Processing method of cold-brewed tea

A processing method and technology for cold-brewed tea, which are applied in the field of beverage processing, can solve the problems of cold-brewed tea products staying in the initial stage, unhealthy, and no mature products are launched into the market, so as to improve physiological health effects, reduce labor intensity, The effect of reducing mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

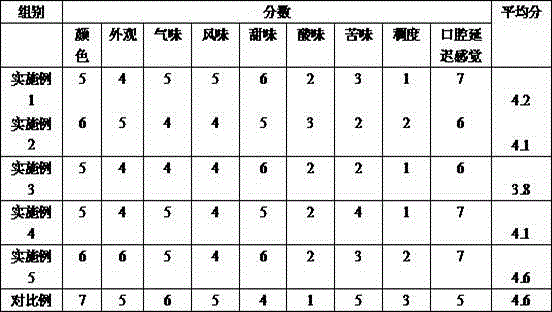

Examples

Embodiment 1

[0024] A processing method for cold-brewing tea, the processing method comprising: S1. Weigh dry tea and add appropriate amount of cold water, control the material-water ratio of dry tea and cold water to 4kg: 3L, and control the temperature of the cold water between 4°C ;S2. Put the dry tea and water together at 0°C for 20 minutes for rehydration, so that the moisture content of the tea leaves is at 40%, and then place the rehydrated tea leaves at -22- -15°C for freezing Indoor freezing treatment for 2.5-6 hours; S3. After the freezing treatment, remove the tea leaves from the freezer to thaw naturally at a constant temperature of 20 °C and rehydrate for 40 minutes; S4. Extrude the thawed and rehydrated tea leaves.

[0025] Further, the specific method of step S4 is as follows: put the rehydrated tea leaves into a variable temperature and pressure difference airflow expansion tank, heat indirectly with steam to 100°C, keep the temperature for 13 minutes, and reduce the pressur...

Embodiment 2

[0028] A processing method for cold-brewed tea, the processing method comprising: S1. Weighing dry tea and adding appropriate amount of cold water, controlling the material-water ratio of dry tea and cold water to be 5kg: 8L, and controlling the temperature of the cold water between 4°C ;S2. Put the dry tea and water together at 0°C for 25 minutes for rehydration, so that the moisture content of the tea leaves is at 43%, and then place the rehydrated tea leaves at -22- -15°C Freezing treatment in the freezer for 2.5-6 hours; S3. After the freezing treatment, remove the tea leaves from the freezer to thaw naturally at a constant temperature of 20°C and rehydrate them for 40 minutes; S4. Extrude the thawed and rehydrated tea leaves .

[0029] Further, the specific method of step S4 is as follows: put the rehydrated tea leaves into a variable temperature and pressure difference airflow expansion tank, heat indirectly with steam to 100°C, keep the temperature for 13 minutes, and r...

Embodiment 3

[0032] A processing method for cold-brewed tea, the processing method comprising: S1. Weigh dry tea and add appropriate amount of cold water, control the material-water ratio of dry tea and cold water to be 10kg: 11L, and control the temperature of the cold water between 0°C ; S2. Put the dry tea and water together at 0°C for 20 minutes for rehydration, so that the moisture content of the tea leaves is at 45%, and then place the rehydrated tea leaves at -22- -15°C Freezing treatment in the freezer for 2.5-6 hours; S3. After the freezing treatment, the tea leaves were removed from the freezer and thawed naturally at a constant temperature of 20°C and rehydrated for 45 minutes; S4. The thawed and rehydrated tea leaves were puffed .

[0033]Further, the specific method of step S4 is as follows: put the rehydrated tea leaves into a variable temperature and pressure difference airflow expansion tank, heat indirectly with steam to 100°C, keep the temperature for 13 minutes, and redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com