the energy accumulators 7 are used to store the gravitational potential energy generated when the mechanical arm 1 falls, and provide energy for the mec...

specific Embodiment approach 2

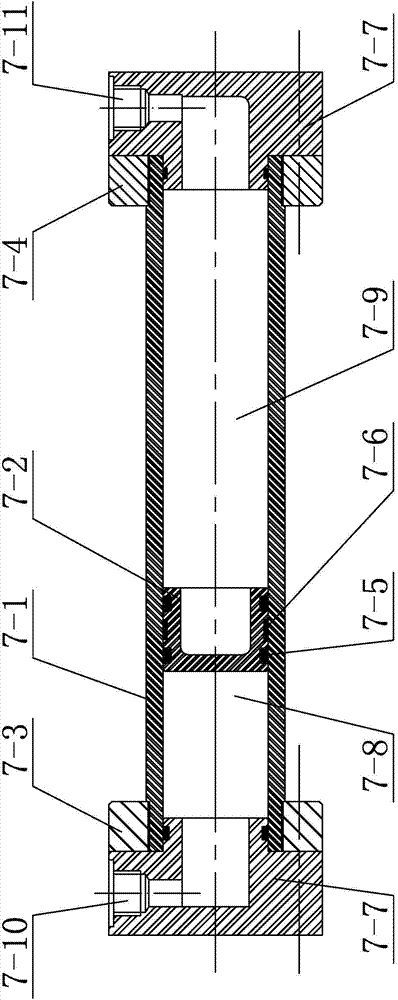

[0026] Specific implementation mode two: combination figure 2 with image 3 This embodiment will be described. In this embodiment, one hydraulic cylinder assembly 2 is correspondingly provided with two accumulators 7 . Through the sample test, it can be concluded that one hydraulic cylinder assembly 2 is equipped with two accumulators 7 so that the energy storage effect of the accumulator 7 on its corresponding hydraulic cylinder assembly 2 is the best. Such setting is scientific and reasonable. Other unmentioned components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

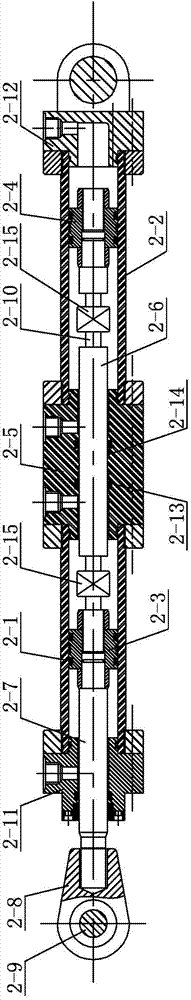

[0027] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 with Figure 5Describe this embodiment. In this embodiment, the hydraulic cylinder assembly 2 includes a first component cylinder 2-1, a second component cylinder 2-2, a first piston 2-3, a second piston 2-4, and an inter-cylinder coupling body 2- 5. Transition piston rod 2-6, first piston rod 2-7, second piston rod 2-10, coupling ring 2-8, first pin shaft 2-9, first end cover 2-11, second end Cover 2-12, two universal joints 2-15, an inter-cylinder coupling body 2-5 is fixedly connected between the first component cylinder 2-1 and the second component cylinder 2-2, the first The first piston rod 2-7 is pierced inside the component cylinder 2-1, and the end of the first component cylinder 2-1 away from the connecting body 2-5 between cylinders is provided with a first end cover 2-11, and the first piston rod 2- 7. There is a first piston 2-3 on the upper sleeve, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com