Automatic processing machine tool for bended tubes

A technology of automatic processing and machine tools, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of low processing efficiency and unguaranteed processing accuracy, and achieve the effect of improving processing efficiency and realizing processing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

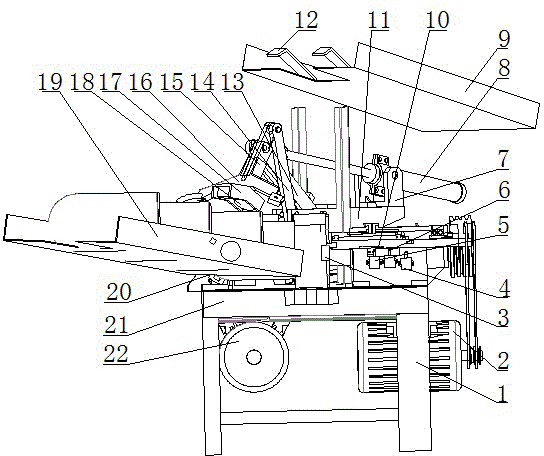

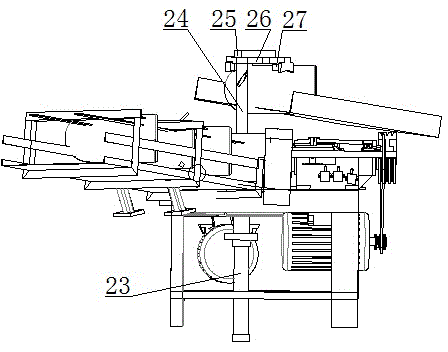

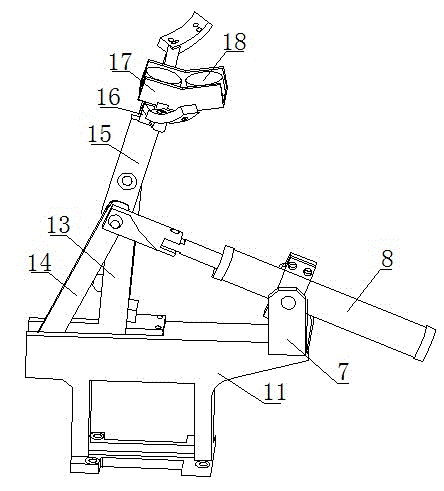

[0014] Such as figure 1 with image 3 As shown, the structure of the pipe bending automatic processing machine tool is as follows: the upper end of the frame body 1 is provided with a rectangular platform 21, and the lower end of the platform 21 corresponds to the pulley of the milling cutter head. The belt pulley is connected to the pulley of the milling cutter head 3. The two adjacent right-angled sides of the upper end of the platform 21 are respectively provided with the milling cutter head 3. The milling cutter head 3 is connected to the sleeve. The included angle of the axis can be set to 120 respectively according to the needs 0 、90 0 、45 0 , the upper end of the milling cutter head 3 sides is equipped with a slide block 10, the side end of the milling cutter head 3 is provided with a vertical plate perpendicular to the platform 21, and the vertical plate is respectively provided with a travel switch one 4, a travel switch two 5 and a travel switch three 6, The plat...

Embodiment 2

[0016] The structure of the pipe bending automatic processing machine tool is as follows: the upper end of the frame body 1 is provided with a rectangular platform 21, and the lower end of the platform 21 corresponds to the pulley of the milling cutter head. The pulley of the cutter head 3, the two adjacent right-angled sides of the upper end of the platform 21 are respectively provided with the milling cutter head 3, the milling cutter head 3 is connected to the sleeve, and the side end of the sleeve is equipped with a screw nut device, and the angle between the two milling cutter heads 3 axes According to needs can be set to: 120 0 、90 0 、45 0 , the upper end of the milling cutter head 3 sides is equipped with a slide block 10, the side end of the milling cutter head 3 is provided with a vertical plate perpendicular to the platform 21, and the vertical plate is respectively provided with a travel switch one 4, a travel switch two 5 and a travel switch three 6, The platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com