A method for extracting mine gas from low-permeability coal seams containing faults

A low-permeability and fault technology, applied in mining equipment, gas discharge, mining fluids, etc., can solve the problems of difficulty in obtaining gas drainage, insignificant hydraulic fracturing effect, and low coal seam permeability, reducing costs, The effect of rapid extraction and efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

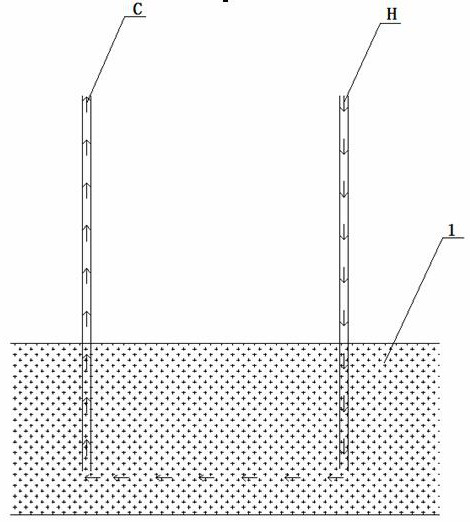

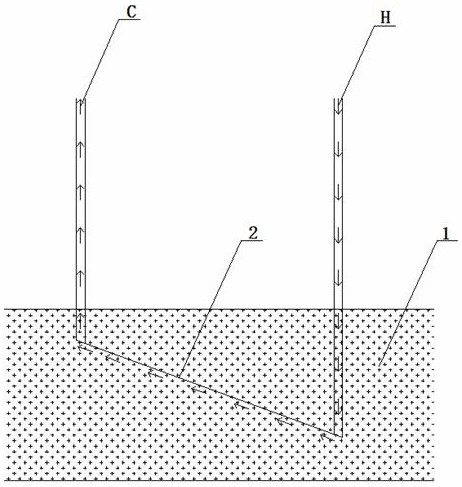

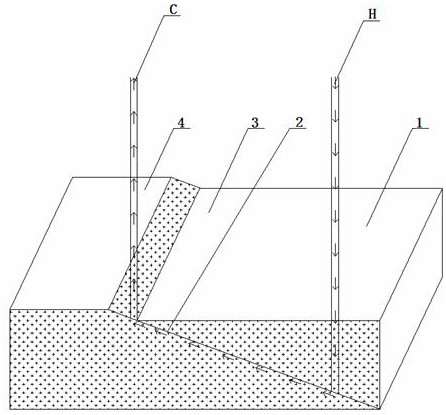

[0019] like figure 2 As shown, a method for extracting mine gas from a low-permeability coal seam containing a fault, the steps are as follows:

[0020] 1. Carry out vertical drilling from the ground, arrange the well pattern, the depth of the drilled vertical well reaches the fault zone 2 of the coal seam 1, and the vertical well is connected to the fault zone 2 in the coal seam 1;

[0021] 2. At least two vertical wells shall be constructed, one of which shall be arranged in the descending wall 3 of the fault zone 2, and cemented with sulfoaluminate cement and steel pipe as the heat injection well 5, and the other wells shall be arranged in the rising wall 4 of the fault zone. , using conventional cementing methods as production well C; the distance between heat injection well H and production well C is 60m~500m, heat injection well 5 is connected to any existing high-temperature steam system, and the high-temperature steam system adjusts the water temperature. regulation;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com