A method for heat injection and enhanced drainage of U-shaped coalbed methane wells

A coalbed methane, U-shaped technology, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of ineffective coalbed methane extraction and low extraction rate, and achieves improved extraction rate, The effect of speeding up the extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description with reference to the accompanying drawings. It should be understood that the present invention can have various changes in different embodiments without departing from the protection scope of the present invention, and the descriptions and illustrations therein are essentially for illustration rather than for limit the invention.

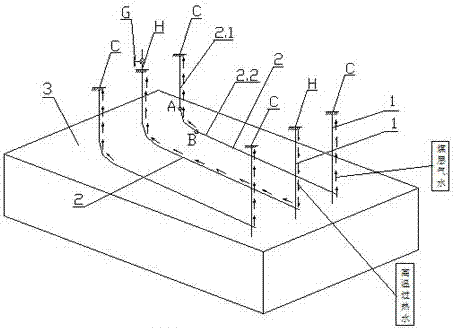

[0024] Such as figure 2 As shown, a U-shaped coalbed methane well heat injection enhanced drainage method, the steps are as follows:

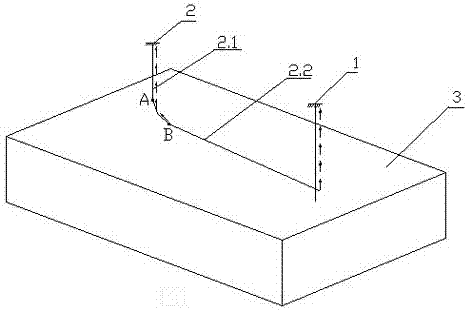

[0025] ① According to the construction requirements and sequence of coalbed methane U-shaped wells, the vertical well 1 and the horizontal well 2 of the U-shaped well are constructed, and the horizontal section of the horizontal well 2 is located in the coal seam 3, and the vertical well 1 and the horizontal well 2 are connected;

[0026] ② At least three U-shaped well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com