Surface insulation spraying device and spraying process of electronic component

A technology of electronic components and spraying equipment, which is applied in the direction of electrical components, insulators, circuits, etc., can solve the problems of different anti-oxidation and anti-salt spray corrosion characteristics, and achieve the effect of good surface appearance, large production capacity, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

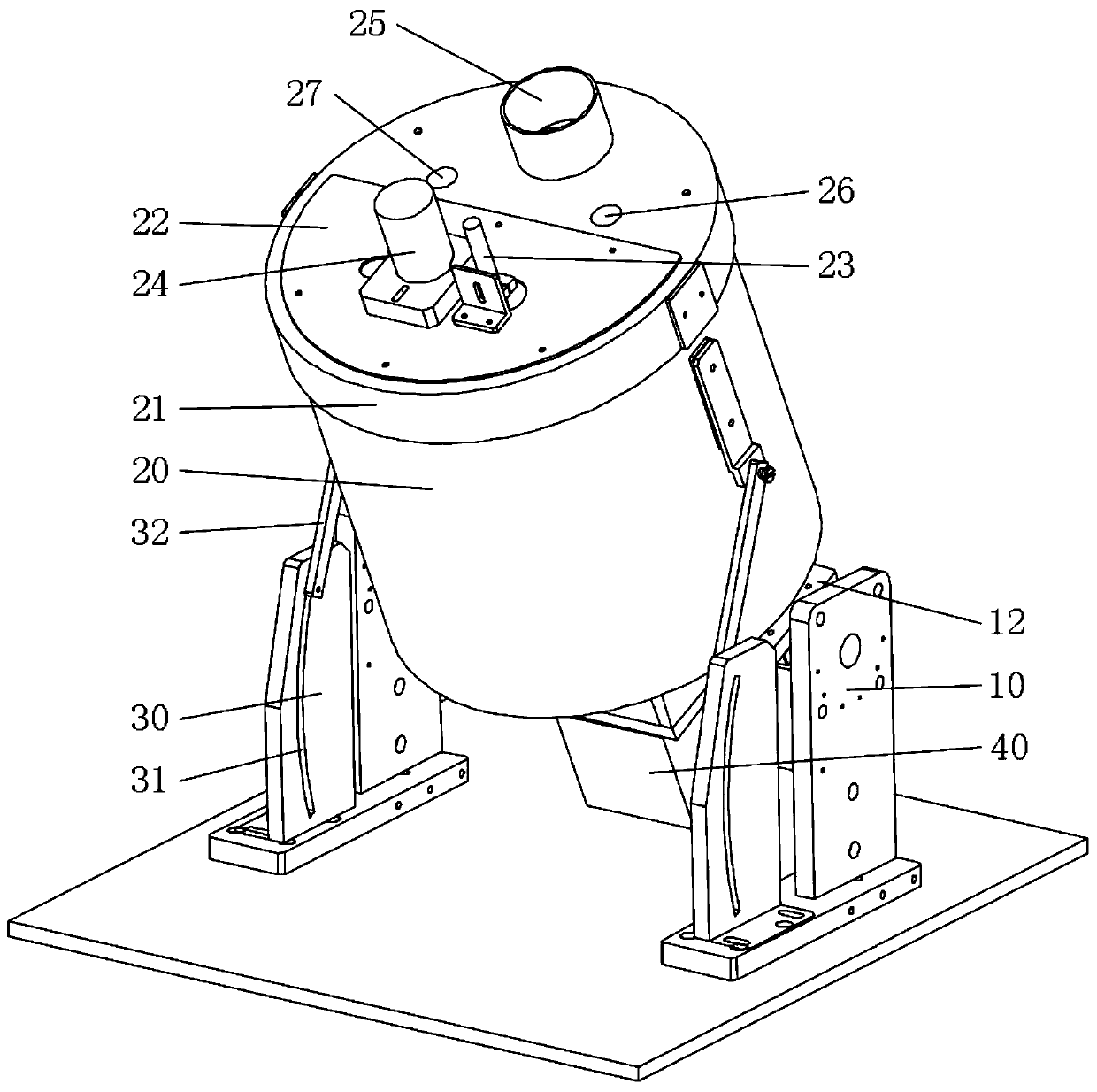

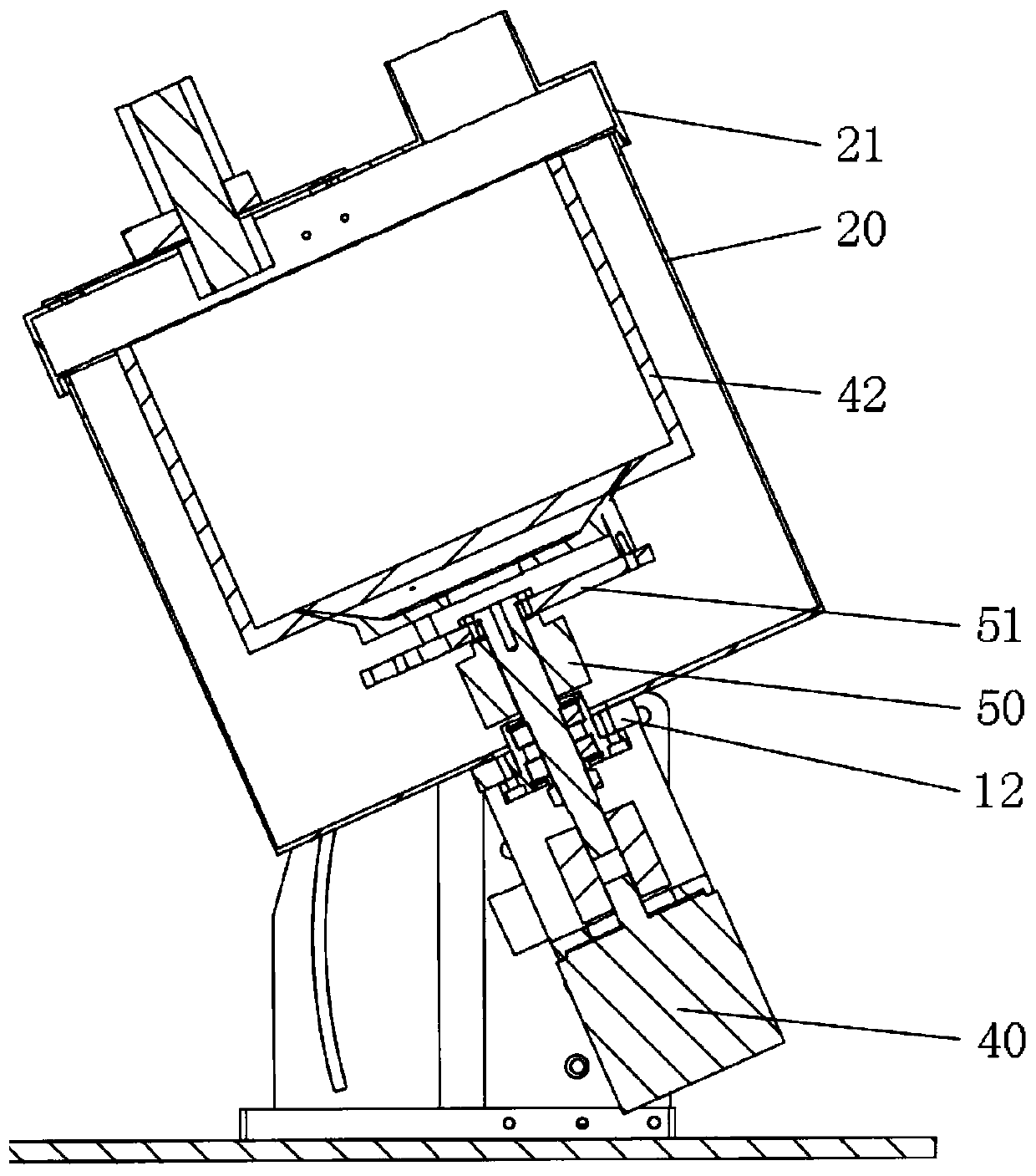

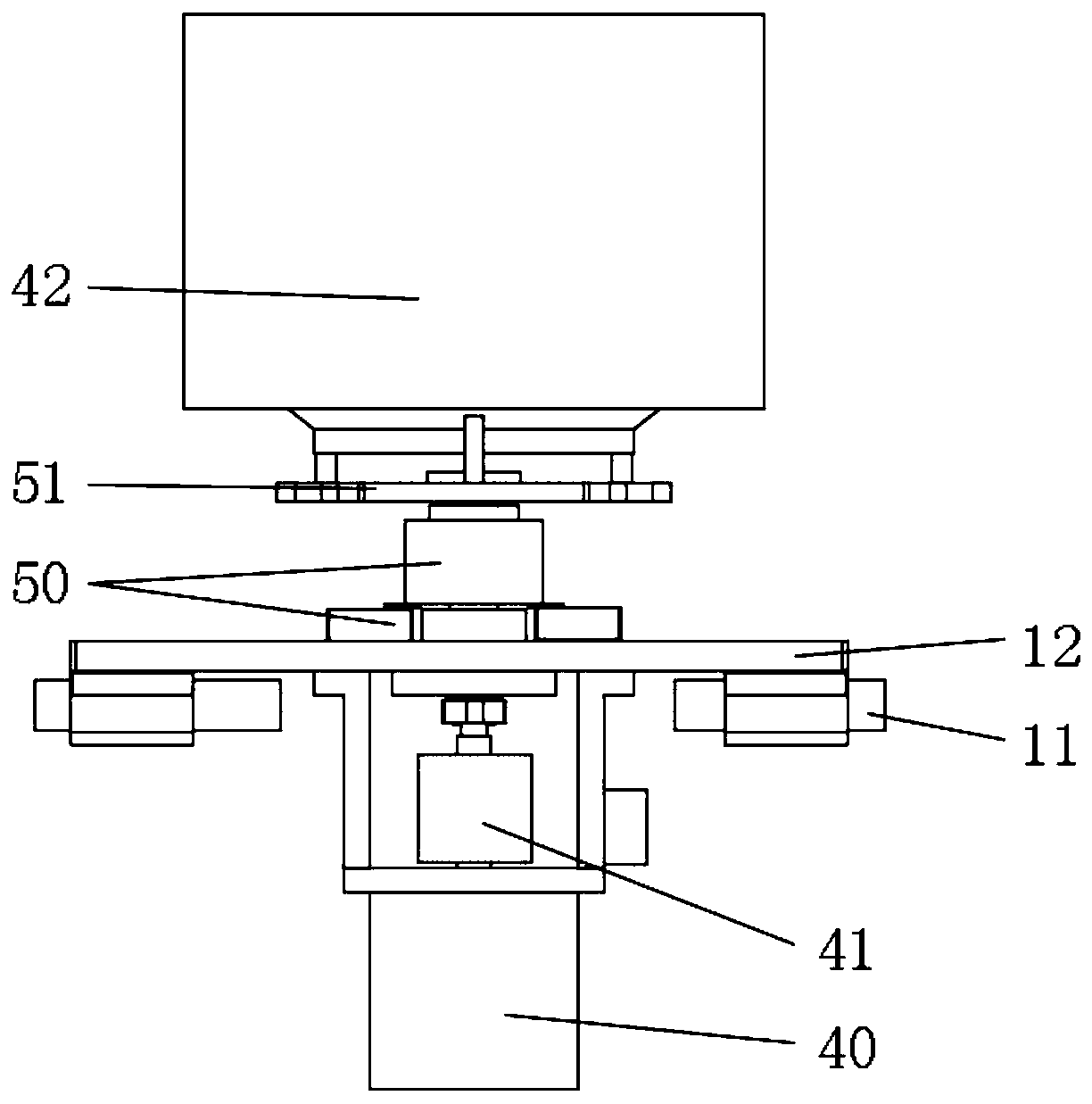

[0037] refer to Figure 1 ~ Figure 3 As shown, the invention discloses a surface insulation spraying device for electronic components, which includes a spraying unit, an inclination unit, a rotating unit and a heating unit.

[0038] Spray unit:

[0039] The above-mentioned spraying unit includes a bracket 10 , a protective cover 20 and a closing cover 21 .

[0040] A rotating shaft 11 is arranged on the support 10 . A fixed plate 12 is arranged on the rotating shaft 11 . The rotating shaft 11 can make the drum 42 rotate obliquely, so that the components in the drum 42 can be dumped out.

[0041] The above-mentioned protective cover 20 is disposed on the fixing plate 12 . The protective cover 20 is a closed casing with an open top. Insulation cotton is adhered on the inner wall of the protective cover 20 .

[0042] The above-mentioned closing cover 21 is provided on the opening of the protective cover 20 . The closing cover 21 can close the protective cover 20 to maintai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com