Stone slab processing system and processing method thereof

A processing system and processing method technology, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of no automatic production line, achieve uniform and stable spraying, solve inconsistent colors, and have strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

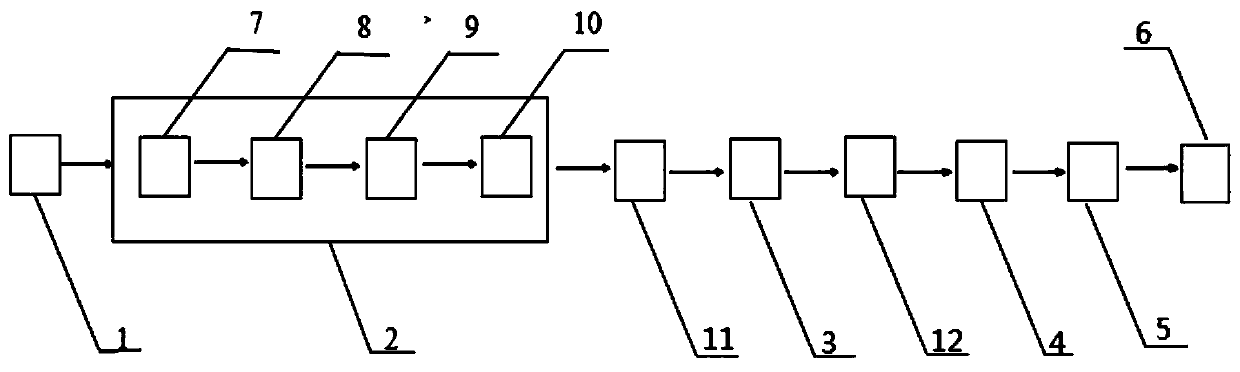

Method used

Image

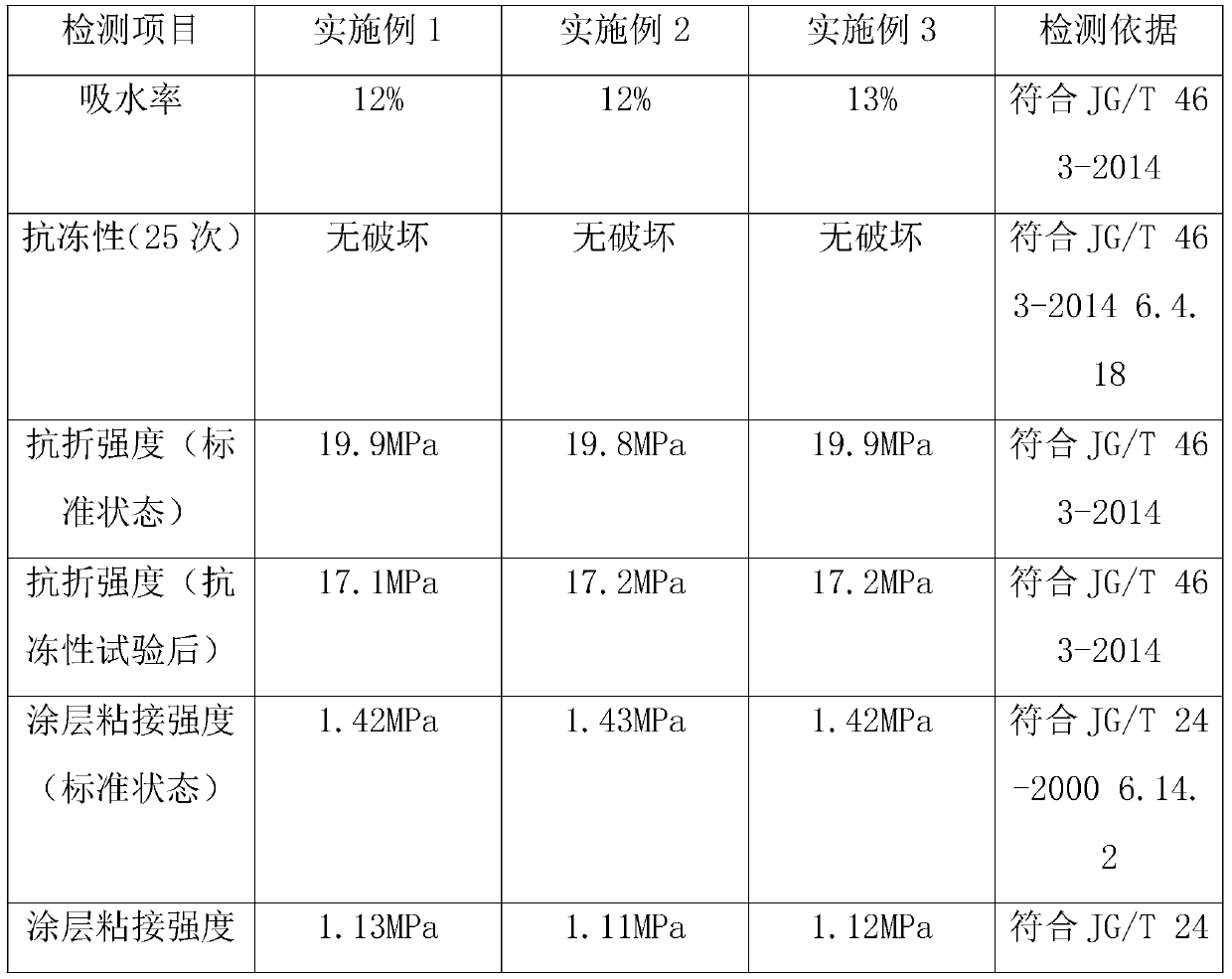

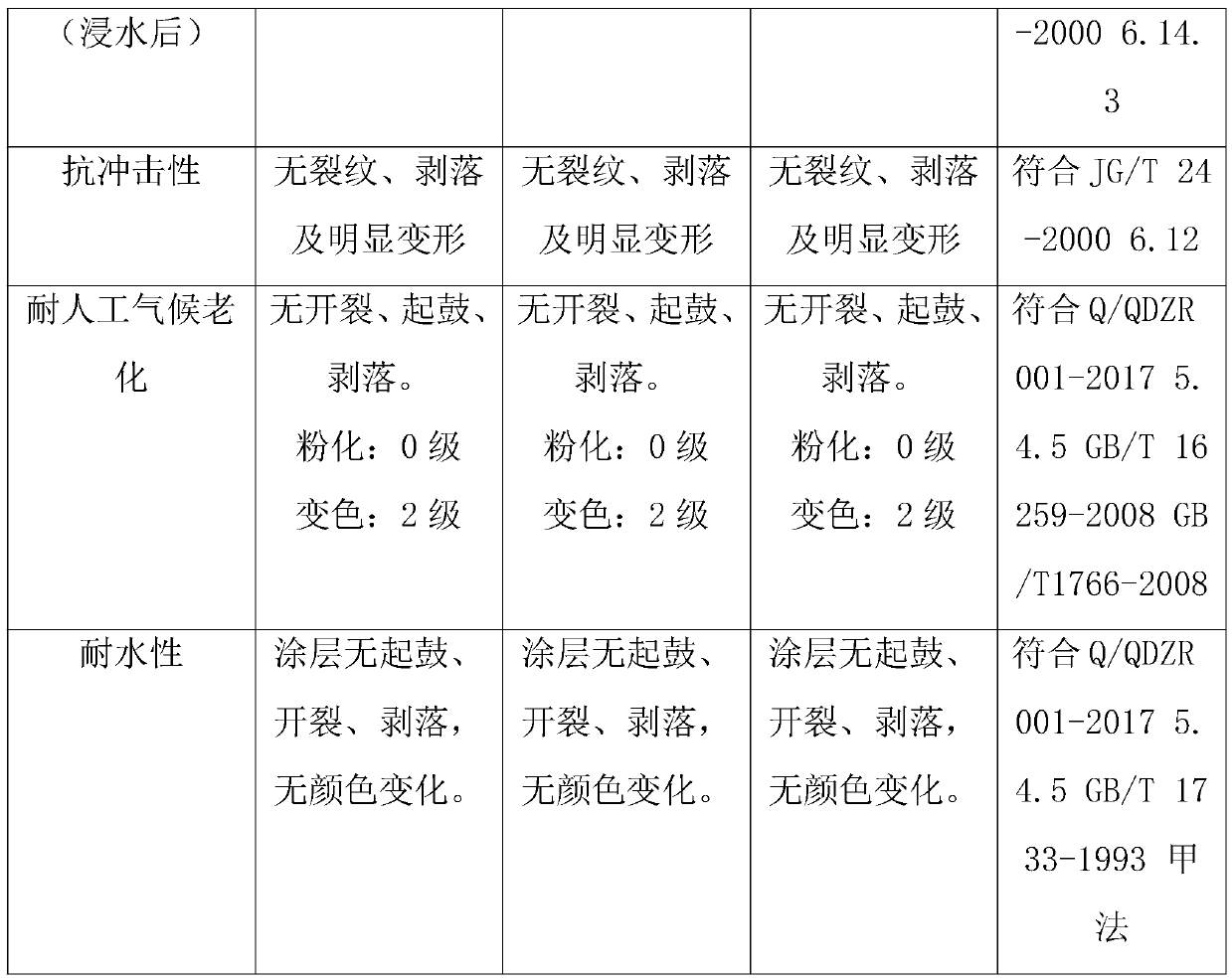

Examples

Embodiment 1

[0043] 1) Clean the dust on the surface of the stone plate, then pre-wet it, and then transport it to the spraying device 2 through the first plate loading device 1 and the conveying line to spray the decorative layer;

[0044] 2) The stone slabs sprayed in step 1) are transported to the steam curing device 3 through the conveying line for steam curing. The steam curing time is 72 hours, the steam curing temperature is 25°C, and the steam curing relative humidity is 90%;

[0045] 3) The steam-cured stone plate in step 2) is left to stand at room temperature for 72 hours, and then transported to the surface treatment device 4 through a conveying line for grinding and sandblasting;

[0046] 4) Clean the dust on the surface of the stone plate after the surface treatment in step 3), and evenly coat a layer of polyethylene self-adhesive film as a protective film;

[0047] 5) according to the requirements, step 4) the stone slab coated with the protective film is transported to the ...

Embodiment 2

[0049] 1) Clean the dust on the surface of the stone slab, then pre-wet it, and then transport it to the spraying device 2 through the first plate loading device 1 and the conveying line to spray the decorative layer;

[0050] 2) The stone slabs sprayed in step 1) are transported to the steam curing device 3 through the conveying line for steam curing. The steam curing time is 80 hours, the steam curing temperature is 30° C., and the steam curing relative humidity is 90%;

[0051] 3) The steam-cured stone slabs in step 2) were left to stand at room temperature for 78 hours, and then transported to the surface treatment device 4 through the conveyor line for grinding, shot blasting, and polishing;

[0052] 4) Clean the dust on the surface of the stone slab after the surface treatment in step 3), and evenly coat a layer of polypropylene self-adhesive film as a protective film;

[0053] 5) according to the requirement, step 4) the stone slab coated with the protective film is trans...

Embodiment 3

[0055] 1) Clean the dust on the surface of the stone plate, then pre-wet it, and then transport it to the spraying device 2 to spray the decorative layer through the first upper plate 1 of the device and the conveying line;

[0056] 2) The stone slabs sprayed in step 1) are transported to the steam curing device 3 through the conveying line and the second upper board device 11 for steam curing. The steam curing time is 96 hours, the steam curing temperature is 35°C, and the steam curing relative humidity is 90°C. %;

[0057] 3) The stone slabs steamed in step 2) were left to stand at room temperature for 72 hours, then passed through the conveying line and the second lower plate device 12, and then transported to the surface treatment device 4 for grinding, polishing, and pickling;

[0058] 4) Clean the dust on the surface of the stone plate after the surface treatment in step 3), and evenly coat a layer of polyethylene self-adhesive film as a protective film;

[0059] 5) acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com