Gun head machining equipment

A technology for processing equipment and gun heads, applied in metal processing equipment, metal processing, metal processing mechanical parts, etc., can solve the problems of low processing efficiency and a large number of operators, improve production efficiency, reduce labor costs, and reduce errors. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

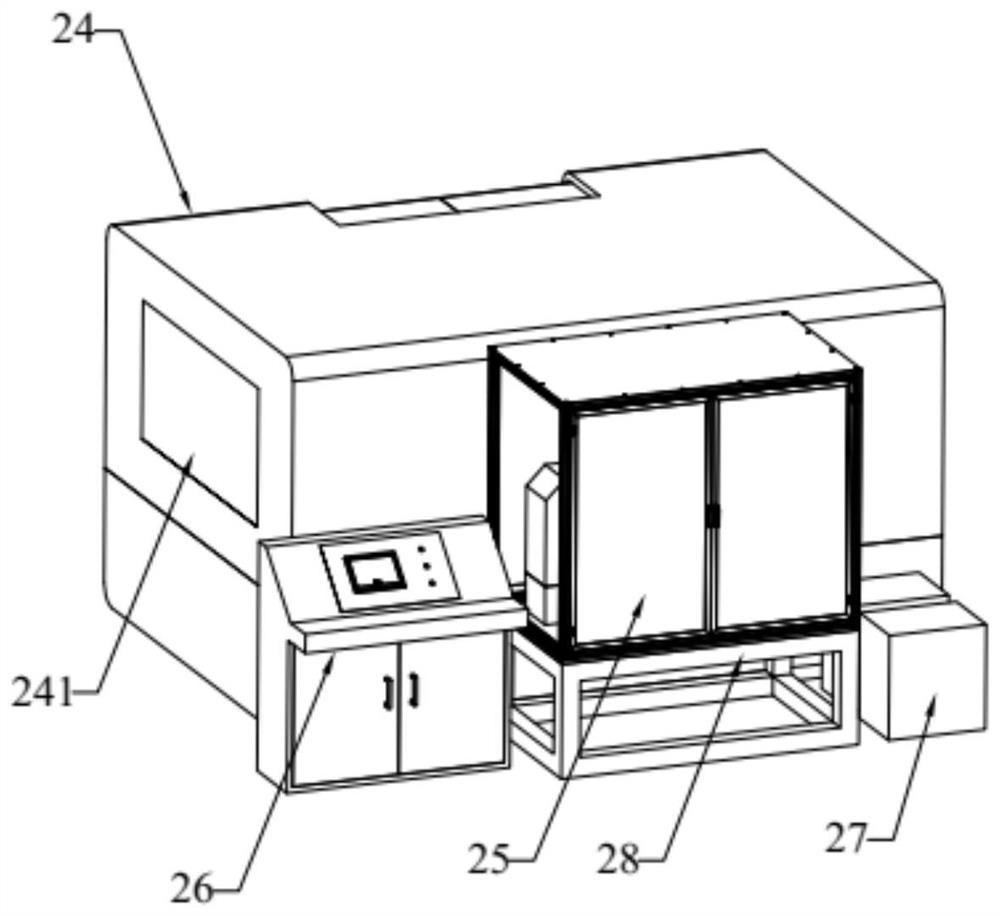

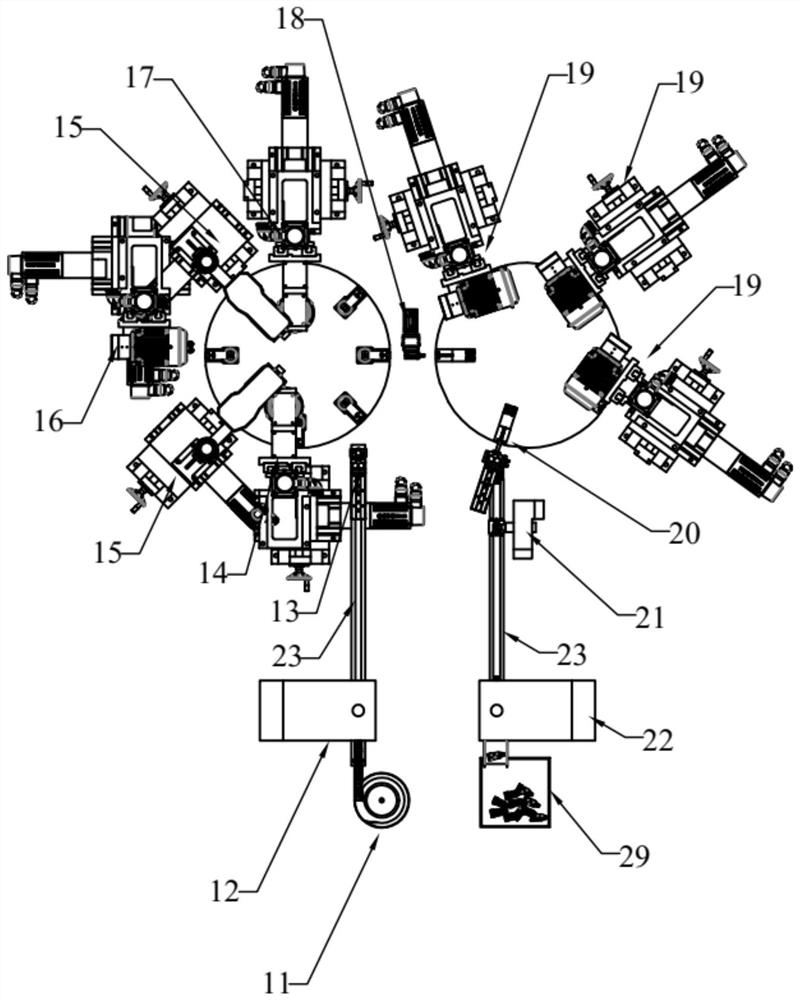

[0026] Such as Figure 1 to Figure 2 Shown is a gun tip processing equipment 10 of the present invention, including: a punch base 28 . The punch base 28 is provided with along the circumference of the punch base 28 in sequence: a vibrating feeding tray 11, a reverse punching burr assembly 12, a turntable feeding assembly 13, a first milling cutter assembly 14, an expanding thread assembly 15, a second milling assembly The cutter head assembly 16 , the third milling cutter head assembly 17 , the conversion disk assembly 18 , the fourth milling cutter head assembly 19 , the turntable blanking assembly 20 , the middle groove deburring assembly 21 and the front punching groove assembly 22 . The vibrating feeding plate 11 is used for vibrating feeding on the gun head, the reverse side punching and burring assembly 12 is used for punching and burring the reverse side of the gun head, the turntable feeding assembly 13 is used for feeding the gun head, and the first milling cutter dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com